Method for dressing, desilicication and desulfuration of sulfur-containing bauxite

A bauxite and desiliconization technology, applied in flotation, solid separation, etc., can solve problems such as complex process, achieve simple process, low cost of flotation, and shorten the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

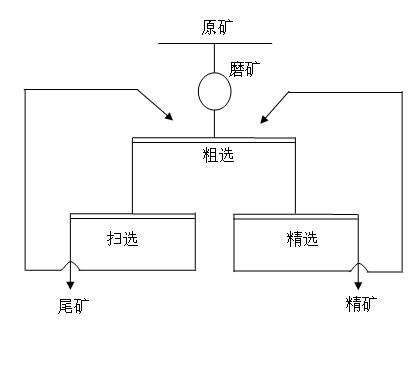

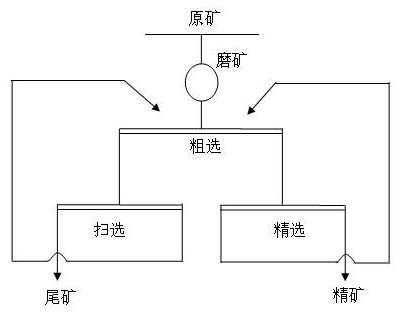

[0018] A low-grade sulfur-containing bauxite with an aluminum-silicon ratio of 4.4 and a sulfur content of 1.98% was used as the test sample. figure 1 The process flow shown is for flotation desulfurization and desiliconization of this low-grade sulfur-containing bauxite. First, grind the ore to a fineness of 75% -0.075mm, adjust the pH to 5.0 with sulfuric acid, add 100g / t sodium fluorosilicate, 50g / t copper sulfate, 200g / t quaternary ammonium salt, 200g throughout the process / t Butylxanthate, using eg figure 1 Flotation is carried out according to the process shown, and the obtained froth product is tailings, and the product in the tank is concentrate. The beneficiation indicators are shown in Table 1.

[0019] The flotation index of table 1 embodiment 1

[0020]

Embodiment 2

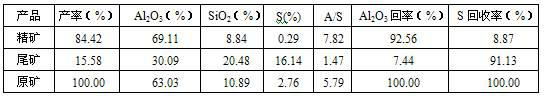

[0022] The sulfur-containing bauxite with an aluminum-silicon ratio of 5.75, a sulfur content of 2.76%, and a calcium sulfate content of 0.5% was used as a test sample. figure 1 The process flow shown is for flotation desulfurization and desiliconization of this low-grade sulfur-containing bauxite. First, grind the ore to a fineness of 80% -0.075mm, adjust the pH to 5.0 with sulfuric acid, add 100g / t sodium fluorosilicate, 50g / t copper sulfate, 200g / t quaternary ammonium salt, 300g in the whole process / t Butylxanthate, using eg figure 1 Flotation is carried out according to the process shown, and the obtained froth product is tailings, and the product in the tank is concentrate, and the beneficiation indicators are shown in Table 2.

[0023] The flotation index of table 2 embodiment 2

[0024]

Embodiment 3

[0026] The aluminum-silicon ratio of the sulfur-containing bauxite is 5.74. After the sulfur-containing bauxite is ground, the pH is adjusted to 3 with sulfuric acid, and the inhibitor is added sequentially. The amount of sodium hexametaphosphate is 50g / t, and the activator is The amount of copper sulfate added is 20g / t. Silicate mineral collector, the collector is dodecylamine, and the addition amount is 100g / t. The sulfur-containing gangue mineral collector is xanthate, and the addition amount is 100 g / t. Flotation is carried out after stirring and pulping; after flotation, impurity ore particles mainly composed of silicate minerals and sulfur-containing minerals float out at the same time as foam tailings. The beneficiation process is one roughing, one selection and one sweep; The pulp after flotation is used as concentrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com