System capable of cooperatively removing multiple contaminants in smoke in ozone type high temperature flame device

A pollutant and oxygen production device technology, applied in the direction of indirect carbon dioxide emission reduction, non-flammable liquid/gas transportation, combustion method, etc., can solve the problems of single removal technology, high operating cost, and low pollutant removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

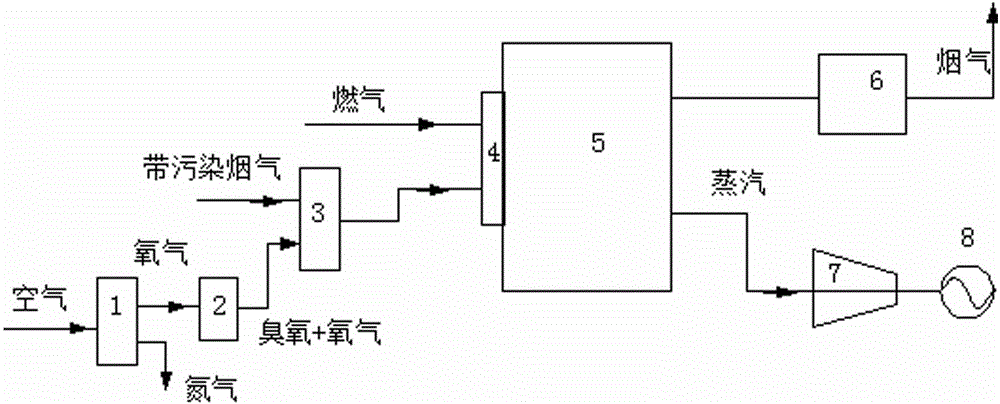

[0014] An ozone-type high-temperature flame device synergistically removes various pollutants in the flue gas system. After the air passes through the oxygen generator 1, the nitrogen is collected and stored for other purposes, and the oxygen enters the ozone generator 2 to form a mixed gas of ozone and pure oxygen. It is fully mixed with the upstream flue gas in the gas mixer 3, and then sent to the burner 4 for pre-mixing with the gas and enters the combustion device 5 for high-efficiency combustion, forming oxygen-enriched combustion with high temperature and uniform temperature field, and obtaining an ozone-type high-temperature combustion flame atmosphere, make full use of the strong oxidation of ozone active molecules and the high-temperature flame produced by oxygen-enriched combustion to fully oxidize and decompose various pollutants in the flue gas, and the newly generated flue gas passes through the pollutant removal device 6 to completely remove the pollutants remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com