Electric test method for thermal expansion coefficient of surface finished polysilicon thin film

A polysilicon film, thermal expansion coefficient technology, applied in the direction of material thermal expansion coefficient, measuring device, material analysis by electromagnetic means, etc., can solve the problem of not meeting the requirements of polysilicon film thermal expansion coefficient online test, complex test structure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

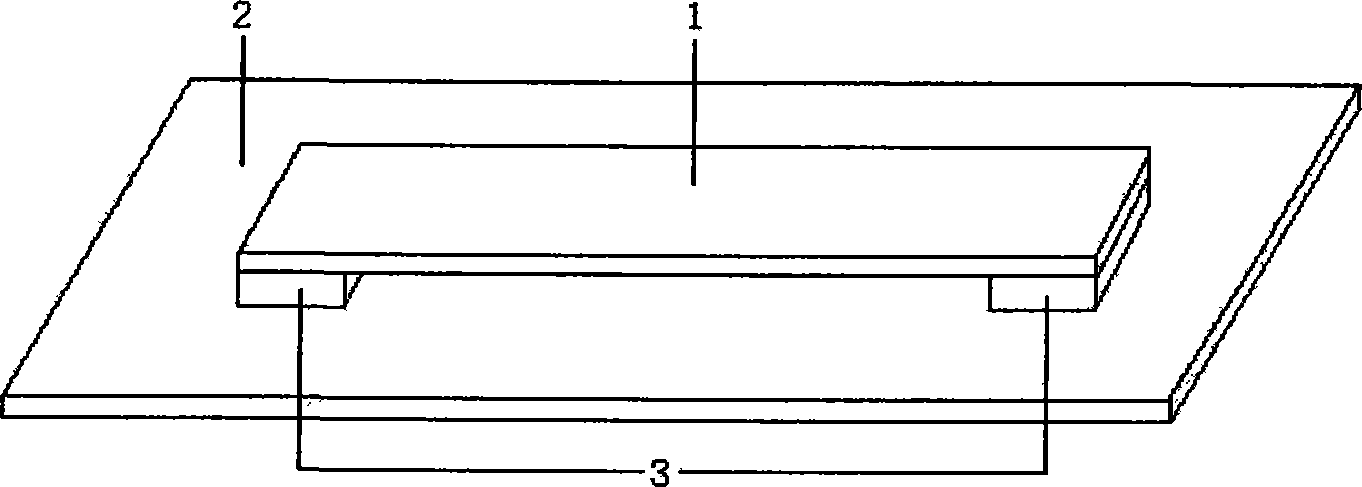

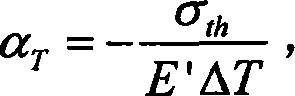

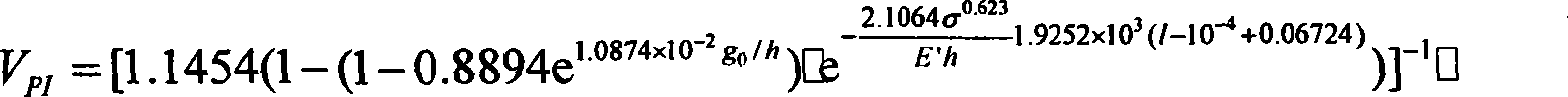

[0026] exist figure 1 Among them, the anchor region 3 fixes the two ends of the double-terminal fixed beam 1 and at the same time insulates the double-terminal fixed beam 1 from the polysilicon substrate 2 . The first step is to apply a voltage between the double-terminal fixed support beam 1 and the polysilicon substrate 2, and measure the pull-in voltage value V when pull-in occurs. PI0 In the second step, after the double-ended fixed beam 1 returns to the initial state, a constant current is passed through the double-ended fixed beam 1, and the change curve of the voltage at both ends of the double-ended fixed beam 1 is recorded with an oscilloscope. After the double-ended fixed-support beam 1 is heated and finally reaches the thermal steady state, the pull-in voltage V when it pulls in is measured PI1 . The thermal stress value σ generated in the double-end fixed beam 1 after current heating is obtained according to the change of the two pull-in voltages before and after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com