Method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings

A flotation tailings and flotation technology, applied in flotation, solid separation and other directions, can solve the problems of high gold recovery rate, difficult industrialization implementation, and high cost, achieve high gold recovery rate, significant environmental benefits, and improve gold recovery. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

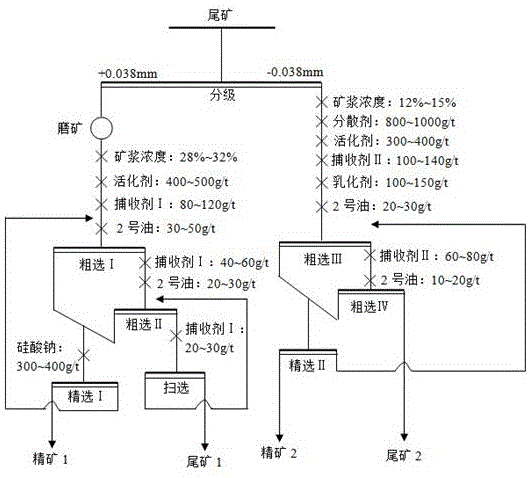

[0027] The flotation tailings of an antimony-containing gold ore in Guizhou were selected. The tailings contained 0.7g / t gold, 1.6% sulfur, 0.29% antimony, 0.92% arsenic, 1.02% carbon, and 5.8% iron; the tailings were directly leached with cyanide on site , but the gold content in the final leaching residue reaches 0.2g / t~0.4g / t, and the gold loss is serious.

[0028] Take the flotation tailings and get +0.038mm coarse-grained products and -0.038mm fine-grained products after hydrocyclone classification, and the content percentage of +0.038mm coarse-grained products after grinding to make the particle size less than 0.074mm 85%, then adjust the pulp concentration to 31%; according to each ton of tailings, add activator copper sulfate 200g / t, lead nitrate 200g / t, ammonium bicarbonate 100g / t, collector butyl xanthate 60g / t and butylamine black drug 40g / t, foaming agent No. 2 oil 30g / t, after pulping, carry out flotation roughing I to obtain flotation roughing I concentrate and ...

Embodiment 2

[0031] The flotation tailings of a complex antimony-bearing gold mine in Gansu were selected. The flotation tailings contained 1.2g / t gold, 1.89% sulfur, 0.83% antimony, 0.94% carbon, and 28.4% silicon dioxide. The treatment process of on-site flotation tailings is direct cyanidation leaching, but the gold content in the leaching residue reaches 0.6g / t~0.8g / t.

[0032] Take the flotation tailings, and obtain +0.038mm coarse-grained products and -0.038mm fine-grained products after hydrocyclone classification, and the +0.038mm coarse-grained products are regrinded so that the weight percentage of the particle size is less than 0.074mm. 88%, then adjust the pulp concentration to 30%; according to each ton of tailings, add activator copper sulfate 150g / t, lead nitrate 150g / t and ammonium bicarbonate 150g / t, collector butyl xanthate 60g / t t and butylamine black drug 30g / t, foaming agent No. 2 oil 40g / t, carry out flotation roughing I to obtain flotation roughing I concentrate and ...

Embodiment 3

[0035] The ore sample was taken from the flotation tailings of an antimony-bearing gold mine in Yunnan. The tailings contained 0.6g / t gold, 14.6g / t silver, 1.6% sulfur, and 0.1% antimony. The flotation tailings on site also used direct cyanidation Gold and silver are recovered by leaching, but the gold content in the leaching residue reaches 0.2g / t.

[0036] Take the flotation tailings and obtain +0.038mm coarse-grained products and -0.038mm fine-grained products after hydrocyclone classification. 90%, then add water to adjust the slurry concentration to 28%; according to each ton of tailings, add activator copper sulfate 200g / t, lead nitrate 200g / t and ammonium bicarbonate 100g / t, collector butyl xanthate 60g / t and butylamine black drug 40g / t, foaming agent No. 2 oil 40g / t, carry out flotation roughing I to obtain flotation roughing I concentrate and flotation roughing I tailings, flotation roughing Add collector butyl xanthate 30g / t, butylamine black powder 20g / t, foaming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com