Patents

Literature

38 results about "Butylxanthate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

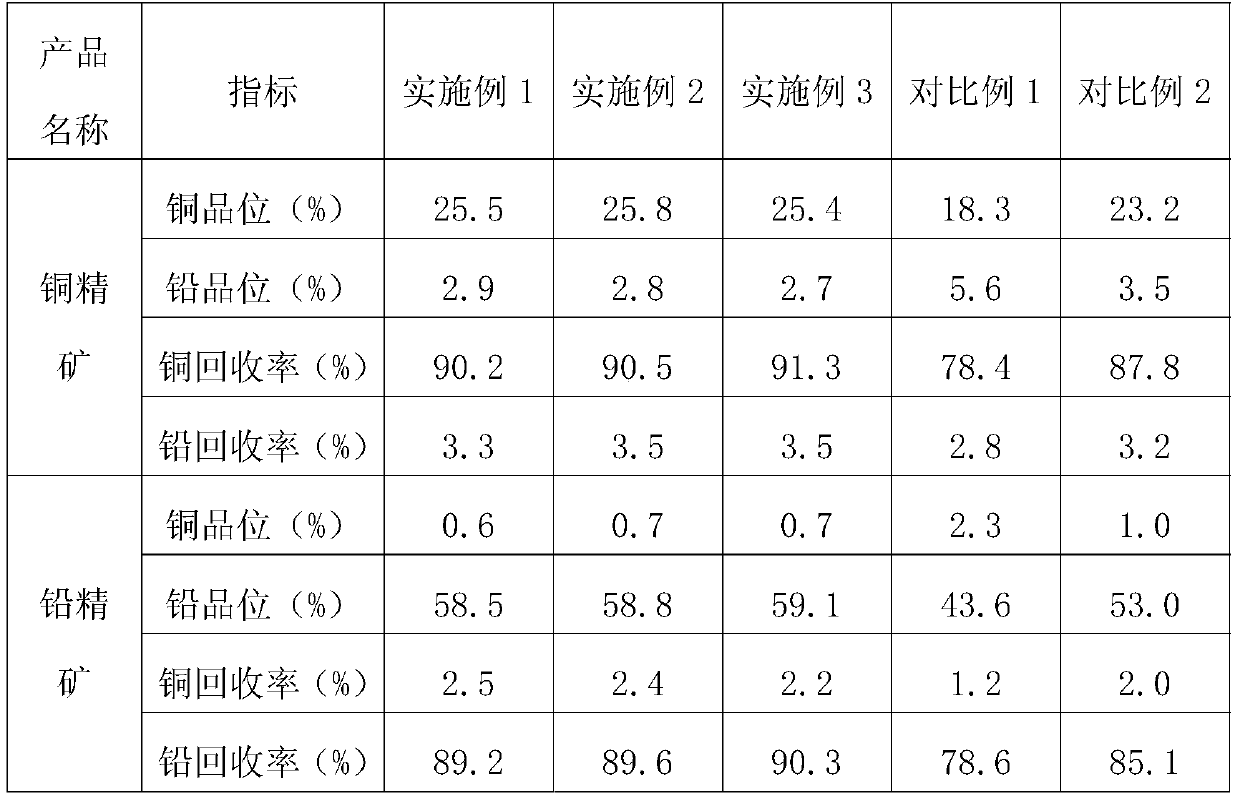

Method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings

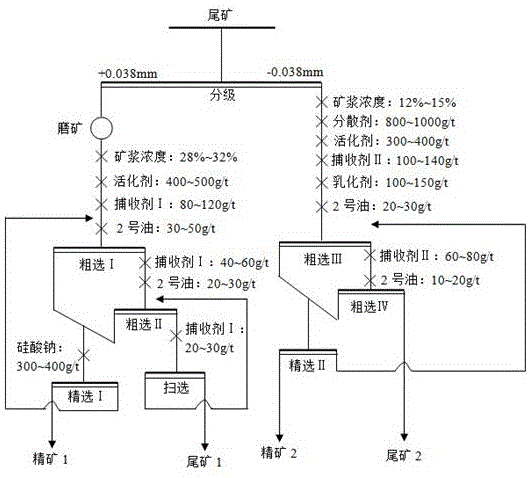

The invention discloses a method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings. By the adoption of the method, the technical problem that if the antimony-containing gold ore flotation tailings are subjected to cyanide leaching directly, the cost is high, and the gold recovery rate is low is solved. Meanwhile, efficient recovery of associated antimony minerals can also be achieved. The method is characterized by comprising the steps that the tailings are rated, the tailings with the particle size being larger than 0.038 mm are subjected to regrinding and size mixing, copper sulfate, lead nitrate and ammonia carbonate are added sequentially as a mixed activating agent, sodium n-butylxanthate and ammonium butyl aerofloat serve as a collecting agent, No.2 oil serves as a foaming agent, and gold and the antimony minerals are recycled through flotation; and water is directly added into the tailings with the particle size being smaller than 0.038 mm for size mixing, grinding is not needed, sodium hexametaphosphate, copper sulfate, lead nitrate, ammonia carbonate, sodium n-butylxanthate, No.25 aerofloat, kerosene (or diesel oil) and No.2 oil are added in sequence, wherein the sodium hexametaphosphate serves a dispersing agent, the copper sulfate, lead nitrate and ammonia carbonate serve as an activating agent, the n-butylxanthate and No.25 aerofloat serve as a collecting agent, the kerosene (or diesel oil) serves an emulsifying agent, and the No.2 oil serves as a foaming agent, and gold and the micro-fine particle antimony minerals are recycled through flotation. The technique is reasonable, procedures are simple, the gold and antimony recovery rate is high, and industrialized implementation is easy.

Owner:KUNMING UNIV OF SCI & TECH

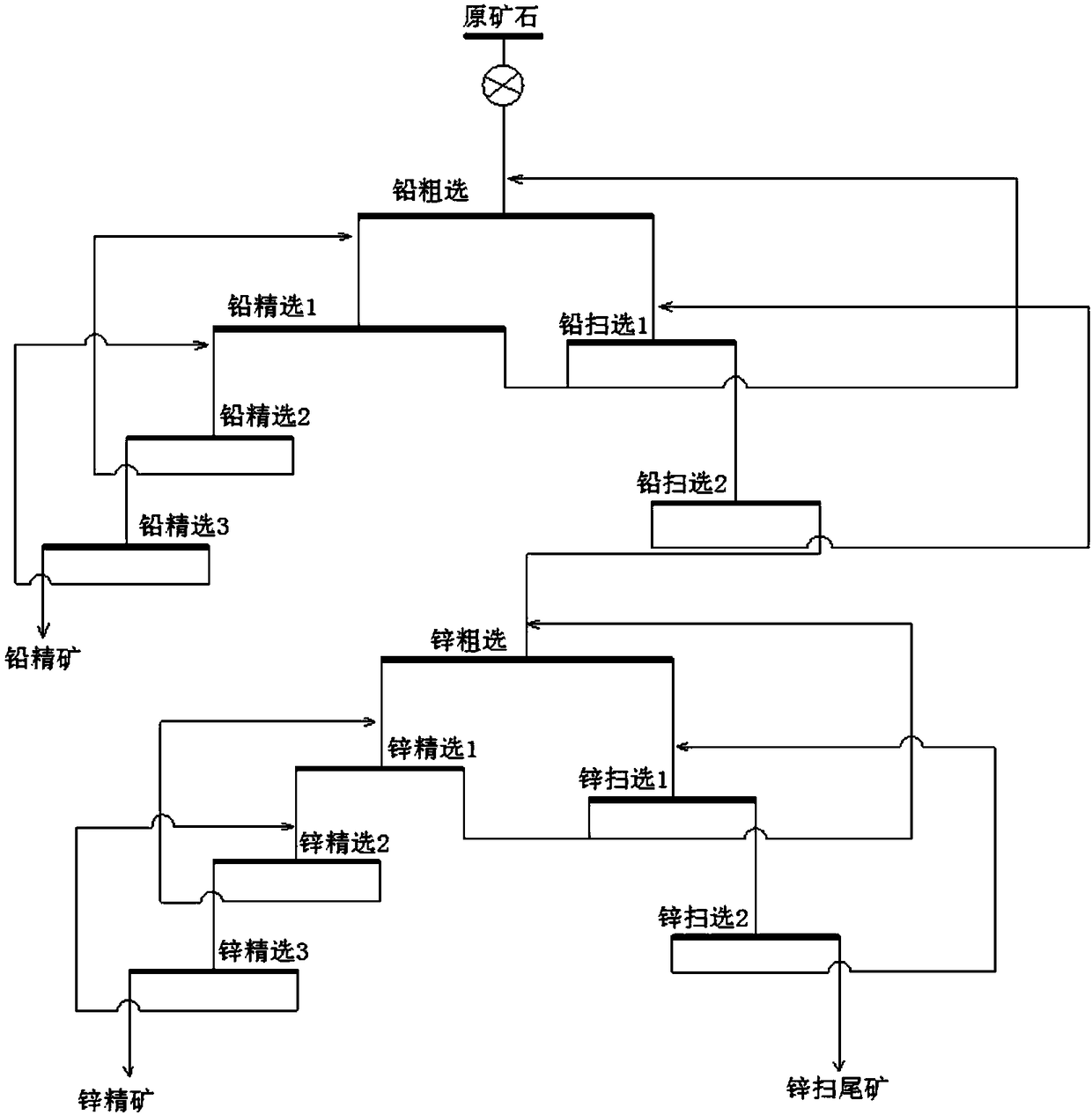

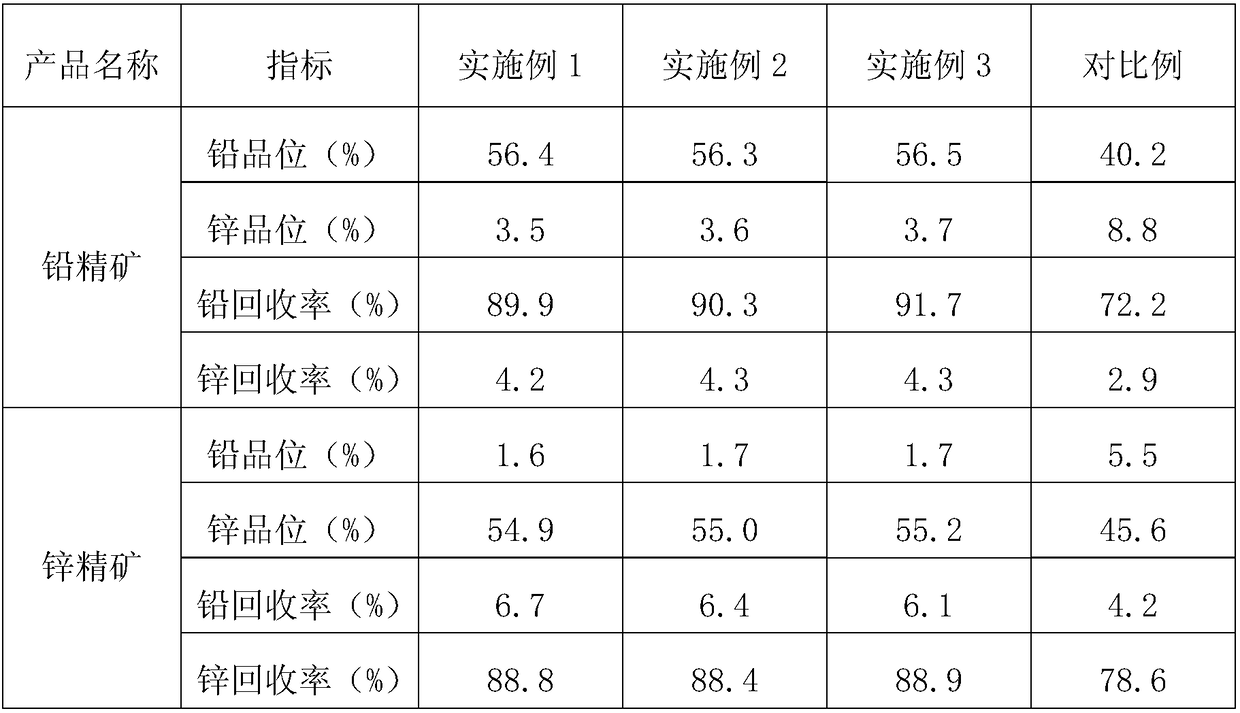

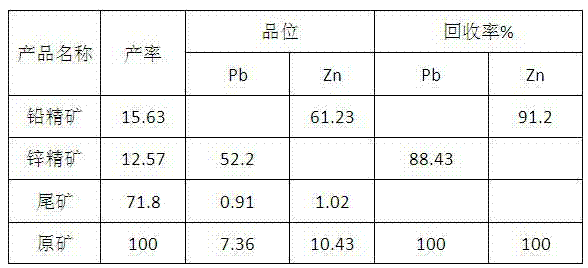

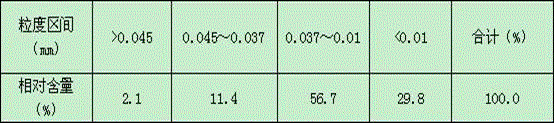

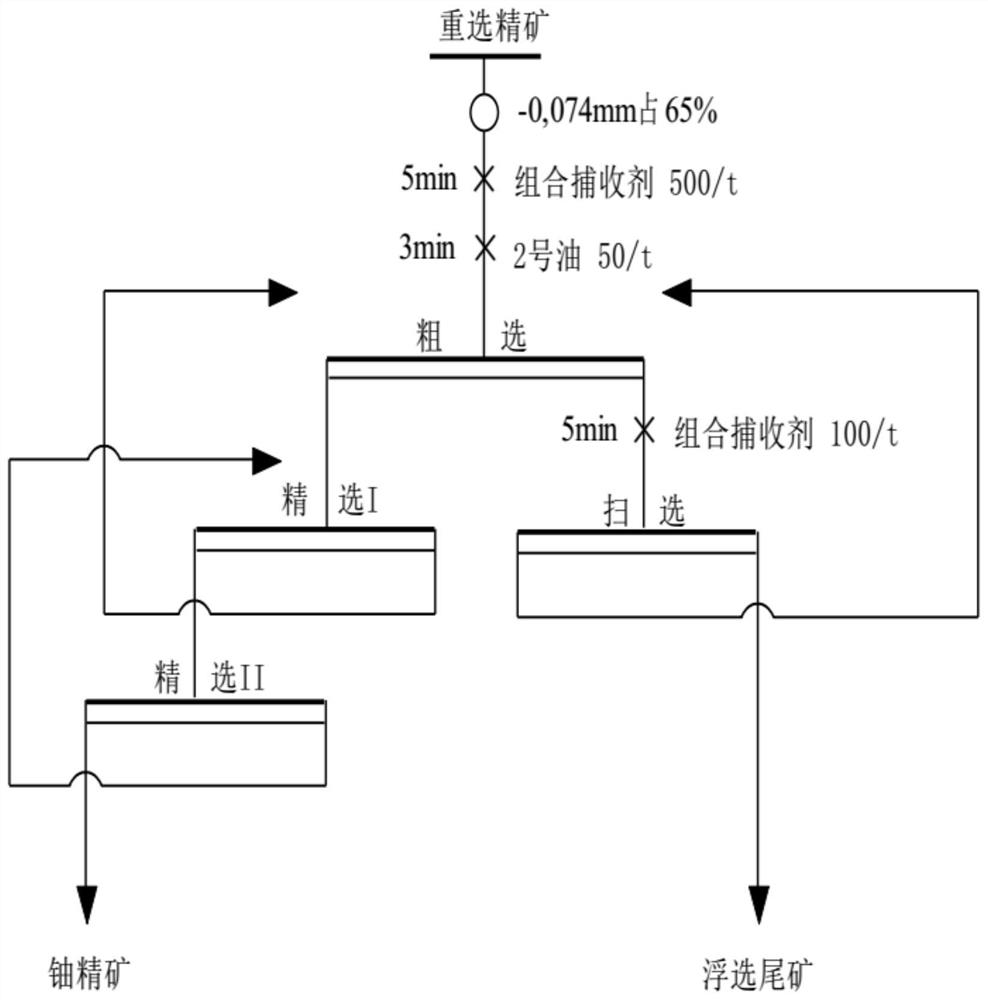

Selection method of lead and zinc sulfide ore

The invention discloses a selection method of lead and zinc sulfide ore, and belongs to the technical field of beneficiation. The selection method comprises the steps of milling of raw ore, flotationof lead and flotation of zinc, wherein during rough flotation of lead, lime, calcium hypochlorite, zinc sulfate, sodium sulfite, sodium sulfide, dimethyl dicarbonate, ethyl thio carbamate, sodium n-butylxanthate, dianilinodithiophosphoric acid, diphenyl amino phosphorodithioic acid and sodium carbonate are added; during fine flotation of lead, lime, zinc sulfate, sodium sulfite and sodium sulfideare added; during scavenging of lead, lime, calcium hypochlorite, zinc sulfate, sodium sulfite, sodium sulfide, dimethyl dicarbonate, ethyl thio carbamate, dianilinodithiophosphoric acid, diphenyl amino phosphorodithioic acid and sodium carbonate are added; during rough flotation of zinc, lime, copper sulfate, ammonium sulfite, sodium n-butylxanthate and terpenic oil are added; during fine flotation of zinc, lime is added; and during scavenging of zinc, lime, copper sulfate, ammonium sulfite, sodium n-butylxanthate and terpenic oil are added. By adoption of the selection method of lead and zinc sulfide ore, the problem that when a traditional flotation method is used for selecting lead and zinc sulfide ore, the recovery rate of lead and zinc is low is solved.

Owner:广西华洋矿源材料有限公司

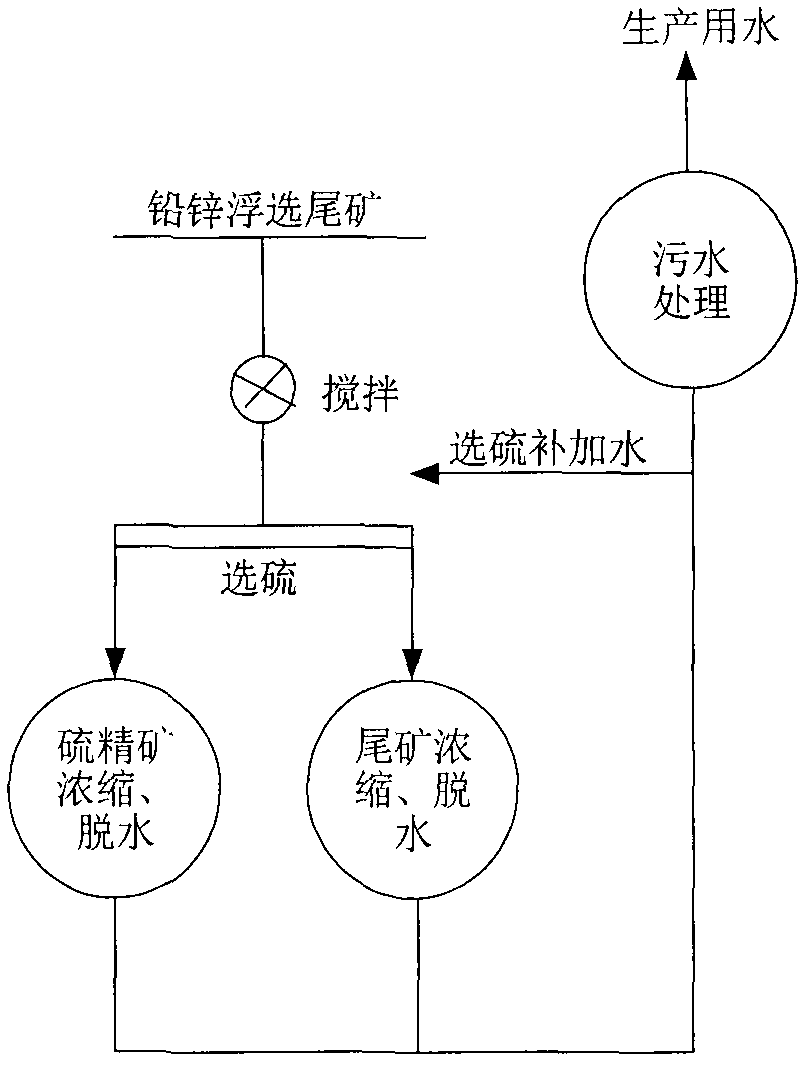

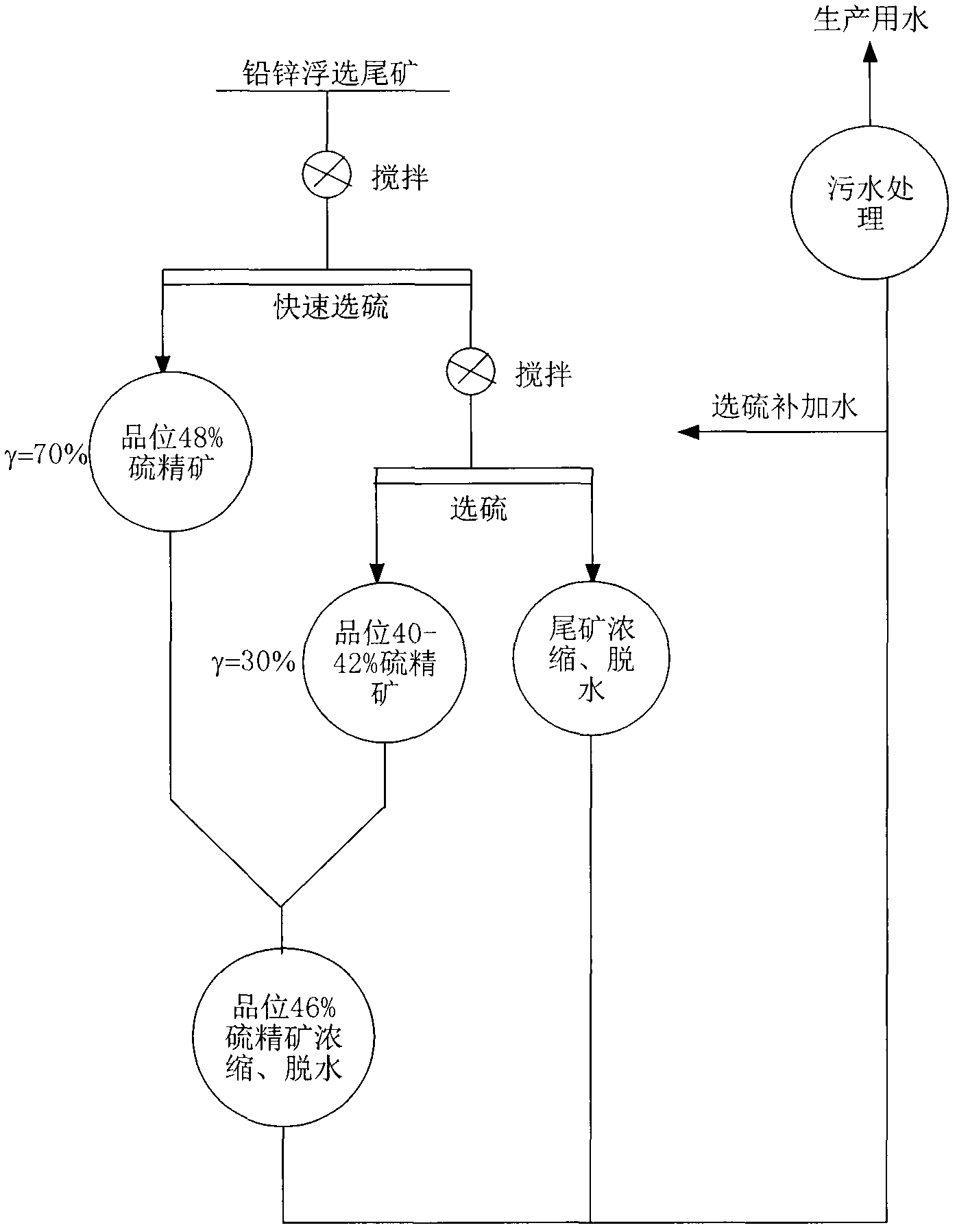

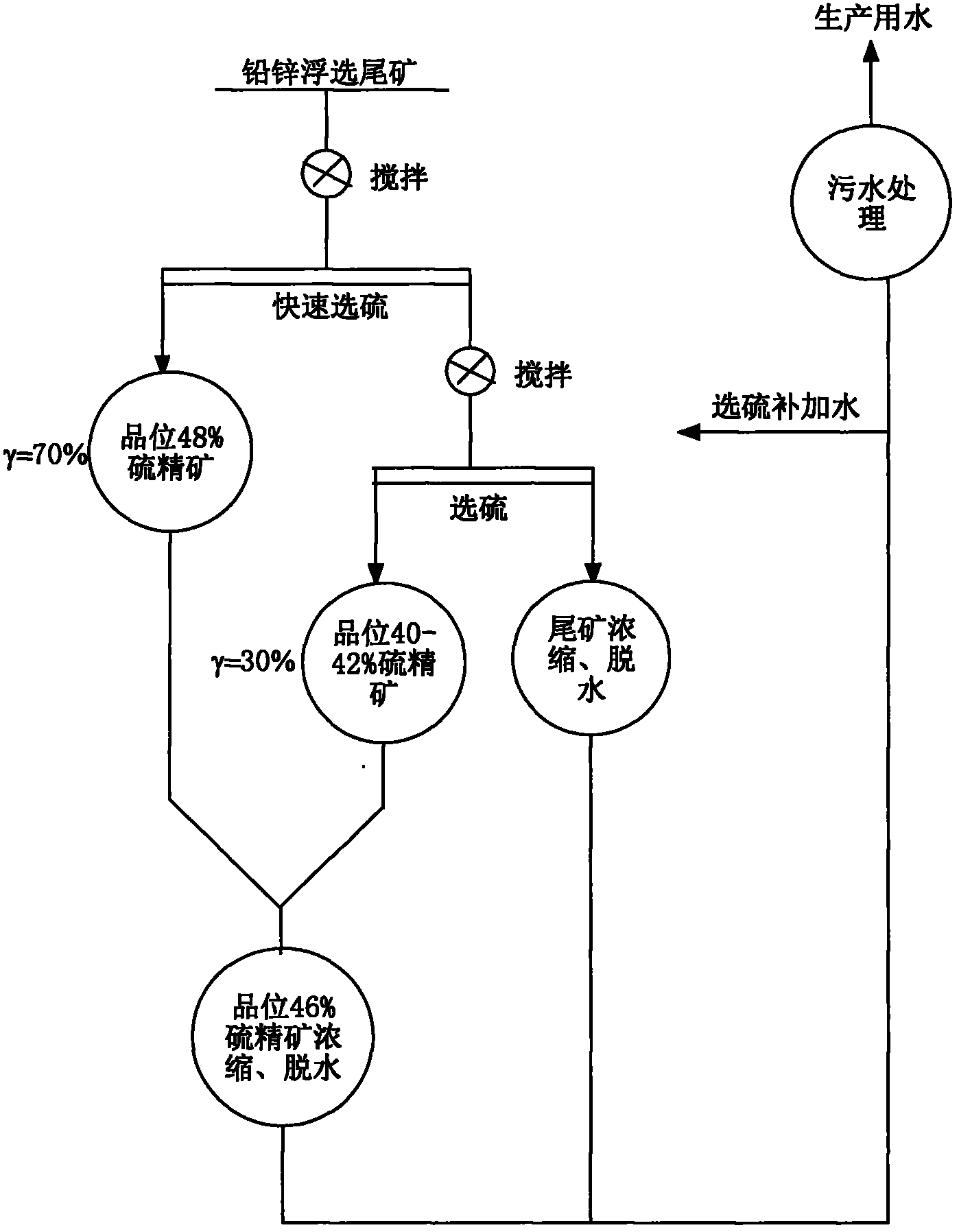

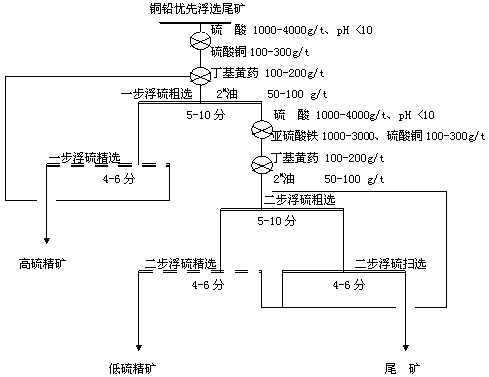

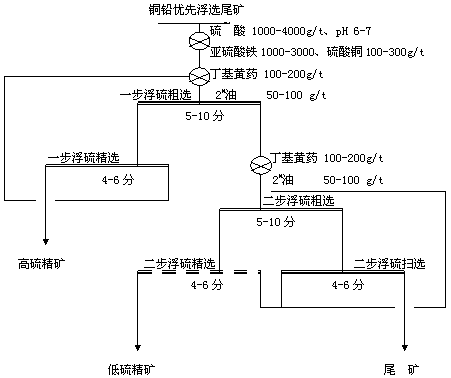

Method for floating high-grade sulfur concentrate from lead-zinc tailings by flow separation and speed division method

InactiveCN102626676AReduce dosageReduce the cost of beneficiationFlotationCell separationFlow diversion

The invention discloses a method for floating high-grade sulfur concentrate from lead-zinc tailings by a flow separation and speed separation method. According to the invention, the flow diversion and speed division method is adopted for carrying out the flotation on iron pyrite according to floatability difference characteristics of the iron pyrite in the lead-zinc tailings so as to obtain high-grade sulfur concentrate; and the problem can be solved that since the concentrate is high in mass, serious sulfur tail deviation is caused, and the recovering rate is low, and the characteristics of saving beneficiation reagent and being low in power consumption for beneficiation are realized. The method comprises the steps of concentrating the lead-zinc flotation tailings, and carrying out the flotation by the flow separation and the speed division method as per the following steps of a, fast flotation: adding sulfuric acid, sodium n-butylxanthate and oil II into the concentrated lead-zinc flotation tailings to float sulfur concentrate, wherein the yield of the sulfur concentrate accounts for more than 70% of the total sulfur concentrate; b. carrying out flotation on tailings after the fast flotation: adding sulfuric acid, sodium n-butylxanthate and oil II into the tailings after the flotation to float sulfur concentrate, wherein the yield of the sulfur concentrate accounts for a range within 30% of the total sulfur concentrate; and finally combing, concentrating and dewatering the sulfur concentrate obtained from step a and the sulfur concentrate obtained from the step b so as to obtain the required mixed sulfur concentrate.

Owner:南京银茂铅锌矿业有限公司

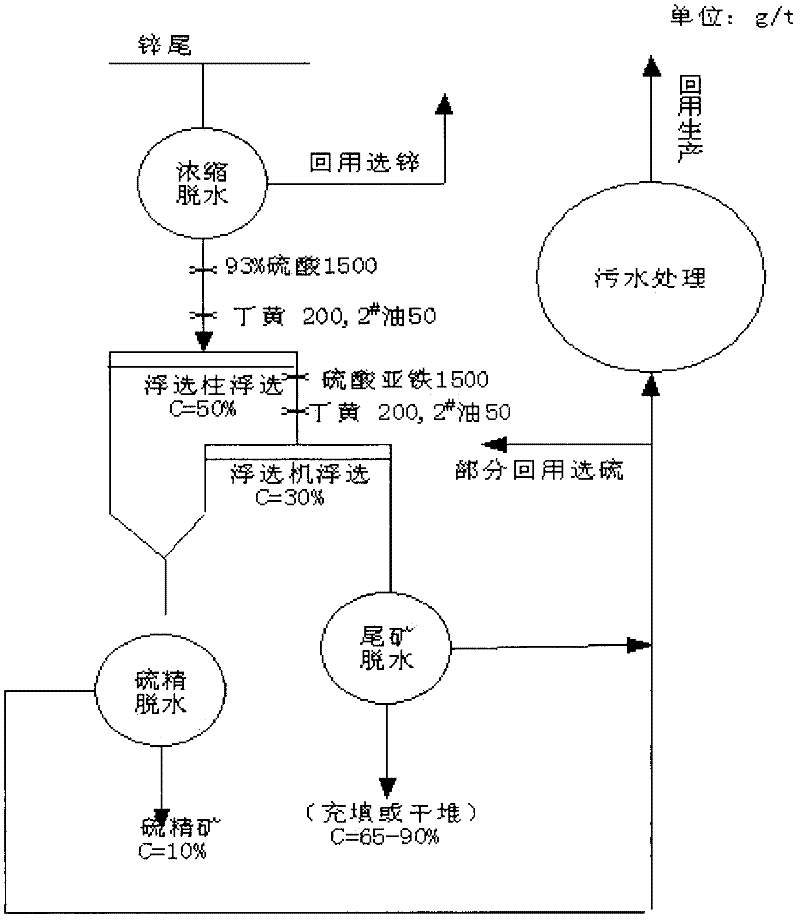

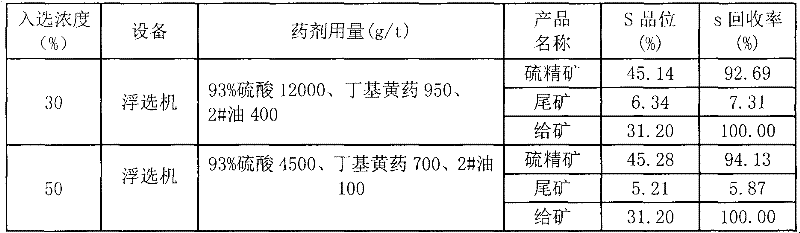

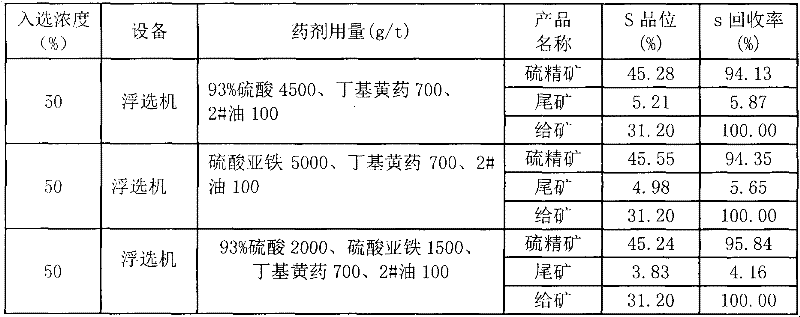

Beneficiation method of iron pyrite in lead-zinc flotation tailings

The invention provides a beneficiation method of iron pyrite in lead-zinc flotation tailings, and by adopting the efficient and clean beneficiation method, the sulfur indexes can be improved, the beneficiation reagent and beneficiation power consumption can be greatly reduced, especially the consumption of sulfuric acid can be reduced, and the corrosion on equipment and pipelines can be relieved. The beneficiation method comprises the following steps: concentrating lead-zinc flotation tailings, adding sulfuric acid, butylxanthate and oil No.2, and carrying out floatation on a first part of soothing concentrate by utilizing a floatation column; adding ferrous sulfate, butylxanthate and oil No.2 into the tailings of the floatation column, and carrying out floatation on a second part of soothing concentrate by utilizing a floatation machine.

Owner:南京银茂铅锌矿业有限公司

Inhibitor for separating blue chalcocite and iron pyrite and mineral separation method thereof

The invention provides an inhibitor for separating blue chalcocite and iron pyrite and a mineral separation method of the inhibitor. The inhibitor is formed by mixing citric acid, sodium sulfite and gallotannic acid according to the mass ratio of 0.5 to 0.65:1.0 to 1.2:1.5 to 1.65. The mineral separation method mainly comprises the technological steps that firstly, raw ore of the blue chalcocite is ground into ore pulp with 30 to 35 percent mass concentration, catching agent sodium n-butylxanthate and ester-112 are added into the ore pulp, stirring is carried out for two minutes to four minutes, copper and sulphur mixing flotation is carried out, and copper and sulphur mixing rough concentrates are obtained; secondly, secondary selection is carried out on the copper and sulphur mixing rough concentrates to obtain copper and sulphur mixing concentrates; thirdly, the inhibitor is added into the copper and sulphur mixing concentrates, copper and sulphur separation is carried through flotation, and copper rough concentrates and sulphur rough concentrates are obtained; fourthly, copper concentrates are obtained through one-time to two-time selection of the copper rough concentrates, and sulphur concentrates are obtained through one-time selection of the sulphur rough concentrates.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

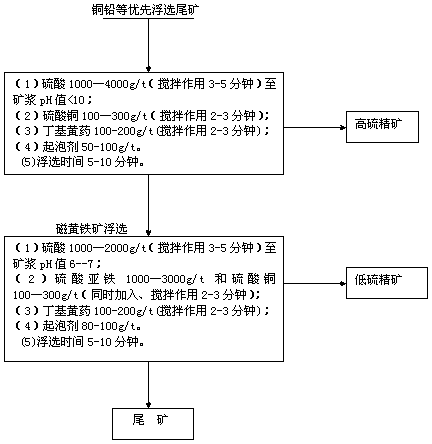

Process for recovering inhibited pyrite and pyrrhotite by utilizing two-step method

The invention discloses a process for recovering inhibited pyrite and pyrrhotite by utilizing a two-step method. The process comprises the following steps of: (1) adding acid, so that a pH (Potential of Hydrogen) value is less than 10; (2) adding copper sulfate; (3) adding sodium n-butylxanthate; (4) adding a foaming agent; (5) obtaining high-sulfur concentrate through flotation; (6) adding the acid into ore pulp after the floatation to enable the pH value to be 6-7; (7) adding the copper sulfate; (8) adding the sodium n-butylxanthate; (9) adding the foaming agent; and (10) obtaining low-sulfur concentrate through the floatation. By utilizing the process provided by the invention, the recovery rate of sulfur and iron can be greatly improved; the comprehensive use ratio of ore resources can be improved; and the problems of environment pollution and land occupation brought by a large amount of stacked cinders can be reduced. The process provided by the invention has great significance in improving a mine and social and economical benefits.

Owner:TONGLING NON FERROUS METAL GROUP CORP

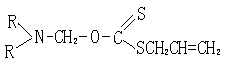

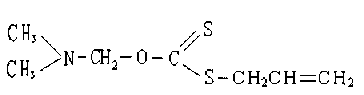

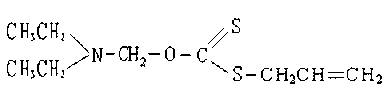

Dialkyl amido amine methyl butylxanthate compound and synthetic method thereof

The invention relates to a dialkyl amido amine methyl butylxanthate compound. According to the compound, a general formula is R2NCH2OC(=S)SCH2CH=CH2, wherein R is alkane having 1 to 4 carbon atoms. A route for synthesizing the dialkyl amido amine methyl butylxanthate compound comprises the following steps of: (1) adding alkylamine and a formaldehyde aqueous solution into a reaction container, stirring for reacting, heating continuously, keeping the temperature for reacting, salting out, cooling, and standing for demixing to separate a superstratum oily product; (2) adding an aqueous solution prepared from carbon disulfide and sodium hydroxide into the reaction container, stirring, dripping alkyl amino methanol with stirring, and keeping the temperature; and (3) dripping chloropropene into the non-separated product with stirring, heating, keeping the temperature, stirring for reacting, standing for demixing to obtain a yellow oily substance, namely the dialkyl amido amine methyl butylxanthate compound. According to the synthetic method, the product is not needed to be purified and separated, and the mixed product containing impurities has high metallic mineral ore dressing collecting performance, and high collecting performance and stability, so that the dialkyl amido amine methyl butylxanthate compound can be used for the flotation of copper nickel ores, copper ores and mixed ores of copper lead zinc.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Novel gold flotation catching agent

The invention discloses a novel gold flotation catching agent. The catching agent is composed of sodium n-butylxanthate, sodium isoamylxanthate and butylamine aerofloat. The weight ratio of the sodium n-butylxanthate to the sodium isoamylxanthate to the butylamine aerofloat is 4 to 8:1 to 5:0.5 to 2. Preferably, the weight ratio of the sodium n-butylxanthate to the sodium isoamylxanthate to the butylamine aerofloat is 6:3:1. The mode that in the traditional gold floatation process, the sodium n-butylxanthate with the single carbon chain is adopted is broken through, different catching properties and selectivity of different carbon chains are adopted, the catching properties of the sodium n-butylxanthate and the selectivity of the sodium isoamylxanthate are complemented, the selectivity of the butylamine aerofloat is added, the three agents are fully mixed, contradiction of the catching capability and the selectivity is resolved, and therefore the catching properties and the selectivity are developed to the great extent. Compared with a traditional agent, the recycling rate of the novel gold flotation catching agent is improved by 0.5 percent, the use number of the agents is reduced by 12 g / t, and the concentrate grade is improved by 0.74 g / t.

Owner:HABAHE JINBA MINING

Ecological management method for heavy metal pollution river

InactiveCN108249694AImprove environmental friendlinessImprove efficiencyWater contaminantsMultistage water/sewage treatmentPhosphatePolyvinyl alcohol

The invention discloses an ecological management method for a heavy metal pollution river. The method comprises sewage flocculating treatment and heavy metal capturing, wherein the sewage treatment flocculating agent comprises the following components in parts by weight: 30-50 parts of sodium xanthate polyamide, 15-20 parts of starch phosphate, 10-15 parts of chitosan, 5-10 parts of acrylamide, 20-30 parts of an initiator, 5-10 parts of ferric sulfate, 10-15 parts of nanometer iron oxide, 20-30 parts of nano ferrous chloride and 5-10 parts of a modifier; the heavy metal capturing agent comprises the following components in parts by weight: 40-50 parts of tetrathiocarbamic acid, 15-20 parts of dithiocar-bamate, 10-15 parts of starch, 8-10 parts of polyacrylamide, 6-8 parts of sodium n-butylxanthate, 5-10 parts of polyvinyl alcohol and 20-30 parts of a filler. The independently developed flocculating agent and heavy metal capturing agent are adopted, so that ecological management of theheavy metal pollution river is realized.

Owner:NINGBO JIANTONG ENVIRONMENTAL PROTECTION TECH

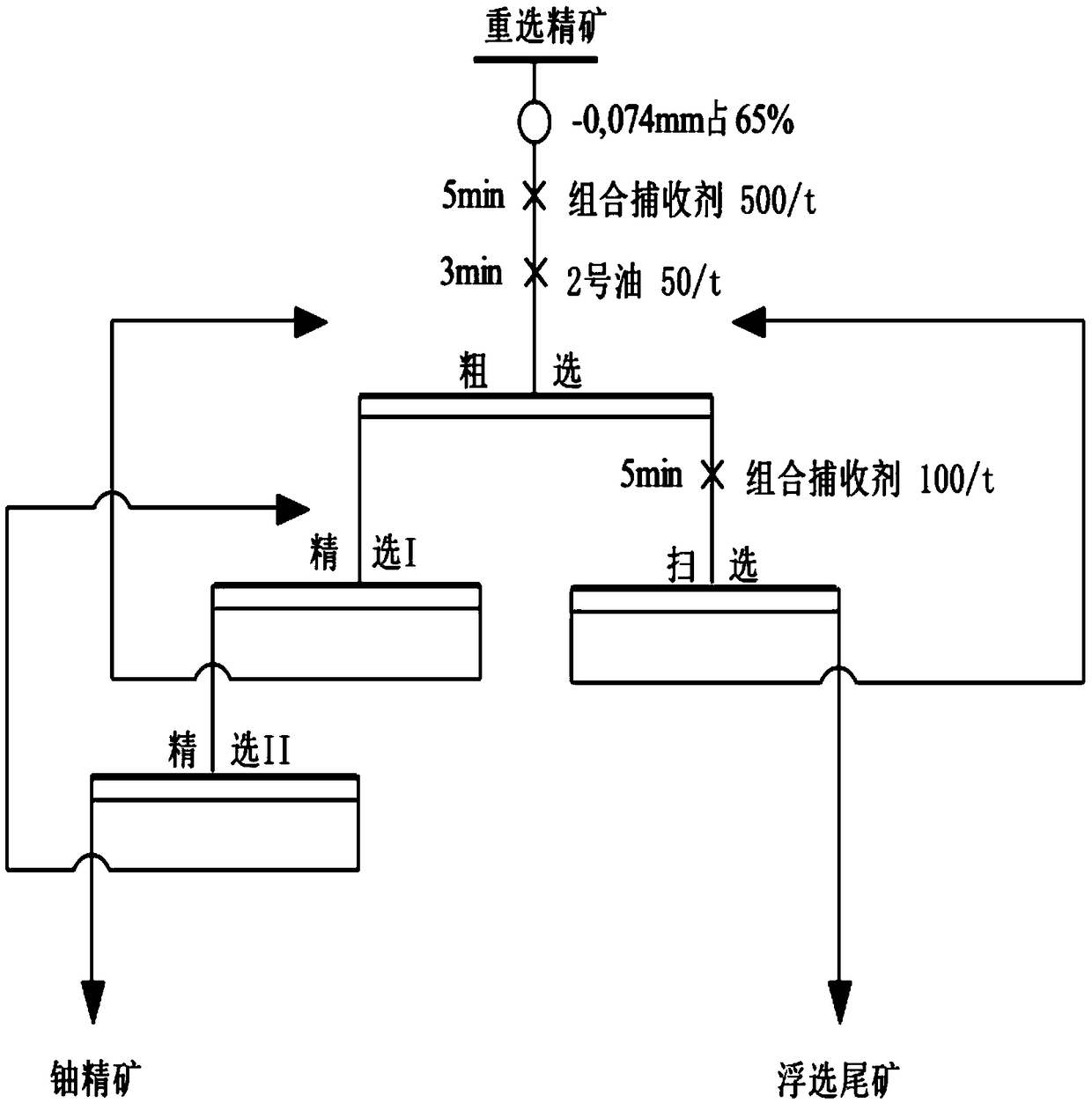

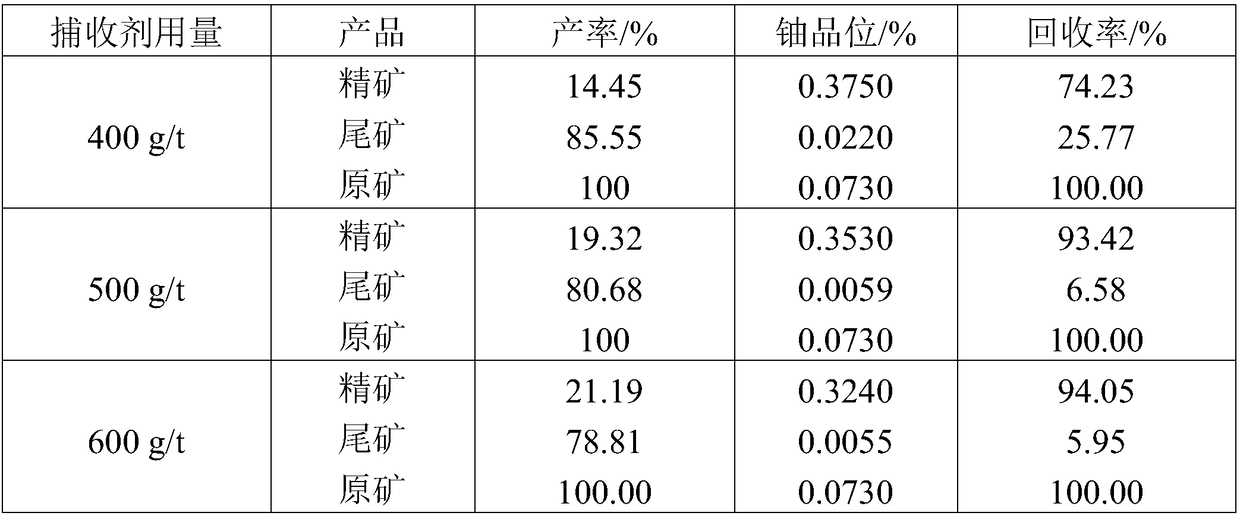

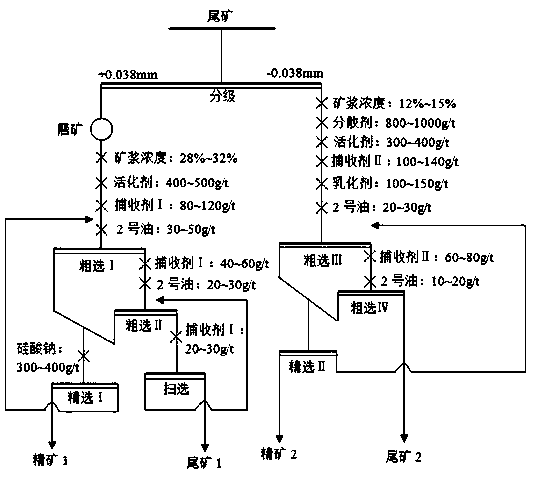

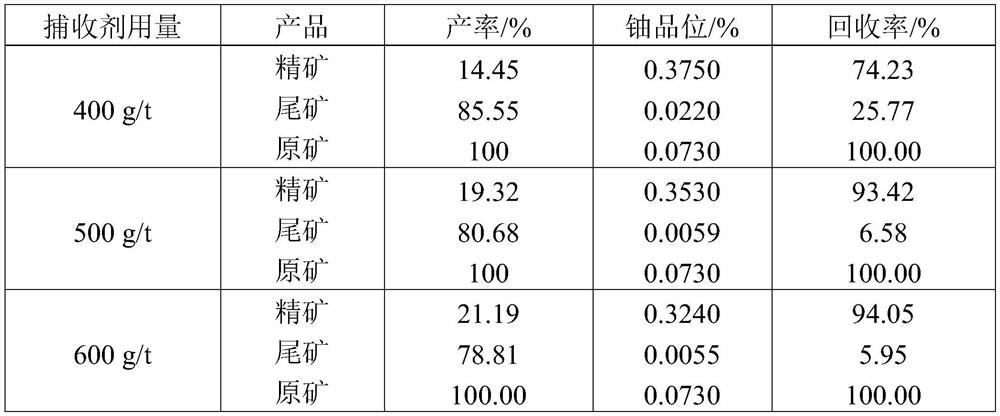

Combined collecting agent for niobium-titanium-uranium ore floatation and niobium-titanium-uranium ore floatation method

The invention relates to a combined collecting agent for niobium-titanium-uranium ore floatation. The combined collecting agent comprises, by mass, 60-90% of methyl benzyl arsonic acid and 10-40% of sodium n-butylxanthate. The methyl benzyl arsonic acid and the sodium n-butylxanthate are both analytically pure. A niobium-titanium-uranium ore floatation method adopts the combined collecting agent claimed in the claim 1 and comprises the following steps of (1) preparing a collecting agent solution; (2) conducting ore grinding; (3) conducting pulp mixing; (4) conducting niobium-titanium-uranium ore floatation; and (5) conducting multiple concentration on niobium-titanium-uranium rough concentration obtained in the step (4) until reaching the ideal floatation index again. Through the combinedcollecting agent provided by the invention, effective floatation of niobium-titanium-uranium ores can be realized. The combined collecting agent has the characteristics of being good in selectivity, high in collecting capacity, low in requirement for floatation temperature, little in use amount and the like. Gravity concentration is subjected to floatation through primary roughing, primary scavenging and secondary concentration closed-loop technological process, the grade of uranium in the floatation concentrate can reach 1% or more, and the recovery rate can reach 92% or more.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Lead-zinc oxide ore flotation agent

The invention discloses a lead-zinc oxide ore flotation agent. The lead-zinc oxide ore flotation agent comprises, by weight, 11-18 parts of dithiophosphate 25, 7.8-14 parts of ammonium dibutyl dithiophosphate, 20-25 parts of sodiumn-butylxanthate, 35.7-50 parts of diethyldithiocarbamate, 4.5-8 parts of kerosene, 150-200 parts of sodium silicate, 30-50 parts of ammonium bicarbonate and 10-20 parts of terpenic oil. The lead-zinc oxide ore flotation agent has the advantages of being good in flotation effect, easy to prepare, low in cost and high in recovery rate, thereby being worthy of intensive study and popularization and application in flotation of lead-zinc ore difficult to separate. During flotation of the lead-zinc oxide ore difficult to separate, it is only required that the eight materials are proportionally mixed to form the new flotation agent, the recovery rate of lead-zinc concentrate can be substantially improved, and operating difficulty is reduced for flotation workers and agentia workers as well.

Owner:玉门大昌矿业有限公司

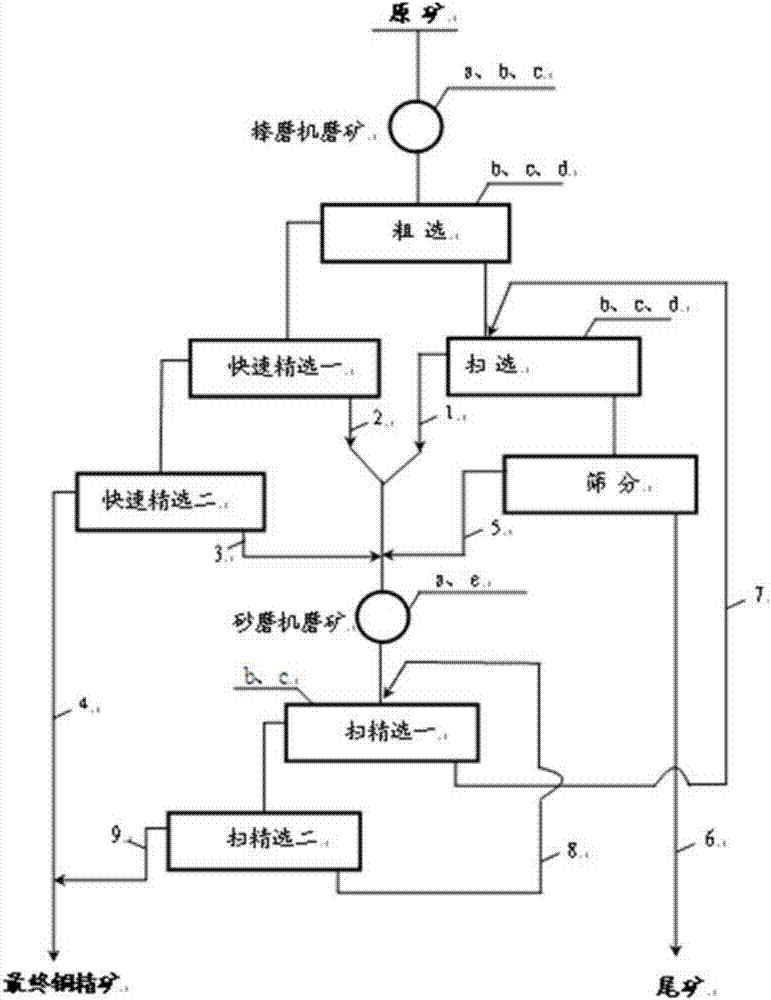

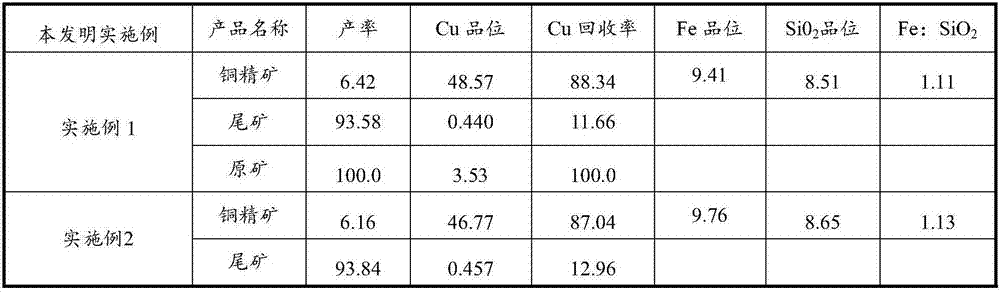

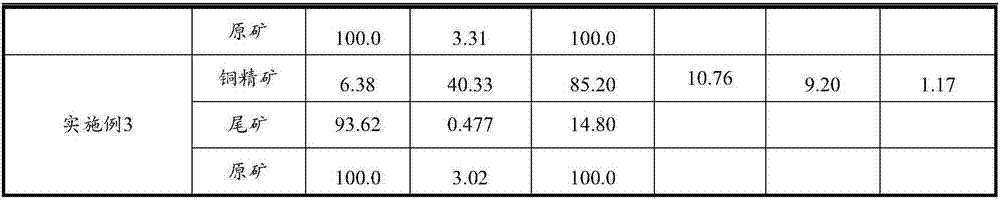

Flotation technology of micro-fine particle inbuilt state copper ore

InactiveCN107138270AGuaranteed RecoveryGuaranteed gradeFlotationGrain treatmentsFoaming agentResource development

The invention discloses a flotation technology of micro-fine particle inbuilt state copper ore. A staged grinding and separation process is adopted, rapid selection and re-grinding selection are adopted to treat and recycle copper ore in different dissociated states, lime serves as a slurry pH adjusting agent, sodium n-butylxanthate and butylamine dithiophosphate serve as a collecting agent, MIBC serves as a foaming agent, the lime and part of the collecting agent are added in a grinding machine, within the proper basicity range caused by the lime, through the selective collecting effect of the collecting agent on the copper, the recycling rate and the grade of the copper are ensured, and the silicon content of concentrates is limited. The technology is particularly suitable for treating copper sulphide ore with the fine inbuilt granularity and with the complex inbuilt relation with the silicate gangue. The reliable beneficiation technical guarantee is provided for the copper ore resource development, and efficient development and utilization can be promoted.

Owner:厦门紫金矿冶技术有限公司

Refractory gold ore collecting agent and preparation method thereof

A refractory gold ore collecting agent comprises, by weight, 23-27 parts of sodium butylxanthate, 3-4 parts of naphthalene sulfonic acid sodium salt, 4-6 parts of pyrophosphoric acid, 35-38 parts of oleic acid, 4-5 parts of sodium thiosulfate, 1-2 parts of sodium sulfide, 16-18 parts of isopropyl ethyl thionocarbamate, 4-6 parts of triethyl citrate, 6-8 parts of sodium ethylxanthate, 12-14 parts of mercaptobenzothiazole, 3-4 parts of gluconic acid and 10-12 parts of activator. The refractory gold ore collecting agent has collecting and foaming functions, stable foam and high collecting capability, so that gold ore recovery rate is high, selectively is good, and gold ore grade is high; through the activator, surface hydrophobicity of gold ore is changed, internal structure of the gold ore is activated, gold ore collecting performance of the collecting agent is improved, good recovery rate is guaranteed for various refractory gold ores, environmental pollution is low, and the collecting agent is easy to recover.

Owner:ANHUI CHAOSHAN NEW MATERIAL

Method for extracting pyrite in cyanide residue breaking cyanide floatation

The invention relates to a method for extracting pyrite in cyanide residue breaking cyanide floatation, which belongs to the method for extracting pyrite by floatation from cyanide tailings. After Colt'ss acid process on cyanide residue, the mass percentage concentration of ore pulp is 30%. H2SO4 is first added to make the PH value of ore pulp reach 4. Then, sodium polyphosphate and sodium fluosilicate are added as regulators, sodium n-butylxanthate as collectors as well as MIBC as a foaming agent. Twice roughing, twice scavenging and twice fine selection work are conducted to get the concentrate product with sulfur grade of 49.01% and recovery rate of 92.96%. The combined regulators provided by the method realize the floatation and enrichment of pyrite, solving the problem of difficulty in floatation of micro-fine particle pyrite. The method allows the cyanide residues that are hard to deal with to be fully utilized, and improves the economic efficiency.

Owner:CHANGCHUN GOLD RES INST

Flotation agent for separating gold from gold-bearing copper sulfide ores and method for manufacturing flotation agent

Owner:ANHUI CHAOSHAN NEW MATERIAL

Preparation method of activating and collecting combined agent for complex copper-lead-zinc sulfide ore

The invention relates to a preparation method of an activating and collecting combined agent for complex copper-lead-zinc sulfide ore and belongs to the technical field of ore beneficiation. The preparation method of the activating and collecting combined agent for the complex copper-lead-zinc sulfide ore comprises the steps that firstly, under the indoor temperature condition, 2-3 parts of sodium n-butylxanthate by mass and 0.25-0.5 part of kerosene by mass are stirred and mixed for 5-8 min at the speed of 800-1000 revolutions per minute; and finally, 0.8-1.6 parts of citric acid is added, and stirring and mixing are conducted for 7-12 min at the speed of 600-800 revolutions per minute, so that the activating and collecting combined agent for the complex copper-lead-zinc sulfide ore is prepared. According to the preparation method, the citric acid, the kerosene and the sodium n-butylxanthate are combined for use, and thus selective activating and collecting effects which are better than the activating and collecting effects of a traditional collecting agent and a traditional activating agent can be achieved on site under the normal temperature condition.

Owner:KUNMING UNIV OF SCI & TECH

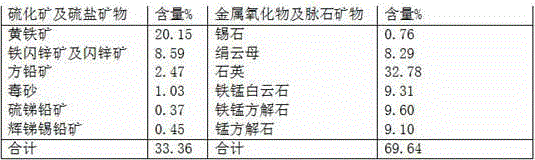

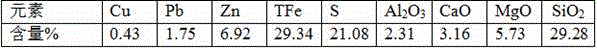

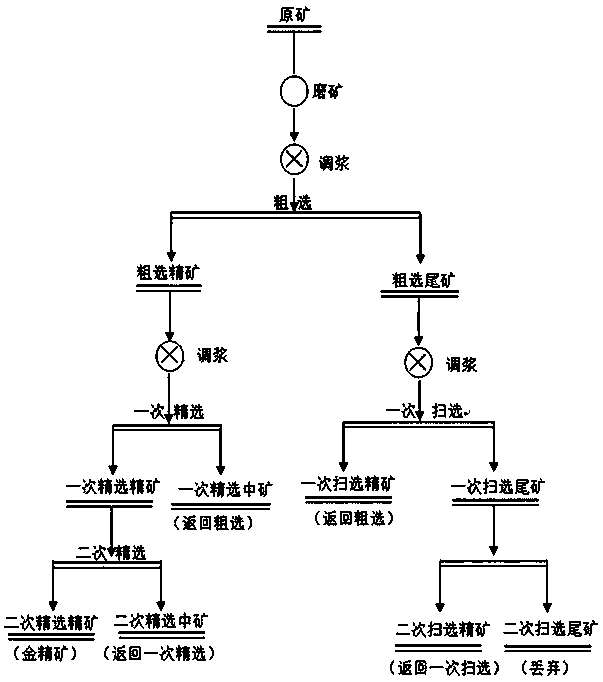

Method for recovering gold from flotation tailings

The invention discloses a method for recovering gold from flotation tailings. The method for recovering the gold from the flotation tailings is characterized in that the method for recovering the goldfrom the flotation tailings comprises the steps that gold minerals are contained in the flotation tailings, that is, the flotation tailings are ground to a certain fineness, the gold minerals are collected by adding a gold mineral regulating agent and a collecting and foaming agent, and within the concentration range of the certain regulating agent and the collecting agent, the flotation of goldminerals is realized; the gold mineral combination regulating agent is sodium sulfide, sodium sulfate and sodium fluorosilicate; and the collecting and foaming agent is sodium n-butylxanthate, hydroxyacid and terpineol oil. The mineral flotation method is simple in technology, managing and operating on the spot is easy, and high economic and technical indexes can be obtained by using the process.The used chemicals are environmental protection, and the final obtained gold fine mineral is higher in grade and recovery rate.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Marmatite flotation activating agent and preparation method and application thereof

The invention relates to a marmatite flotation activating agent, a preparation method and application thereof, belonging to the field of mineral processing flotation reagents. The invention aims at solving the technical problems that the activation selectivity of the marmatite flotation activating agent is weak, thereby leading the existence of lots of minerals such as ferric sulfide in marmatiteand the low recovery rate of the marmatite. According to the technical scheme, the marmatite flotation activating agent is prepared by reaction of 52-56% of copper sulfate, 12-15% of lead nitrate, 10-13% of sodium sulfide, 8-11% of oxidized paraffin soap and 9-12% of lauric acid under high temperature and high pressure. The marmatite flotation activating agent has good stability and strong selectivity. Marmatite concentrate with the grade of 46.53%-49.54% and the recovery rate of 78%-83.34% is obtained by a three-rough one-sweeping two-refining floatation technology under the combined action of the marmatite flotation activating agent and other flotation reagents such as lime, sodium n-butylxanthate and oil NO.2 in the marmatite flotation process.

Owner:四川省有色矿冶科技有限公司

Preparation and application of copper oxide ore flotation composite collecting agent

The invention relates to preparation and application of a copper oxide ore flotation composite collecting agent. The composite collecting agent comprises sodium n-butylxanthate, aviation kerosene and transformer oil, and the mass ratio of the sodium n-butylxanthate to the aviation kerosene to the transformer oil is 80:1:1 through mixing. The composite collecting agent further comprises water, and the mass of the water accounts for 90%-95% of the mass of the composite collecting agent. According to the composite collecting agent, the original nature of components can be kept, and an efficient synergistic effect can be generated. The composite collecting agent is used for replacing sodium n-butylxanthate of a traditional collecting agent, the number of times of copper concentration operation can be shortened by one time, and the total quantity of the collecting agent is reduced by 20%-30%; the beneficial effects of shortening the beneficiation process and reducing reagent consumption are achieved; the aims of reducing the production cost and improving economic benefits are achieved; and the copper oxide ore flotation composite collecting agent is suitable for copper oxide ore flotation.

Owner:云南省地质矿产勘查开发局中心实验室

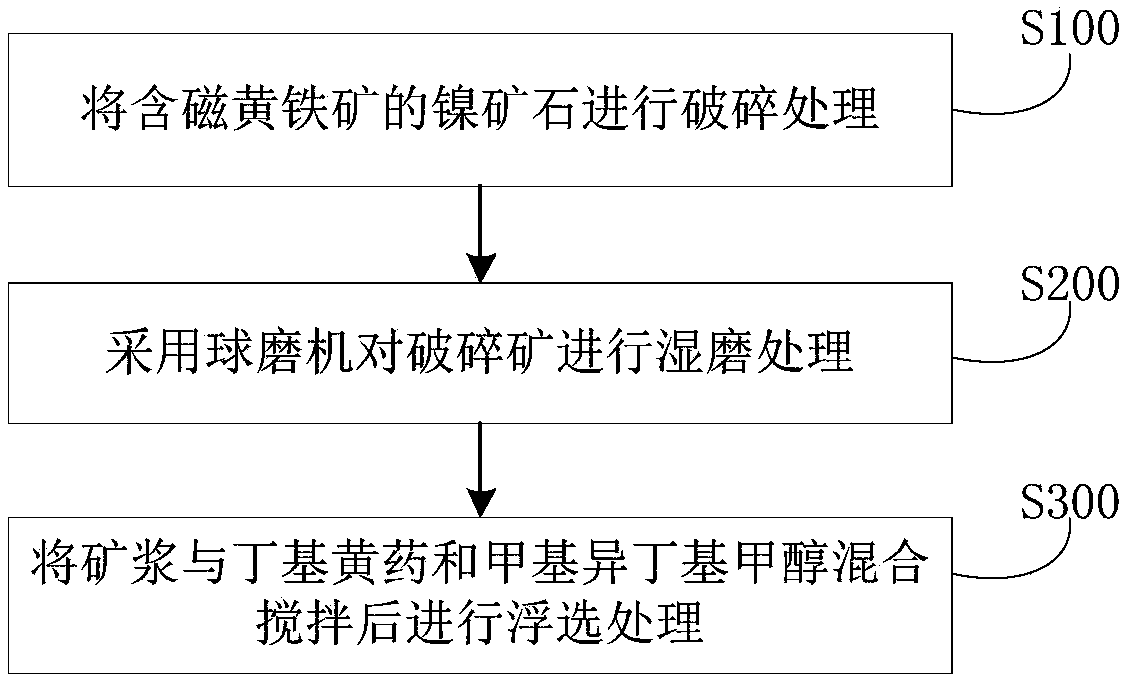

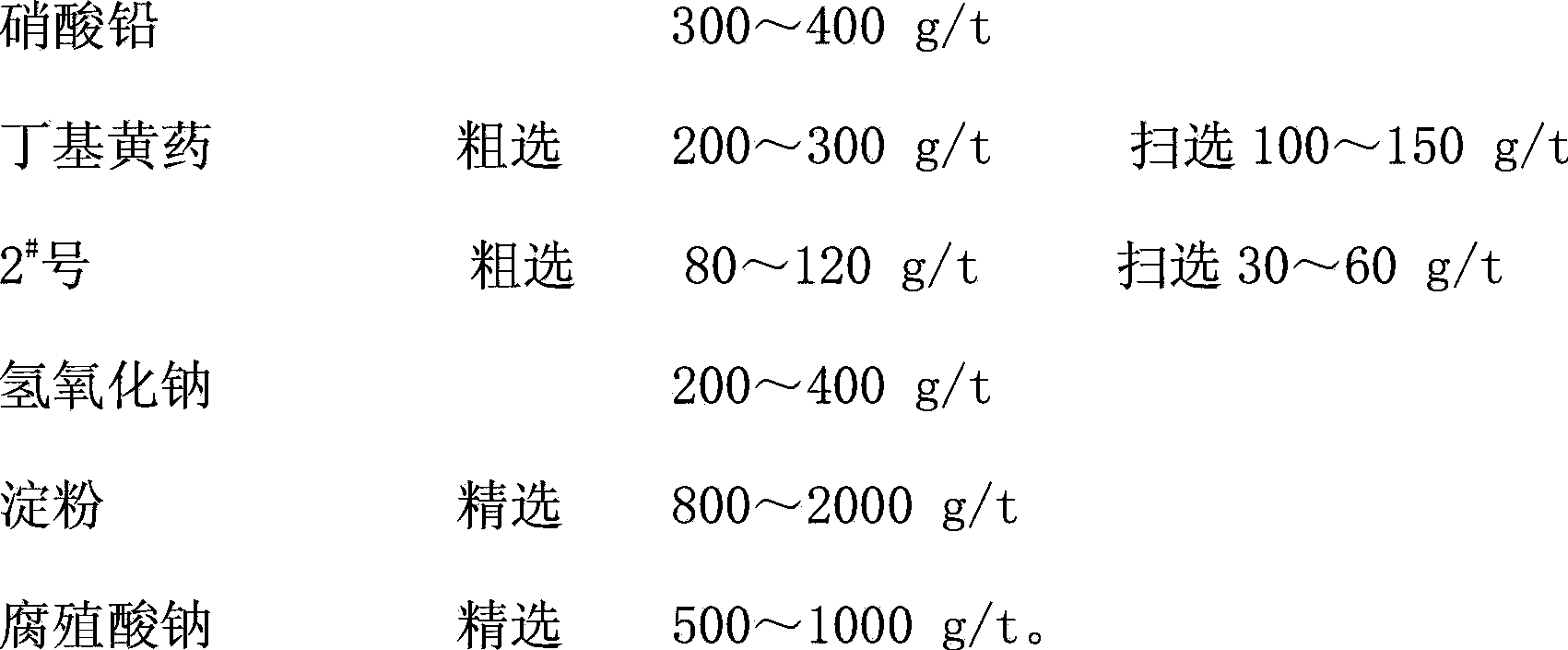

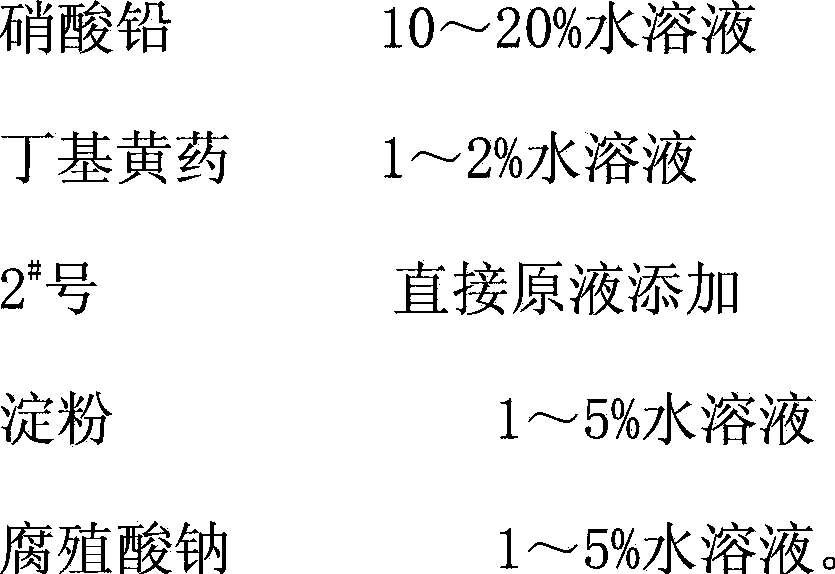

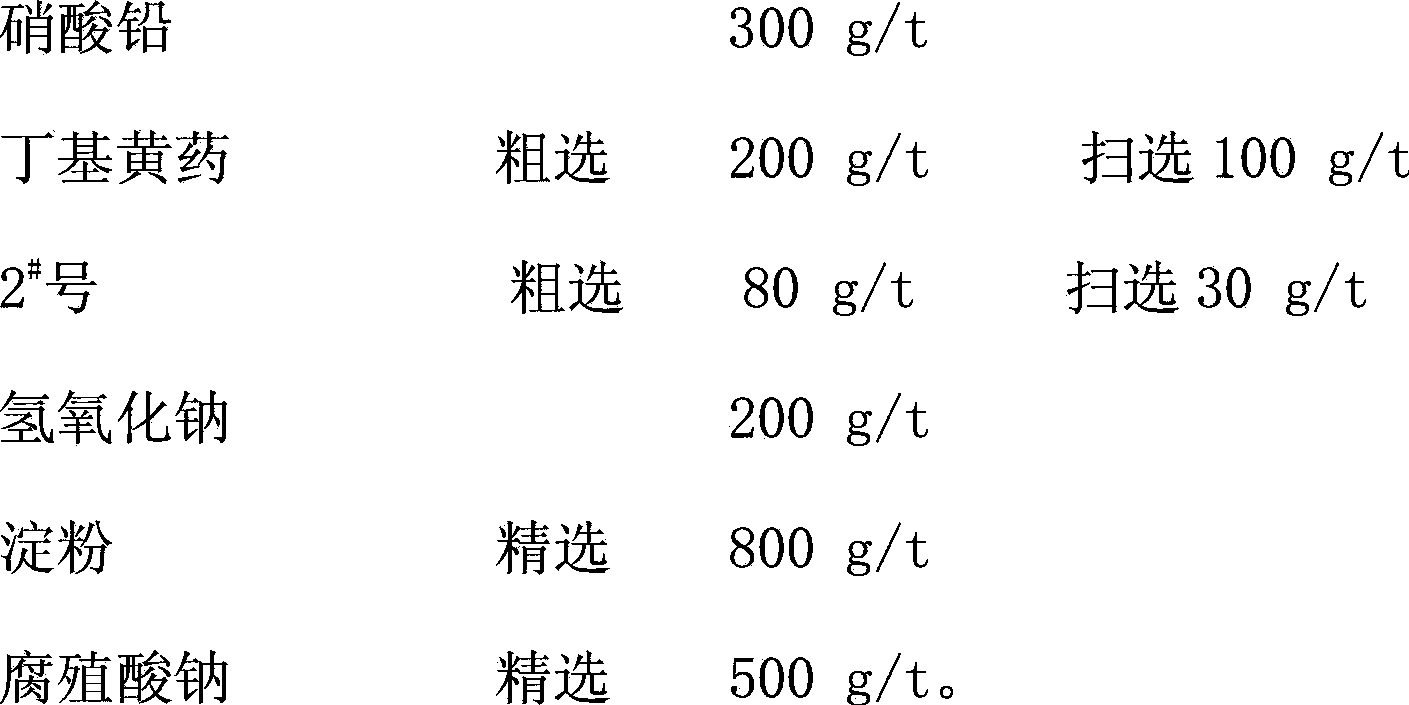

Method for machining pyrrhotite containing nickel ore

InactiveCN107670843ADeactivationReduce contentFlotationGrain treatmentsMethyl isobutyl carbinolButylxanthate

The invention discloses a method for machining pyrrhotite containing nickel ore. The method comprises the steps that (1) the pyrrhotite containing nickel ore is subjected to smashing treatment so thatsmashed ore can be obtained; (2) the smashed ore is subjected to wet grinding treatment through a ball grinder so that ore pulp can be obtained, wherein a lining plate and balls of the ball grinder are all made of stainless steel; and (3) the ore pulp, sodium n-butylxanthate and methyl isobutyl carbinol are mixed and stirred and then subjected to floatation treatment so that nickel concentrate and pyrrhotite can be obtained separately. According to the method, no inhibitor needs to be added, the environment-friendly effect is achieved, moreover, the cost is low, operation is convenient, the grade and the recovery rate of the nickel concentrate are remarkably improved, and remarkable economical benefits are achieved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Flotation separation method of antimony sulfide gold minerals

A flotation separation method of antimony sulfide gold minerals comprises the steps of performing bulk flotation to obtain antimony-gold mixed concentrate firstly and then separating the antimony-gold mixed concentrate to obtain antimony concentrate and gold concentrate, wherein in the bulk flotation, lead nitrate is taken as an activator for the antimony gold minerals, while sodium n-butylxanthate is used as a collecting agent and 2# oil is taken as a foaming agent; and in the flotation separation process, active carbon is used for reagent removal, while sodium hydroxide is used for adjusting the pH value to be 8.5-9.5, sodium humate and starch are used as a gold-containing mineral inhibitor and N, N-sodium diethyldithiocarbamate is used as the antimony mineral collecting agent. According to the flotation separation method, the antimony sulfide minerals can be effectively separated from the gold-carrying minerals through flotation, so that the antimony concentrate having the antimony grade of 33.82%-37.28% and the recovery rate of 87.21%-91.62% is obtained, and simultaneously, the gold concentrate having the grade of 40.27-45.81g / ton and the recovery rate of 85.64%-92.16% is obtained, through bulk flotation and further separation under the conditions that the feeding antimony grade is 0.37%-0.87% and the gold grade is 1.86-3.26 g / ton.

Owner:白银金锑矿业科技有限公司

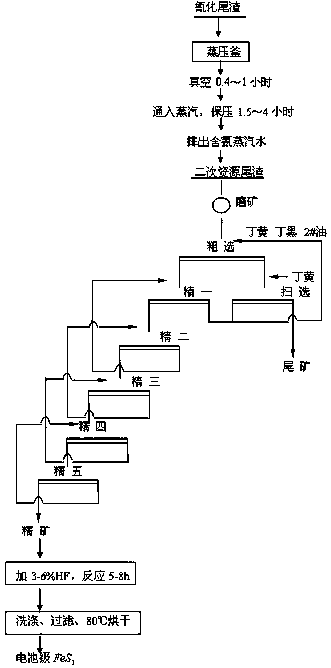

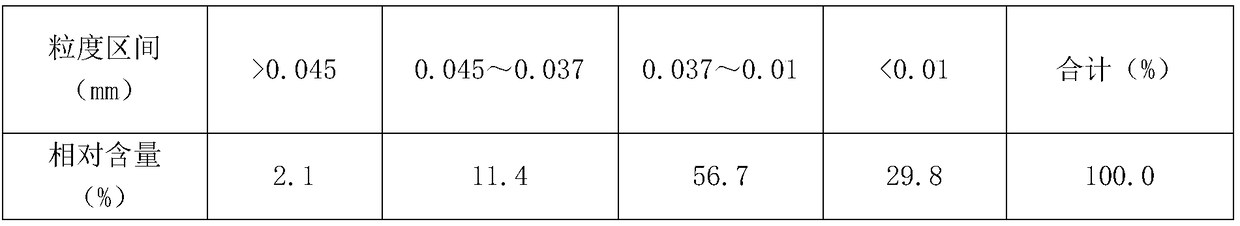

Technology for extracting ferrous sulfide from gold-bearing cyanide tailings

InactiveCN108043587AImprove qualityGood cyanide removal effectSolid waste disposalFlotationDibutyl dithiophosphateGold content

The invention relates to a technology for extracting ferrous sulfide from gold-bearing cyanide tailings. The technology comprises the steps that firstly, cyanide in the gold-bearing cyanide tailings is hydrolyzed by an autoclaving process, obtained secondary tailings are ground till a material in the secondary tailings, of which the fineness reaches 400 meshes, accounts for 95-98% of the secondarytailings; then, slurry blending is carried out to allow a liquid-solid mass ratio to be (3-4):1; and beneficiation reagents, namely, 60-120 g / t sodium n-butylxanthate and 15-35 g / t ammonium dibutyl dithiophosphate are added, a system pH value is adjusted to be between 6 and 9, and after one time of roughing, one time of scavenging and five times of cleaning are carried out, high-grade pyrites with the sulfur content being 52.87%, the gold content being 5.8 g / t, and the purity reaching 99.19% is obtained. With the adoption of the technology, the gold-bearing cyanide tailings in a smelting plant are recycled, secondary utilization of resources and the high value purpose are realized, and the amount of discharged pollutants is reduced substantially.

Owner:FUJIAN SHUANGQISHAN MINING +1

A kind of method of cyanide slag broken cyanide flotation pyrite

The invention relates to a method for extracting pyrite in cyanide residue breaking cyanide floatation, which belongs to the method for extracting pyrite by floatation from cyanide tailings. After Colt'ss acid process on cyanide residue, the mass percentage concentration of ore pulp is 30%. H2SO4 is first added to make the PH value of ore pulp reach 4. Then, sodium polyphosphate and sodium fluosilicate are added as regulators, sodium n-butylxanthate as collectors as well as MIBC as a foaming agent. Twice roughing, twice scavenging and twice fine selection work are conducted to get the concentrate product with sulfur grade of 49.01% and recovery rate of 92.96%. The combined regulators provided by the method realize the floatation and enrichment of pyrite, solving the problem of difficulty in floatation of micro-fine particle pyrite. The method allows the cyanide residues that are hard to deal with to be fully utilized, and improves the economic efficiency.

Owner:CHANGCHUN GOLD RES INST

Flotation method for reducing sulfur in bauxite concentrate

Disclosed is a flotation method for reducing sulfur in bauxite concentrate. The method includes the following steps: grinding raw material ore with 40%-70% of Al2o3 grade and 2%-24% of sulfur grade to mineral monomer, and then separating the mineral monomer; adding sulphide ore activator oxalate ethylamine; activating flotation of sulphide ore which is difficult to float; adding sodium n-butylxanthate and dithiophosphate BA compounded collectors and foaming agent oil 2; floating out sulfur-containing mineral with a mechanical-stirring-type flotation machine; and acquiring bauxite concentrate with the sulfur content less than 0.5%. Smelting requirements can be met.

Owner:广西冶金研究院有限公司

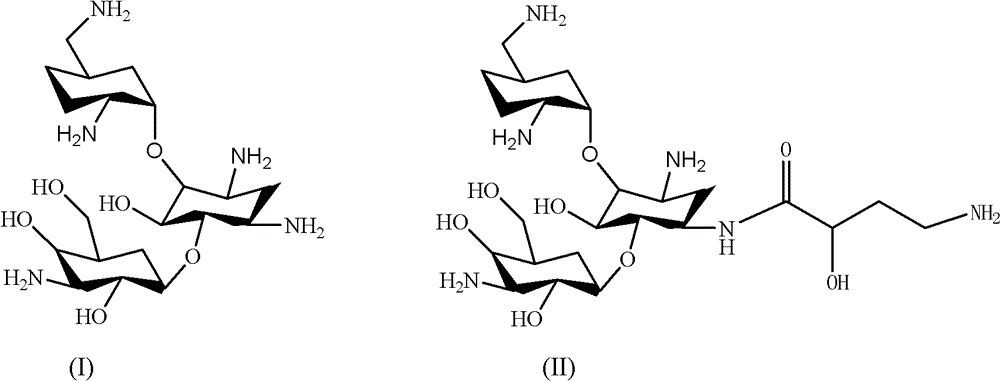

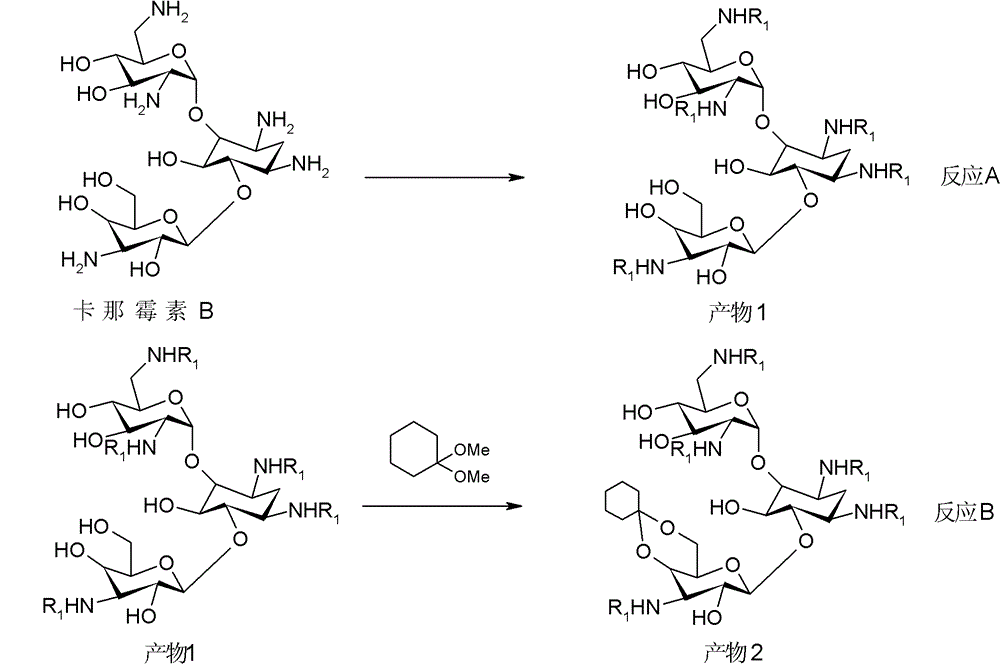

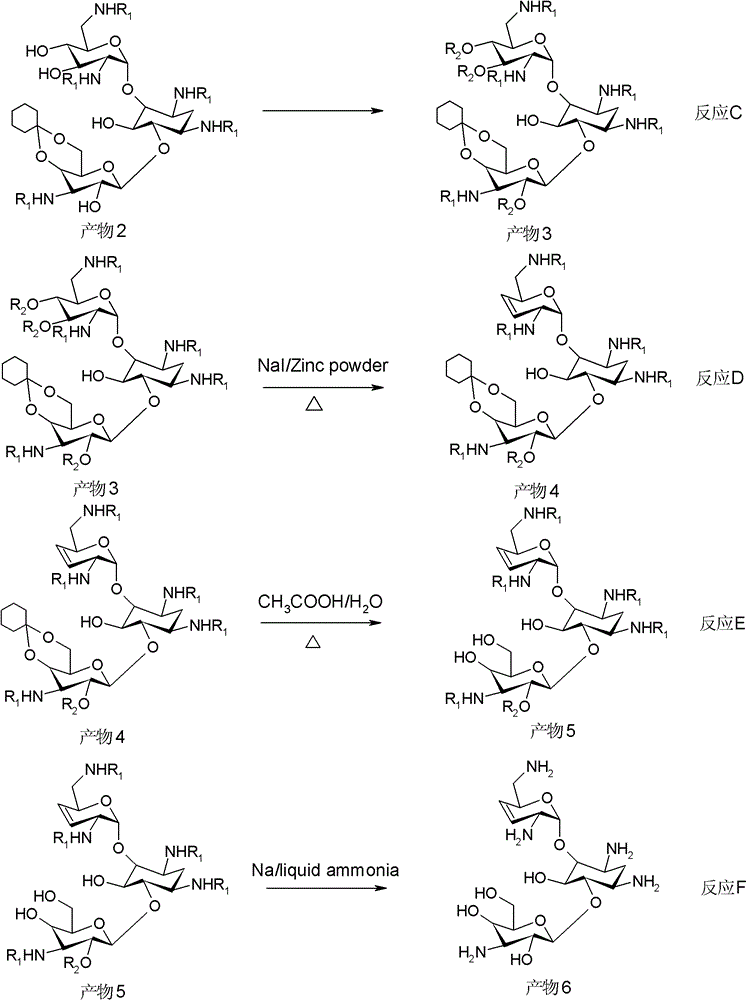

New synthetic method of arbekacin and intermediate of dibekacin thereof

InactiveCN102786564BHigh yieldReduce usageSugar derivativesSugar derivatives preparationTert-Butyloxycarbonyl protecting groupSide chain

The invention relates to a new synthetic method of arbekacin and an intermediate of dibekacin thereof. The method adopts kanamycin B as an initial synthetic raw material; five amino groups of kanamycin B are protected by butoxycarbonyl; 4''-position and 6''-position hydroxyls are protected by aldol condensation; 3'-position and 2''-position hydroxyls are selectively acylated; a 4'-position hydroxyl is sulfonylated; then an epoxy structure is formed; the epoxy structure is treated by potassium n-butylxanthate to form double bonds; and catalytic hydrogenation is performed to obtain dibekacin; dibekacin is used as a raw material; all amino groups and hydroxyls of the dibekacin are protected by hexamethyl disilyamine; side chain connection of 1-position amino group is performed with synthetic active ester; the silyl protection is removed; and finally arbekacin is obtained by hydrazine hydrate hydrazinolysis. The synthetic method is simple in operation, high in yield, friendly for environment, low in production cost, and quite suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH +1

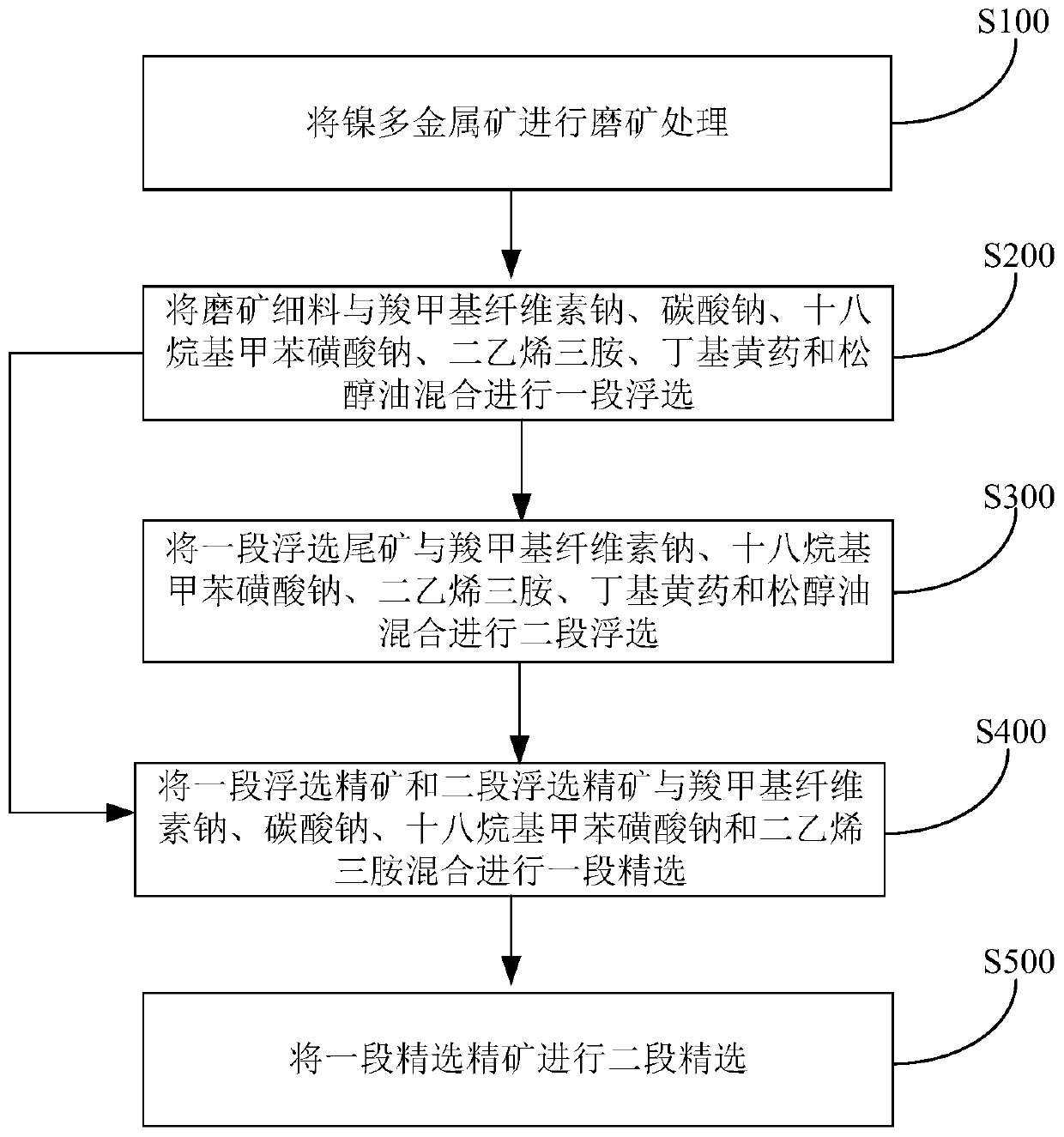

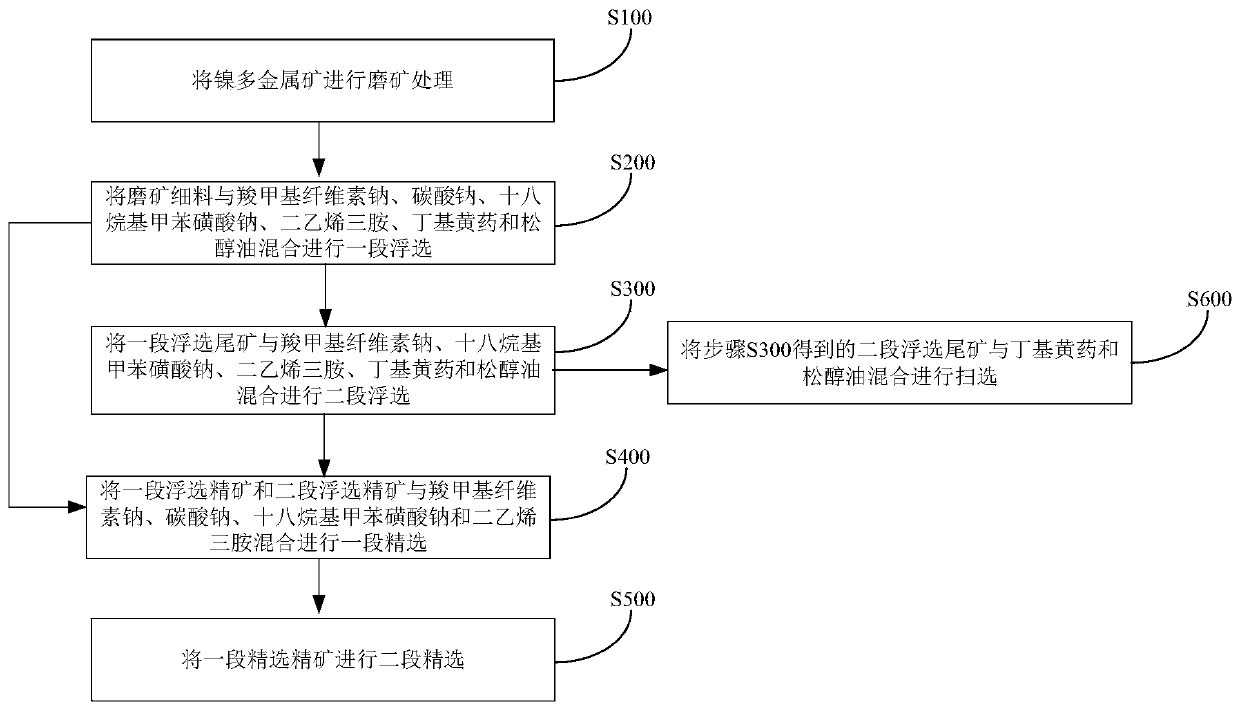

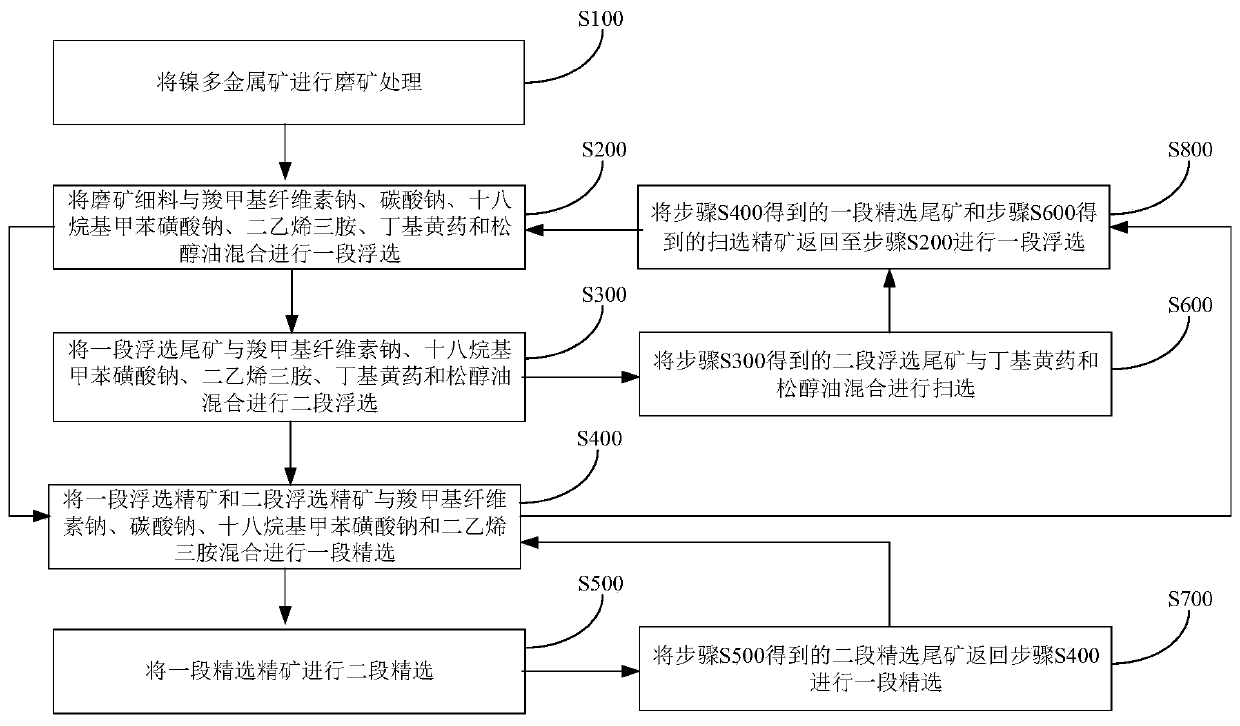

Method for recovering Ni-Co-Cu from Ni polymetallic ores

ActiveCN110918248ARealize resource utilizationImprove qualityFlotationProcess efficiency improvementCelluloseCarboxymethyl cellulose

The invention discloses a method for recovering Ni-Co-Cu from Ni polymetallic ores. The method comprises the steps of (1) conducting ore grinding treatment on the Ni polymetallic ores to obtain ore grinding fines; (2) mixing the ore grinding fines with sodium carboxymethyl cellulose, sodium carbonate, sodium p-octadecyl toluene sulfonate, diethylenetria, sodium n-butylxanthate and terpenic oil, and conducting first-stage flotation to obtain first-stage flotation concentrates and first-stage flotation tailings; (3) mixing the first-stage flotation tailings with sodium carboxymethyl cellulose, sodium p-octadecyl toluene sulfonate, diethylenetria, sodium n-butylxanthate and terpenic oil, and conducting second-stage flotation to obtain second-stage flotation concentrates and second-stage flotation tailings; (4) mixing the first-stage flotation concentrates and the second-stage flotation concentrates with sodium carboxymethyl cellulose, sodium carbonate, sodium p-octadecyl toluene sulfonateand diethylenetria, and conducting first-stage cleaning to obtain first-stage cleaned concentrates and first-stage cleaned tailings; and (5) conducting second-stage cleaning on the first-stage cleaned concentrates to obtain second-stage cleaned concentrates and second-stage cleaned tailings.

Owner:CHINA ENFI ENGINEERING CORPORATION

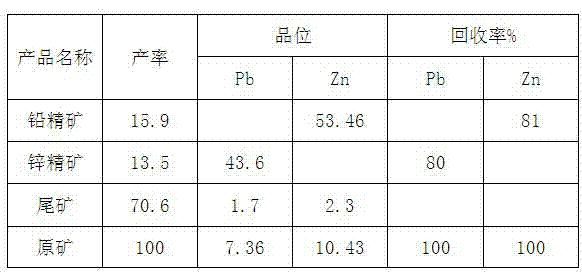

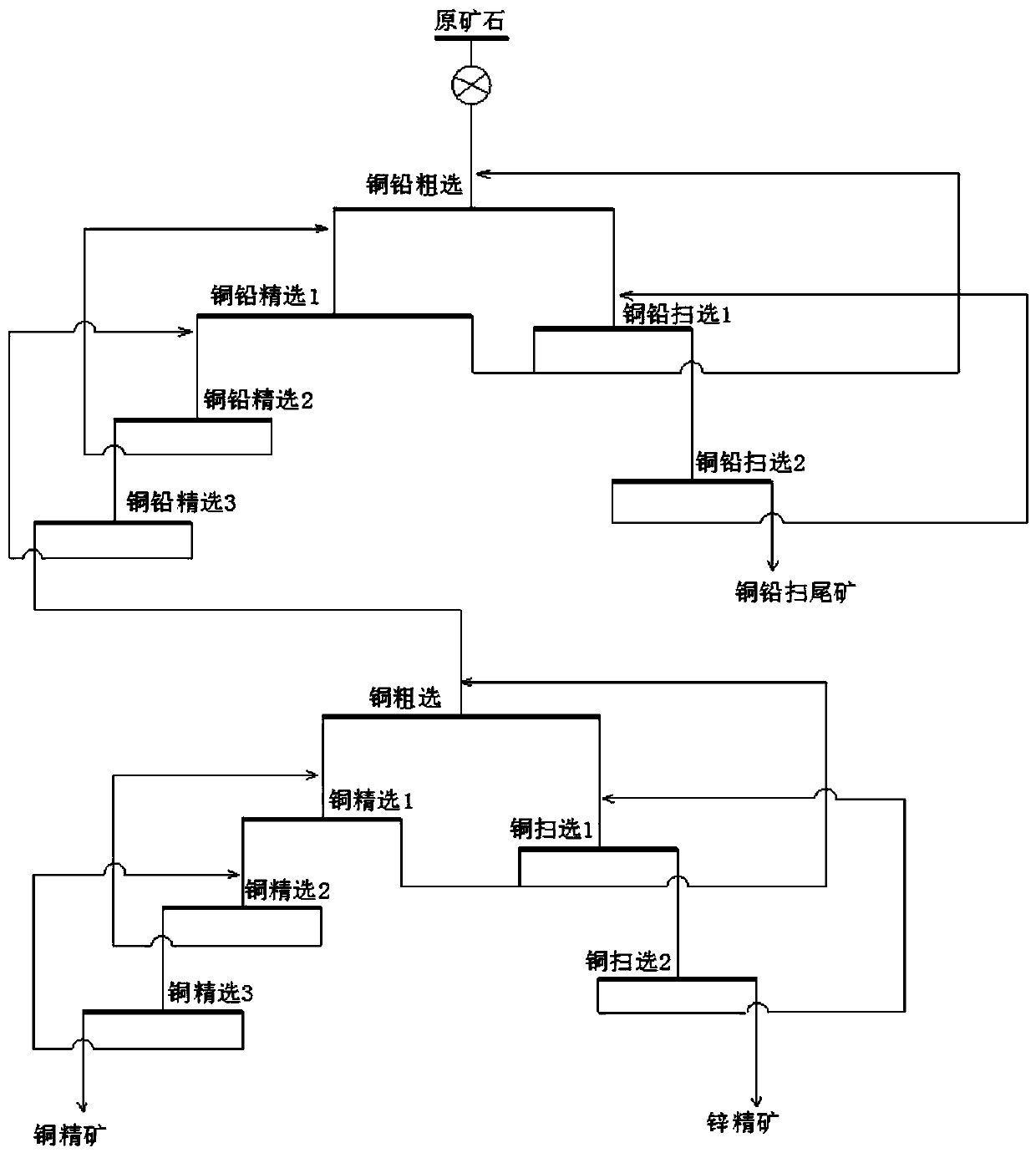

A kind of selection method of copper-lead sulfide ore

The invention discloses a beneficiation method for copper-lead sulphide ore, and belongs to the technical field of beneficiation. The method comprises raw ore grinding, copper-lead mixing flotation and copper-lead separation. Copper-lead mixing flotation comprises primary copper-lead roughing, tertiary copper-lead fine selecting and secondary copper-lead scavenging. Copper-lead separation comprises primary copper roughing, tertiary copper fine selecting and secondary copper scavenging. Lime, calcium hypochlorite, zinc sulfate, sodium sulfite, sodium sulphide, dimethyl dicarbonate, sodium pyrophosphate, sodium citrate, ethionine ester, ethyl thio carbamate, sodium n-butylxanthate, aniline aerofloat, diphenyl amino phosphorodithioic acid and sodium carbonate are added in the copper-lead roughing and copper-lead scavenging processes. Lime, water glass, sodium phosphate starch, carboxymethyl starch, phthalic acid, thiosalicylic acid, ethionine ester and sodium ethylxanthate are added in the copper roughing and copper scavenging processes. The beneficiation method solves the problem that in the process of beneficiation of the copper-lead sulphide ore through a traditional flotation method, the copper and lead recycling rate is low.

Owner:广西华洋矿源材料有限公司

A method for recovering gold and fine antimony minerals in flotation tailings of antimony-containing gold ore

The invention discloses a method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings. By the adoption of the method, the technical problem that if the antimony-containing gold ore flotation tailings are subjected to cyanide leaching directly, the cost is high, and the gold recovery rate is low is solved. Meanwhile, efficient recovery of associated antimony minerals can also be achieved. The method is characterized by comprising the steps that the tailings are rated, the tailings with the particle size being larger than 0.038 mm are subjected to regrinding and size mixing, copper sulfate, lead nitrate and ammonia carbonate are added sequentially as a mixed activating agent, sodium n-butylxanthate and ammonium butyl aerofloat serve as a collecting agent, No.2 oil serves as a foaming agent, and gold and the antimony minerals are recycled through flotation; and water is directly added into the tailings with the particle size being smaller than 0.038 mm for size mixing, grinding is not needed, sodium hexametaphosphate, copper sulfate, lead nitrate, ammonia carbonate, sodium n-butylxanthate, No.25 aerofloat, kerosene (or diesel oil) and No.2 oil are added in sequence, wherein the sodium hexametaphosphate serves a dispersing agent, the copper sulfate, lead nitrate and ammonia carbonate serve as an activating agent, the n-butylxanthate and No.25 aerofloat serve as a collecting agent, the kerosene (or diesel oil) serves an emulsifying agent, and the No.2 oil serves as a foaming agent, and gold and the micro-fine particle antimony minerals are recycled through flotation. The technique is reasonable, procedures are simple, the gold and antimony recovery rate is high, and industrialized implementation is easy.

Owner:KUNMING UNIV OF SCI & TECH

Washer material of cylinder cover bolt and preparation method of washer material

The invention discloses a washer material of a cylinder cover bolt. The washer material is prepared from the following materials in parts by weight: 32 to 38 parts of carbon fibers, 10 to 15 parts of maleic anhydride grafted polyphenylene ether, 6 to 10 parts of bentonite, 11 to 16 parts of n-butyl methacrylate, 20 to 25 parts of ethylene acrylic acid, 9 to 13 parts of polyurethane, 11 to 14 parts of anilmomethyl triethoxy silane, 5 to 8 parts of carbon black, 6 to 10 parts of titanium dioxide, 13 to 16 parts of polycarbonate, 8 to 15 parts of paraffin, 7 to 12 parts of magnesium hydroxide, 2 to 5 parts of dioctyl sebacate, 6 to 8 parts of sodium fluoride, 15 to 20 parts of melamine, 12 to 15 parts of methyl cyclohexane, 22 to 24 parts of silica gel, 4 to 8 parts of thiourea, 6 to 9 parts of zinc n-butylxanthate, 2 to 6 parts of succinic acid, 3 to 8 parts of lactic acid, and 7 to 10 parts of oleic acid. The washer material of the cylinder cover bolt has good elasticity and good high temperature resistance, has a flame-retardant function, and has good abrasion resistance.

Owner:芜湖天鸿汽车零部件有限公司

A method of flotation of niobium-titanium-uranium ore and application of combined collector

The invention relates to a combined collecting agent for niobium-titanium-uranium ore floatation. The combined collecting agent comprises, by mass, 60-90% of methyl benzyl arsonic acid and 10-40% of sodium n-butylxanthate. The methyl benzyl arsonic acid and the sodium n-butylxanthate are both analytically pure. A niobium-titanium-uranium ore floatation method adopts the combined collecting agent claimed in the claim 1 and comprises the following steps of (1) preparing a collecting agent solution; (2) conducting ore grinding; (3) conducting pulp mixing; (4) conducting niobium-titanium-uranium ore floatation; and (5) conducting multiple concentration on niobium-titanium-uranium rough concentration obtained in the step (4) until reaching the ideal floatation index again. Through the combinedcollecting agent provided by the invention, effective floatation of niobium-titanium-uranium ores can be realized. The combined collecting agent has the characteristics of being good in selectivity, high in collecting capacity, low in requirement for floatation temperature, little in use amount and the like. Gravity concentration is subjected to floatation through primary roughing, primary scavenging and secondary concentration closed-loop technological process, the grade of uranium in the floatation concentrate can reach 1% or more, and the recovery rate can reach 92% or more.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com