Patents

Literature

382results about How to "Simple process structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

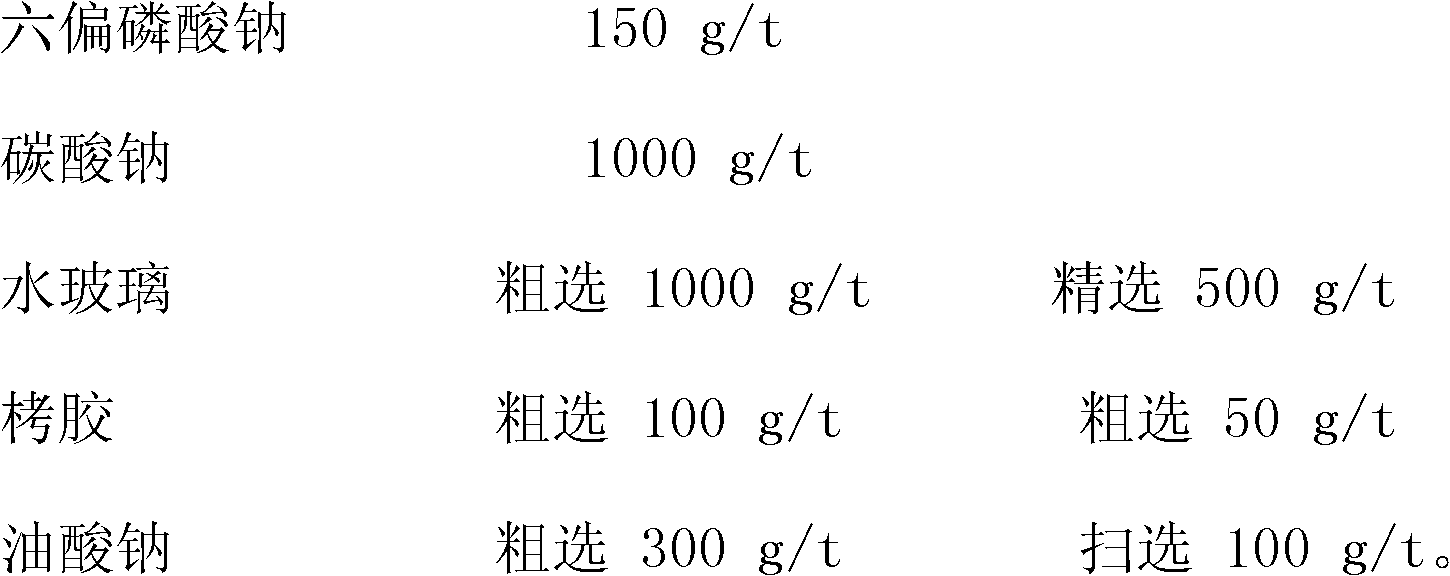

Low grade fluorite and barite flotation separation method

A low grade fluorite and barite flotation separation method uses waterglass as the inhibitor for silicious mineral and calcium carbonate mineral; uses oleic acid as the collector for fluorite and barite; and uses starch, sodium sulphate, hydrochloric acid and sodium hexametaphosphate as the inhibitor for barite mineral. The invention can perform flotation separation of low grade fluorite and barite effectively; under the condition that the given fluorite grade is 33.92%-40.41%, and the barite grade is 34.67%-35.33%, by mixing, flotation and separation, can achieves the fluorite concentrate with grade of above 95% and recovery rate of 75.5%-78.5%, and the barite concentrate with grade of 92.3%-93.27% and recovery rate of 75.2%-79.73%.

Owner:GUANGXI UNIV

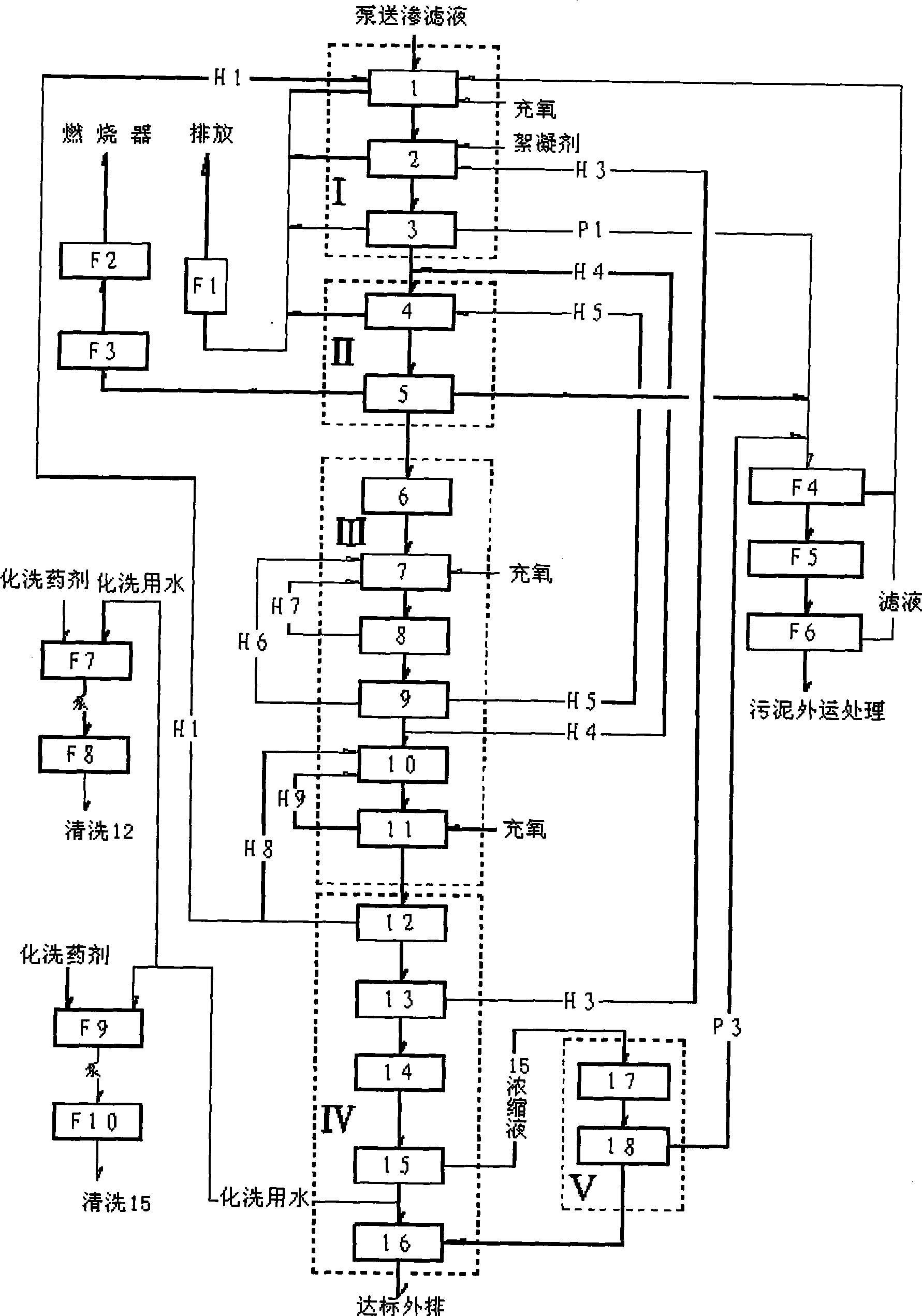

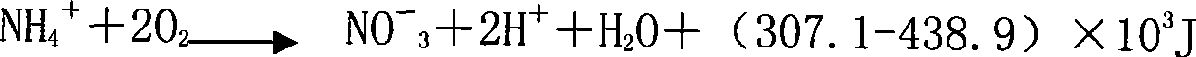

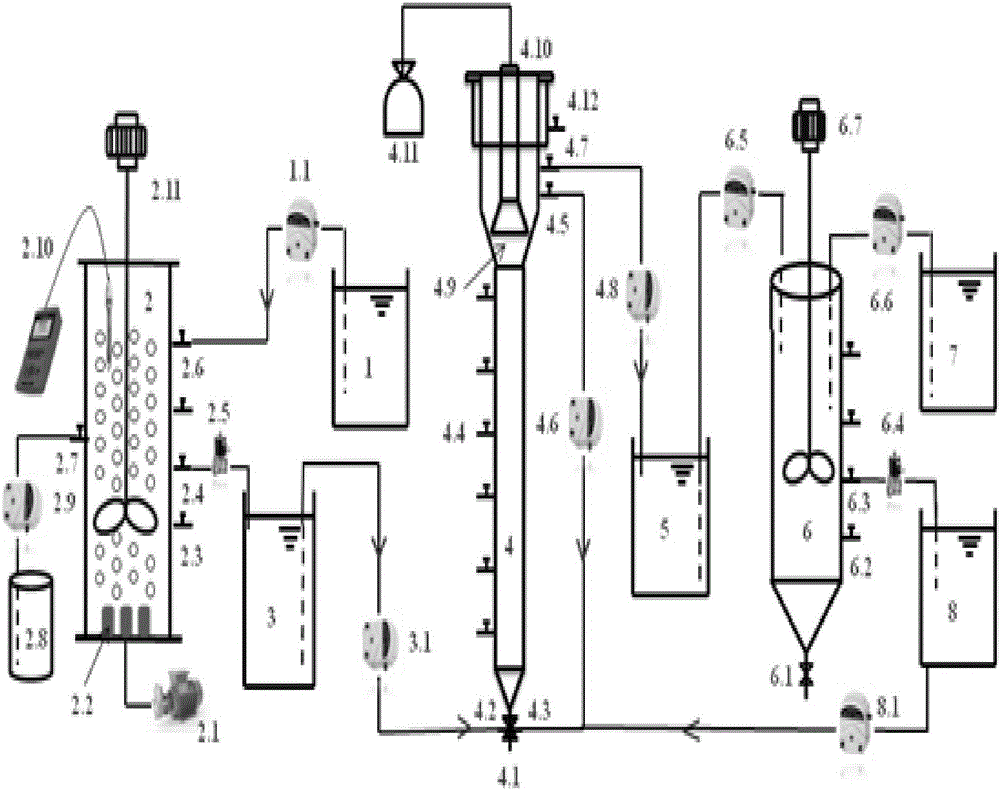

Treatment process for garbage leachate

ActiveCN101428938AImprove biodegradabilityPrevent rancidityTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationHydrolysis

The invention discloses a method for treating landfill leachate, which orderly comprises flocculation precipitation pretreatment, hydrolysis pre-acidification treatment, anaerobic treatment, aerobic treatment comprising shortcut nitrification-denitrification and secondary nitrification-denitrification, membrane separation treatment and oxidation flocculation treatment. The method has the advantages of having higher removal rate of ammonia nitrogen and lower energy consumption, realizing the up-to-standard discharge of leachate concentrated solution, ensuring sound operation of the whole system, greatly lowering the oxidation-reduction potential in the anaerobic reaction, and improving the anaerobic treatment effect, thereby making the landfill leachate fully meet the first-level discharge standard of the Integrated Wastewater Discharge Standard.

Owner:浙江永峰环保科技股份有限公司 +1

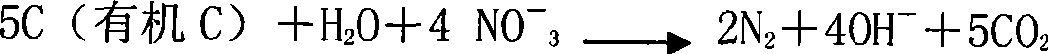

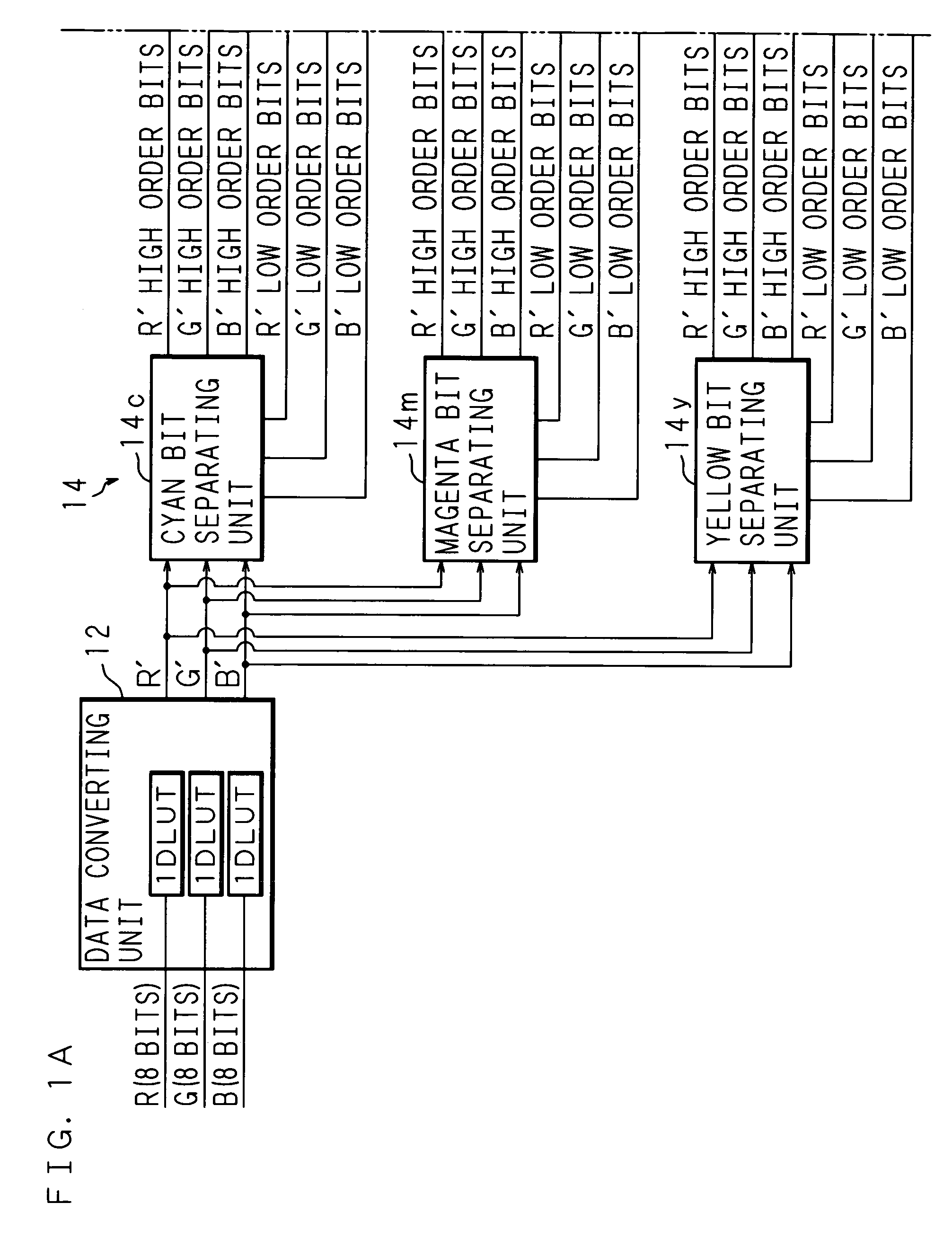

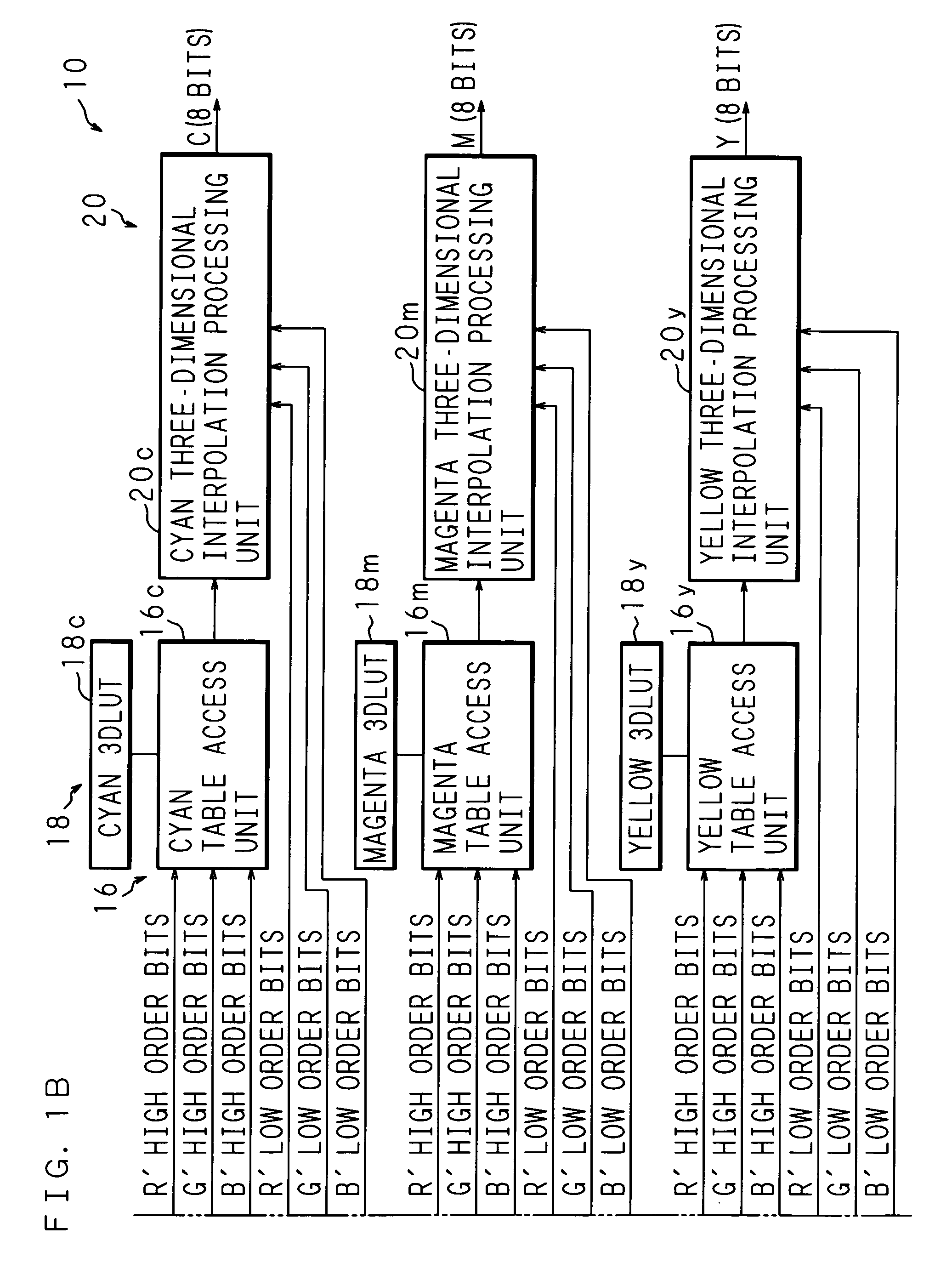

Color converting device, image forming apparatus, color conversion method, computer program and recording medium

ActiveUS20050264836A1Improve color conversion accuracyMinimize lowering of color conversion accuracyDigitally marking record carriersDigital computer detailsColor transformationColor correction

In a color converting device for converting input image data based on a plurality of first color components (the number of bits of each color component is k) into output image data based on plural of second color components by interpolation processing using a 3DLUT storing color correction values at grid points obtained by dividing a color space composed of the plurality of first color components, the distance of the grid points is 2n (where n is an integer smaller than k), the number Dn of grid points of the plurality of first color components is an integer satisfying 2m−1+1<Dn<2m+1+1 (where Dn≠2m+1, and m=k−n), and input image data is converted into output image data by converting each color component data of the input image data according to the number of grid points, and performing interpolation processing by reading color correction values corresponding to the converted color components from the 3DLUT.

Owner:SHARP KK

Method for recovering fine mud cassiterite

The invention discloses a method for recovering fine mud cassiterite. The method comprises the following steps of dispersing a fine mud cassiterite mineral in an agitator by using sodium hexametaphosphate as a dispersing agent, grading the fine mud cassiterite mineral by using a high frequency fine screen, recovering the graded fine mud cassiterite mineral through gravity separation by using a fine mud cassiterite table concentrator to obtain fine mud rough concentrates in different particle sizes, and combining the fine mud rough concentrates in different particle sizes and performing floatation recovery on the fine mud cassiterite to obtain a cassiterite concentrate. By the method, the fine mud cassiterite can be effectively recovered, and the fine mud cassiterite concentrate of which the cassiterite grade is 45.87-46.21 percent and the recovery rate is 52.51-56.75 percent can be obtained under the condition that the fed mineral has the cassiterite grade of 0.37-0.45 percent.

Owner:广西华锡集团股份有限公司

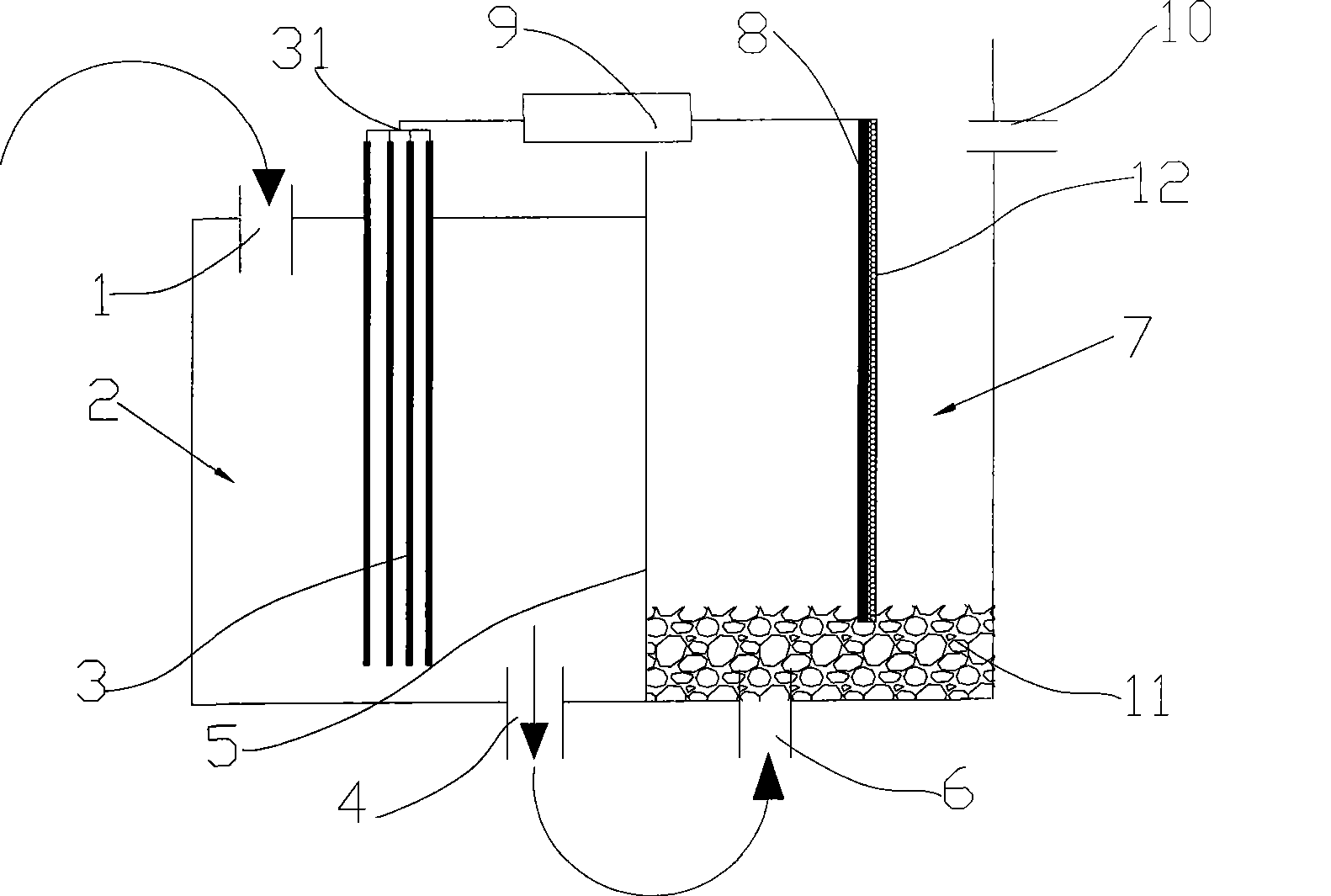

Two segment type biological fuel cell

InactiveCN101383425AReduce processing costsLow costFinal product manufactureBiochemical fuel cellsHigh current densityMicrobial agent

The invention discloses a two-section type microbiological fuel cell which comprises a cathode chamber and an anode chamber, wherein a cathode is inserted in the cathode chamber, an anode is inserted in the anode chamber, an aerobic microorganism culture medium is arranged in the cathode chamber, and an aerobic microorganism film is hung on the surface of the cathode. The two-stage sewage treatment process is combined with the electric power generation process to cause the waste water to be thoroughly degraded by adopting the two-step anaerobic and aerobic process; in addition, the electrochemical activity of the aerobic microorganism is taken as the cathode microbial agent, and oxygen gas is taken as the electron acceptor, therefore, the continuous electric power generation is realized, the current density is improved, the cost of the conventional cathode catalyst is reduced, and the sewage water BOD can be tested by using the cathode aerobic microorganism; the invention has the advantages that the process structure is simple, the operation is easy, the latent electrical energy in the sewage water is 10 times of the processing cost of the sewage water, and the sewage treatment plant can solve the problem of cost of sewage treatment by utilizing 1 / 20 of the latent electrical energy.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

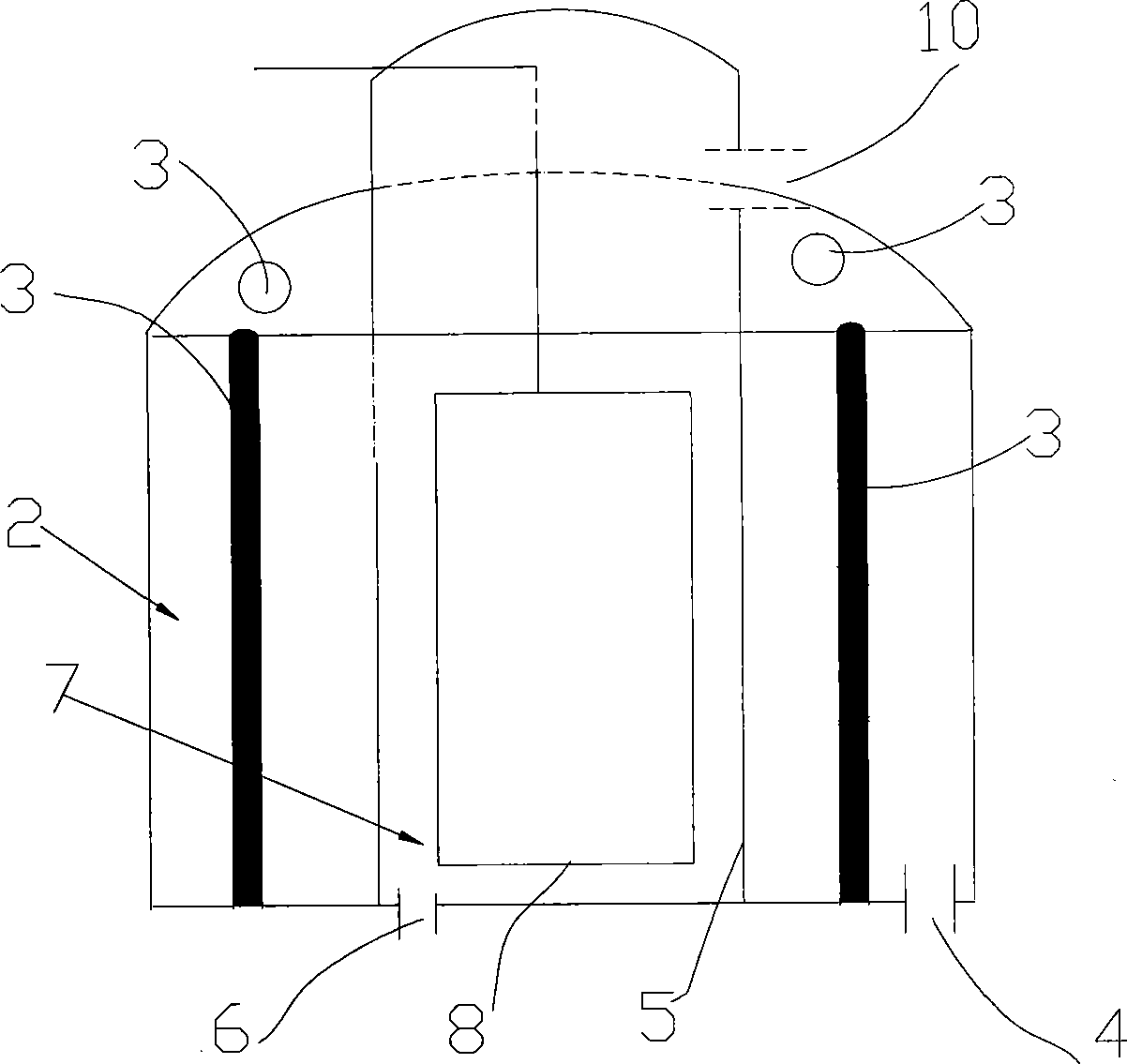

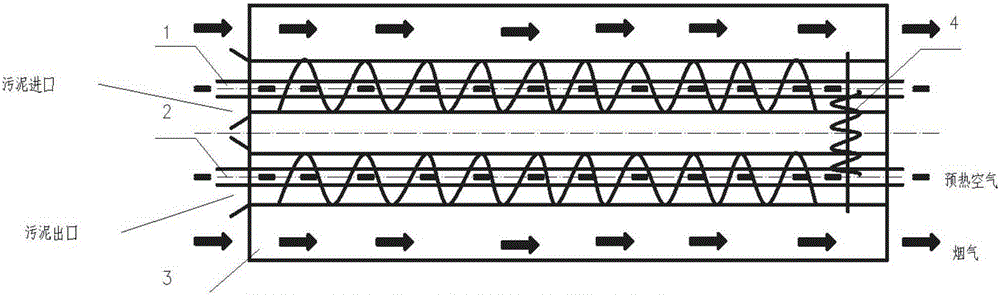

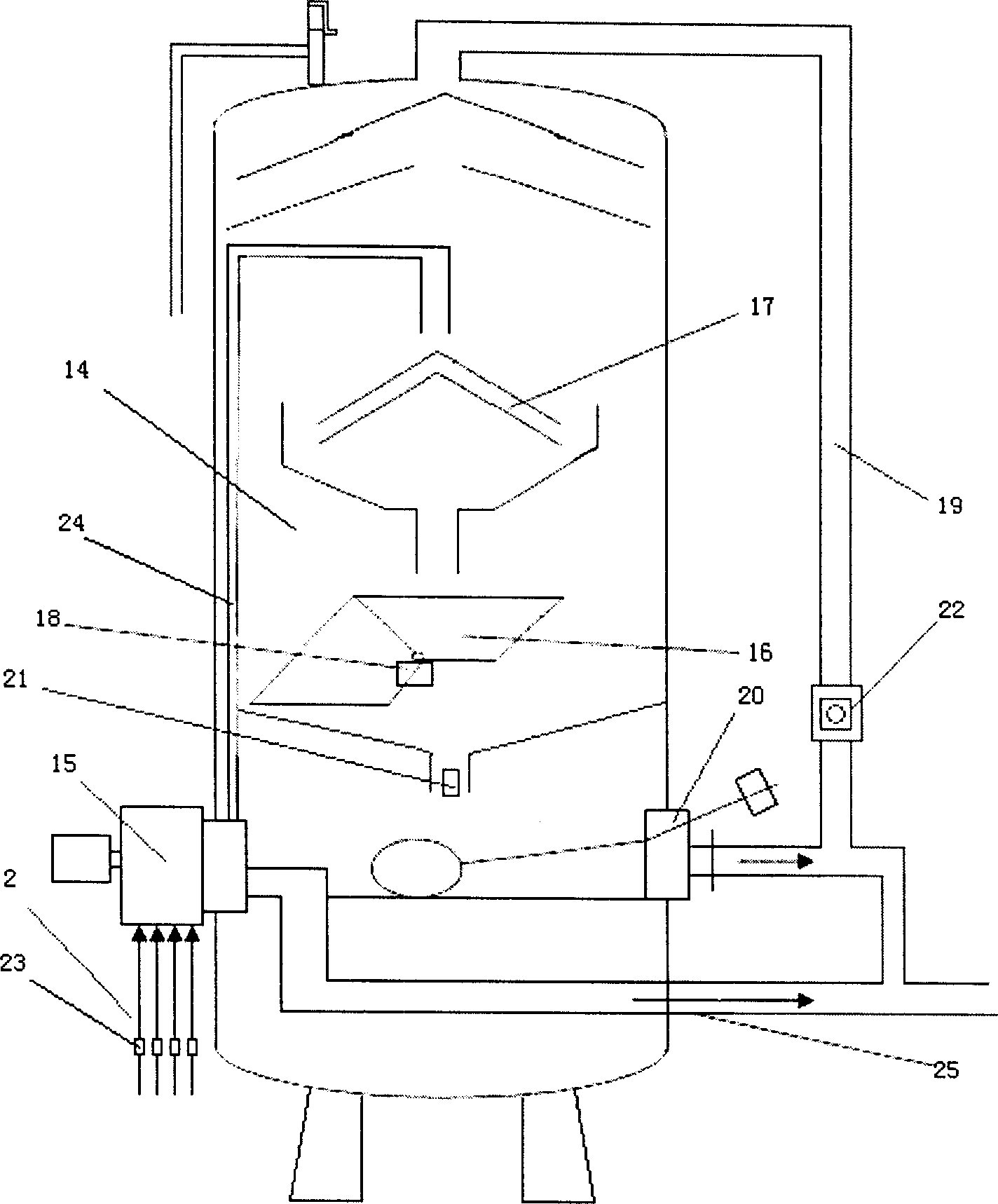

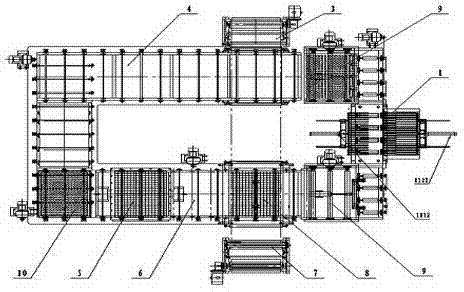

Sludge incineration treatment system

InactiveCN105198185AEmission reductionRealize harmless dischargeSludge treatment by de-watering/drying/thickeningEngineeringTreatment system

The invention relates to a sludge incineration treatment system which comprises a sludge purification treatment device, a gas-liquid separation device, a tail gas purification device, a drying device, a blower and an induced draft fan. The sludge incineration treatment system is characterized in that the drying device and the tail gas purification device respectively comprise an inner layer and an outer layer, smoke generated by the sludge purification treatment device enters the outer layer of the drying device, so as to indirectly dry sludge, and the smoke which enters the outer layer of the drying device enters the outer layer of the tail gas purification device from an outlet of the outer layer of the drying device; hot air generated by the sludge purification treatment device enters the inner layer of the tail gas purification device for preheating, preheated air enters the inner layer of the drying device from an outlet of the inner layer of the tail gas purification device, so as to directly dry the sludge, and the preheated air enters the gas-liquid separation device from an outlet of the inner layer of the drying device and is blown in the sludge purification treatment device by the blower for burning.

Owner:WEIMING BIOLOGY ENVIRONMENT TECH GRP

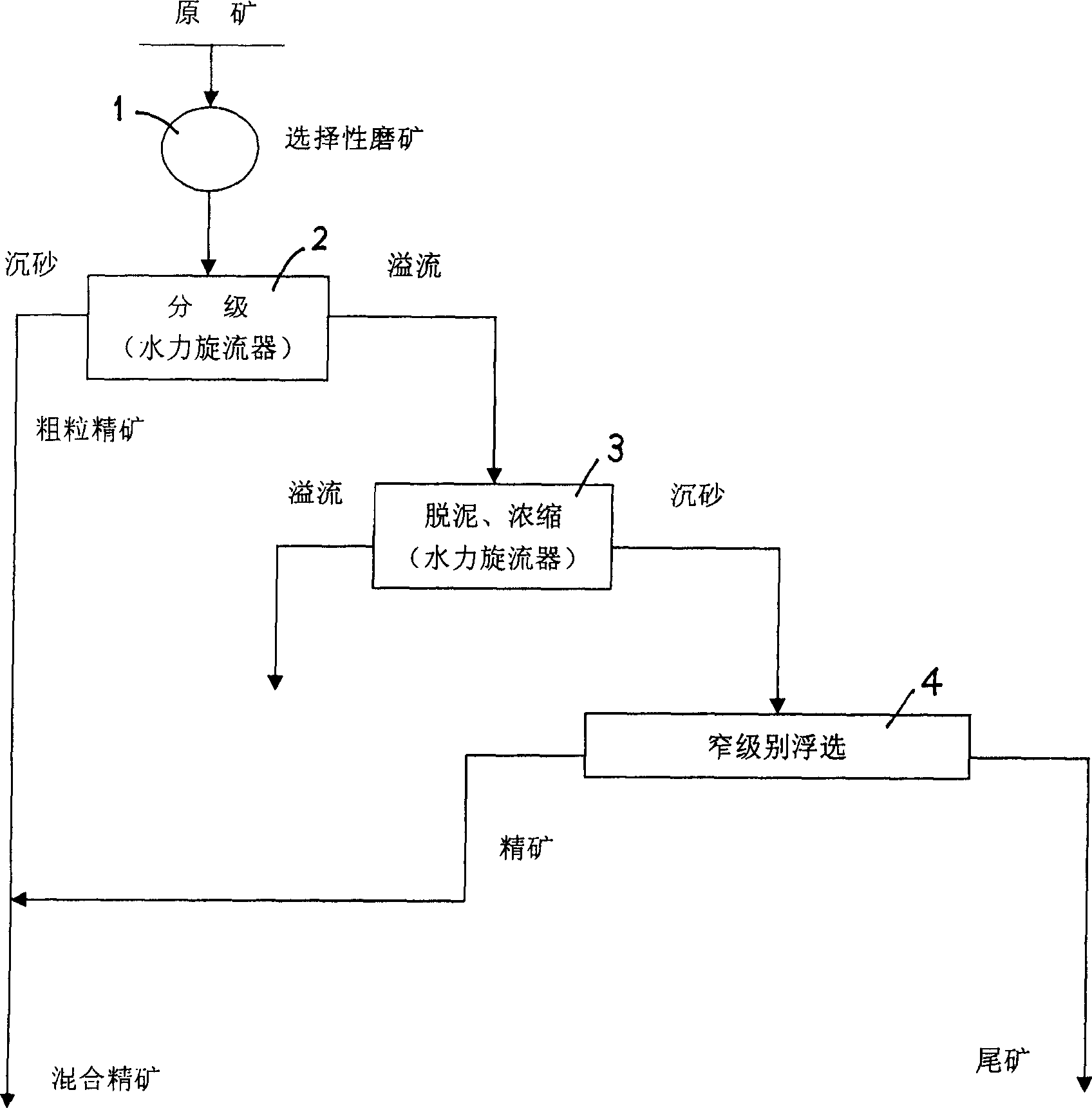

Highly efficient ore dressing system of medium-low class aluminium ore

InactiveCN1603002ASimple process structureReduce manufacturing costFlotationGrain treatmentsAluminiumLow graded

The invention designs the center low-grade bauxite dressing method, takes the center low-grade one water duralumin stone bauxite as the raw material, the main point is uses the 'selective rubbing, the graduation, escapes the putty, the concentration, the narrow rank flotation process' technical process, the selective rubbing uses the ball mill or the vibration rub; The graduation is separates the qualified large grain ore concentrate, chooses water used grain-by-grain selection flowing; escapes the putty, the concentration is carries on the escapes the putty to the ore slime which is smaller than 10mu m and to cause the pulp concentration, satisfies the pulp density request of the following flotation process, uses the water power cyclone; The narrow rank flotation process uses the flotation process craft, the flotation reagent is the ore-dressing;the catche receive medicinal preparation is the fatty acid, the dispersing agent is the sodium carbonate,merges the graduation work obtained large grain ore concentrate with the flotation concentrate and final obtain the ore concentrate,the aluminum silicon ratio in the large grain ore concentrate is bigger than 9, the production rate 30~50%, the Al2O3returns-ratio 40~50%, the mix ore concentrate aluminum silicon ratio is 9~10, the Al2O3returns-ratio is bigger than 88%.The technical process structure is simple,the production cost is low, the movement is steady, the target is stable, has a stronger adaptiveness to the center low-grade one water duralumin stone bauxite.

Owner:NORTHEASTERN UNIV

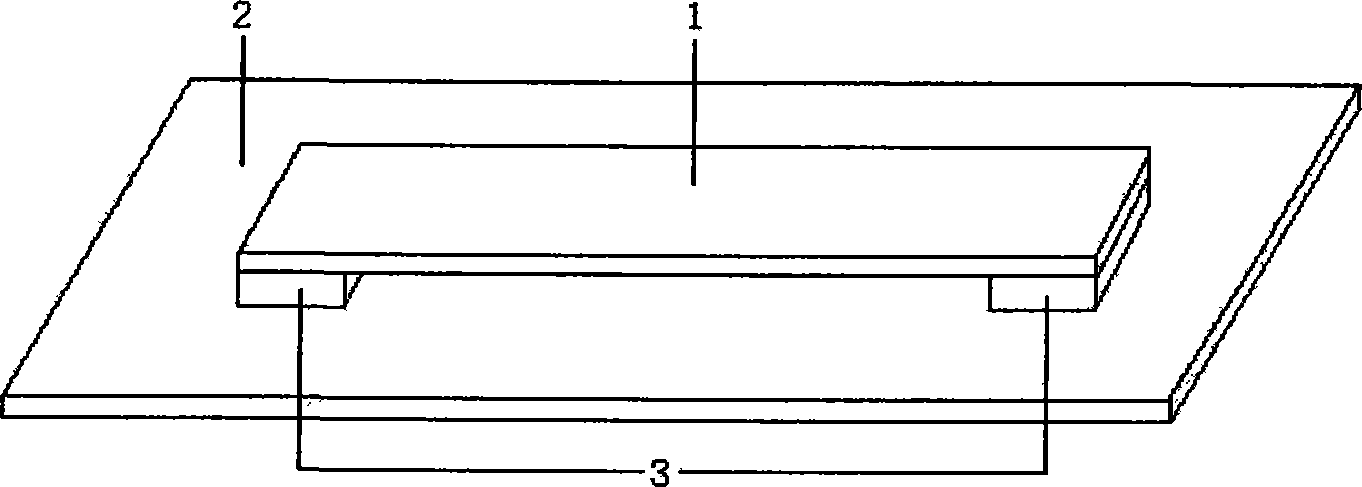

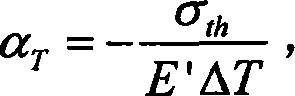

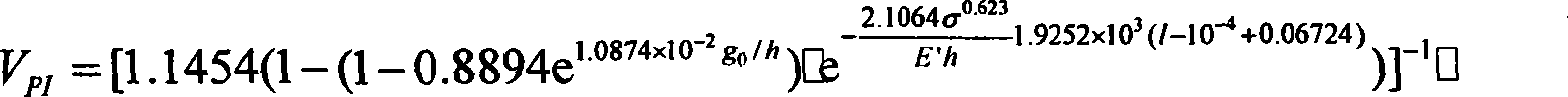

Electric test method for thermal expansion coefficient of surface finished polysilicon thin film

InactiveCN101246136ASimple test methodSimple process structureMaterial thermal coefficient of expansionMaterial analysis by electric/magnetic meansSurface finishElectricity

A method for electrically testing the thermal expansion coefficient of the film which is processed with polysilicon on the surface is presented basing on the suction phenomenon of the double-end clamped beam (1), the heat stress value generated in the double-end clamped beam (1) which is heated by the current according to the variation of the two suction voltage before and after the heating of the double-end clamped beam (1); and according to the variation curve of electric voltage in two ends of the double-end clamped-end beam (1) in the heating process recorded by the oscillograph, the variation value of the temperature on the heated double-end clamped beam is obtained; and at last according to the obtained heat stress value and the variation value of the temperature on the double-end clamped beam (1) the thermal expansion coefficient of the polysilicon film can be calculated with the relational expression.

Owner:SOUTHEAST UNIV

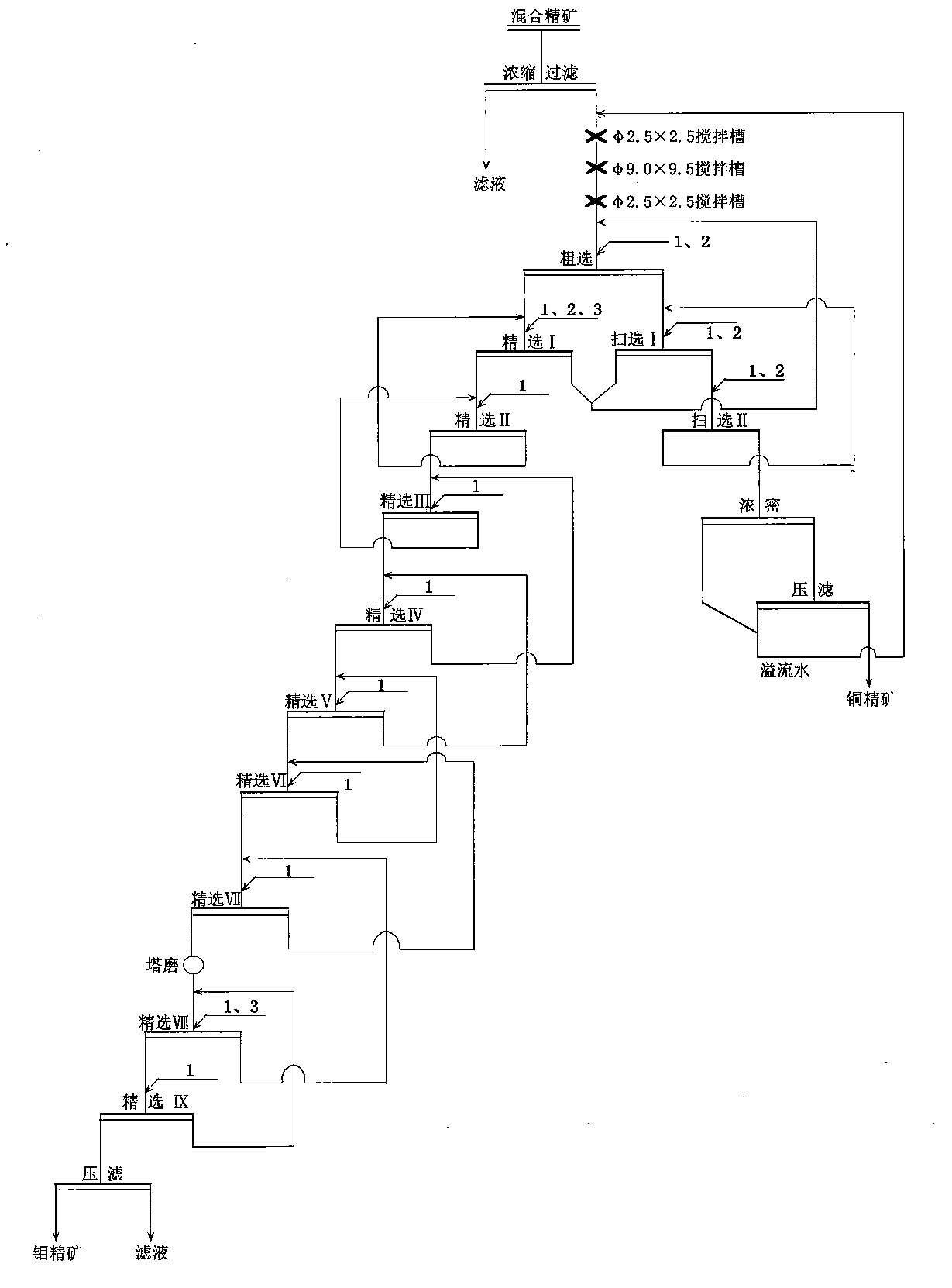

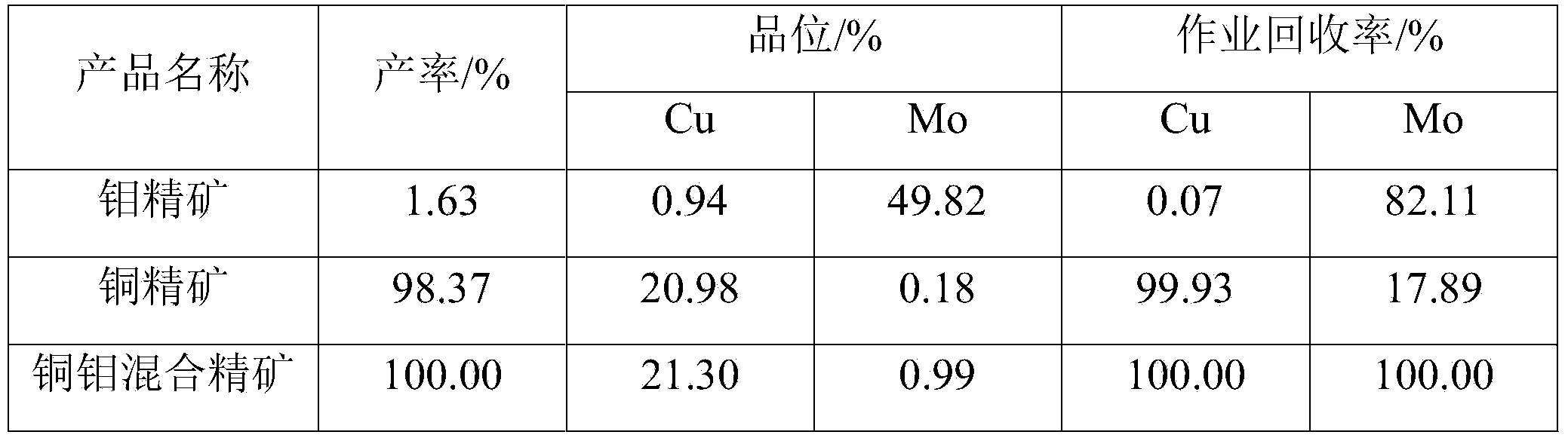

Method for separating copper-molybdenum mixed concentrate high in secondary copper content

InactiveCN103521347AEfficient separationSave waterSolid separationWater resourcesSodium hydrosulfide

The invention discloses a method for separating copper-molybdenum mixed concentrate high in secondary copper content. The method includes the steps of concentrating and filtering, water returning and size mixing, floatation separation, concentrate filtering and the like. The method abides by floatability property difference between copper molybdenum minerals, adopts sodium hydrosulfide to effectively inhibit primary copper and secondary copper and realizes high-efficiency separation of the copper-molybdenum mixed concentrate according to an idea of 'light pressing and slow selecting'. Copper concentrate going through dense overflow water can be used for size mixing of the copper-molybdenum mixed concentrate after concentrating and filtering, so that water resources are saved, and pollution caused by discharging of medicament is reduced. The method has the advantages of simplicity in medicament system and flowage structure, easiness in management operation, stability in technical process and production index and the like.

Owner:CHANGCHUN GOLD RES INST +1

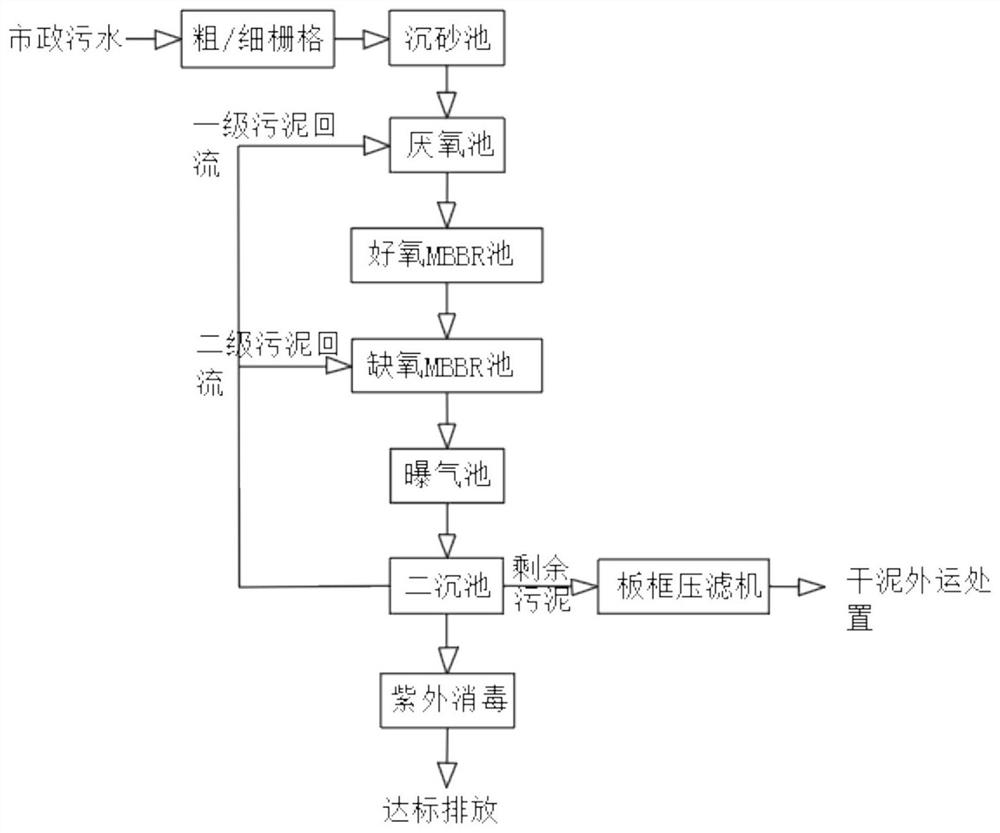

Method for deeply treating sludge anaerobic digestion solution and urban sewage with partial-nitrification, ANAMMOX and short-cut-denitrification technology

ActiveCN106006967ALow concentration of effluent total nitrogenSimple process structureWater contaminantsTreatment with aerobic and anaerobic processesChemistryNitrite nitrogen

The invention discloses a method for deeply treating a sludge anaerobic digestion solution and urban sewage with a partial-nitrification, ANAMMOX and short-cut-denitrification technology. The method includes the steps that the sludge anaerobic digestion solution enters a partial-nitrification reactor, a part of ammonia and nitrogen is converted into nitrite nitrogen, the product is pumped into an ANAMMOX reactor for removing, drained water with nitrate nitrogen and sanitary sewage enter a short-cut-denitrification reactor, the nitrate nitrogen is converted into nitrite nitrogen under organic carbon sources in the sanitary sewage, the product flows back to the ANAMMOX reactor, the nitrite nitrogen, and ammonia and nitrogen in the sanitary sewage are synchronously removed, and therefore the sludge anaerobic digestion solution and the urban sewage are synchronously and deeply treated. According to the method, the nitrogen removing rate is high, drained water can be discharged without following treatment, and the problem that excessive nitrate is contained in high-ammonia-nitrogen low-carbon-nitrogen-ratio sludge digestion solution ANAMMOX treatment drained water is solved; meanwhile, synchronous treatment of the urban sewage is achieved, and the running cost of a sewage treatment plant is greatly reduced.

Owner:BEIJING UNIV OF TECH

AOA coupled anaerobic ammonia oxidation deep nitrogen and phosphorus removal process

InactiveCN113173640AIncrease hydraulic retention timeReduce lossWater contaminantsTreatment with aerobic and anaerobic processesPhosphateMunicipal sewage

The invention discloses an AOA coupled anaerobic ammonia oxidation deep nitrogen and phosphorus removal process, which comprises an anaerobic zone for internal carbon source storage and phosphate release, an aerobic zone for aerobic excessive phosphorus uptake and short-cut nitrification-anaerobic ammonia oxidation, and an anoxic zone for internal carbon source short-cut denitrification-anaerobic ammonia oxidation, wherein an active biological filler is added into the aerobic zone and the anoxic zone to enrich main functional bacteria, the anaerobic zone has long hydraulic retention time and can store an internal carbon source, the anoxic zone is located at the rear end of the aerobic zone and does not need nitrification liquid backflow, and an aeration zone is added at the rear end of the anoxic zone to improve sludge settleability. The AOA coupled anaerobic ammonia oxidation deep nitrogen and phosphorus removal process solves the problems of insufficient carbon source and incapability of synchronously and deeply removing nitrogen and phosphorus in the nitrogen and phosphorus removal process, reduces the loss of the carbon source, improves the utilization rate of the carbon source, reduces the operation energy consumption of a sewage treatment system, and bring a better application prospect to deep nitrogen and phosphorus removal of urban sewage.

Owner:JIANGSU YULONG ENVIRONMENTAL PROTECTION

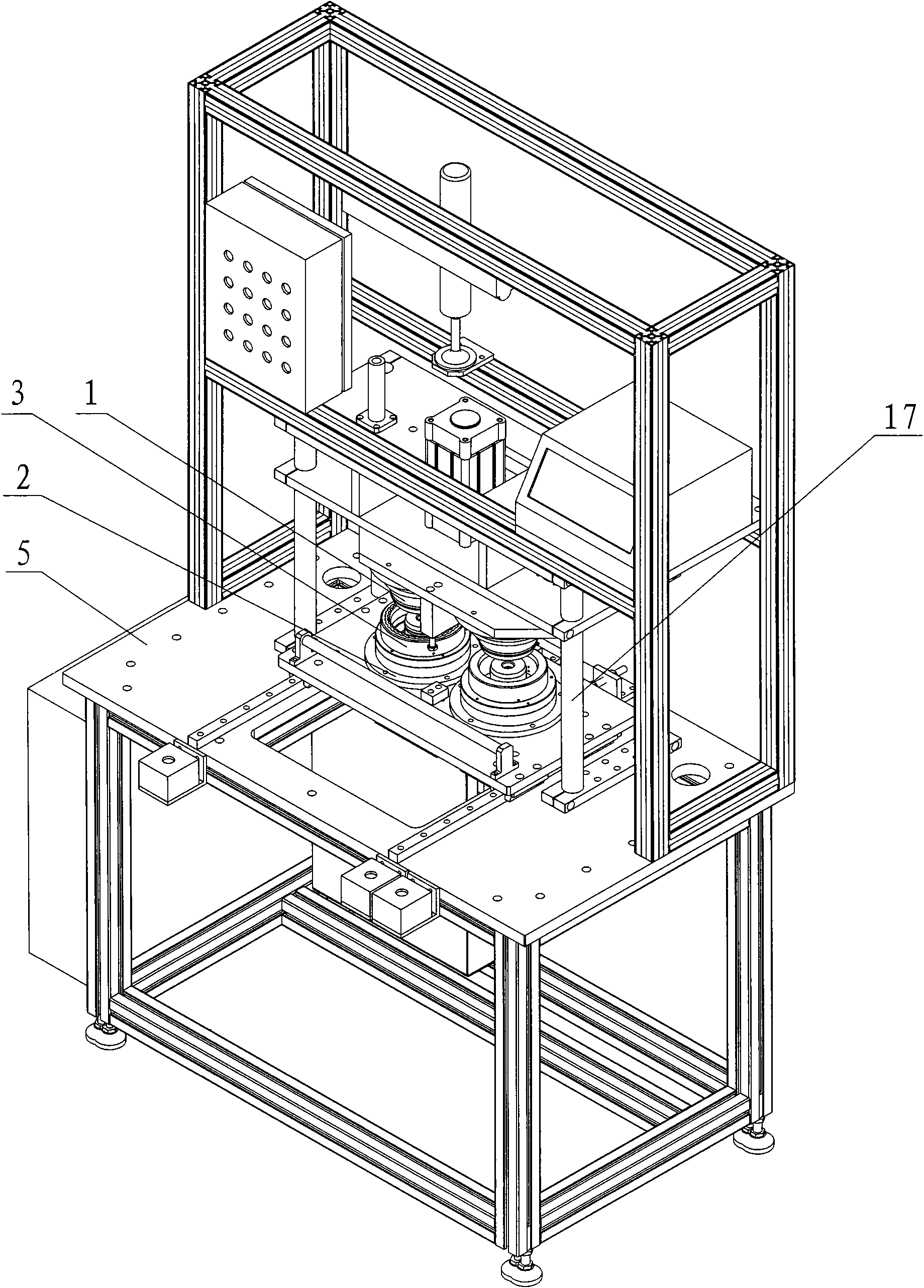

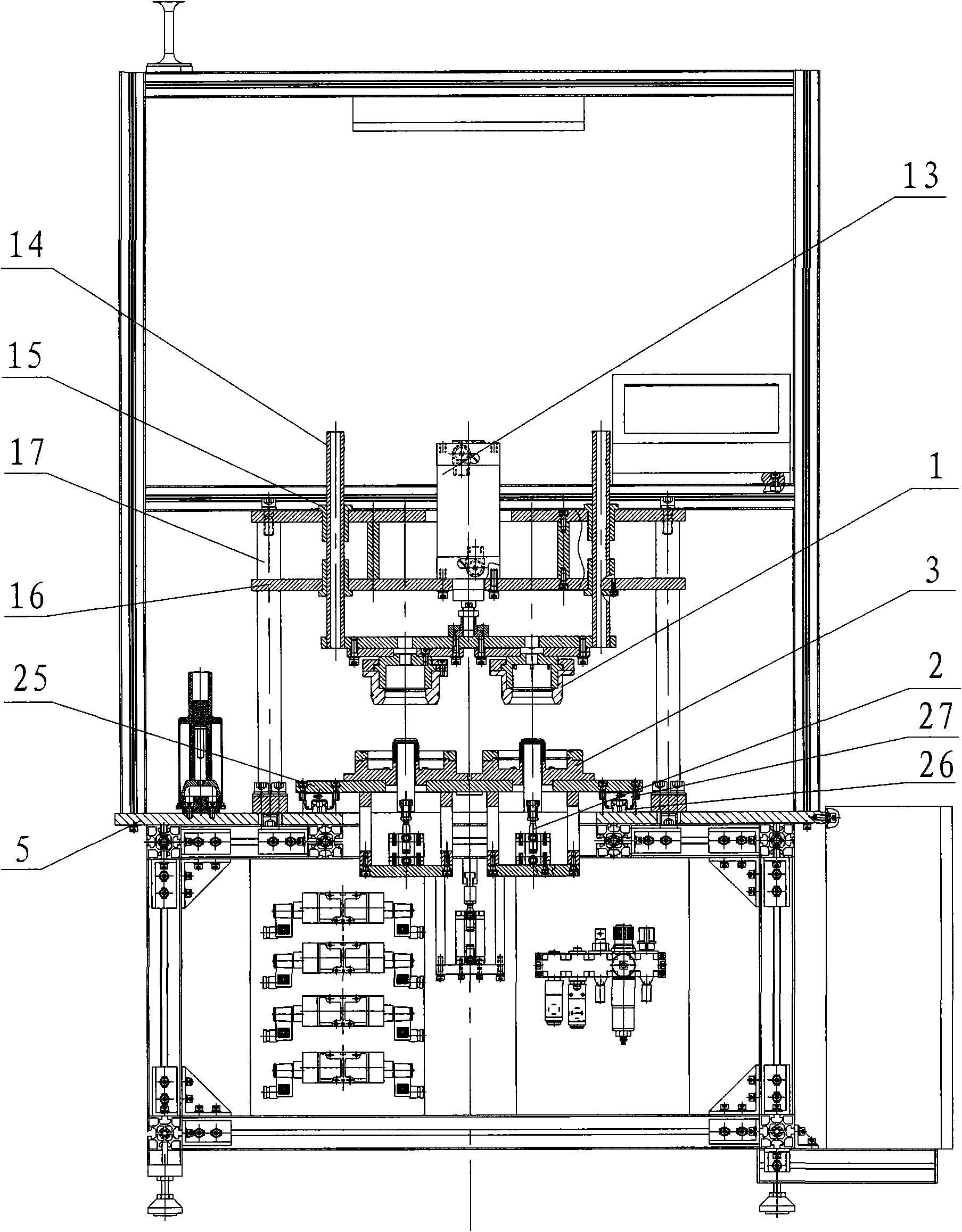

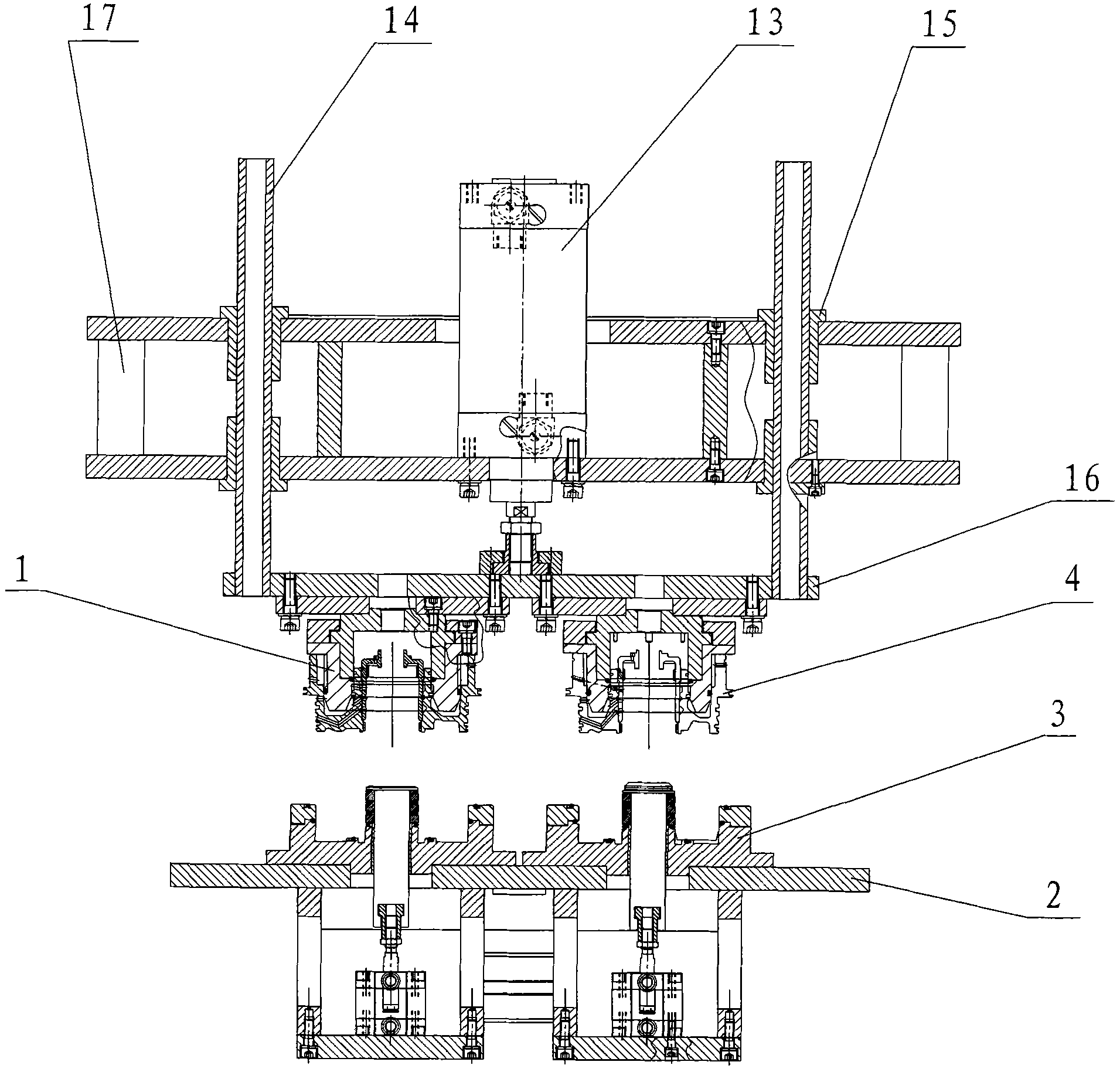

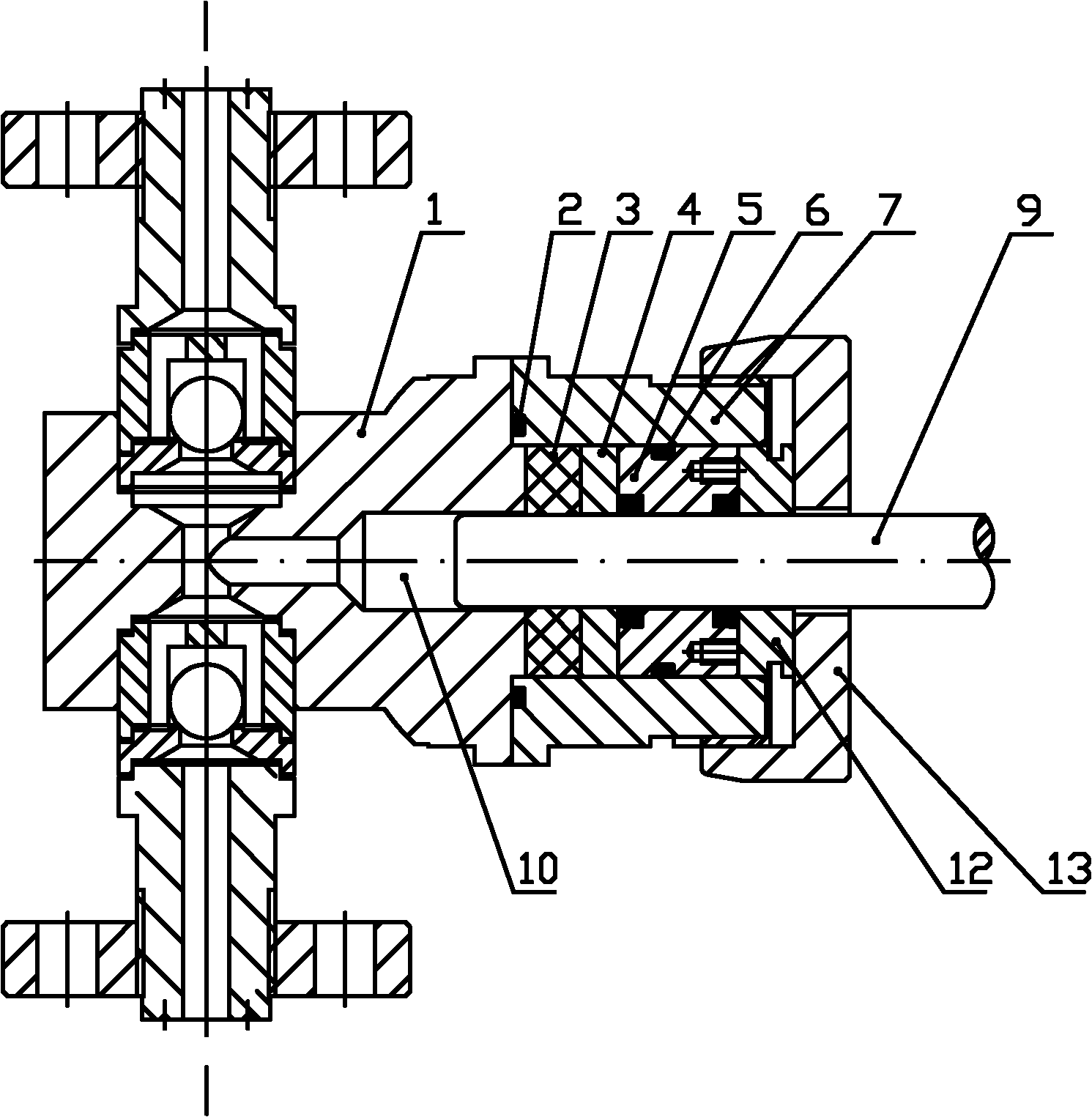

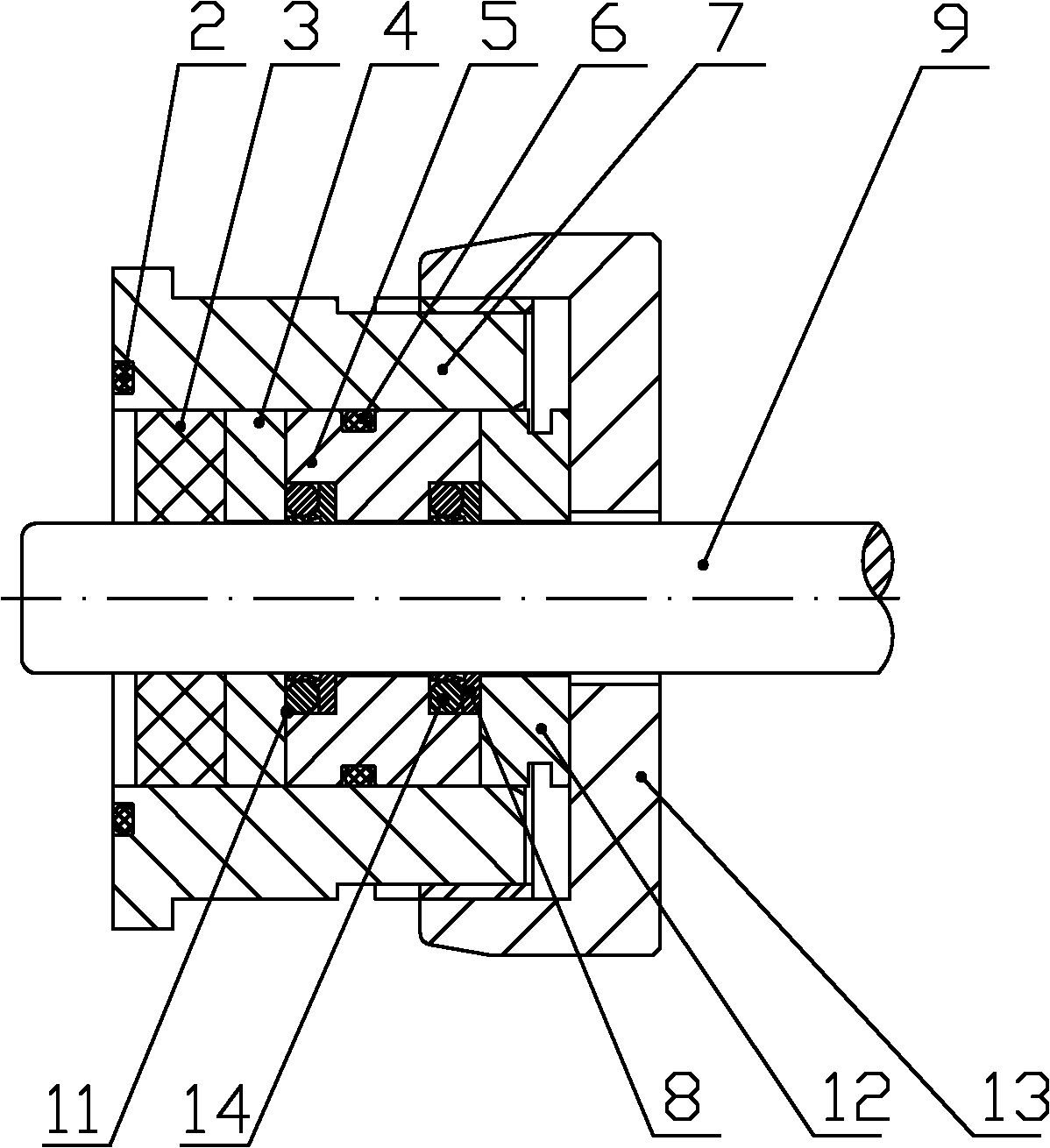

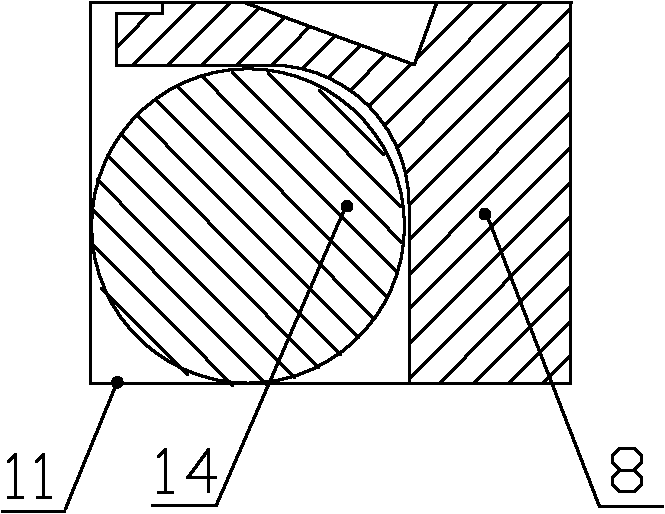

Sealing structure of automatic transmission clutch shell sealing tester

ActiveCN101876578ALow costSolution to short lifeFluid-tightness measurement using fluid/vacuumTest fixtureMechanical construction

Owner:上海新松机器人有限公司

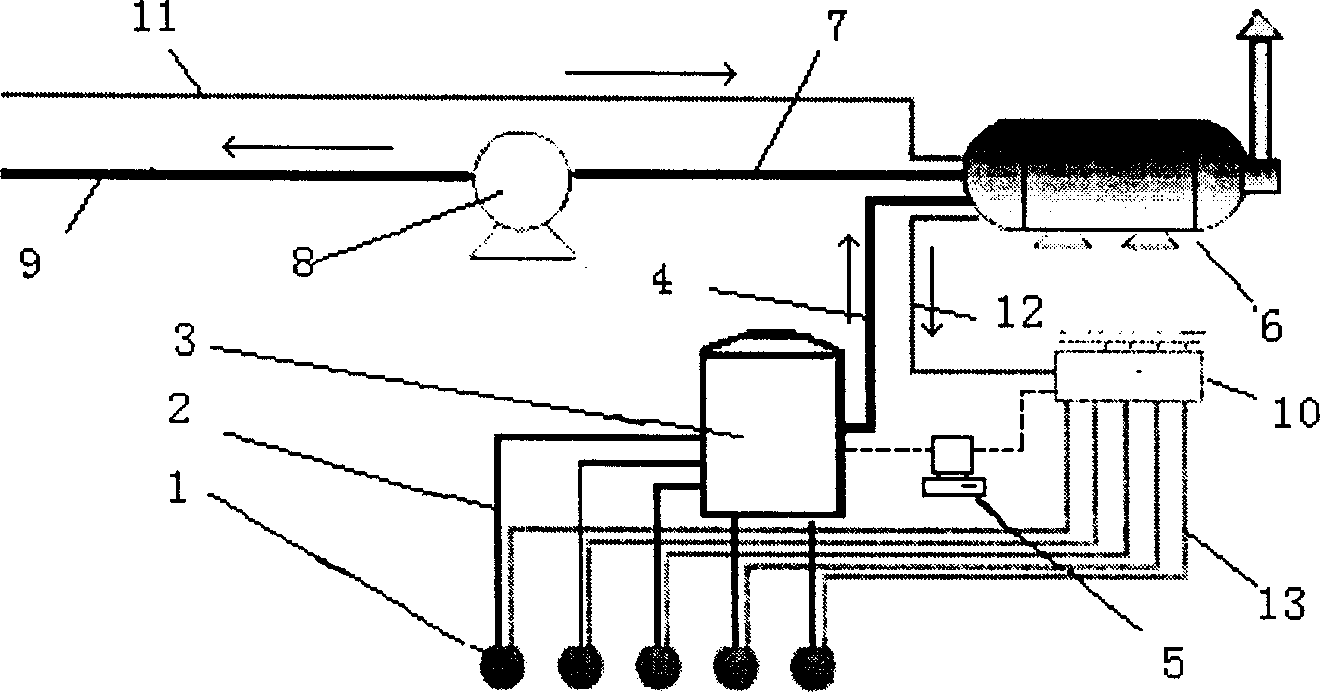

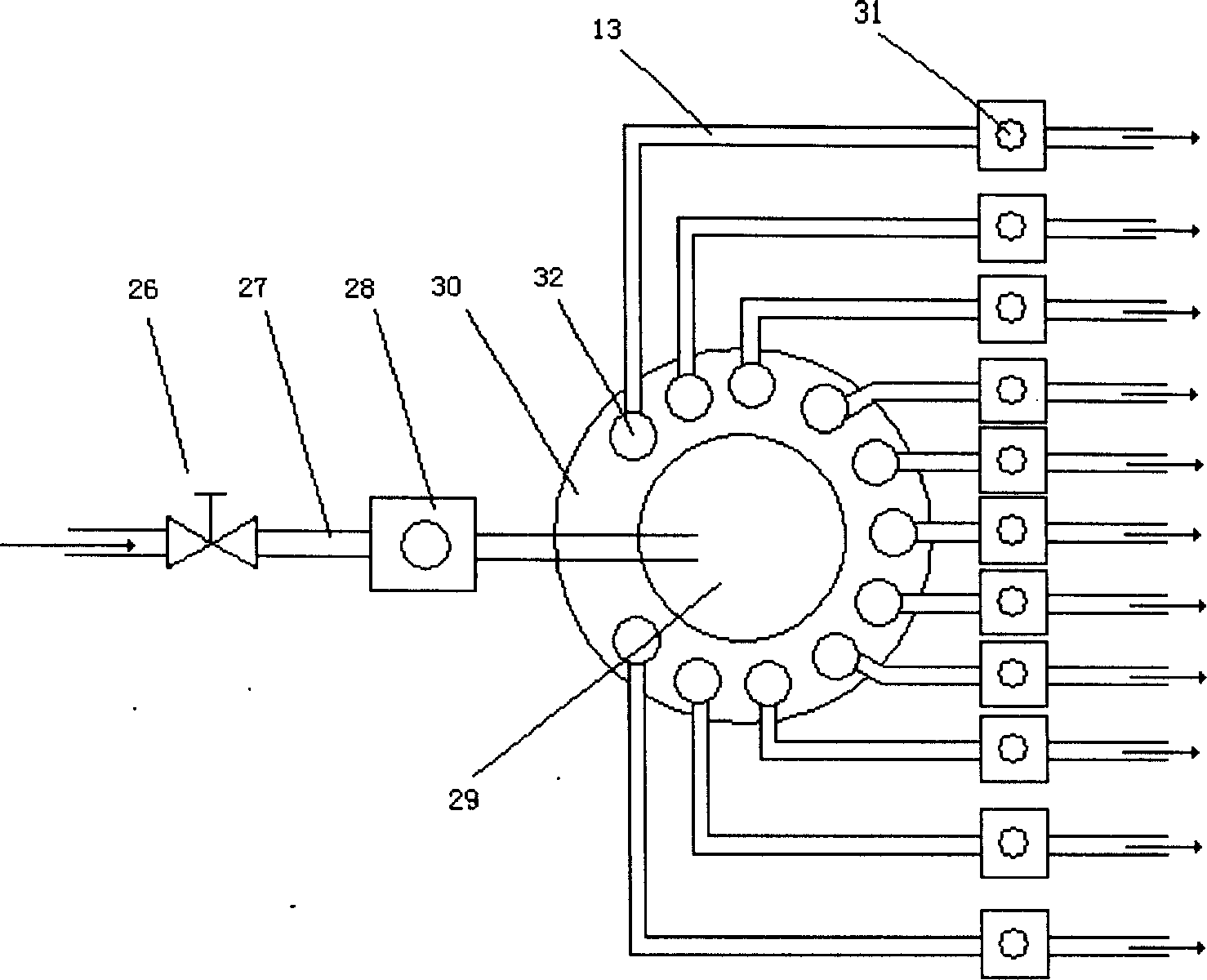

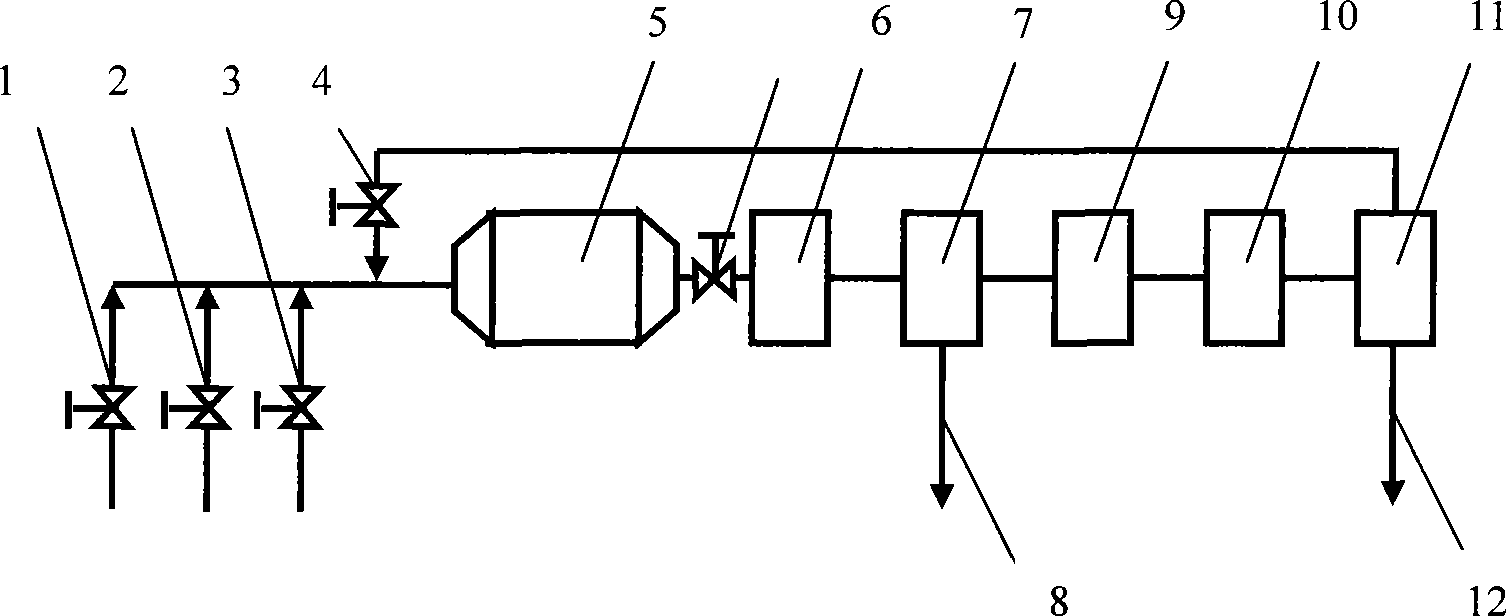

Overground gathering and transporting system for petroleum exploitation and method thereof

InactiveCN1828009ARealize automatic dosingImplement gas-liquid direct transmissionSurveyFluid removalPetroleumOil well

The invention relates to an oil exploitation ground transmission system and relative method, belonging to the oil exploitation technique. Said invention can measure the oil well, add liquid into oil well, heat the oil well and mixed transmit the oil gas. And said invention comprises four parts as aforementioned functions. Wherein, the oil well measuring part uses a liquid automatic measurer, which comprises a skip measurer, an automatic oil well switcher and a transmission tube. The invention uses industry computer to realize said functions, with high automatic degree, high practicability, and unmanned management.

Owner:岳玉全 +1

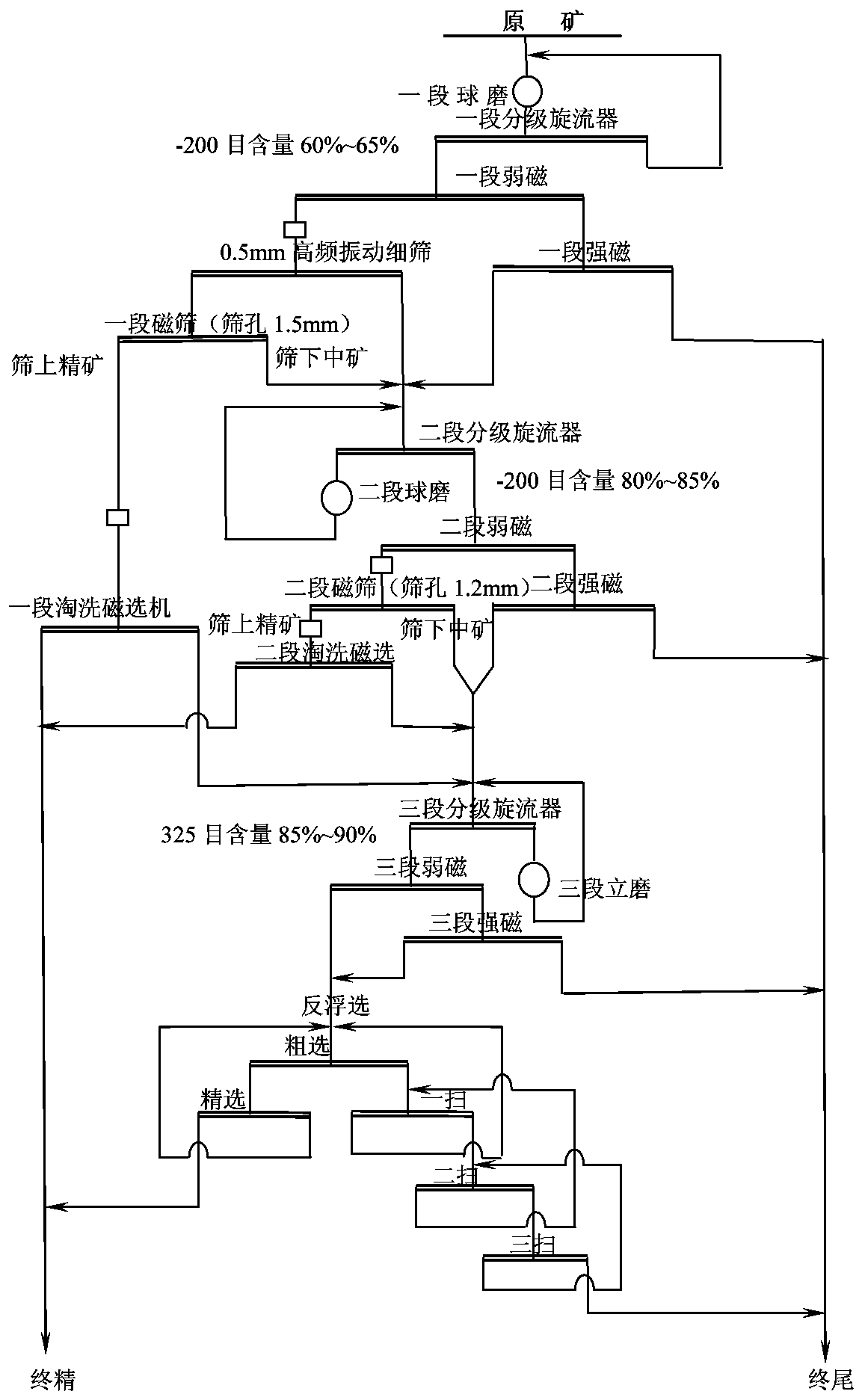

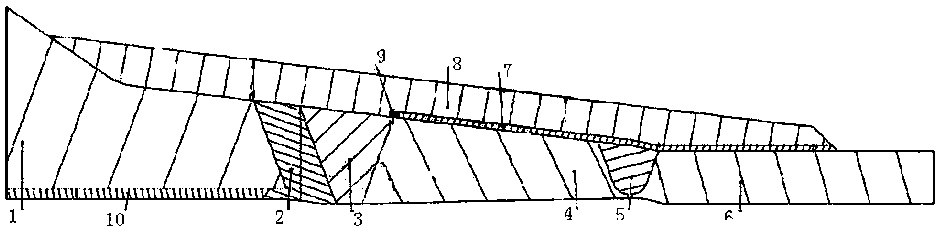

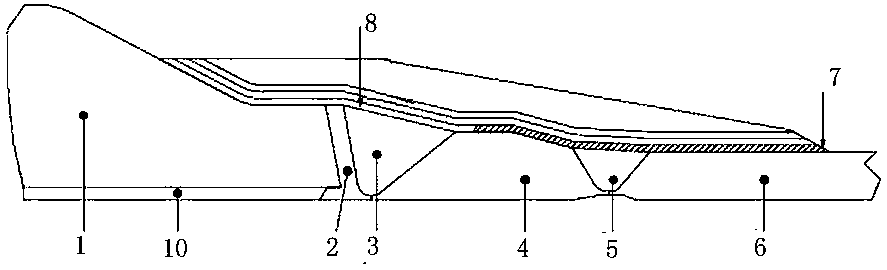

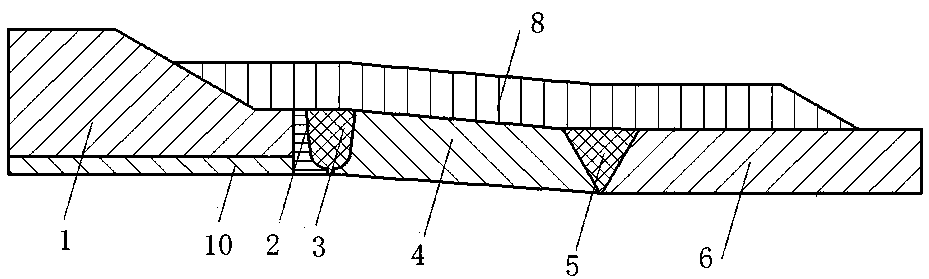

Separation process for magnetic red mixed ore based on iron material disseminated particle size treatment

ActiveCN109351467AReduce grinding energy consumptionReduce overgrindingSolid separationOre concentrateSeparation process

The invention relates to a separation process for magnetic red mixed ore based on iron material disseminated particle size treatment. The process comprises the operation of feeding the mixed ore withthe grade of 27%-29% and with magnetite as a main raw material into first-section closed circuit ore grinding operation to obtain a primary grading overflow product, and is characterized by further comprising first-section weak magnetic and strong magnetic operation, fine screening operation, first-section magnetic separation and first-section washing magnetic separation operation, second-sectionclosed circuits ore grinding operation, second-section weak magnetic strong magnetic operation, second-section magnetic separation and washing magnetic separation operation, third-section closed circuit ore grinding, third-section weak magnetic strong magnetic operation and reverse flotation operation. The final concentrate with the grade of 66%-66.5% is obtained through the operation. Compared with the prior art, the separation process has the advantages that 1) an efficient separation process which is characterized in that the concentrate can be obtained once dissociation is achieved and segmented ore grinding, segmented concentrate taking and segmented tailings discharging are achieved is provided for the magnetic red mixed ore with the non-uniform iron material disseminated particle sizes, so that overgrinding is reduced, and energy conservation and consumption reduction are achieved; 2) magnetic separation equipment is adopted for upgrading, and three sections of ore grinding is carried out by adopting vertical mills; and 3) the process is simple in structure, free of middling circulation, easy to implement on site and easy to produce and manage.

Owner:ANSTEEL GRP MINING CO LTD

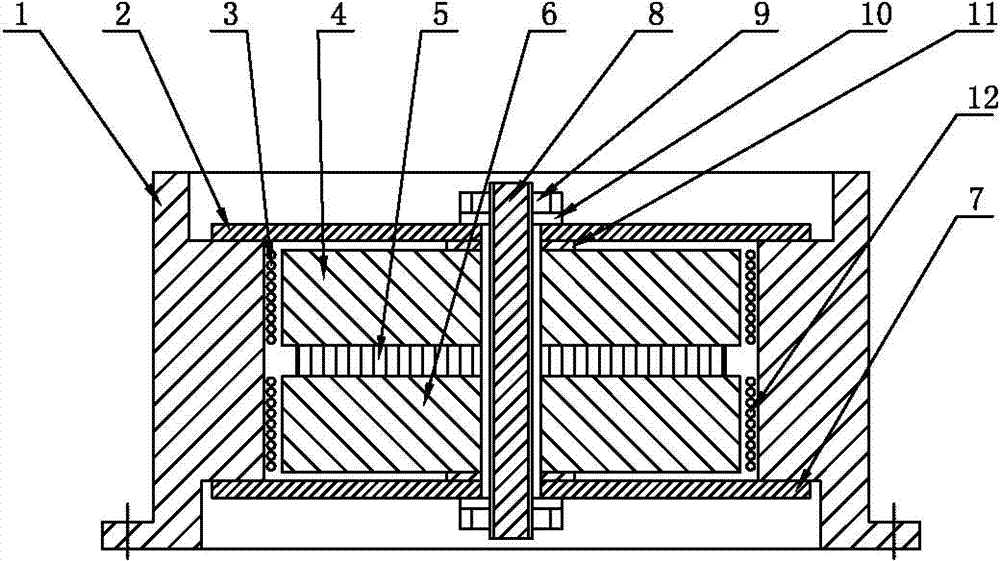

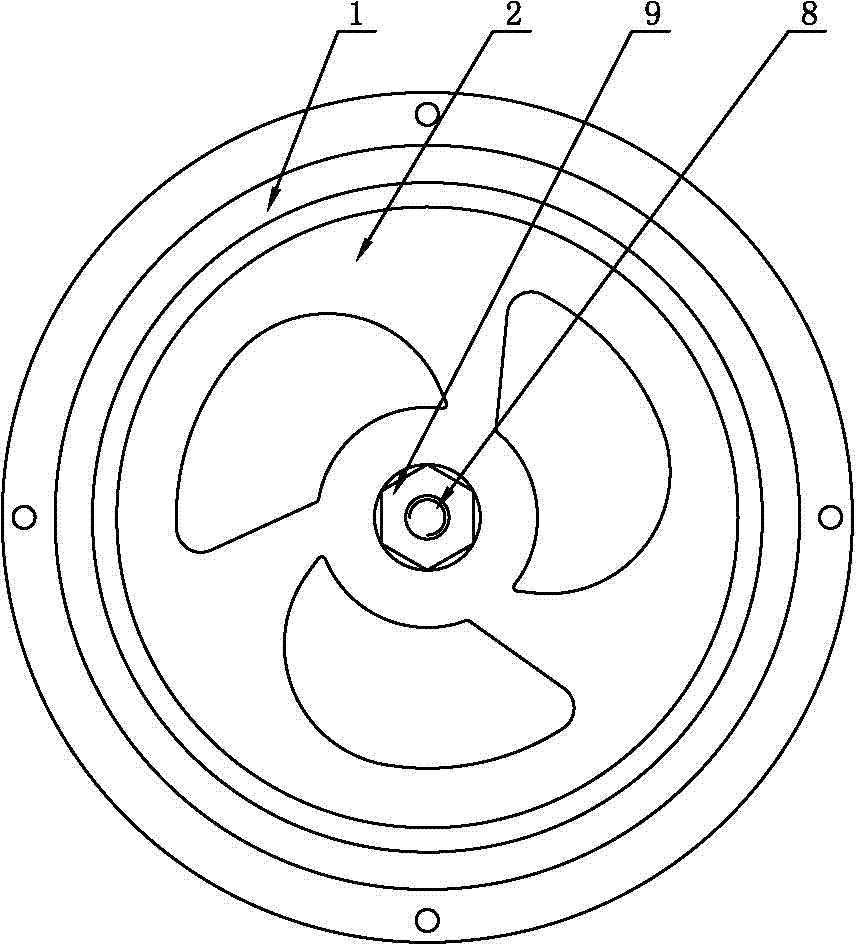

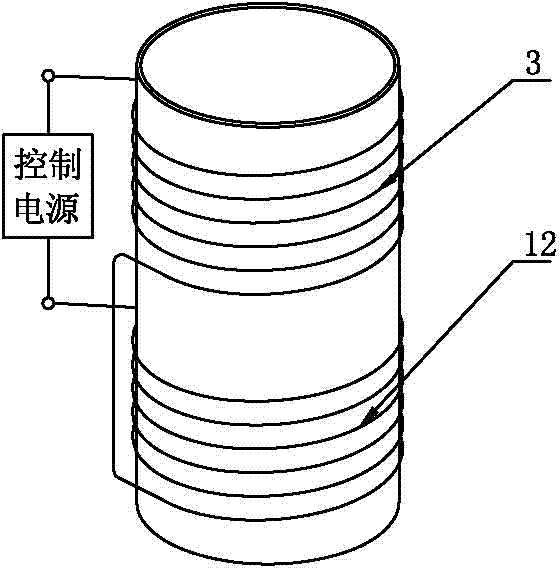

Electromagnetic actuator for active noise control for amorphous alloy transformers

InactiveCN103050216ACancel noiseSimple process structureTransformers/inductances noise dampingElectromagnetsMagnetAmorphous metal transformer

The invention discloses the field of active noise control and particularly relates to an electromagnetic actuator for active noise control for amorphous alloy transformers. The electromagnetic actuator comprises a support disposed on the surface of a transformer. The top and bottom of the support are provided with circular inner steps corresponding to each other. An upper spring plate and a lower spring plate are disposed on the two inner steps respectively. An upper moving core, permanent magnet steel and a lower moving core are disposed between the upper spring plate and the lower spring plate sequentially from top to bottom. The upper spring plate, the upper moving core, the permanent magnet steel, the lower moving core and the lower spring plate are serially connected through bolts and are fixed together through nuts at two ends of the bolts, an upper coil and a lower coil are wound outside the upper moving core and the lower moving core respectively. After serially connected oppositely, the upper coil and the lower coil are connected with a control power supply. The electromagnetic actuator is simple in structure, low in manufacturing cost, adjustable in mode, convenient and flexible to install and applicable to transformer denoising.

Owner:SOUTHEAST UNIV +1

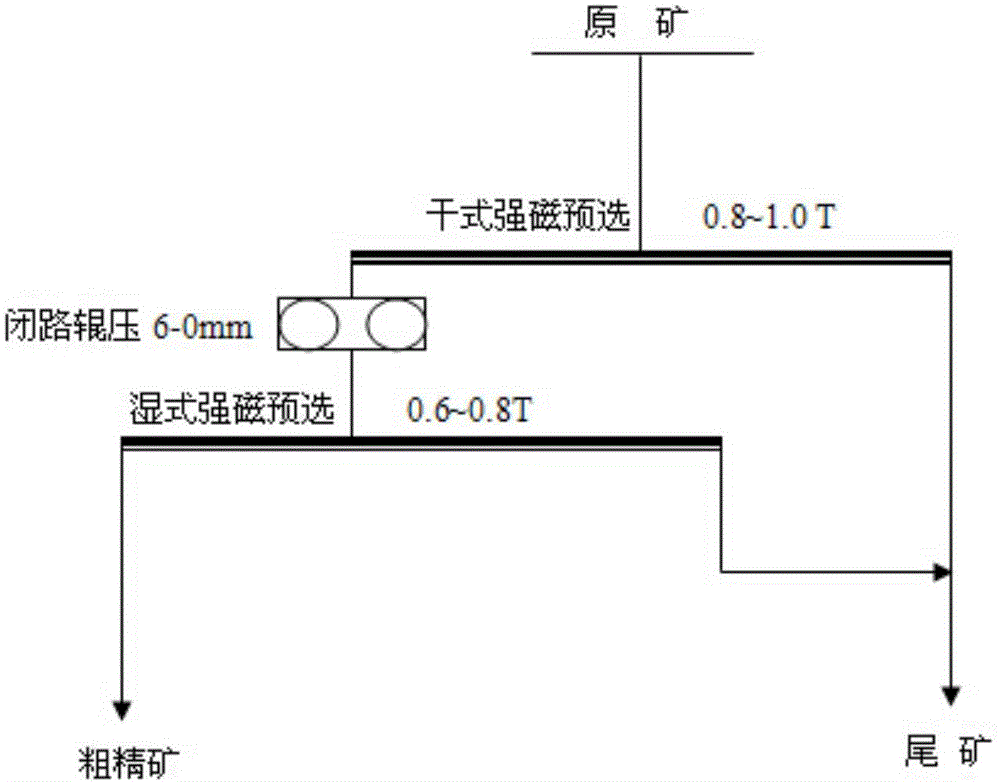

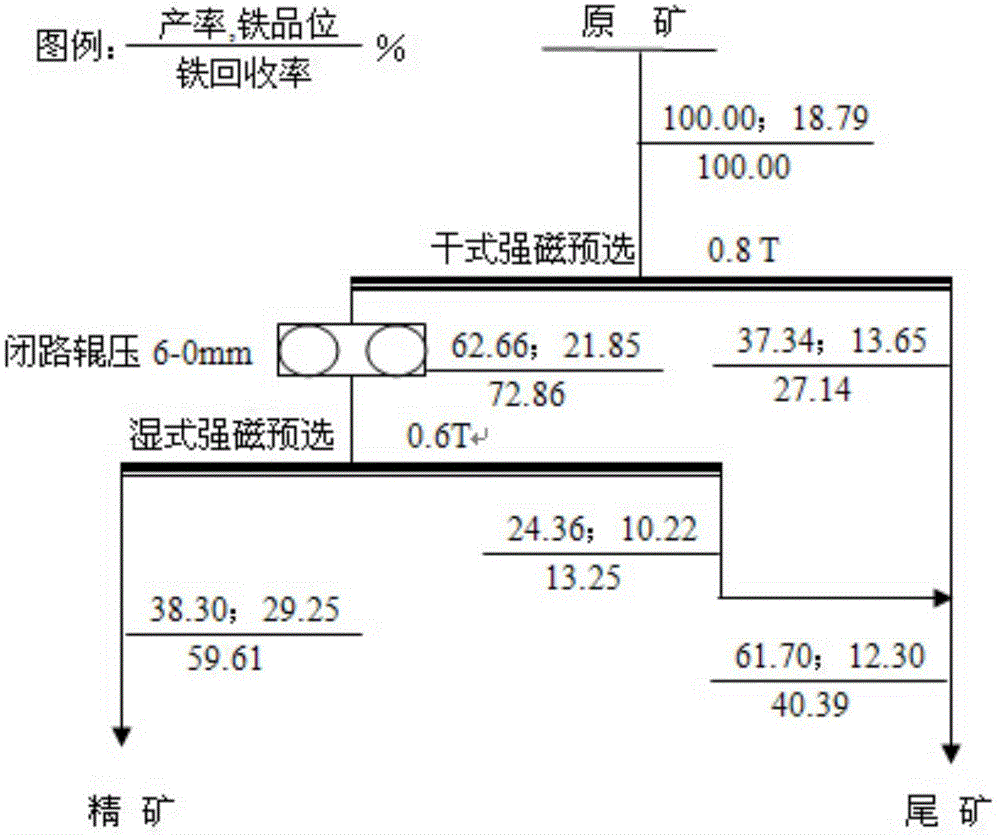

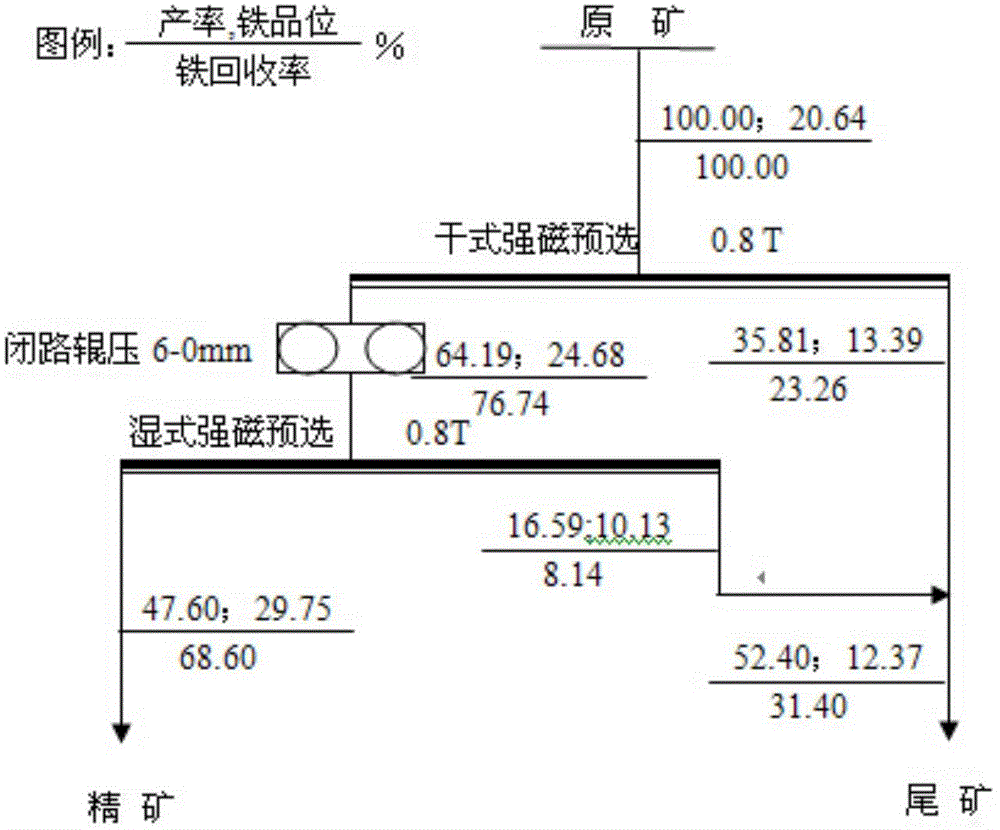

Pre-selection method for low-grade hematite-containing waste rock

ActiveCN104399578AEmission reductionExtended service lifeMagnetic separationHigh pressureLayer thickness

The invention discloses a pre-selection method for low-grade hematite-containing waste rock. The pre-selection method comprises: fragmenting low-grade hematite-containing waste rock raw ore with the iron grade of 18-23% to 40-0 mm through coarse crushing and intermediate crushing work, employing a permanent-magnet dry type high-intensity magnetic separator to perform pre-selection, controlling the cylinder surface magnetic field intensity of the permanent-magnet dry type high-intensity magnetic separator to be 0.8-1.0 T, controlling the cylinder surface linear velocity, the separation baffle plate distance and the material layer thickness, and throwing out coarse-grain tailings with the iron grade less than 14.0%; grinding the rough concentrate obtained through permanent-magnet dry type high-intensity magnetic separation to 10-0 mm through a high-pressure roller, then preselecting by an electromagnetic pulsation high-gradient coarse-grain wet-type high-intensity magnetic separator, and then throwing out fine-grain tailings with the iron grade of 11% or less, so as to obtain rough concentrate which is sent to a main workshop for grading through a grinding selection technology. According to the method, a large amount of tailings are thrown out through magnetic pre-selection before ore grinding, the ball milling amount of the ore is reduced, the ball milling grade is improved, the ore grinding energy consumption is reduced, the method has the advantages of simple structure, short flow, low energy consumption, strong adaptability and high ore selection technology index, is widely applicable to hematite selection factories, and is especially suitable for pre-selection of low-grade hematite-containing waste rock.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

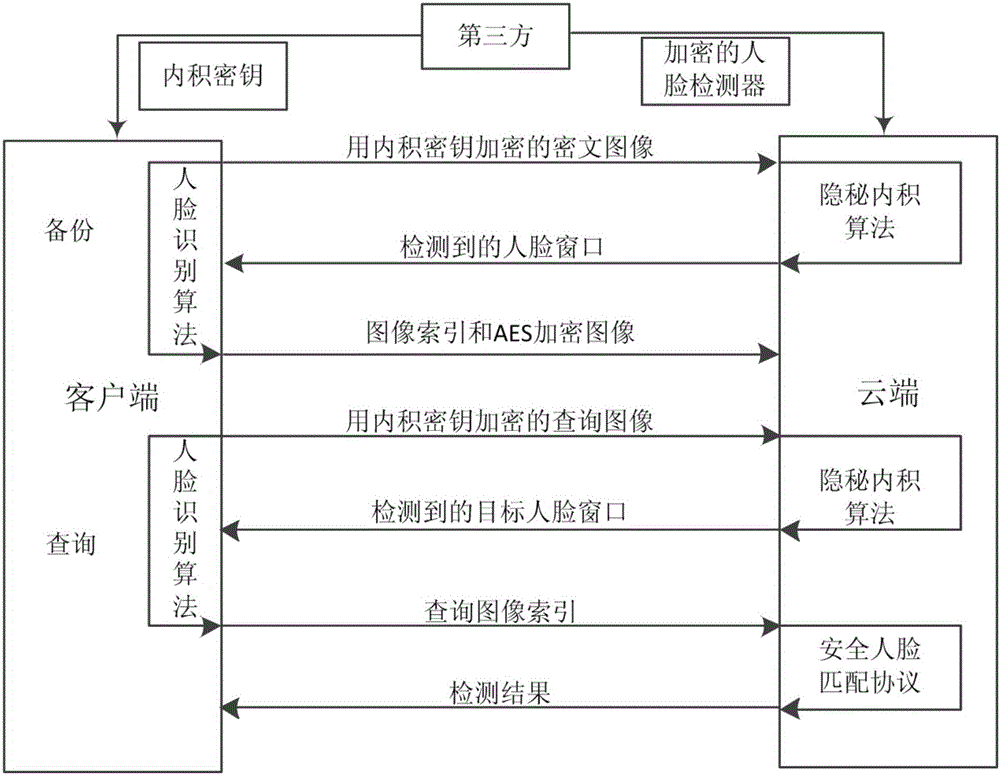

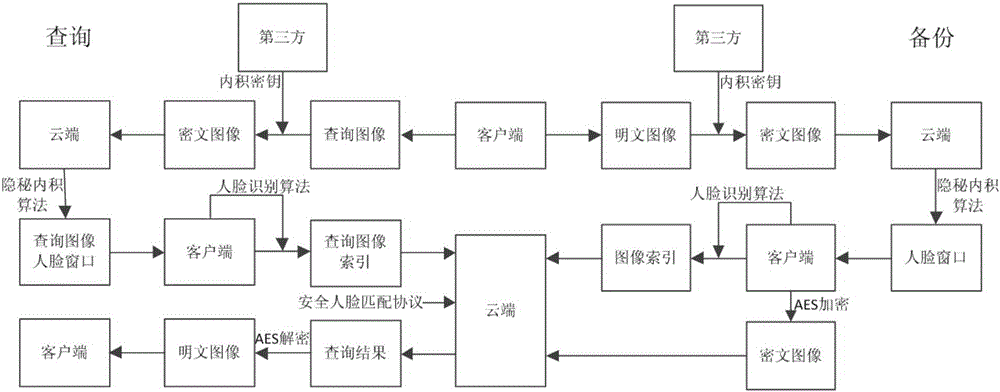

Multiple intelligent terminal sharing face confidential identification method based on cloud environment

ActiveCN106096548AProtection securityReduce complexityCharacter and pattern recognitionDigital data protectionFace detectionThird party

The invention provides a multiple intelligent terminal sharing face confidential identification method based on a cloud environment, which can be carried out under a secure protocol, and meanwhile simultaneously protect the privacy of user image data and the privacy of a third party face detector. The method applies a secure inner product algorithm to security face detection under a cloud environment for the first time, realizes user image storage in ciphertexts, provides an image query function under a ciphertext state, and prevents the third party face detector from being discovered. In addition, user images storage forms are enciphered in a standard encryption algorithm, and data security can be guaranteed; the secure inner product algorithm is employed for each query, and algorithm complexities are related to selected encryption matrix dimensions; the algorithm complexities are low, and can be flexibly configured according to computational capabilities and security demands; a lot of computation depends on the cloud with a great computational capability, so as to effectively shorten detection time; in addition, the encryption method is easy to realize through software. The multiple intelligent terminal sharing face confidential identification method can be widely applied to cloud computation, face identification, etc.

Owner:韶鼎人工智能科技有限公司

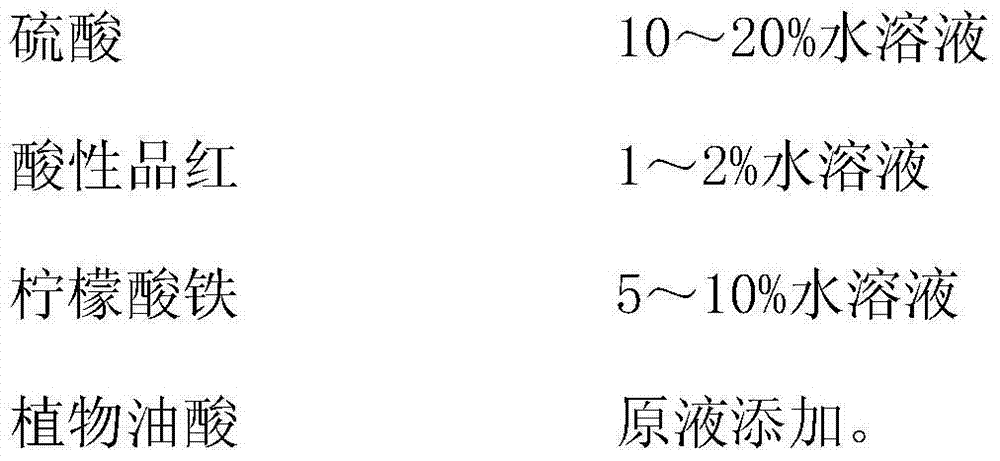

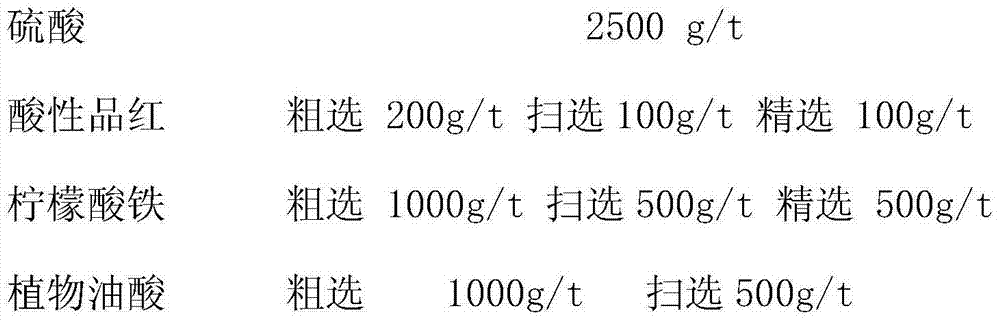

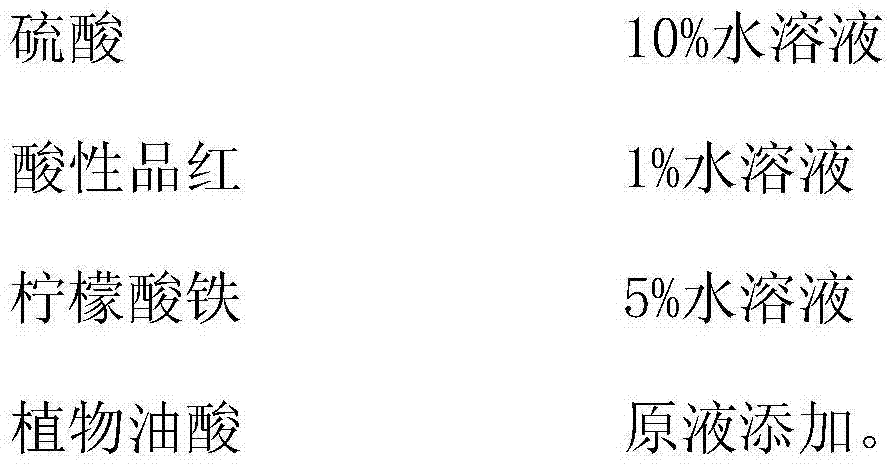

Flotation separation method of fluorite and dolomite in acidic conditions

A flotation separation method of fluorite and dolomite in the acidic conditions comprises the steps of utilizing sulfuric acid as a pH (potential of hydrogen) adjusting agent; utilizing acid magenta and ferric citrate as an inhibitor of the dolomite and other impurity minerals; utilizing plant oleic acid as a collecting agent of a fluorite mineral. According to the flotation separation method of the fluorite and the dolomite in the acidic conditions, the fluorite mineral can be separated from the dolomite and the other impurity minerals through flotation and a fluorite concentrate can be obtained, wherein the grade of the fluorite is 97.11 to 97.75% and the recovery rate of the fluorite is 79.25 to 83.90%.

Owner:江西鼎帆实业有限公司

Method for synchronously removing ammonia nitrogen and nitrate nitrogen in continuous flow USB reactor through short-range denitrification reinforcement DEAMOX technology

ActiveCN106045032ASolve difficult problems in depthReduce processing costsWater contaminantsTreatment with anaerobic digestion processesSludgeContinuous flow

The invention discloses a method for synchronously removing ammonia nitrogen and nitrate nitrogen in a continuous flow USB reactor through a short-range denitrification reinforcement DEAMOX technology, and belongs to the field of sewage treatment. The method comprises the steps that a USB reactor is inoculated with DEAMOX granule sludge, nitrate nitrogen is converted into nitrite nitrogen through an organic carbon source in fed water in short-range denitrification, ammonia nitrogen in the fed water is removed through the in-situ anaerobic ammonia oxidation effect, and the purpose of efficiently removing nitrogen is achieved by optimizing the mass concentration ratio of nitrate nitrogen to ammonia nitrogen in wastewater and controlling and adjusting the flow of organic carbon source in fed water. The problems that treatment of wastewater containing ammonia nitrogen and nitrate nitrogen is low in treating efficiency and high in energy consumption are effectively solved, aeration consumption in the aerobic stage is not needed, the external carbon source consumption is reduced, the residual sludge yield is low, and the follow-up treating cost is greatly reduced; in addition, the DEAMOX technology achieved in the continuous flow USB reactor has the advantages that the reaction speed is high, nitrate nitrogen produced in anaerobic ammonia oxidation process is removed in situ, and the total nitrogen removal rate and the denitrifying load are high.

Owner:BEIJING UNIV OF TECH

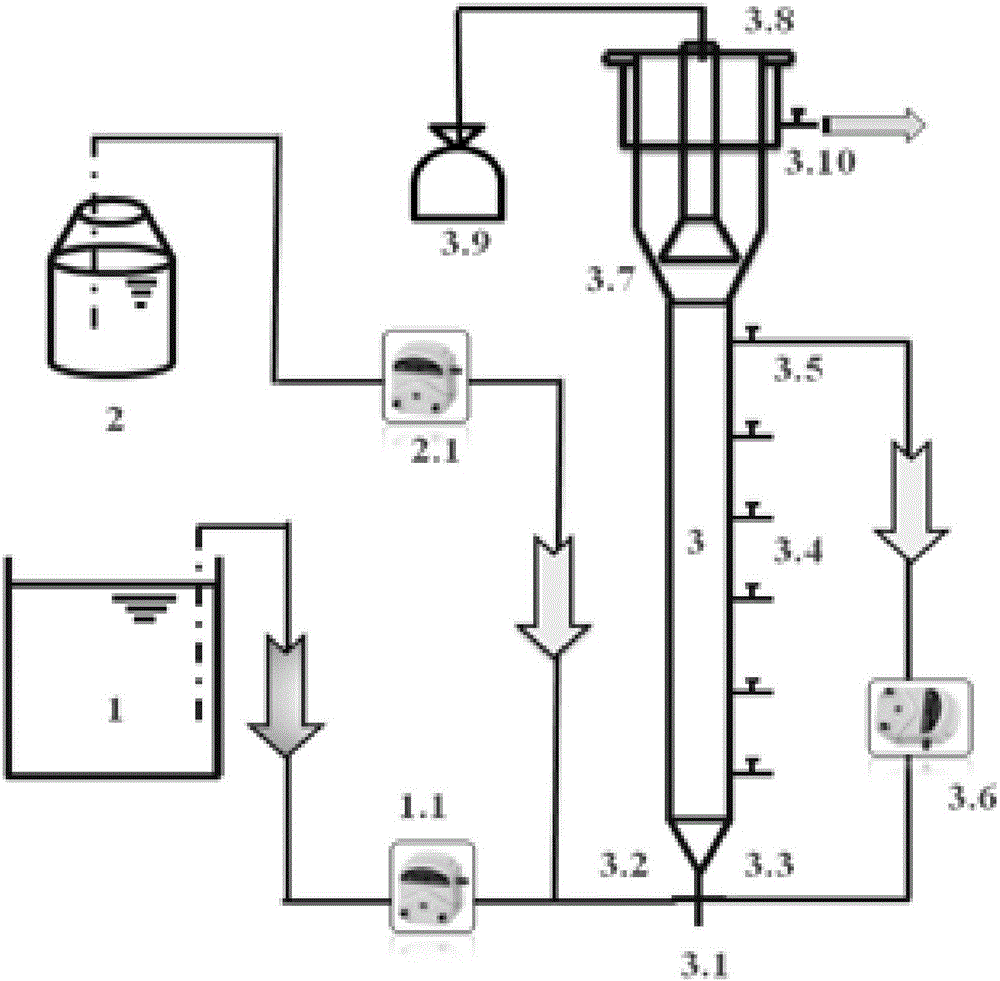

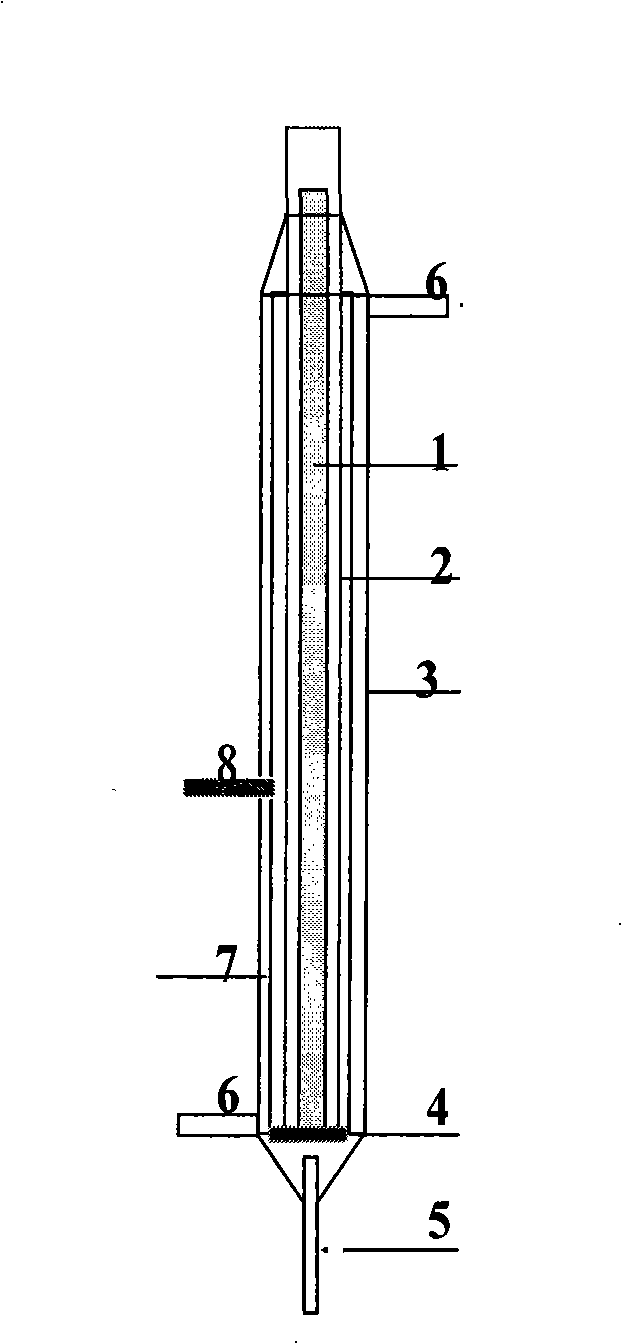

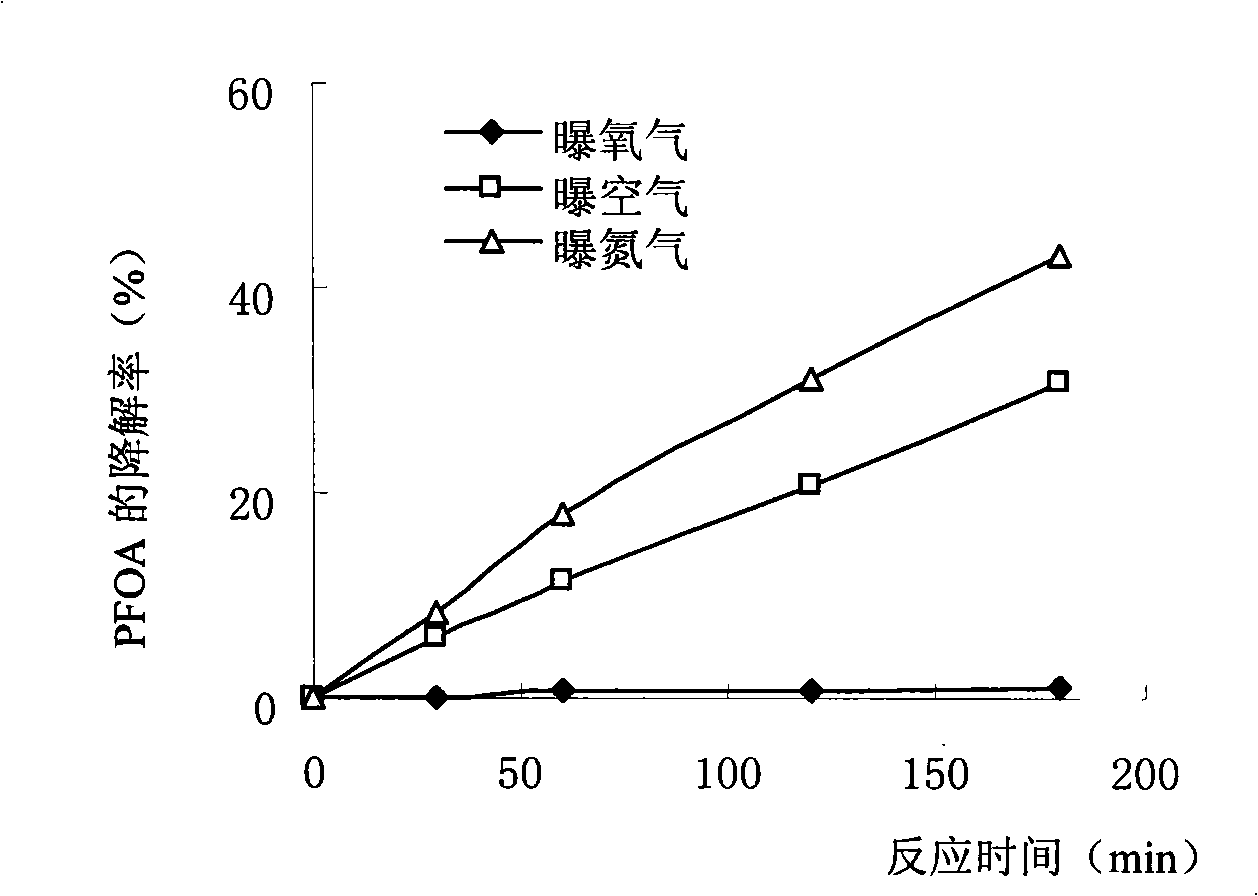

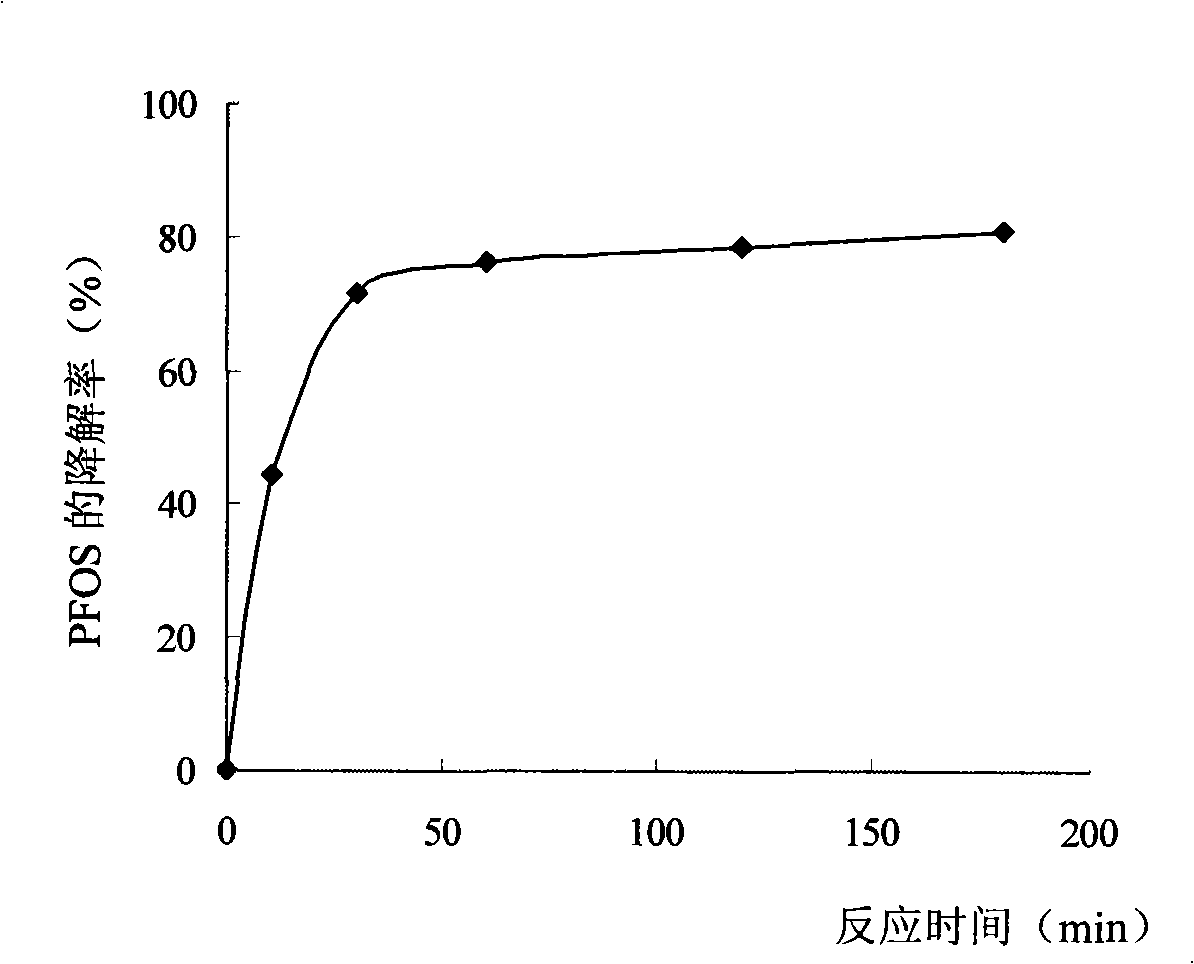

Method for degrading perfluorinated compounds

InactiveCN101524583ALow toxicitySimple process structureWater/sewage treatment by irradiationWater contaminantsUltravioletOxygen

The invention discloses a method for degrading perfluorinated compounds, comprising the following steps: under the oxygen-free condition, belta-Ga2O3 is adopted as a photocatalyst. Ultraviolet with the wavelength of 185-254nm is used for irradiating the perfluorinated compounds to be degraded. The method for degrading the perfluorinated compounds has the advantages that: the technique has a simple structure and can be implemented under normal temperature and normal pressure without complex equipment; the initial concentration of the perfluorinated compounds is not required, and the perfluorinated compounds with any concentration and any pH value can be processed by the method of the invention; the toxicity of degraded products is lowered, and the products can be further processed by other methods.

Owner:TSINGHUA UNIV

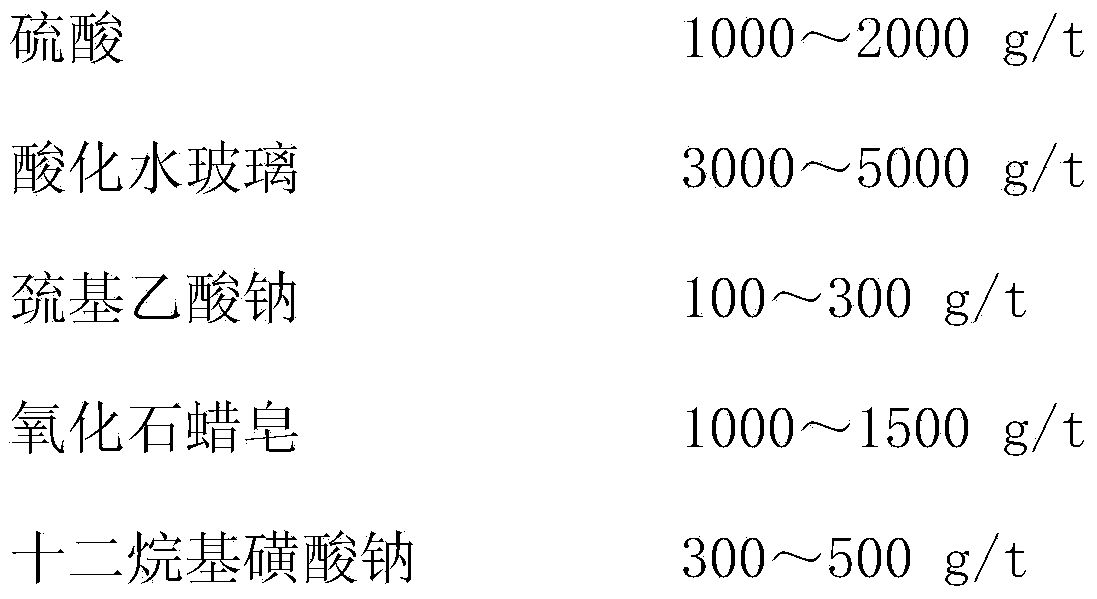

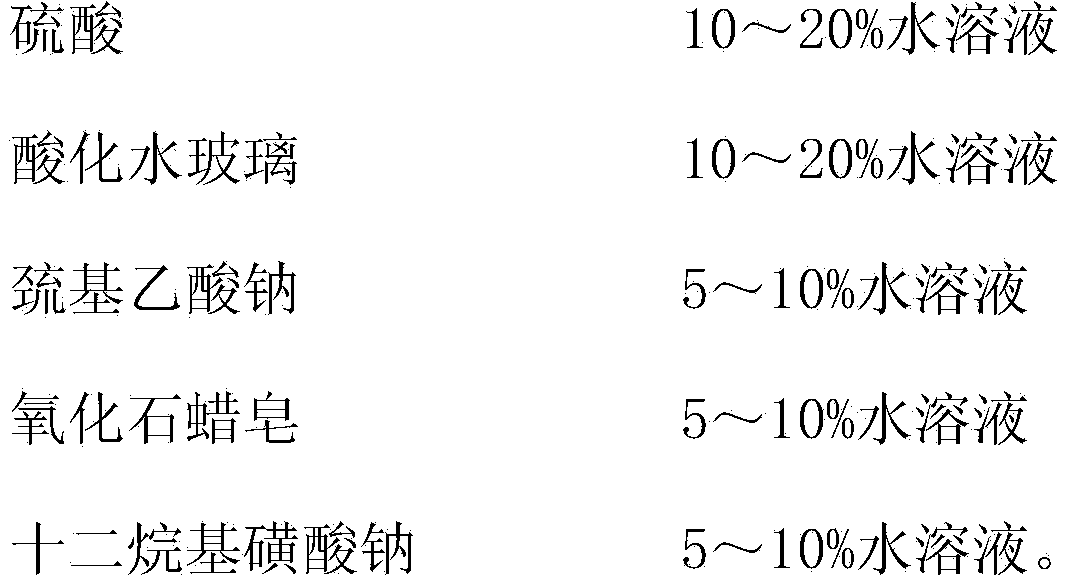

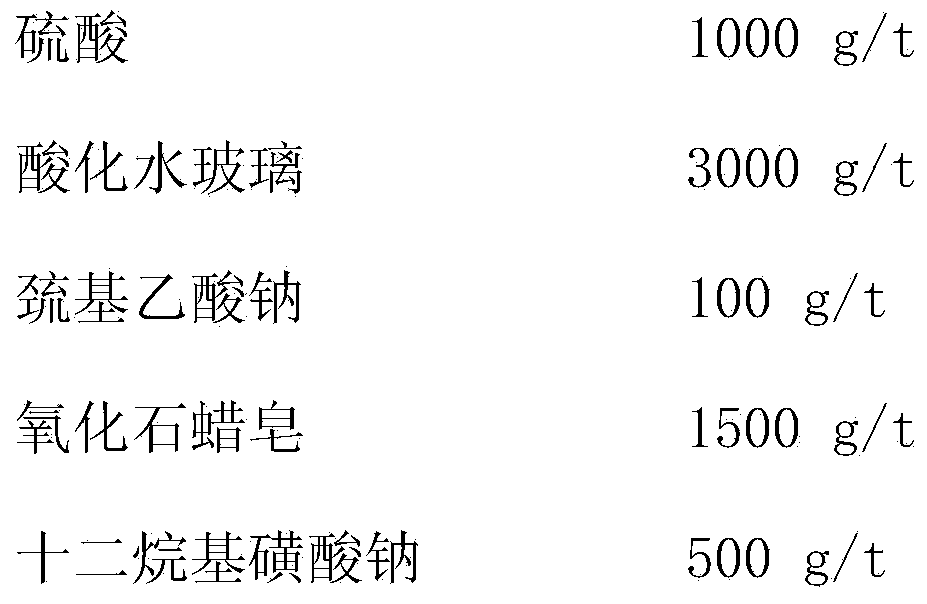

Method for reverse flotation of enriched zinc silicate mineral in acidic condition

A method for reverse floatation of an enriched zinc silicate mineral in an acidic condition comprises the following steps: using sulfuric acid as a pH value regulator, using acidified sodium silicate and sodium thioglycollate as an inhibitor for the zinc silicate mineral, and using oxidized paraffin soap and sodium dodecyl sulfate as a collector for the zinc silicate mineral. By the adoption of the method, the zinc silicate mineral can be effectively recycled, and under the condition that the feeding zinc grade is 11.27-17.80%, the zinc silicate concentrate with the grade being 39.24-44.90% and the recycling rate being 82.55-88.20% can be obtained after three-time reverse floatation.

Owner:GUANGXI UNIV

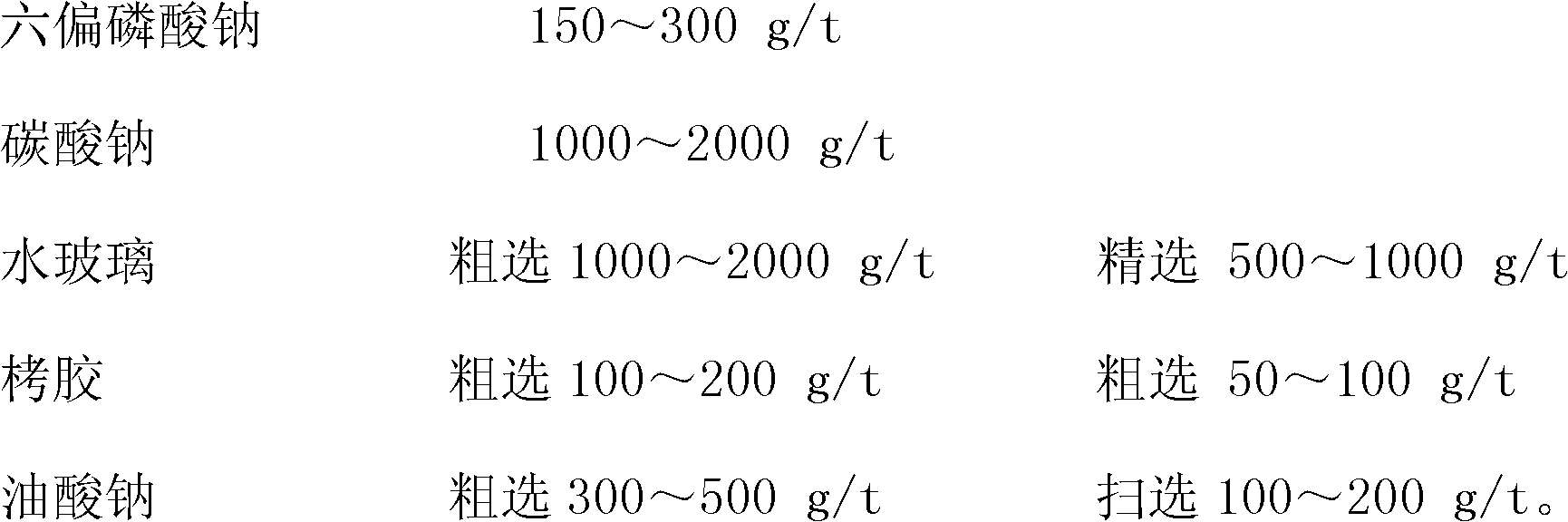

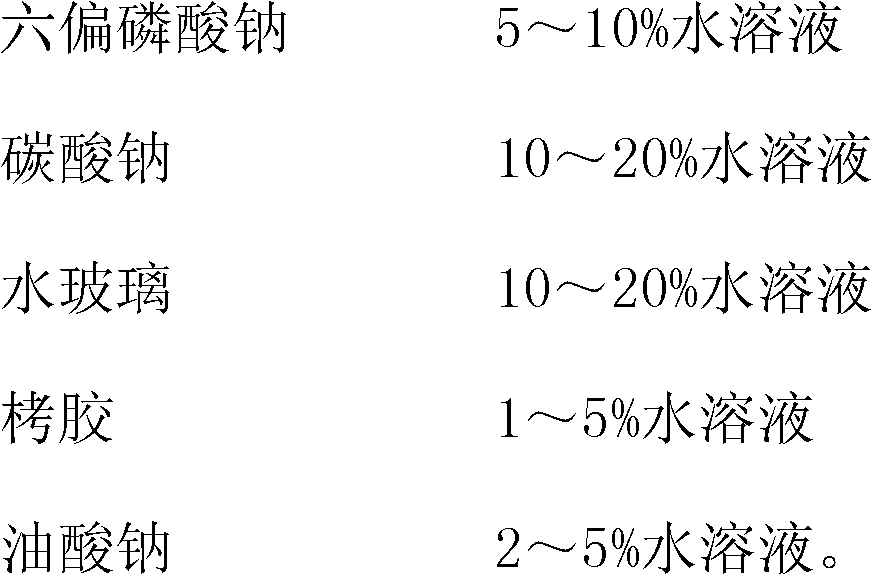

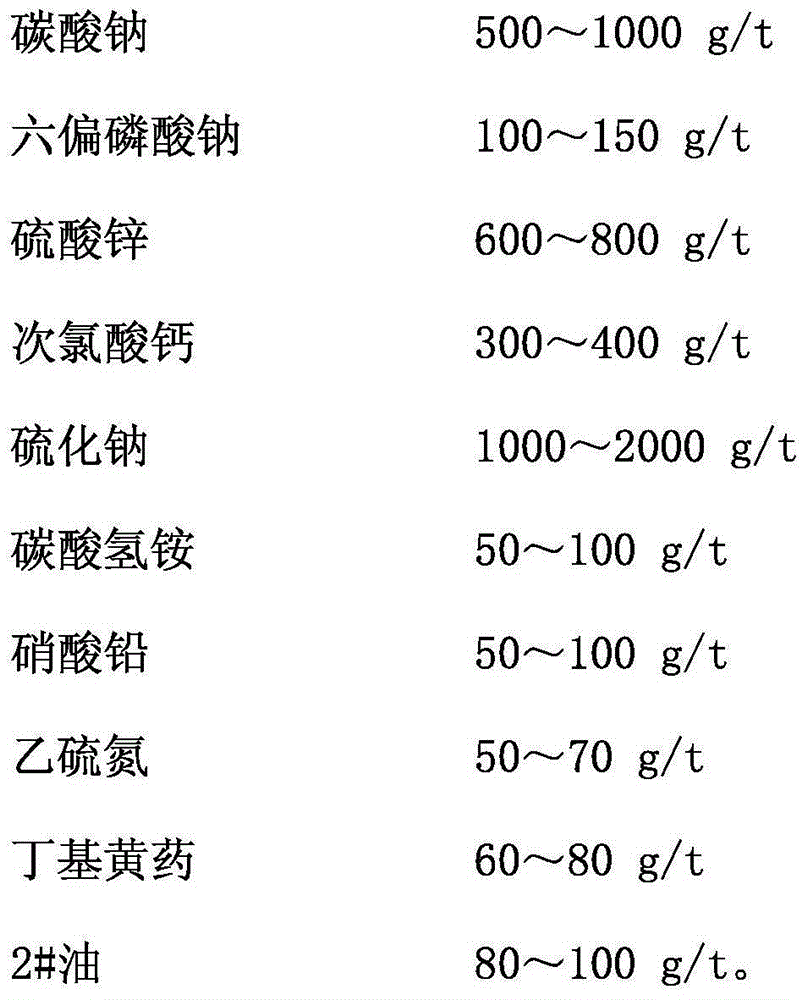

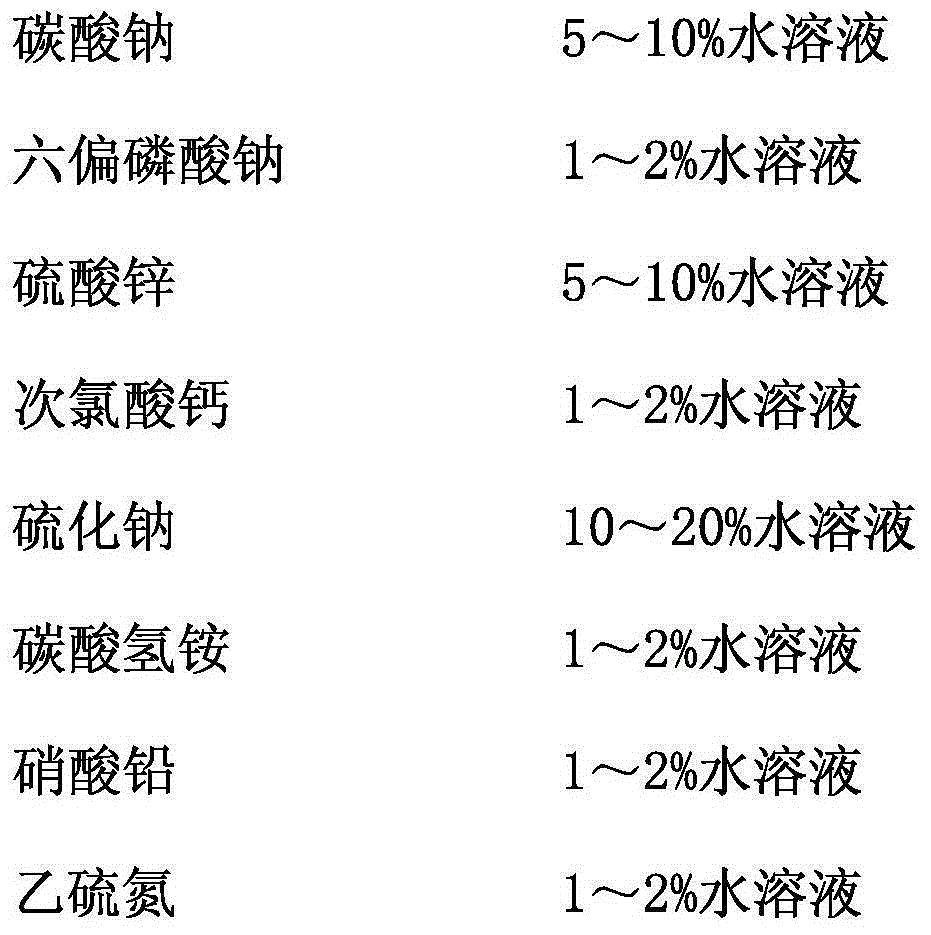

Floatation method of sulfur-oxygen mixed lead antimony ore

The invention relates to a floatation method of sulfur-oxygen mixed lead antimony ore. Sodium carbonate is used as a pH regulator, sodium hexametaphosphate is used as a fine sludge mineral dispersing agent, zinc sulfate and calcium hypochlorite are used as a gangue mineral inhibitor, sodium sulfide, ammonium bicarbonate and lead nitrate are used as a lead antimony ore activator, diethyl dithiocarbamate and butyl xanthate are used as a lead antimony ore collector, and 2# oil is used as a foaming agent, thereby performing floatation on the sulfur-oxygen mixed lead antimony ore to obtain the lead antimony mixed concentrate. The method can effectively recover the sulfur-oxygen mixed lead antimony ore. Under the conditions that the lead grade of the feed ore is 0.28-1.07% and the antimony grade is 0.24-0.83%, the lead antimony mixed concentrate, of which the lead grade is 20.87-34.55% and the antimony grade is 17.53-28.40%, can be obtained. The lead recovery rate is 75.21-82.77%, and the antimony recovery rate is 73.60-80.75%.

Owner:GUANGXI UNIV

Ilmenite-containing ilmenite separation beneficiation method

The invention relates to an ilmenite-containing ilmenite separation beneficiation method, and belongs to the field of mineral processing. The ilmenite-containing ilmenite separation beneficiation method comprises the following process steps that strong magnetic pre-selection is carried out on the titanium-containing hematite powder under the condition of the magnetic field intensity of 5000 Gs-13000 Gs, so as to obtain the titanium-iron mixed coarse concentrate; the titanium-iron mixed crude concentrate is roasted in a reducing atmosphere, wherein the roasting temperature is 500-620 DEG C, sothat the weakly-magnetic hematite is subjected to a reduction reaction to be converted into strong magnetic iron ore; cooling and grinding is carried out; and weak magnetic separation is carried out on the ground product under the condition that the magnetic field intensity is 750-1600 Gs, and the weak magnetic separation concentrate and the tailings are obtained. The method has the advantages ofhigh titanium recovery rate, high iron recovery rate, simple process structure and high production efficiency; and the comprehensive cost is low, the economical efficiency is good, the environment isprotected, the pollution is avoided, and the resources can be efficiently utilized, and the like.

Owner:NORTHEASTERN UNIV

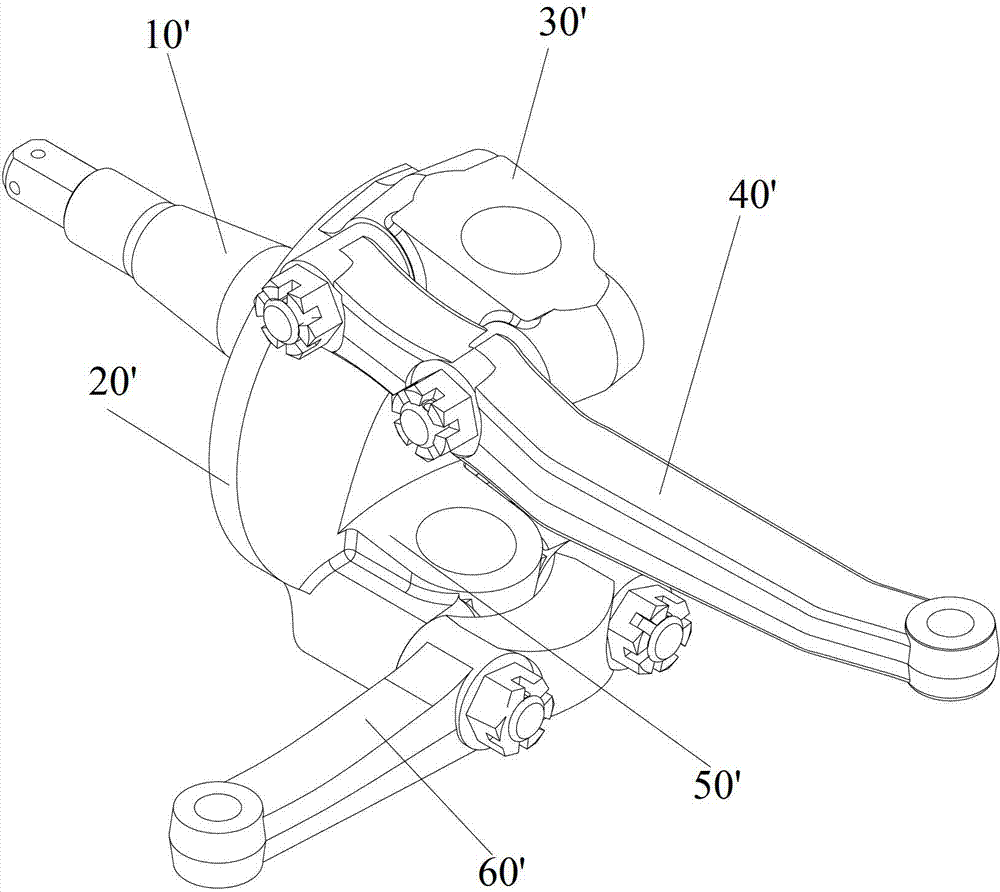

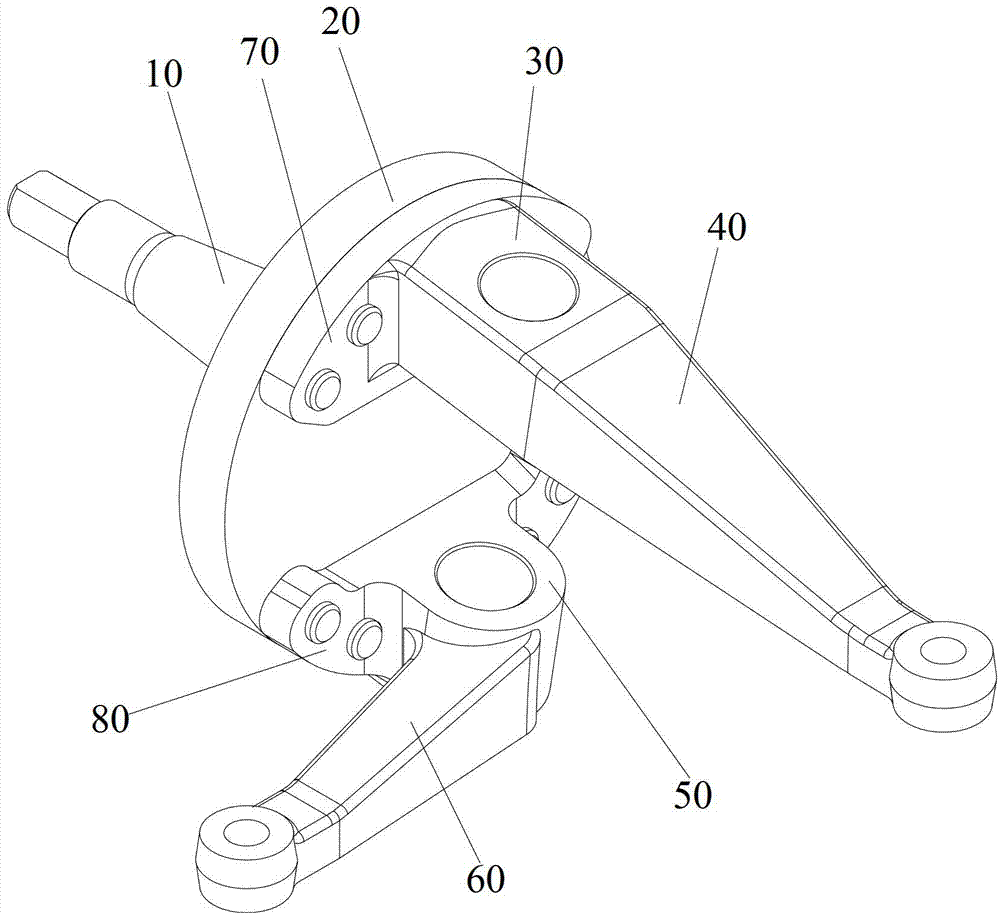

Knuckle assembly, processing method thereof and vehicle comprising knuckle assembly

ActiveCN103042154AWith transition arcSimple process structureSteering linkagesRailway componentsFlangeKnuckle

The invention provides a knuckle assembly, a processing method thereof and a vehicle comprising the knuckle assembly. The processing method of the knuckle assembly includes: integrally processing and forming a finger shaft (10) and a shaft end flange (20); processing a first lug plate (30) and a straight lever arm (40) and fixedly connecting the first lug plate (30) and the straight lever arm (40) to the shaft end flange (20); processing a second lug plate (50) and a tie rod arm (60) and fixedly connecting the second lug plate (50) and the tie rod arm (60) to the shaft end flange (20). The knuckle assembly which is processed by the processing method is simple in structure and easy to process, and thus, work efficiency can be effectively improved.

Owner:湖南中联重科车桥有限公司

Method for converting methyl hydride into methyl hydride chloride

InactiveCN101244980AIncrease profitImprove reaction efficiencyHalogenated hydrocarbon preparationLiquid productChemical reaction

The invention discloses a method for transforming methane into methane chloride, which is characterized in that: gas with methane, chlorine and inert gas are introduced into discharge plasma reactors; methane is excited under the effect of discharge plasma in the reactor, and generates methane chloride by free radical reaction with chlorine; the obtained liquid product is the methane chloride after the reacted mixture is cooled, dehydrochlorinated, dried, dewatered, compressed and condensed gas-liquid, and separated, and the obtained gas returns the reactor and reacts again. The reaction of the invention can be done in normal temperature and pressure, and improves greatly energy utilization ratio, compared with the traditional methane chloride-heating technique processed in high temperature and pressure. Meanwhile, by adopting inert gas as the background gas of plasma chemical reaction, the reaction efficiency of the methane chloride is improved and increased; the inert gas can be used repeatedly; the whole technique is reasonable and simple in structure, easy in operation and application and low in moving cost.

Owner:黄立维

Surfacing repair method for dissimilar metal pipeline of safety end of voltage stabilizer in nuclear power station

ActiveCN105945393ASimple structureSimple process structureArc welding apparatusWelding/soldering/cutting articlesAlloy surfaceDissimilar metal

The invention discloses a surfacing repair method for a dissimilar metal pipeline of a safety end of a voltage stabilizer in a nuclear power station. The surfacing repair method comprises the following steps: depositing a stainless steel cladding layer on the inner wall of a low-alloy steel pipe section; surfacing a buttering layer onto the end surfaces of the low-alloy steel pipe section and the stainless steel cladding layer; enabling the buttering layer and a transition connection pipe to form a U-shaped groove, and connecting the two parts in a welding manner to form a buttering weld; excavating out a stainless steel weld from a weld between the transition pipe section and the pipe section, carrying out repair welding on the stainless steel weld, and polishing a repair welding weld to enable the repair welding weld to be level with the pipe section; and surfacing a nickel-based alloy surfacing layer on the low-alloy steel pipe section, the buttering layer, the buttering weld and the pipe section. With the adoption of the method, the stress state of the surfacing layer is improved, the surfacing repair process is simplified, the field surfacing repair difficulty is lowered, and safe, reliable and efficient surfacing repair for a dissimilar metal joint of the safety end of the voltage stabilizer is realized.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

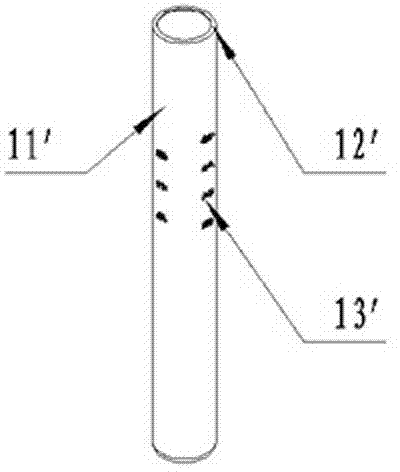

Long-acting no-leakage plunger sealing structure for plunger type measuring pump

InactiveCN102080651AImprove sealingNo leaksPositive displacement pump componentsPumpsEngineeringFriction force

The invention relates to a hydraulic end sealing structure for a measuring pump, and aims at providing a long-acting no-leakage plunger sealing structure for a plunger type measuring pump. The plunger sealing structure comprises a stuffing box, a gland and a compression nut screwed to the stuffing box; the inner part of the stuffing box is a cylindrical through hole which is sequentially provided with a guide ring, a spacer ring and a combined sealing sleeve in a movable fit way; the plunger of the plunger type measuring pump sequentially passes through the compression nut, the gland, the combined sealing sleeve, the spacer ring and the guide ring in a movable fit way; the combined sealing sleeve is of an annular column shape, and the outer column surface of the combined sealing sleeve is provided with at least one annular groove internally provided with an O-shaped sealing ring; two annular counter bores are respectively arranged at both ends of the inner side surface of the combined sealing sleeve, and a group of O-shaped sealing ring and L-shaped sealing ring is arranged in each annular counter bore. The structure has the characteristics of constant preload force, mechanism of self-sealing action, excellent sealing effect and no leakage; the friction force between a sealing component and the plunger is very small so that the service life is long; and the technical structure is simple, and the installation and maintenance are convenient.

Owner:HANGZHOU DACHAO PETROCHEM EQUIP

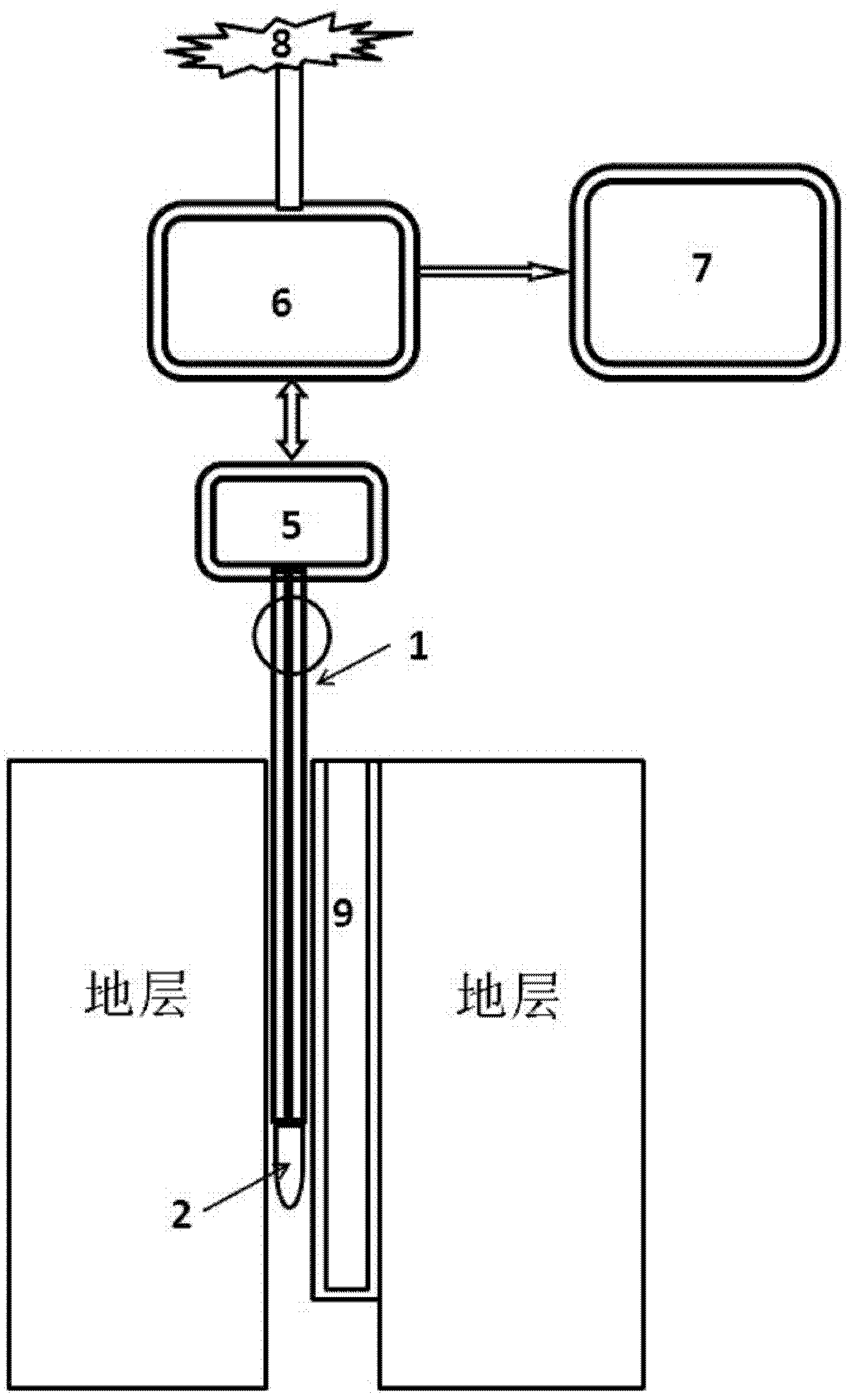

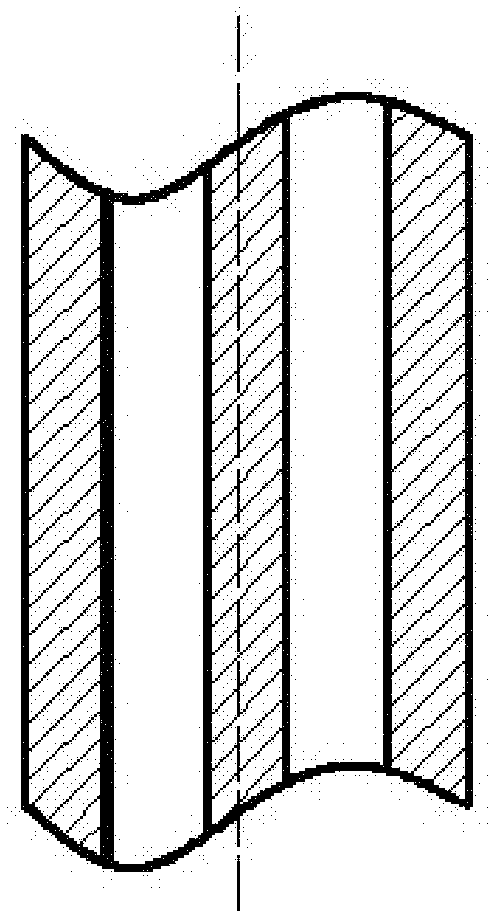

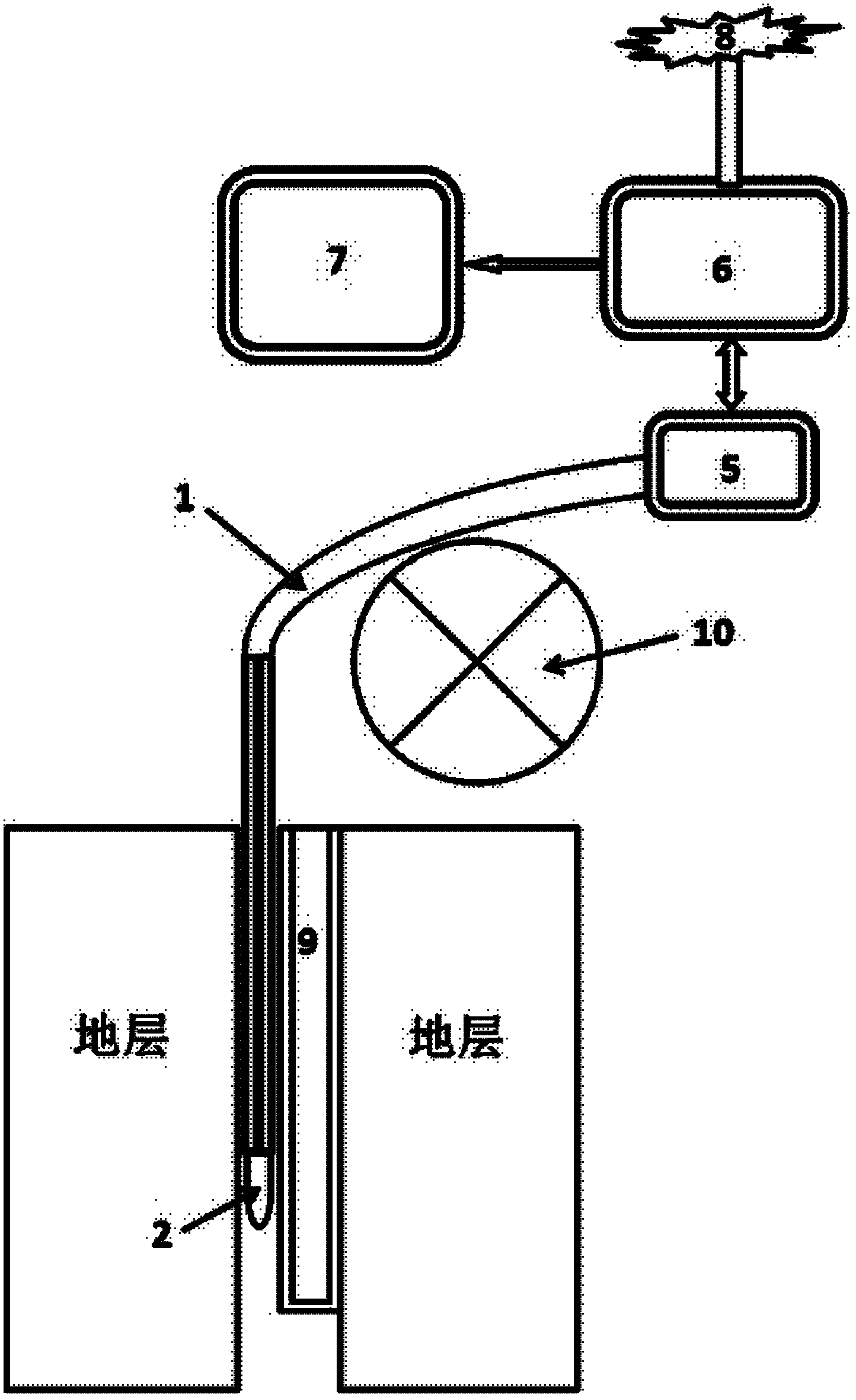

System for continuously monitoring temperature and pressure during steam injection and soaking process

ActiveCN102206995ASimple process structureSimple equipment structureSurveyTemperature stressMonitoring temperature

The invention discloses a system for continuously monitoring temperature and pressure during steam injection and soaking process. The system comprises an armoured cable (1), a pressure and temperature sensor (2), a ground data processor (5) and a ground controller (6). The armoured cable (1) comprises a pair of capillaries (3 and 4), namely a temperature measuring capillary (3) and a pressure measuring capillary (4). Both the two capillaries are filled with a high-temperature pressure conductive medium. Both the aboveground end parts of the two capillaries are connected with the ground data processor (5). Both the underground end parts of the two capillaries are exposed outside the armoured cable (1). Underground pressure is conducted to the pressure measuring capillary (4) through a clean pipe at the underground end part of the pressure measuring capillary (4). The underground end part of the temperature measuring capillary (3) is communicated with the pressure and temperature sensor(2). The ground data processor (5) is used for amplifying and conditioning two pressure signals transmitted by the pressure measuring capillary (4) and the temperature measuring capillary (3) and sending to the ground controller (6) so as to correct the two pressure signals into pressure and temperature engineering values of an underground oil layer.

Owner:河南省科学院同位素研究所有限责任公司 +1

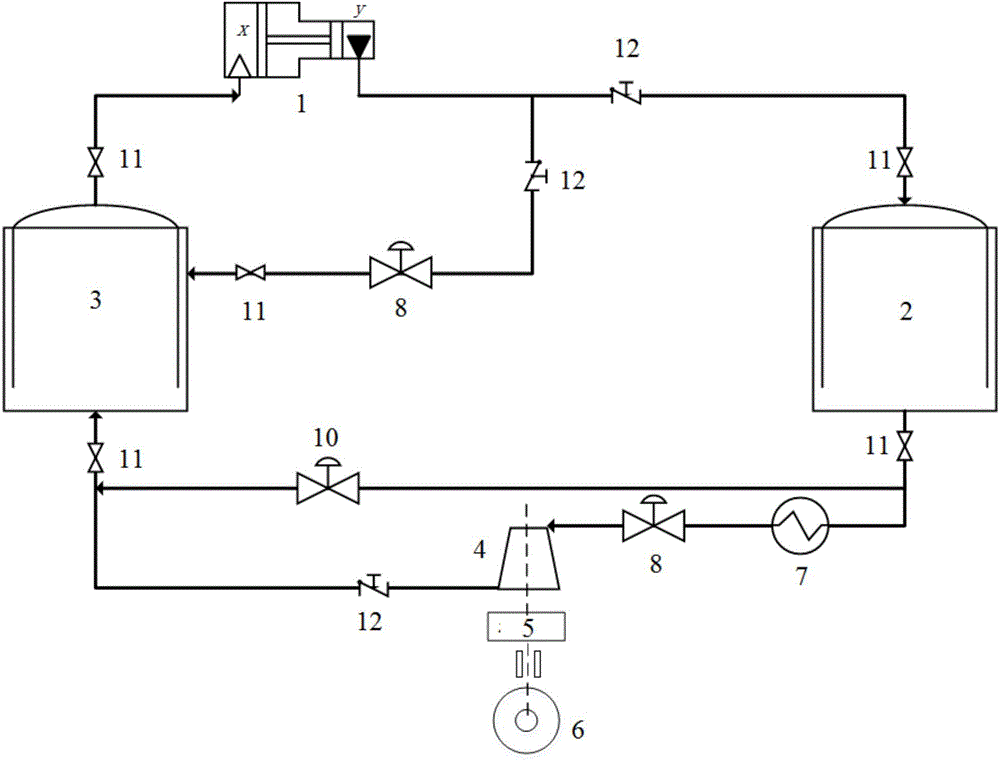

Gas expansion device closure test system and test method

ActiveCN104931658ASimple process structureGuaranteed uptimeMaterial analysisCompression deviceDynamometer

The invention discloses a gas expansion device closure test system and test method. The basic operation process of the system includes that the gas working medium of a low pressure gas storage tank is compressed to raise pressure through a gas compression device, the gas working medium enters a high pressure gas storage tank, the high pressure gas is regulated to drive a gas expansion device to be tested to meet test conditions, the high pressure gas expands, the pressure goes down, the gas enters the low pressure gas storage tank, and one circle is completed; the gas expansion device to be tested is connected to a dynamometer through a gearbox, the rotating speed control and power measurement are implemented, pressure, temperature and vibration sensors measure the inlet, outlet and internal pressure, temperature distribution and rotor vibration parameters of the gas expansion device as required, and the test development and performance detection of the gas expansion device can be implemented. The inlet and outlet pressure control, rotating speed control and long-term continuous operation of the gas expansion device can be implemented easily; in addition, owing to the closure teat system, the working medium can be complex one, single one, flammable one, explosive one or toxic one; the system has the advantages of simple operation, low operation cost and wide application range.

Owner:中科九朗(北京)能源科技有限公司

Industrial powder explosive loading process and explosive loading machine set thereof

InactiveCN102229517APrevent moistureConvenient sealing processExplosive working-up apparatusBlow moldingSmall footprint

The invention discloses an industrial powder explosive loading process and an explosive loading machine set thereof, wherein the process comprises five basic steps such as loading powder explosive in a pipe, loading the powder explosive in a locating manner, sealing, cutting-off, unloading the pipe, transporting and discharging. The explosive loading machine set comprises a circulating traction transporting device, a turnover mold, a vibrating explosive loading device, a sealing device, a sealing membrane rolling / unrolling device, an overturning device and a mould pipe unloading and loading device; the plastic pipe is arranged on the turnover mold; the vibration explosive loading, the sealing and the pipe unloading and loading are sequentially finished on the plastic pipe through the circulating traction device. The adopted plastic pipe is manufactured by carrying out blow molding on polyethylene, which is convenient for carrying out the sealing working procedure and simultaneously can prevent the powder explosive from dampening and meet warning signs specified by the nation, such as the production unit, the production data and the like printed on the external surface of the plastic pipe. The process has the advantages of simple structure, convenience for operation, little occupied area, more than 320 volumes of loaded explosive at a time; and each set of explosive loading machine set charges more than 3.8 tons of powder explosive per hour.

Owner:SHIJIAZHUANG SUCCESS MACHINERY ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com