Method for recovering Ni-Co-Cu from Ni polymetallic ores

A polymetallic ore, nickel-cobalt technology, applied to the improvement of process efficiency, solid separation, flotation, etc., can solve the problems of treatment process that needs to be improved, waste of resources, little attention to the recovery of associated valuable element cobalt, etc., to achieve Utilization of resources and the effect of improving the economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

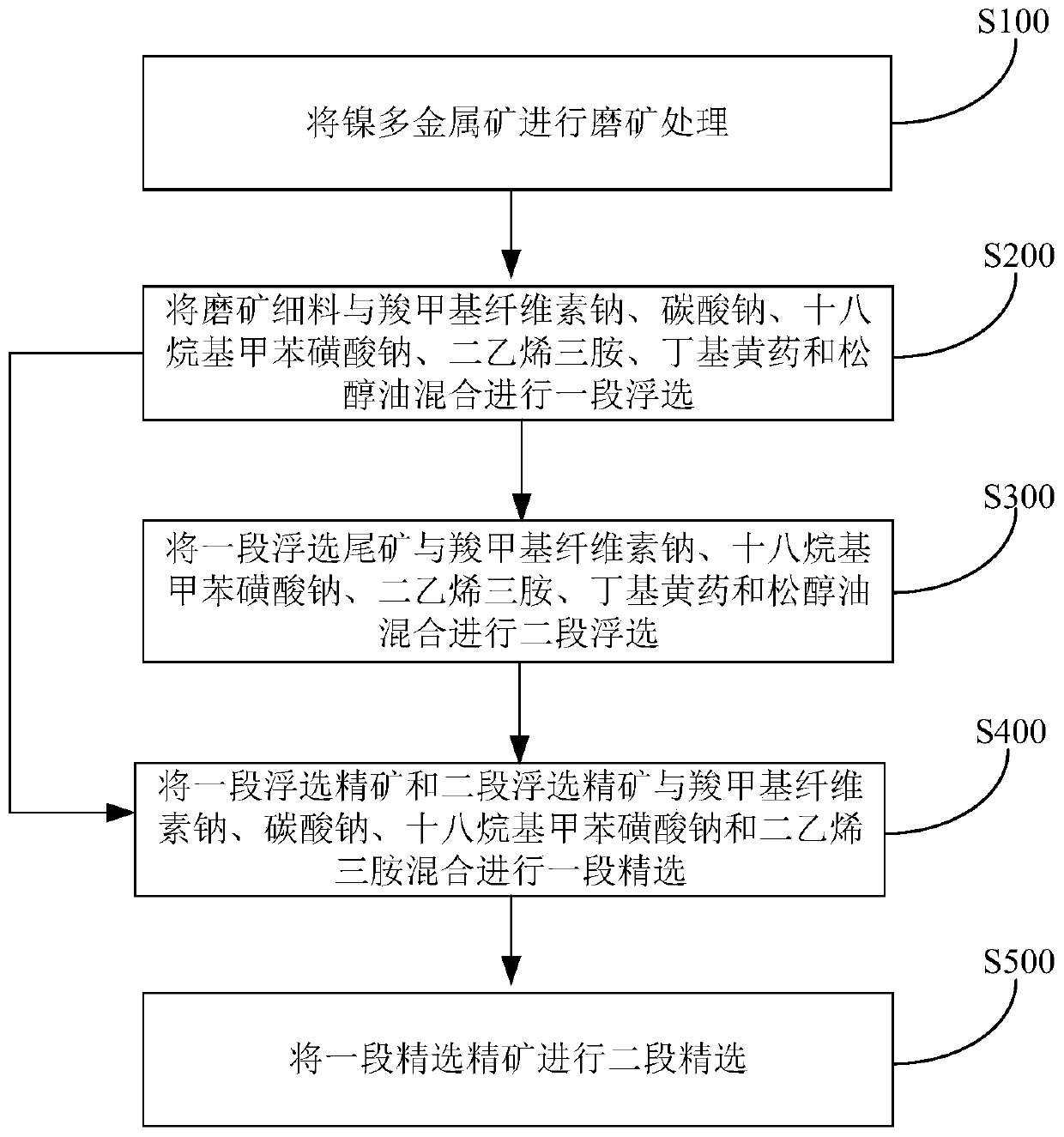

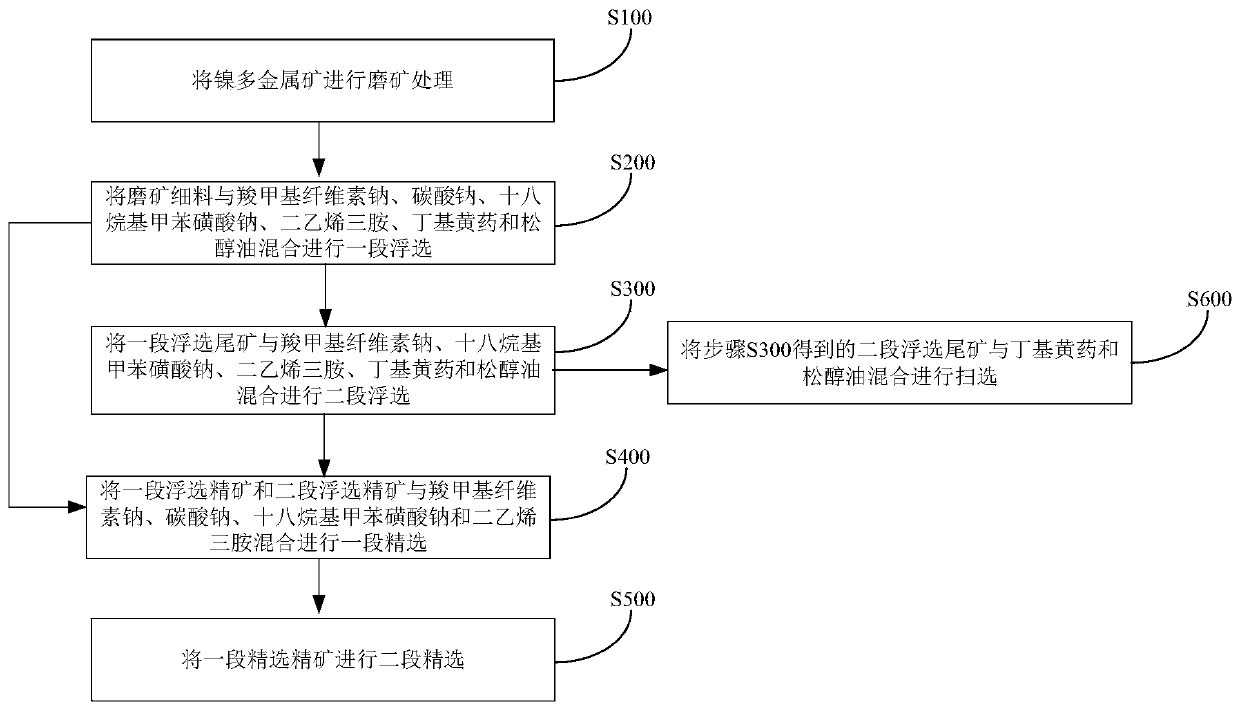

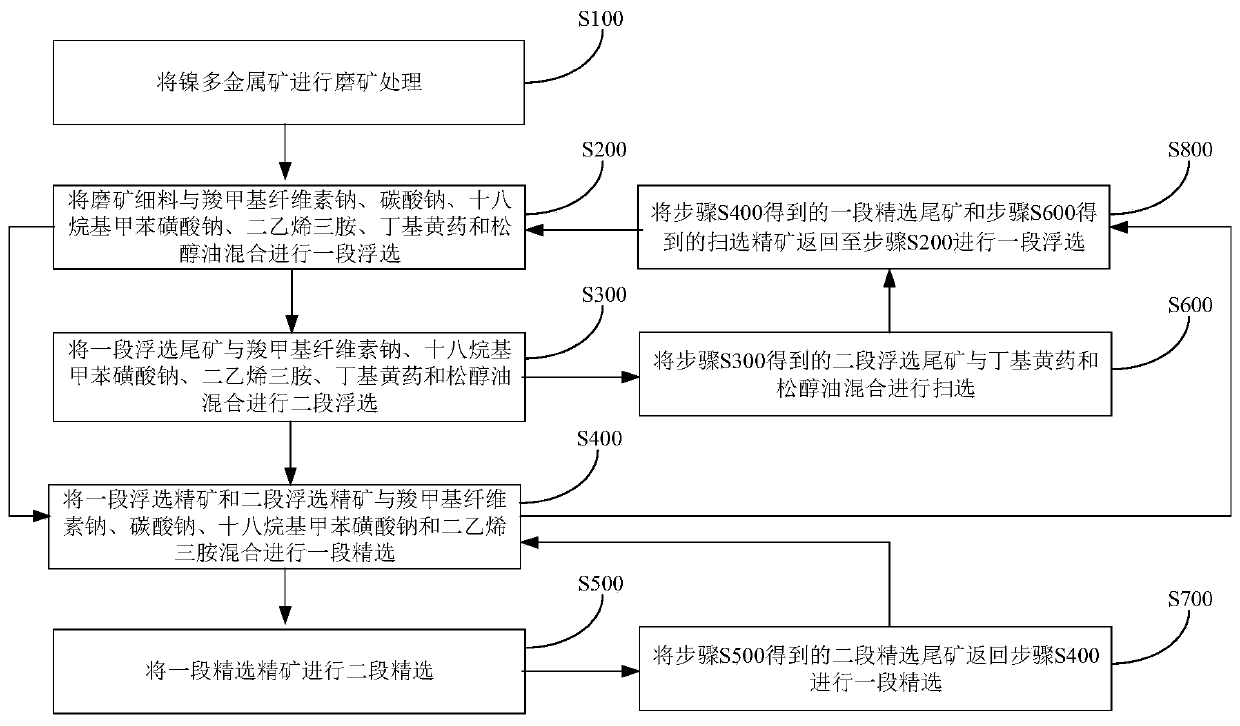

[0051] see Figure 4 A process flow chart of nickel-cobalt-copper recovery from nickel polymetallic ore. The nickel grade in a nickel polymetallic mine is 0.85wt%, the copper grade is 0.18wt%, and the cobalt grade is 0.032wt%.

[0052] (1) Grinding the nickel polymetallic ore with a ball mill, the obtained grinding fines have a particle size not higher than 0.074mm and account for 70%;

[0053] (2) Mix the grinding fines with sodium carboxymethyl cellulose, sodium carbonate, sodium octadecyl toluene sulfonate, diethylenetriamine, butyl xanthate and terpineol oil for one-stage flotation to obtain one-stage flotation Concentrate and one-stage flotation tailings, wherein, based on 1t of nickel polymetallic ore, the amount of sodium carboxymethyl cellulose is 600g, the amount of sodium carbonate is 1000g, and the amount of sodium octadecyltoluenesulfonate is 800g, The consumption of diethylenetriamine is 100g, the consumption of butyl xanthate is 80g, the consumption of pinitol ...

Embodiment 2

[0062] see Figure 4 A process flow chart of nickel-cobalt-copper recovery from nickel polymetallic ore. The nickel grade in a nickel polymetallic mine is 0.80wt%, the copper grade is 0.15wt%, and the cobalt grade is 0.029wt%.

[0063] (1) Grinding the nickel polymetallic ore with a ball mill, the obtained grinding fines have a particle size not higher than 0.074mm and account for 70%;

[0064] (2) Mix the grinding fines with sodium carboxymethyl cellulose, sodium carbonate, sodium octadecyl toluene sulfonate, diethylenetriamine, butyl xanthate and terpineol oil for one-stage flotation to obtain one-stage flotation Concentrate and one-stage flotation tailings, wherein, based on 1t of nickel polymetallic ore, the amount of sodium carboxymethyl cellulose is 600g, the amount of sodium carbonate is 1000g, and the amount of sodium octadecyltoluenesulfonate is 800g, The consumption of diethylenetriamine is 100g, the consumption of butyl xanthate is 80g, the consumption of terpineo...

Embodiment 3

[0073] see Figure 4 A process flow chart of nickel-cobalt-copper recovery from nickel polymetallic ore. The nickel grade in a nickel polymetallic mine is 0.92wt%, the copper grade is 0.21wt%, and the cobalt grade is 0.036wt%.

[0074] (1) Grinding the nickel polymetallic ore with a ball mill, the obtained grinding fines have a particle size not higher than 0.074mm and account for 70%;

[0075] (2) Mix the grinding fines with sodium carboxymethyl cellulose, sodium carbonate, sodium octadecyl toluene sulfonate, diethylenetriamine, butyl xanthate and terpineol oil for one-stage flotation to obtain one-stage flotation Concentrate and one-stage flotation tailings, wherein, based on 1t of nickel polymetallic ore, the amount of sodium carboxymethyl cellulose is 600g, the amount of sodium carbonate is 1000g, and the amount of sodium octadecyltoluenesulfonate is 800g, The consumption of diethylenetriamine is 100g, the consumption of butyl xanthate is 80g, the consumption of pinitol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com