Patents

Literature

75results about How to "Simple test structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric test method for thermal expansion coefficient of surface finished polysilicon thin film

InactiveCN101246136ASimple test methodSimple process structureMaterial thermal coefficient of expansionMaterial analysis by electric/magnetic meansSurface finishElectricity

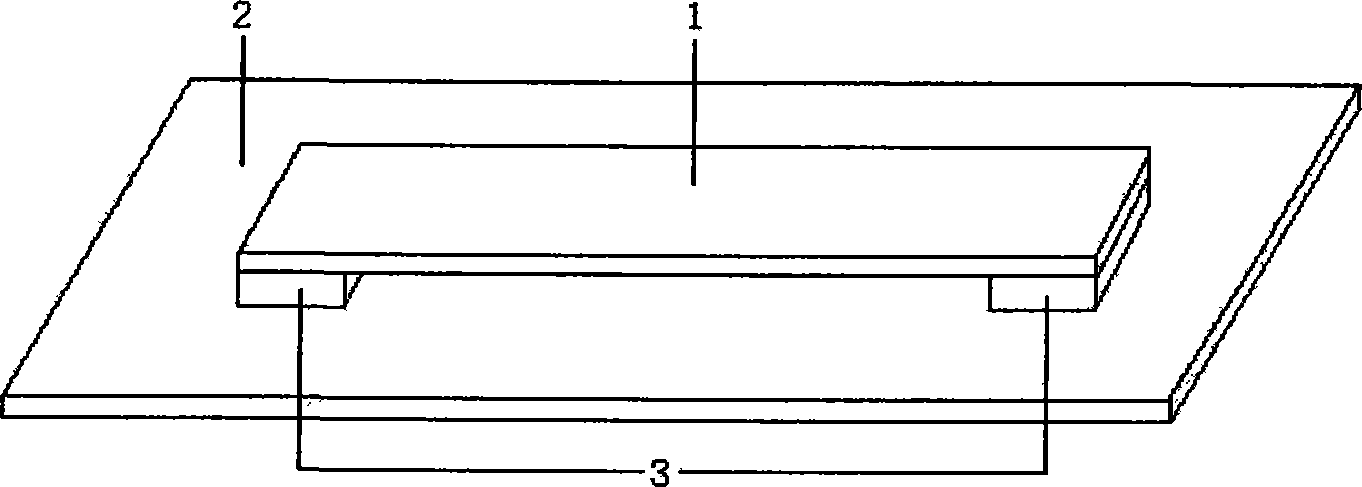

A method for electrically testing the thermal expansion coefficient of the film which is processed with polysilicon on the surface is presented basing on the suction phenomenon of the double-end clamped beam (1), the heat stress value generated in the double-end clamped beam (1) which is heated by the current according to the variation of the two suction voltage before and after the heating of the double-end clamped beam (1); and according to the variation curve of electric voltage in two ends of the double-end clamped-end beam (1) in the heating process recorded by the oscillograph, the variation value of the temperature on the heated double-end clamped beam is obtained; and at last according to the obtained heat stress value and the variation value of the temperature on the double-end clamped beam (1) the thermal expansion coefficient of the polysilicon film can be calculated with the relational expression.

Owner:SOUTHEAST UNIV

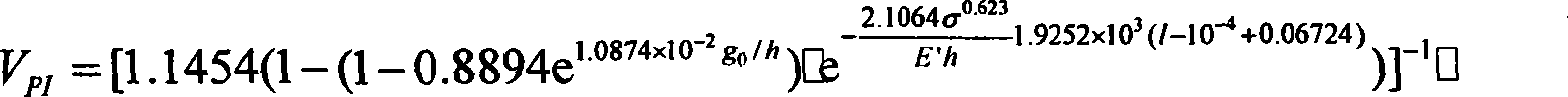

Frequency response test device and method of all-in-one photoelectric device

ActiveCN110187177AAvoid susceptibility to jitter problems caused by the external environmentStable Frequency Response Test StructureSpectral/fourier analysisTesting optical propertiesFrequency spectrumEngineering

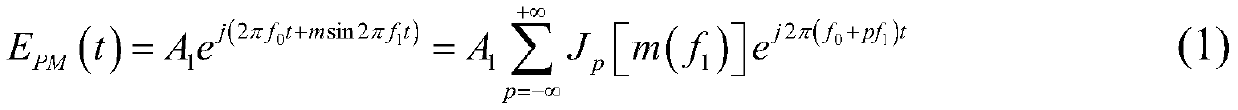

The invention requests and protects a frequency response test device and method of an all-in-one photoelectric device. The frequency response test device comprises a laser, a frequency-shift heterodyne interference module, a to-be-measured detector and a spectral analysis module, wherein the frequency-shift heterodyne interference module comprises a to-be-measured photoelectric modulator and a frequency shifter which are respectively placed in an Mach-Zehnder arm and a lower Mach-Zehnder arm of an interference module, the laser, the frequency-shift heterodyne interference module and the to-be-measured photoelectric detector are sequentially and optically connected, a microwave signal source is electrically connected with an input electrode end of the to-be-measured photoelectric modulator,and an output end of the to-be-measured photoelectric modulator is electrically connected with the spectral analysis module. A power ratio of a corresponding constituent is obtained by the spectral analysis module under the condition that the microwave signal source is driven by two different output voltages under the same working frequency, frequency response test of the to-be-measured photoelectric modulator is achieved, the frequency response of the to-be-measured photoelectric modulator is further inversely calculated, and automatic calibration test of the frequency response is finally achieved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

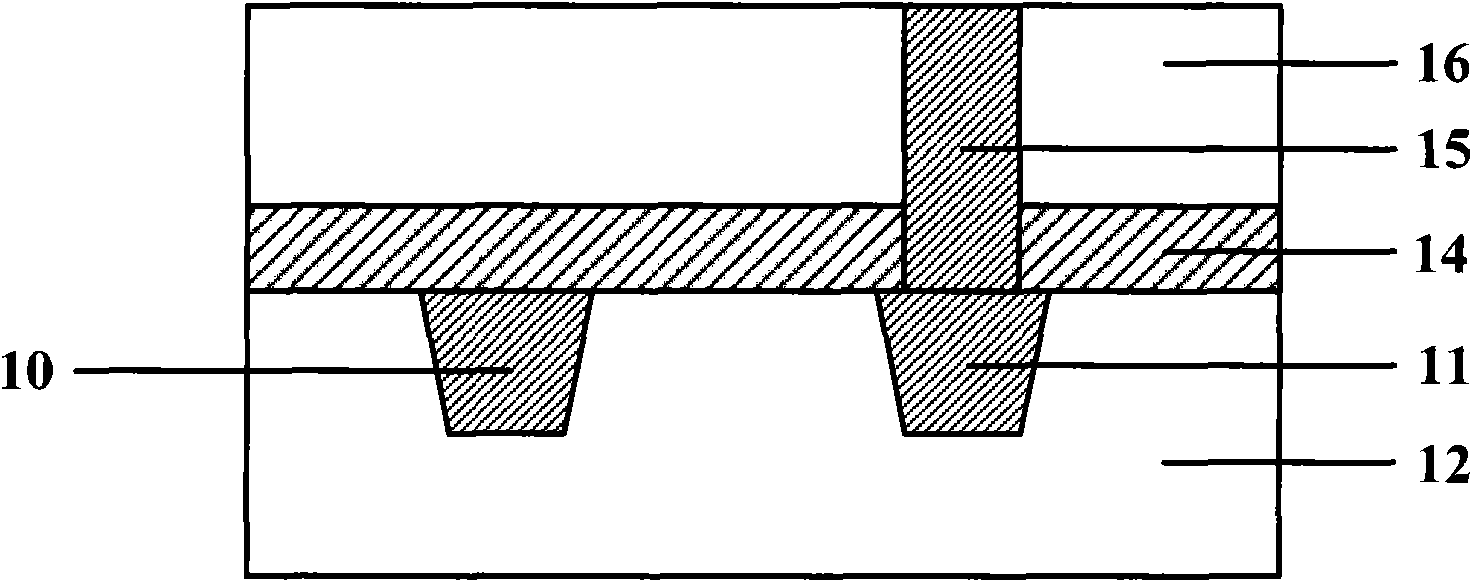

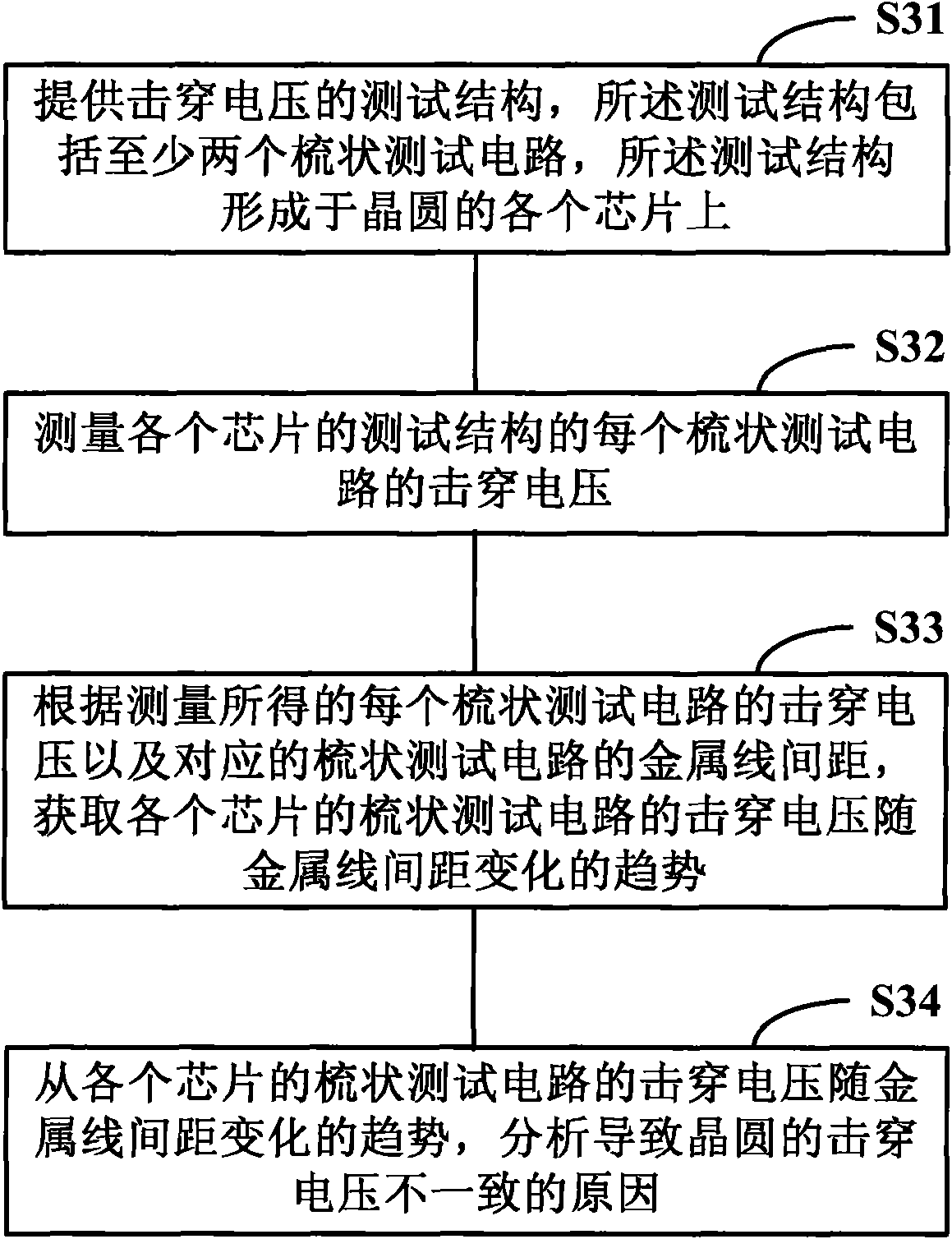

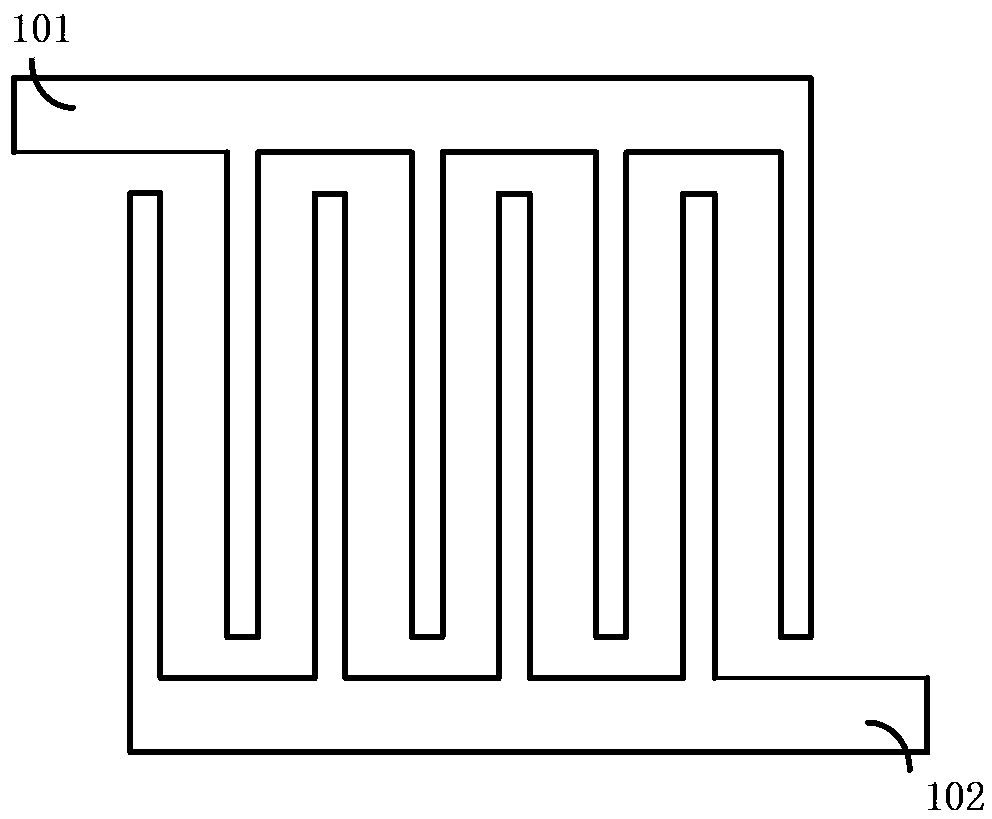

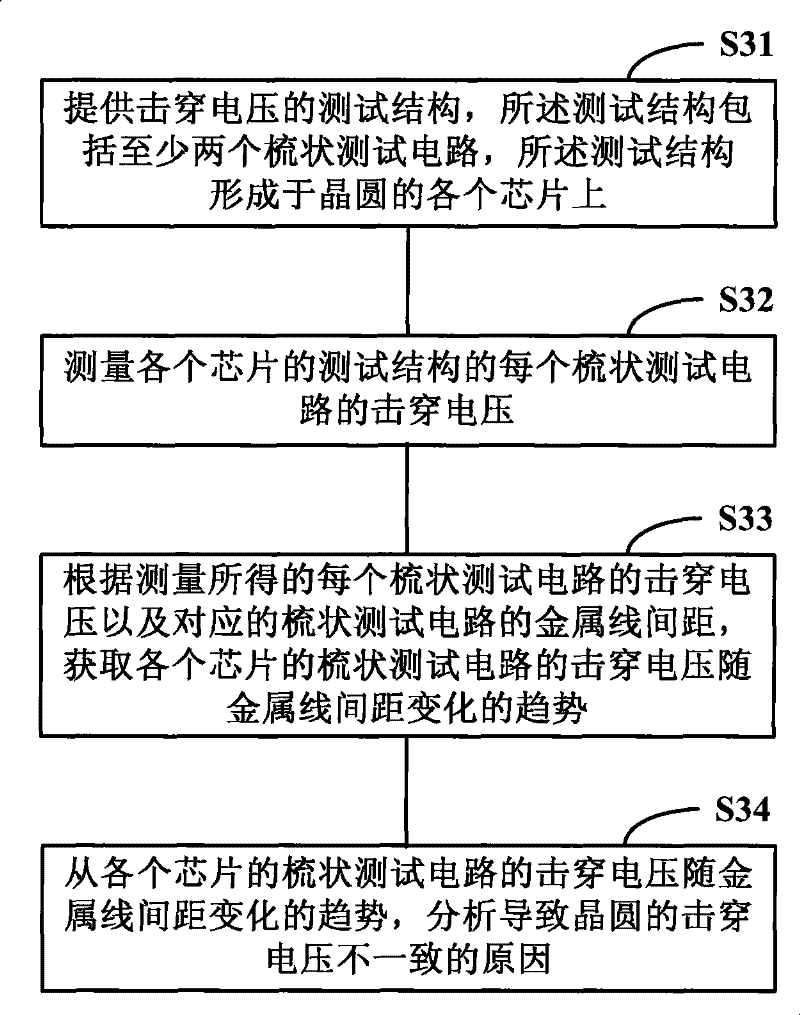

Test structure of breakdown voltage, analytic procedure applying same and wafer

InactiveCN101577265ASimple test structureEasy to implementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsAnalysis methodBreakdown voltage

The invention discloses a test structure of breakdown voltage, an analytic procedure applying the same and a wafer. The test structure comprises at two comb test circuits with metal connection wires, wherein the distances among metal wires in each comb test circuit are equal, the distances among metal wires of the comb test circuits are not equal, and the distances of the metal wires are the distance between any two adjacent metal wires in the comb test circuits. The analytic procedure comprises the following steps: measuring breakdown voltage of each comb test circuit of a test structure of each chip formed on the wafer; obtaining the change trend of breakdown voltage of each comb test circuit of the each chip along with the distance change among the metal wires; and analyzing the reason of uneven distribution of breakdown voltage of the wafer according to the change trend of breakdown voltage of each comb test circuit of each chip along with the distance change among the metal wires. The invention can quickly analyze the reason of uneven distribution of breakdown voltage of interlamination media of the wafer.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

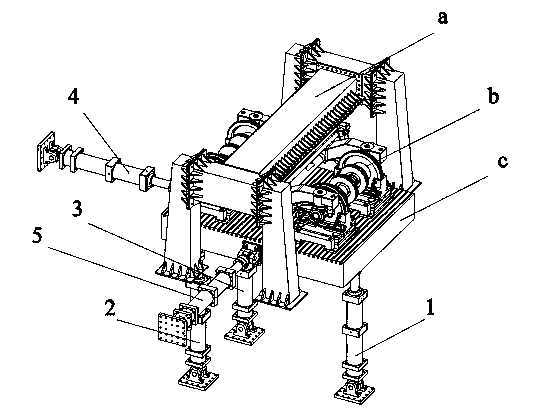

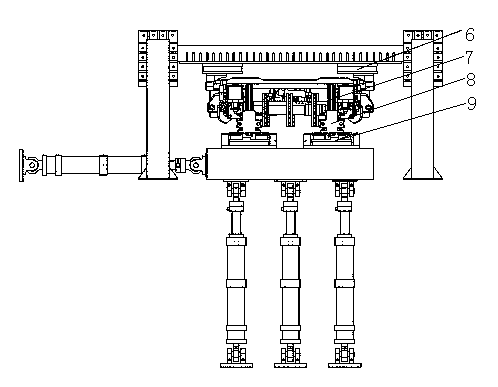

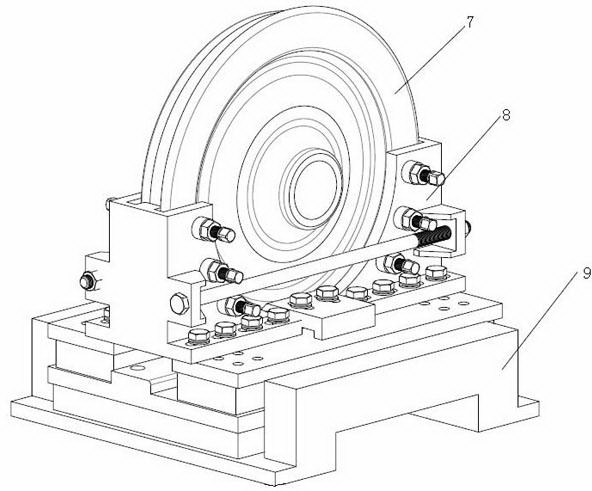

Bogie hanging system parameter testing device and method

ActiveCN104006979AImprove test efficiencySimple test structureRailway vehicle testingBogieClassical mechanics

A bogie hanging system parameter testing device comprises a gantry frame, a moving platform and actuators. Two upper three-dimensional force measuring platforms are connected to the lower face of a horizontal beam of the gantry frame. Switching plates are arranged on the upper three-dimensional force measuring platforms. Locating holes are formed in the switching plates. The upper three-dimensional force measuring platforms are connected with a bogie upper swing bolster through the locating holes and the switching plates. Four lower three-dimensional force measuring platforms are arranged on a lower moving platform. A clamp is arranged in each lower three-dimensional force measuring platform. The clamps are connected with wheel pairs of a tested bogie. Three vertical actuators are connected below the moving platform. The front face of the moving platform is connected with a horizontal actuator. The side face of the moving platform is connected with a longitudinal actuator. According to the testing method of the device, convenience and quickness are achieved, testing efficiency is improved, a testing structure is simple, and the rigidity parameters of a primary suspension system and a secondary suspension system in a reorganize-and-outfit state can be tested. When loading force borne by a bogie suspension is tested, the three-dimensional force measuring platforms are used for measuring stress situations in various directions directly. Interference of friction force and retardation force between the platforms and the bogie and between the platforms and a foundation is overcome, and testing accuracy is high.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

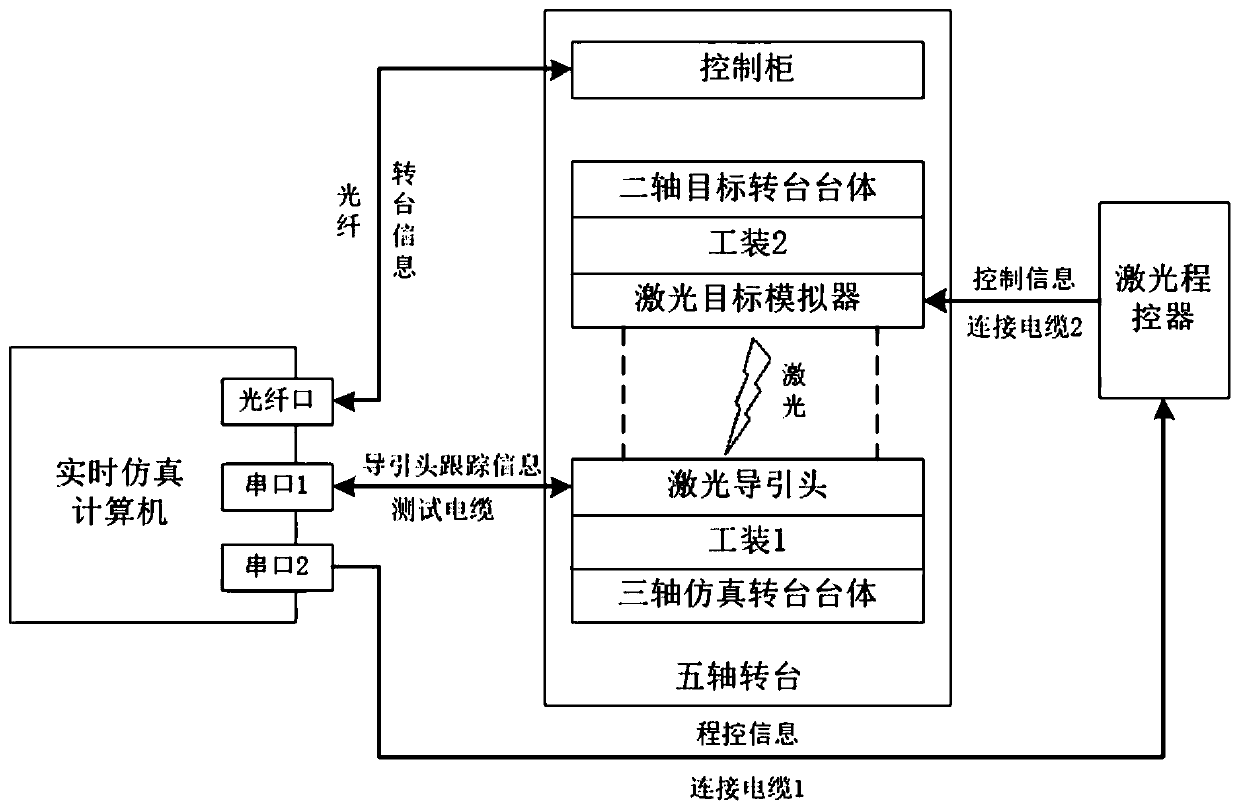

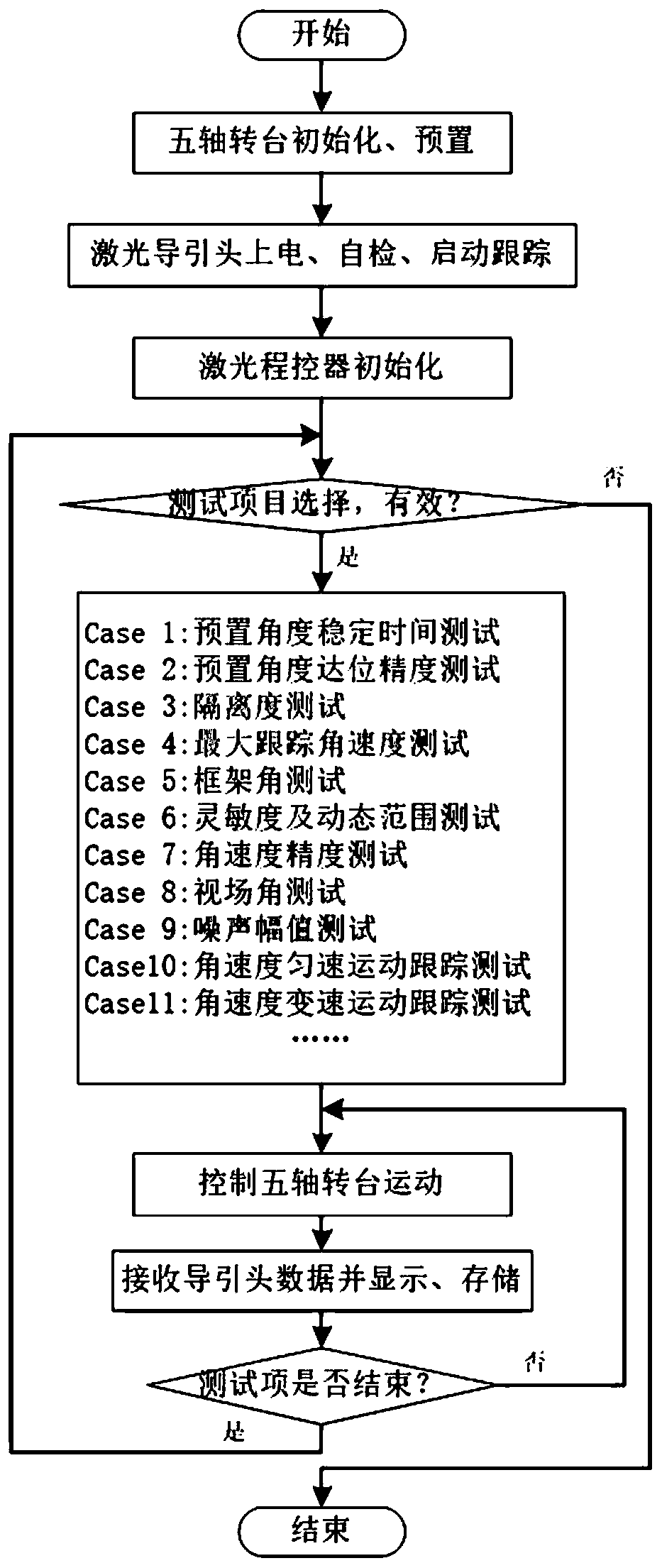

Automatic testing system and method for dynamic performance of laser seeker for terminal guided missile

ActiveCN110108173AEasy to installSimple test structureAmmunition testingOptical apparatus testingReal-time simulationLaser target

The invention discloses an automatic testing system for the dynamic performance of a laser seeker for a terminal guided missile. The automatic testing system comprises a real-time emulation computer,the laser seeker, a five-axis turntable, a laser target simulator and a laser program controller. The invention further discloses an automatic testing method for the dynamic performance of the laser seeker for the terminal guided missile. The automatic testing method includes the steps that the real-time emulation computer runs a test item, the relative motion position of the laser seeker and thelaser target simulator is calculated, turntable information is sent to a control cabinet, and program control information is sent to the laser program controller; a control cabinet drives a three-axisemulation turntable body and a two-axis target turntable body to rotate; the laser program controller is used for generating a laser signal; the laser seeker receives and tracks the laser signal, andgenerated seeker tracking information is sent back to the real-time emulation computer; and the real-time emulation computer displays and stores testing data. The whole testing system is real-time and can be used for testing the delay characteristic, the tracking characteristic and other dynamic performance relevant to time of the laser seeker.

Owner:SICHUAN AEROSPACE SYST ENG INST

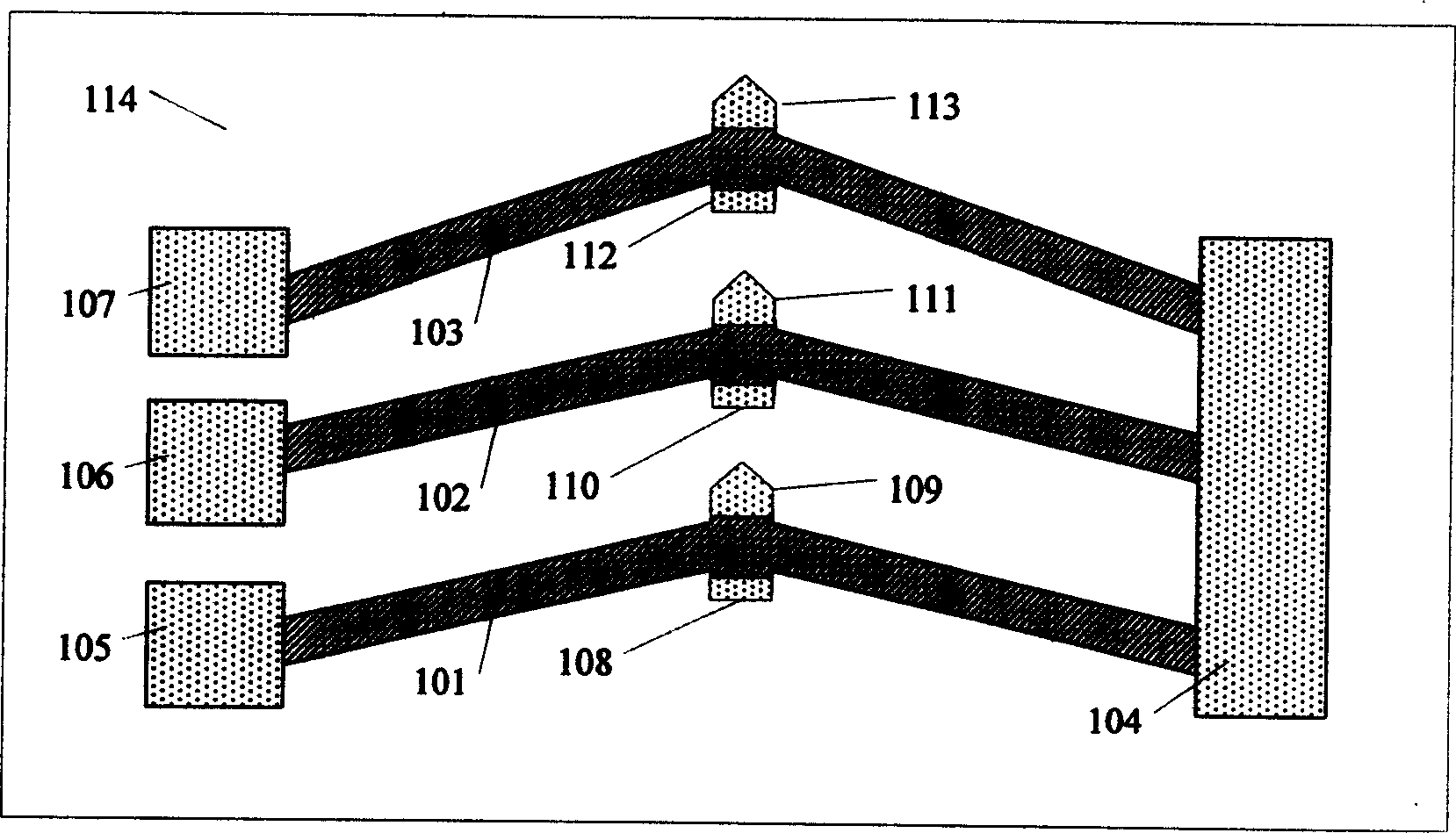

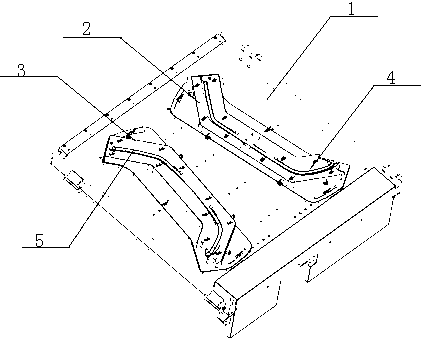

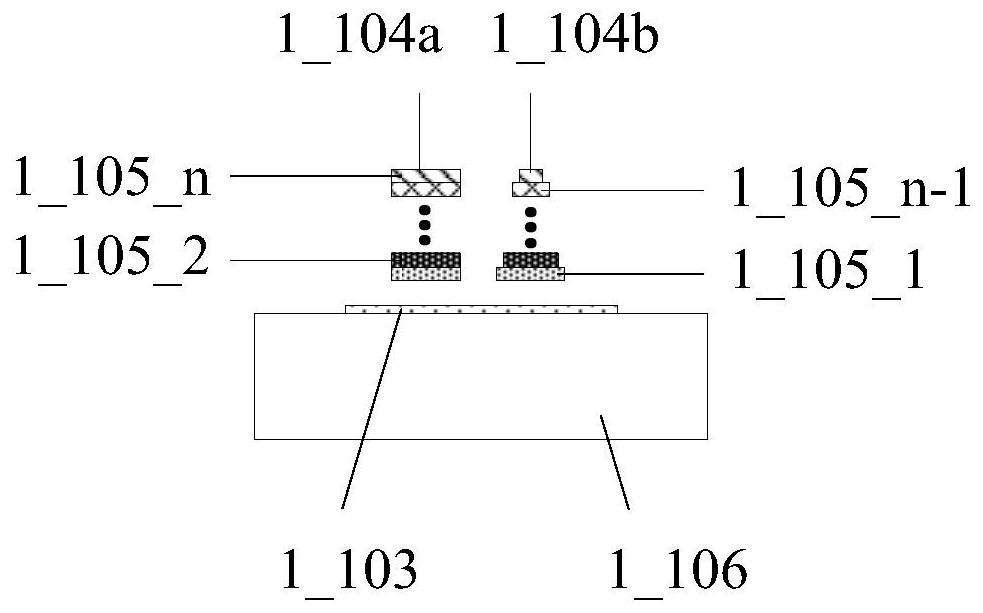

Online measuring structure of residual strain of polysilicon film and testing method

InactiveCN1687698ALower requirementSimple process structureElectrical/magnetic solid deformation measurementResidual strainEngineering

The invention is the online detecting structure and method of polysilicon film residue deformation. The detecting structure comprises the first curved girder, the second curved girder, the third curved girder, the primary pressure welding block, the second pressure welding block, the third pressure welding block and the fourth pressure welding block. The three polysilicon curved girders parallel with each other; the contactors are at the two sides of the central point of the girders and the space between the contactors is equal. The two ends of the first curved girder separately connect the primary and the forth pressure welding blocks; the two ends of the second girder separately connect the second and the forth pressure welding blocks; the two ends of the third girder connect the third and the forth pressure welding blocks. The invention has fast detecting speed and low requirement for the detected equipment.

Owner:SOUTHEAST UNIV

Pipeline reliability testing device

PendingCN107478403ASimple test structureSimple structureMaterial thermal analysisVibration testingTemperature controlEngineering

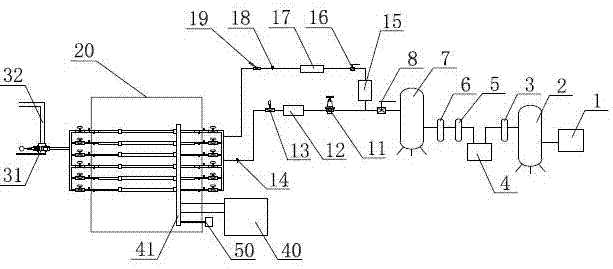

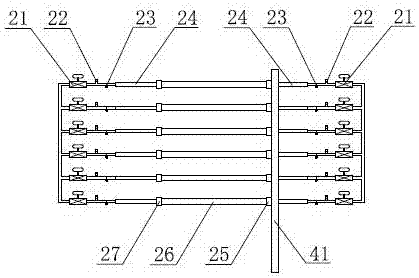

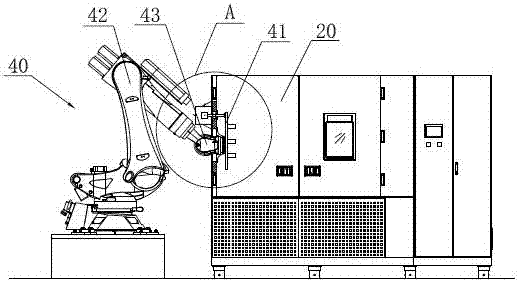

The present invention provides a pipeline reliability testing device which comprises a drying module, a temperature control module, a testing module and a pulse pressure generator installed in order. The gas outlet end of the drying module is divided into two paths which are respectively connected with the heating gas path and the cooling gas path of the temperature control module, the testing module is at least one testing gas paths which are installed in parallel, the hand of the robot of a vibration device stretches into a test box, a testboard is installed at the end portion of the handle, and the handle drives the testboard and pipeline samples to realize three-axial vibration. The vibration device is simple in structure so as to simulate different temperatures, pulse pressures and vibration conditions of an engine in a working process and test the reliability of a turbocharging tube with no need for configuration of a special engine, the test structure is simple, and the cost is saved. The vibration detection device is connected with the testboard, the amplitudes and frequencies of the three-axial directions of the vibration block are the completely same as these of the handle, and displacement sensors of three directions are employed to accurately detect the amplitudes and the frequencies of three-axial direction vibration so as to ensure that the real vibration effect accords with the test requirements.

Owner:无锡帕捷科技有限公司

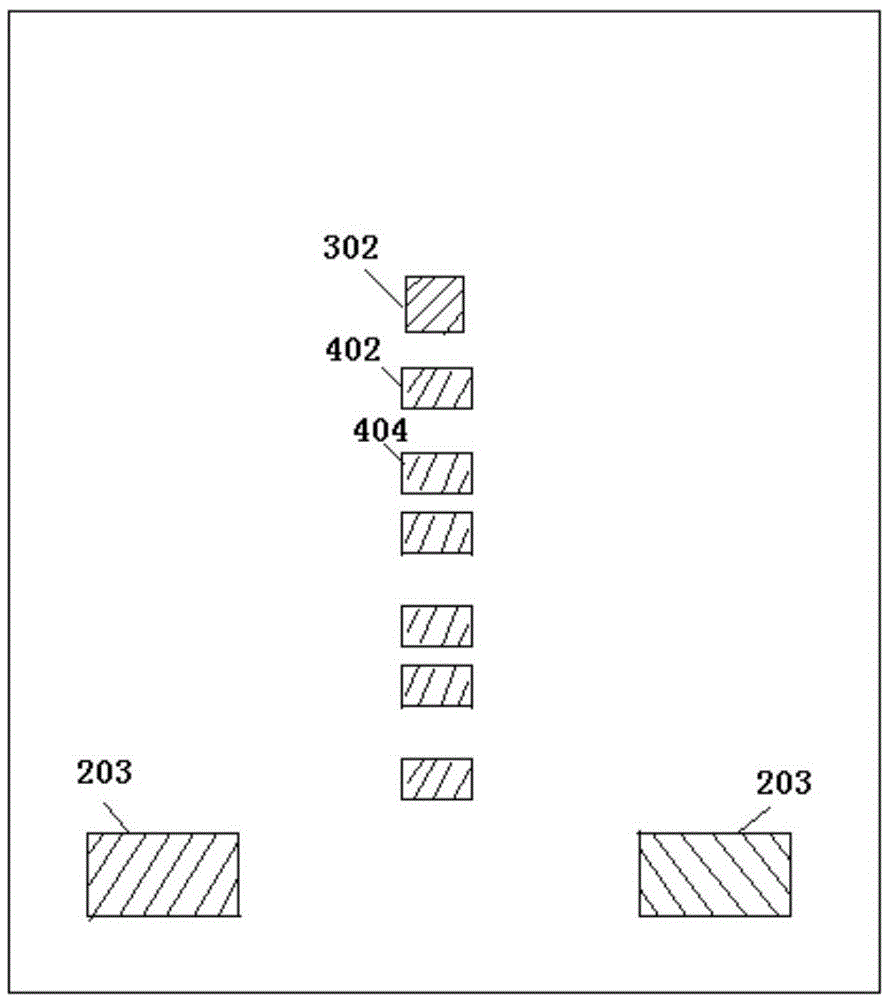

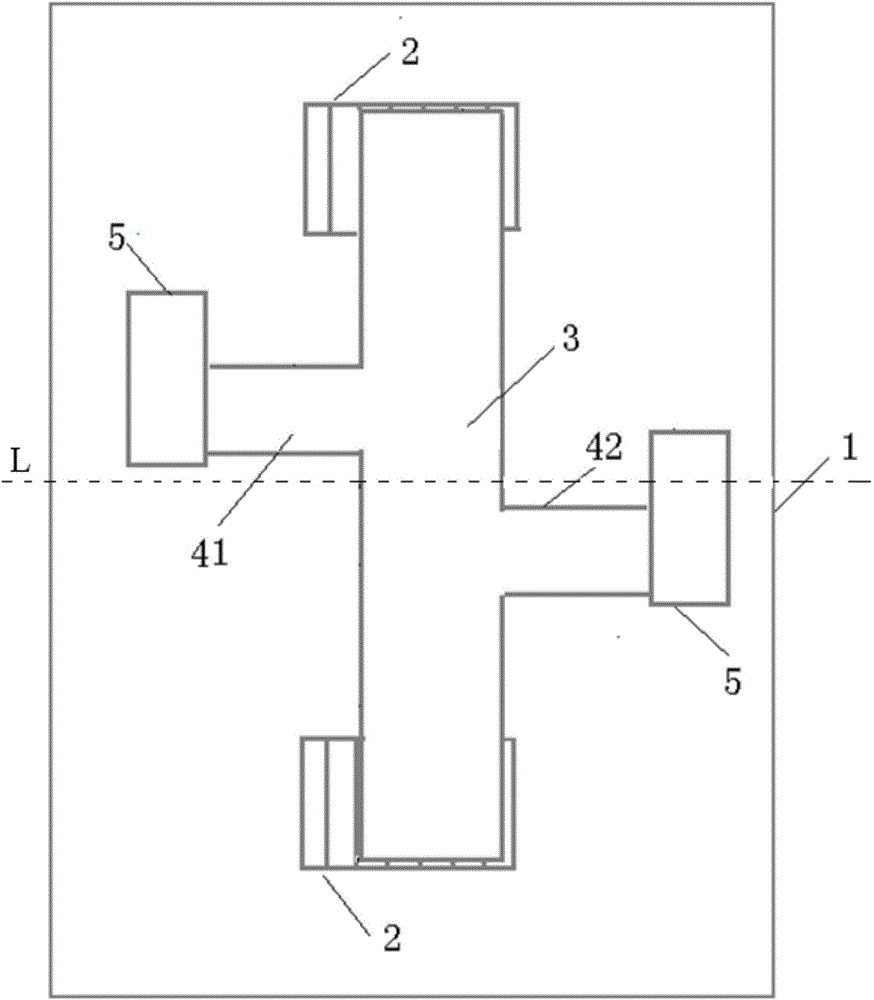

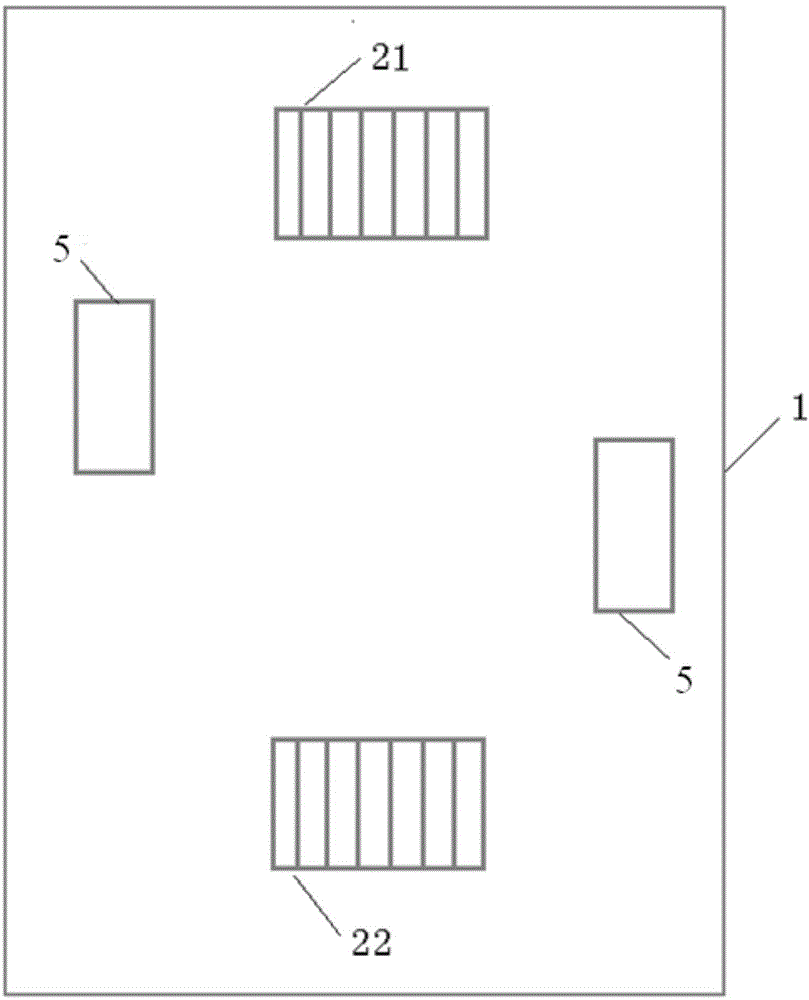

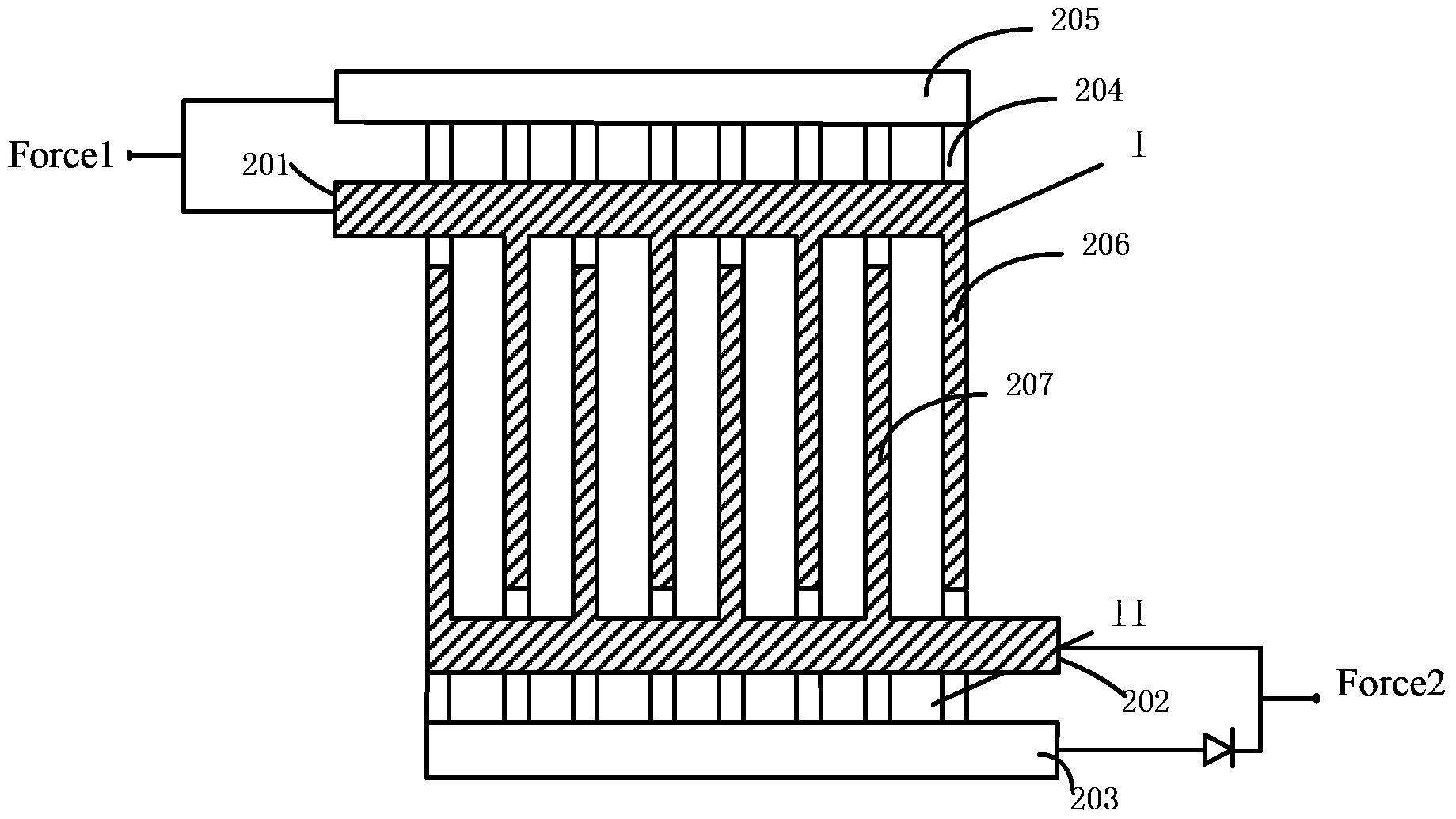

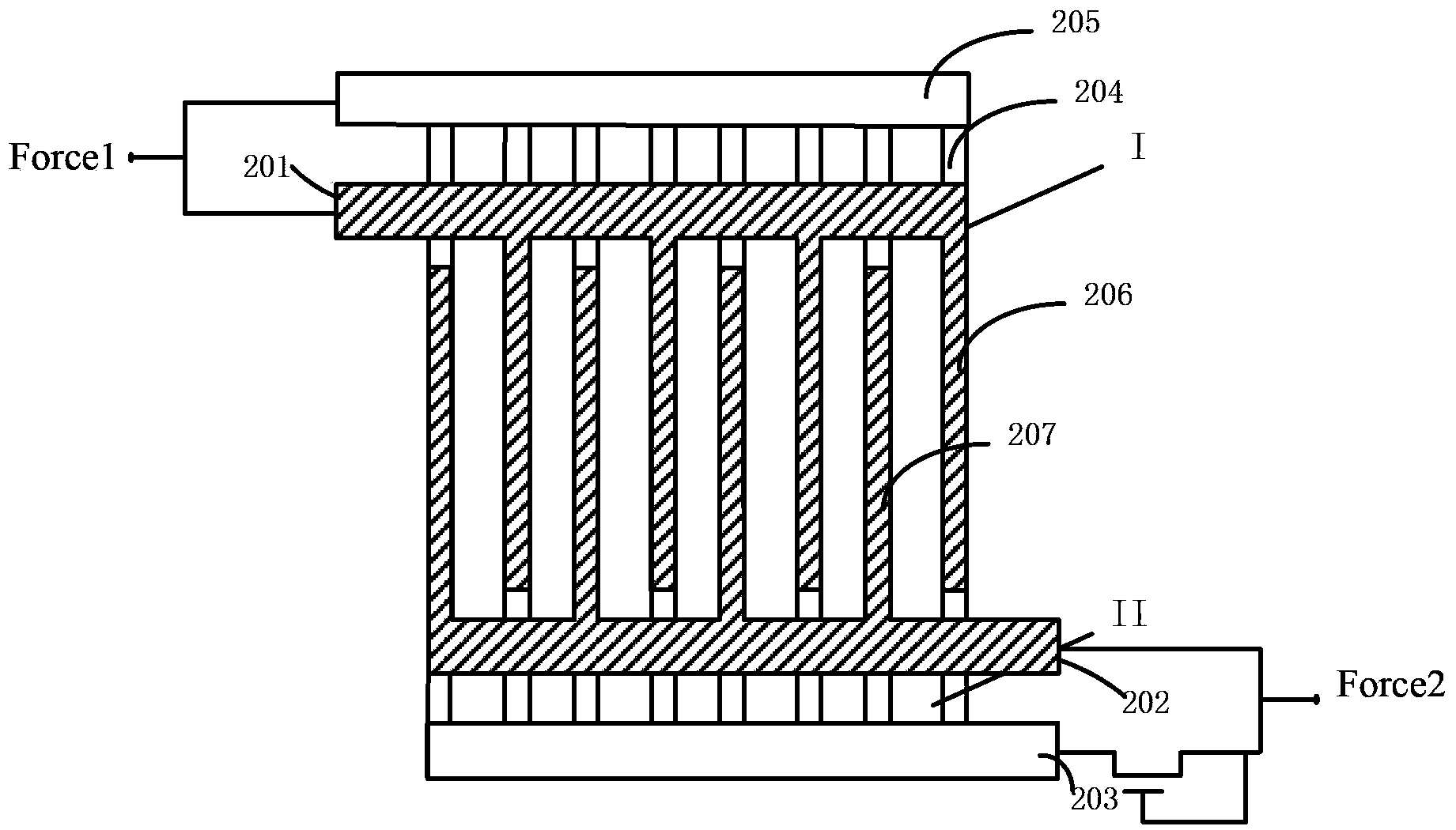

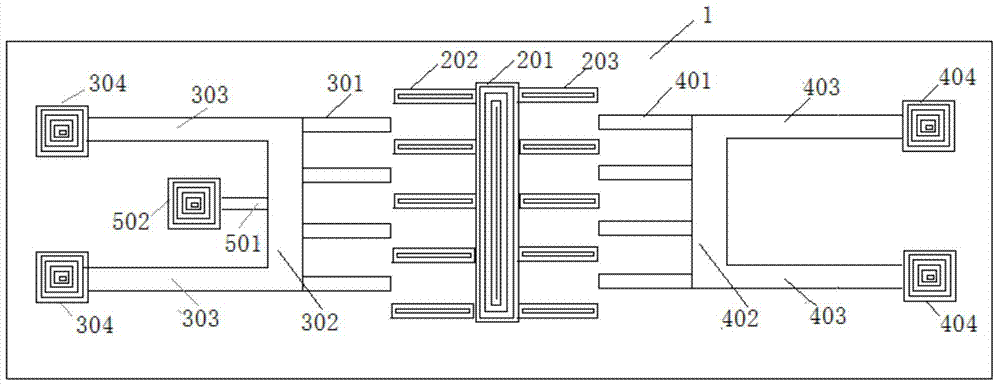

Test structure of micro-beam fracture strength based on lateral comb tooth type capacitance

InactiveCN104483196ASimple test structureHigh sensitivityMaterial strength using tensile/compressive forcesUsing electrical meansCapacitanceEngineering

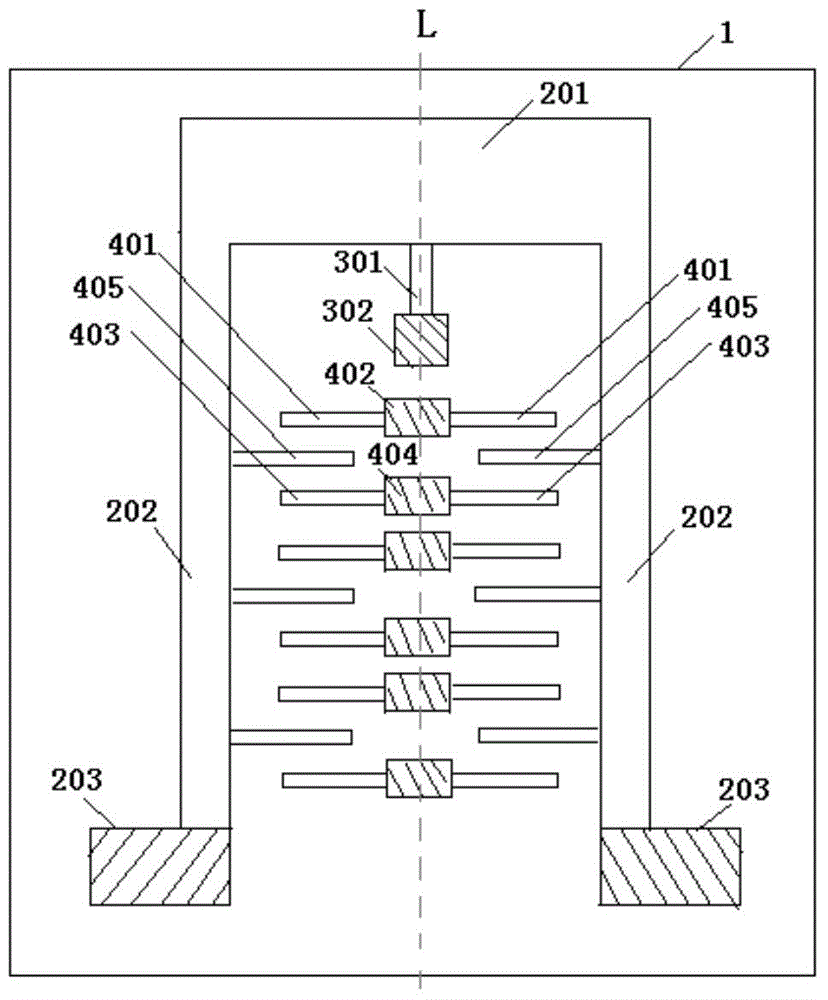

The invention discloses a test structure of micro-beam fracture strength based on lateral comb tooth type capacitance. The test structure comprises a substrate, a door-shaped hot execution structure, a lateral comb tooth capacitance detection structure and a to-be-tested micro-beam structure, wherein the entire test structure is completely symmetrical with respect to a longitudinal central axis L; two longitudinal beams (202) of the door-shaped hot execution structure are respectively vertically connected with two tail ends of a wide cross beam (201), and the other end of each longitudinal beam (202) is fixed on the side surface of a lower anchor area (203); a to-be-tested micro beam (301) is parallel to the two longitudinal beams (202) of the door-shaped hot execution structure and is positioned in right middle of the two longitudinal beams (202), one end of the to-be-tested micro beam (301) is vertically connected to the middle part of the inner side of the wide cross beam (201), and the other end of the to-be-tested micro beam (301) is connected to one side surface of an upper anchor area (302); and the lateral comb tooth capacitance detection structure is sequentially arrayed at the rear part of the to-be-detected micro-beam anchor area (302) by virtue of three groups of completely same comb tooth structures positioned in the door-shaped structure. The invention also discloses a specific working mode for detecting tensile elongation by using lateral comb tooth differential capacitance and further determining tensile force. The test structure disclosed by the invention is high in sensitivity, and is convenient and feasible.

Owner:SOUTHEAST UNIV

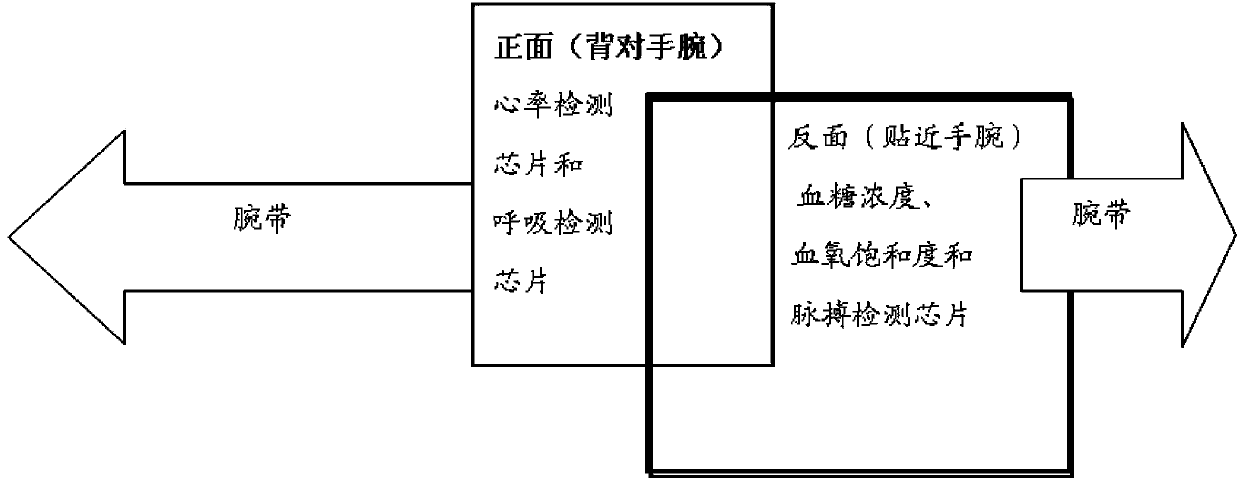

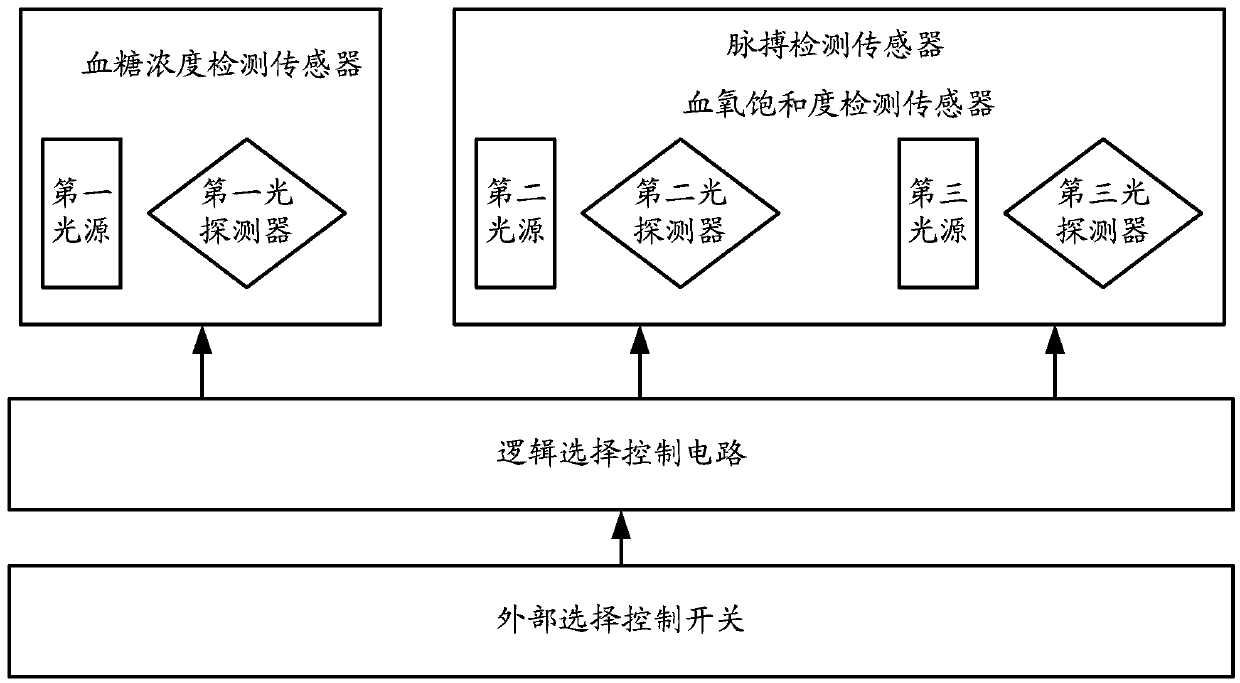

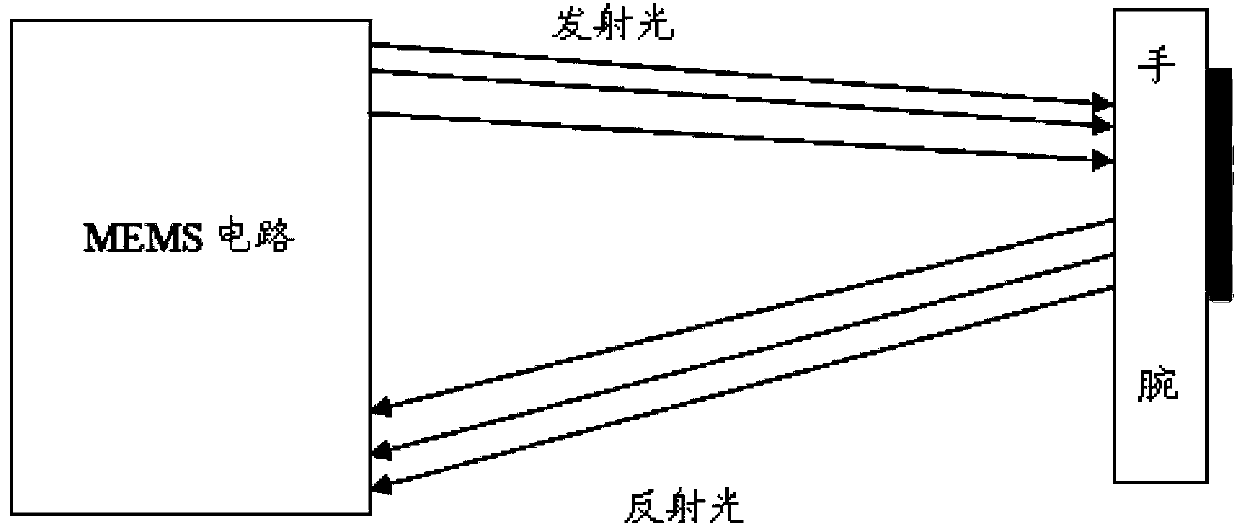

MEMS -based human body physiological parameter detection device

ActiveCN103385711AReduce volumeEasy to carryDiagnostic recording/measuringSensorsHuman bodyEngineering

The invention provides an MEMS-based human body physiological parameter detection device. The human body physiological parameter detection device comprises an integrated circuit chip integrated on the basis of an MEMS technology and a wrist strap, wherein the wrist strap is worn on a wrist when the device is used; the integrated circuit chip is divided into a front face and a reverse face; the reverse face is a face which faces the wrist; the front face is a face which backs on to the wrist; a blood sugar concentration detection sensor, a blood oxygen saturation detection sensor and a pulse detection sensor are integrated on the reverse face of the integrated circuit chip; a heart rate detection sensor and a respiration detection sensor are integrated on the front face of the integrated circuit chip. The invention provides the MEMS-based human body physiological parameter detection device, which has the advantages of small size, easiness in carrying, various testing functions, easiness in operation, low cost and the like.

Owner:临沂市拓普网络股份有限公司

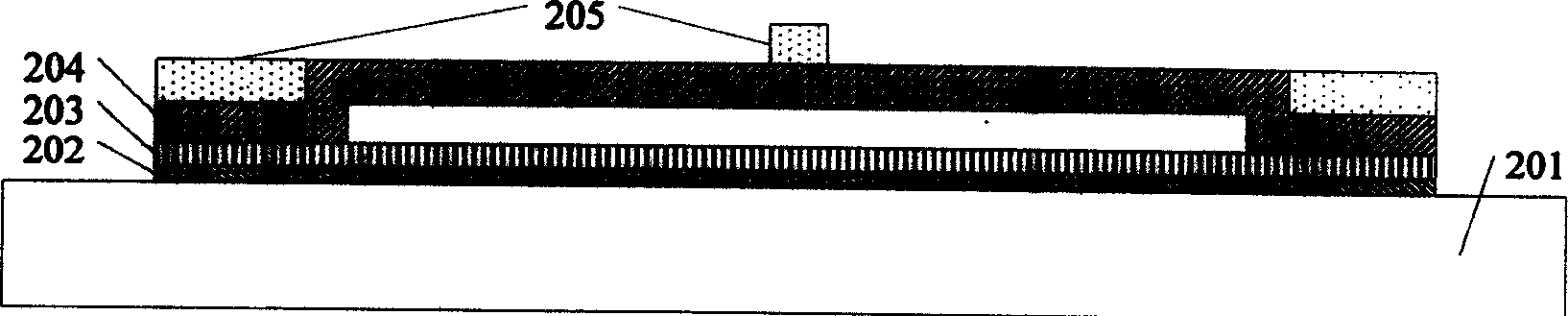

Test structure of micro-machining residual stress of deflection capacitive surface

The invention discloses a test structure of micro-machining residual stress of a deflection capacitive surface. The test structure comprises a substrate, two lower electrode plates, an upper electrode plate, a left beam, a right beam and two anchoring zone. The lower electrode plates are deposited on the upper surface of the substrate, and the two anchoring zones are arranged on the substrate. The upper electrode plate is arranged above the lower electrode plates in a suspended mode, and the left beam and the right beam are identical and located on the two side of the horizontal central axis L of the upper electrode plate respectively, wherein the distance between the left beam and the central axis L is equal to that between the right beam and the central axis L. The right side of the left beam is connected with the left side of the upper electrode plate, and the left side of the left beam is fixed on the side face of one anchoring zone. The left side of the right beam is connected with the right side of the upper electrode plate, and the right side of the right beam is fixed on the side face of the other anchoring zone. The upper electrode plate, the left beam and the right beam are located in the same plane. The test structure is simple and easy to process, and in addition, test equipment is simple and high in precision. The measuring precision can be improved by increasing the area of the upper electrode plate and the area of the lower electrode plates in the test structure, and in addition, with the method for rotating the upper electrode plate in the test structure, a larger capacitance variation can be more easily obtained compared with a horizontally-moving method.

Owner:SOUTHEAST UNIV

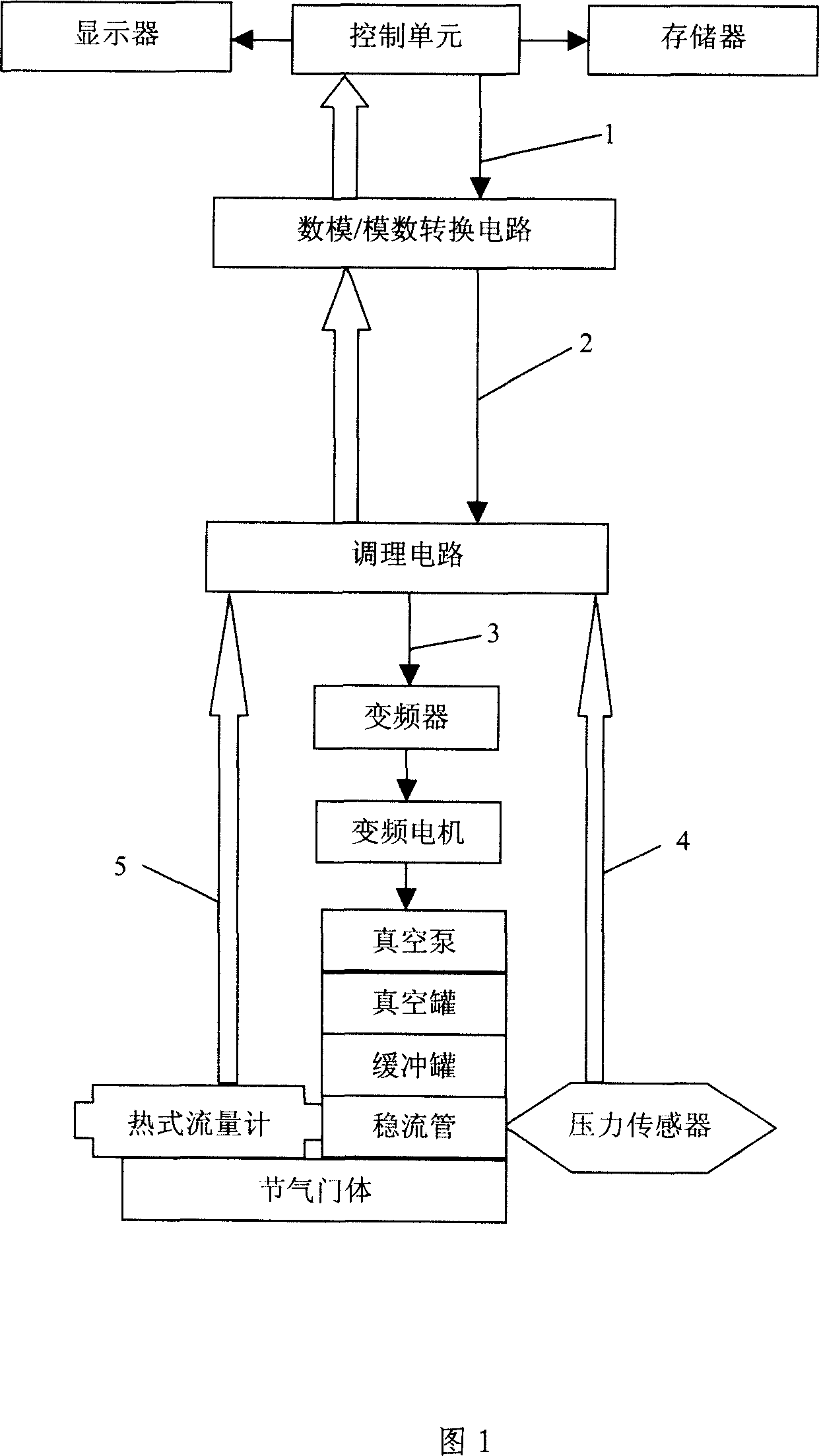

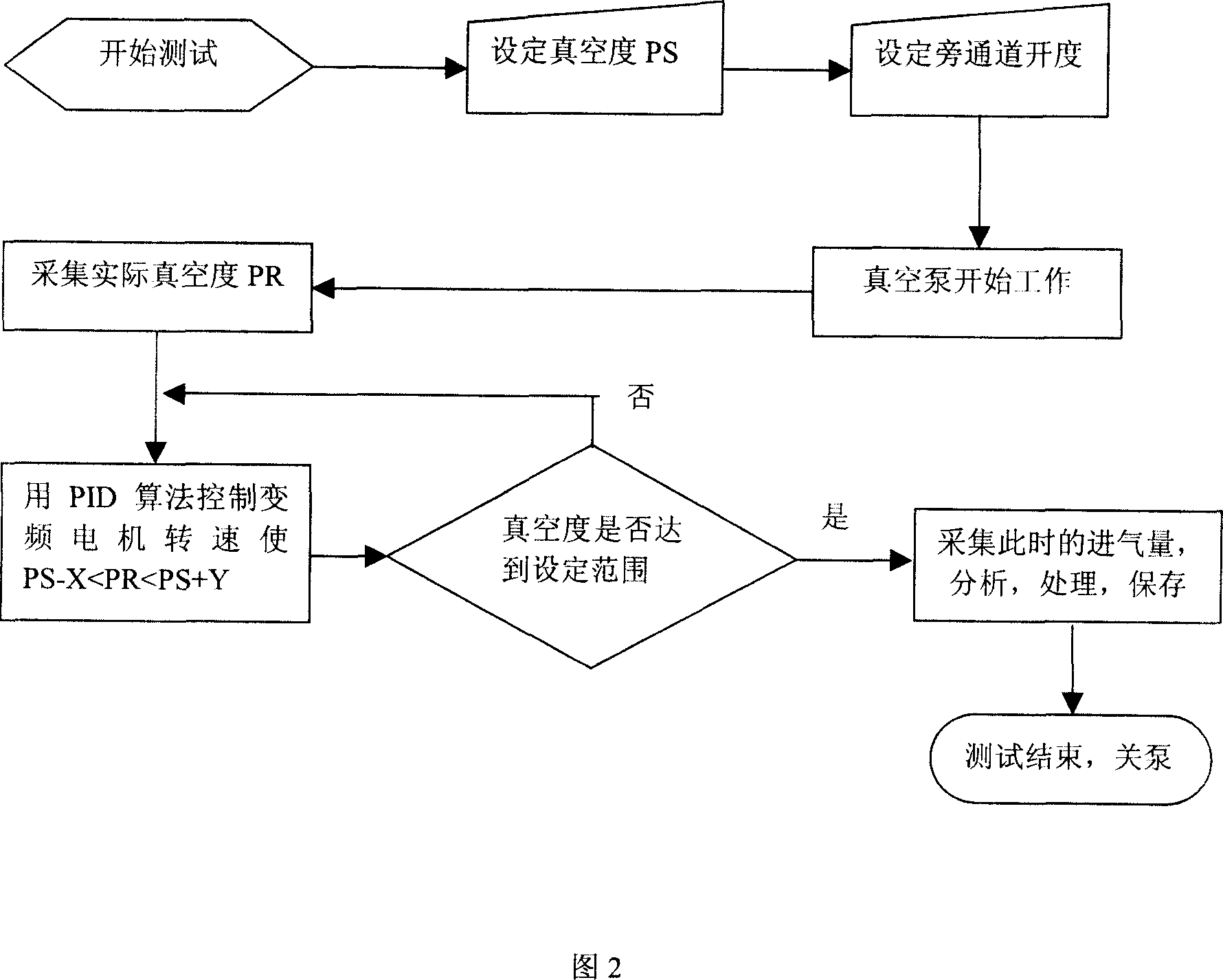

Vehicle air throttle air inflow test system and testing method

InactiveCN1932453AEasy to buyEasy CalibrationVolume/mass flow by thermal effectsIndirect mass flowmetersEngineeringThrottle

The invention discloses an air input testing system and testing method of the motor car air throttle which includes the vacuum source, the pressure sensor, the thermal gas flowmeter and the control unit. The vacuum source includes the air guiding hollow connected with the air vent of the throttle which provides the vacuum condition for the air vent; the control unit can keep the vacuum degree in a stable error range and collect the flow rate signal outputted by the thermal gas flowmeter and compute the air flow according to the airflow sectional area. The invention can measure the air flow directly and has the simple structure and low cost.

Owner:BYD CO LTD

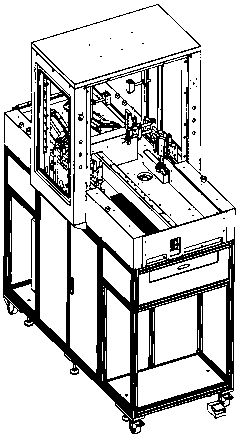

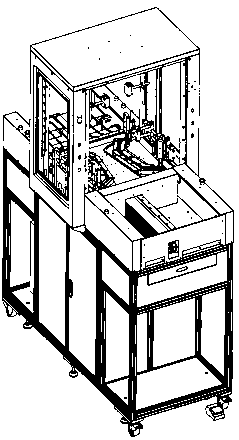

On-line detection system and method for LED (light emitting diode) light guide light distribution quality of automobile daytime running lamp

InactiveCN102928205AThe test structure is simple and reasonableEasy maintenanceTesting optical propertiesOptical pathLight pipe

The invention relates to an on-line detection system and method for LED (light emitting diode) light guide light distribution quality of an automobile daytime running lamp. A discharge station, a test station and a taking station are sequentially connected from front to rear, a tray tool is moved to a set station under the control of a computer to be fixed, the test station is a closed light-tight box, an LED light source module is located on the front end surface of a light pipe by a front locating cylinder in the test station, and the light emitted by the LED light source is coupled to the front end surface of the light pipe and is transmitted to the terminal surface along the light pipe; and at the same time, a light path terminal module is located at the terminal surface of the light pipe by a rear locating cylinder, light is reflected to the light pipe, a picture sensor above the tray tool collects data and transmits to the computer, and the computer comprehensively measures and judges the light distribution quality of the LED light guide from light intensity, illuminance homogeneity and colorimetric parameters, so that on-line detection is objectively, effectively and rapidly realized, and the work efficiency of the system is improved. The system has higher intellectualization and reliability, and the working continuity and stability of the system are improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

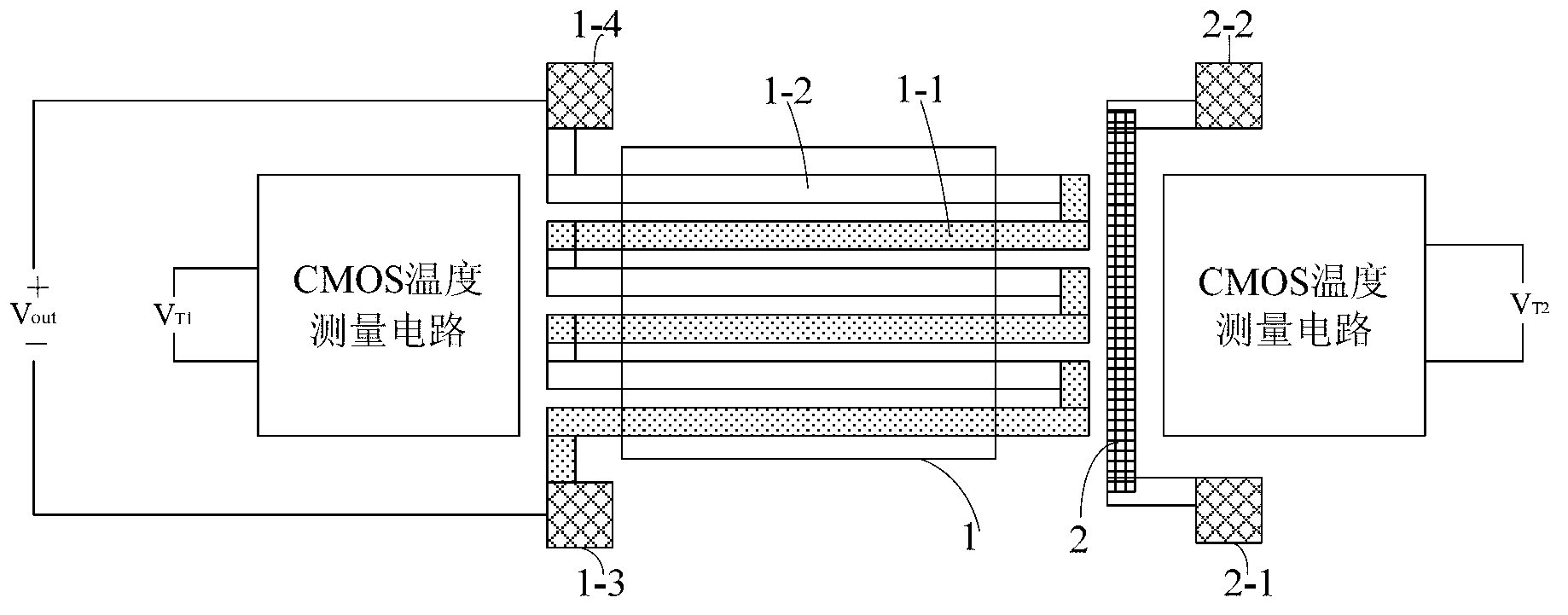

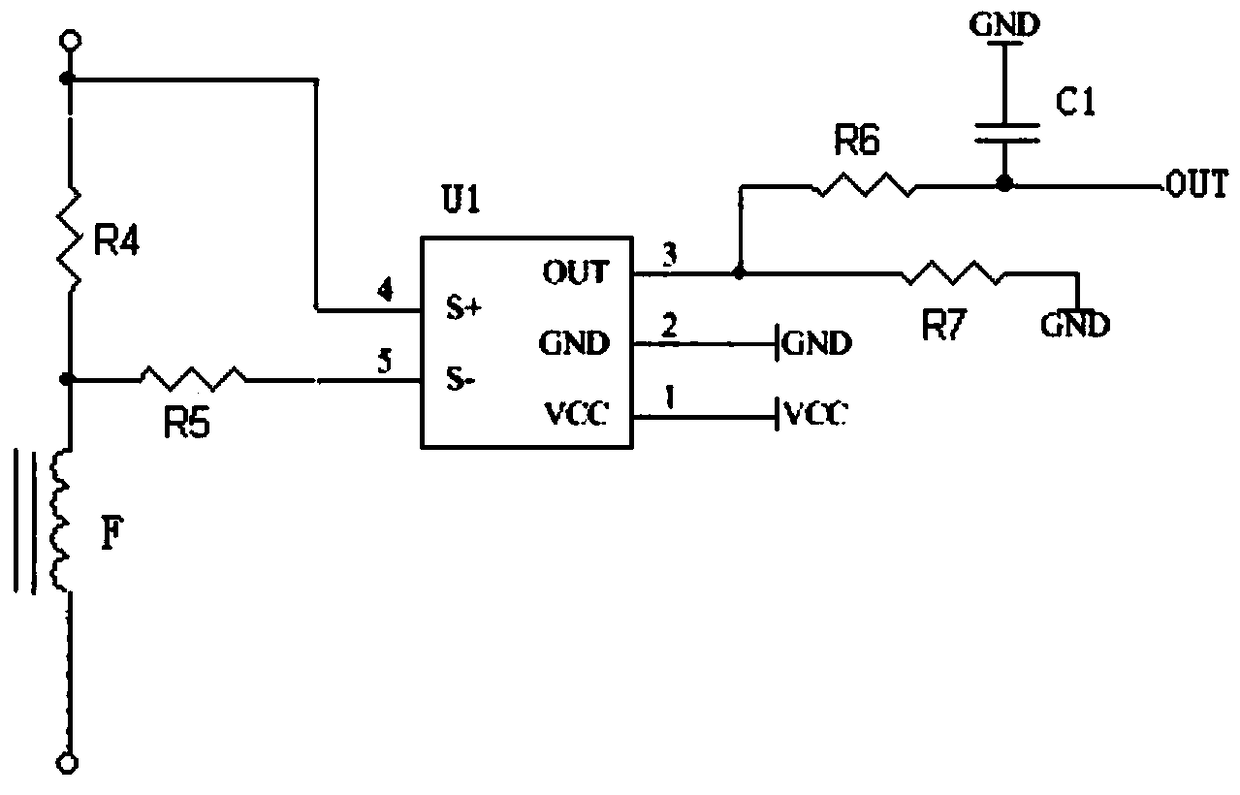

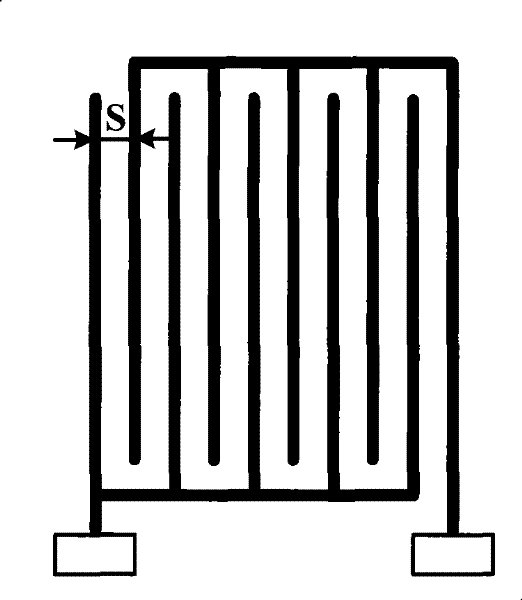

Micro-nano-scale material seebeck coefficient online measurement method

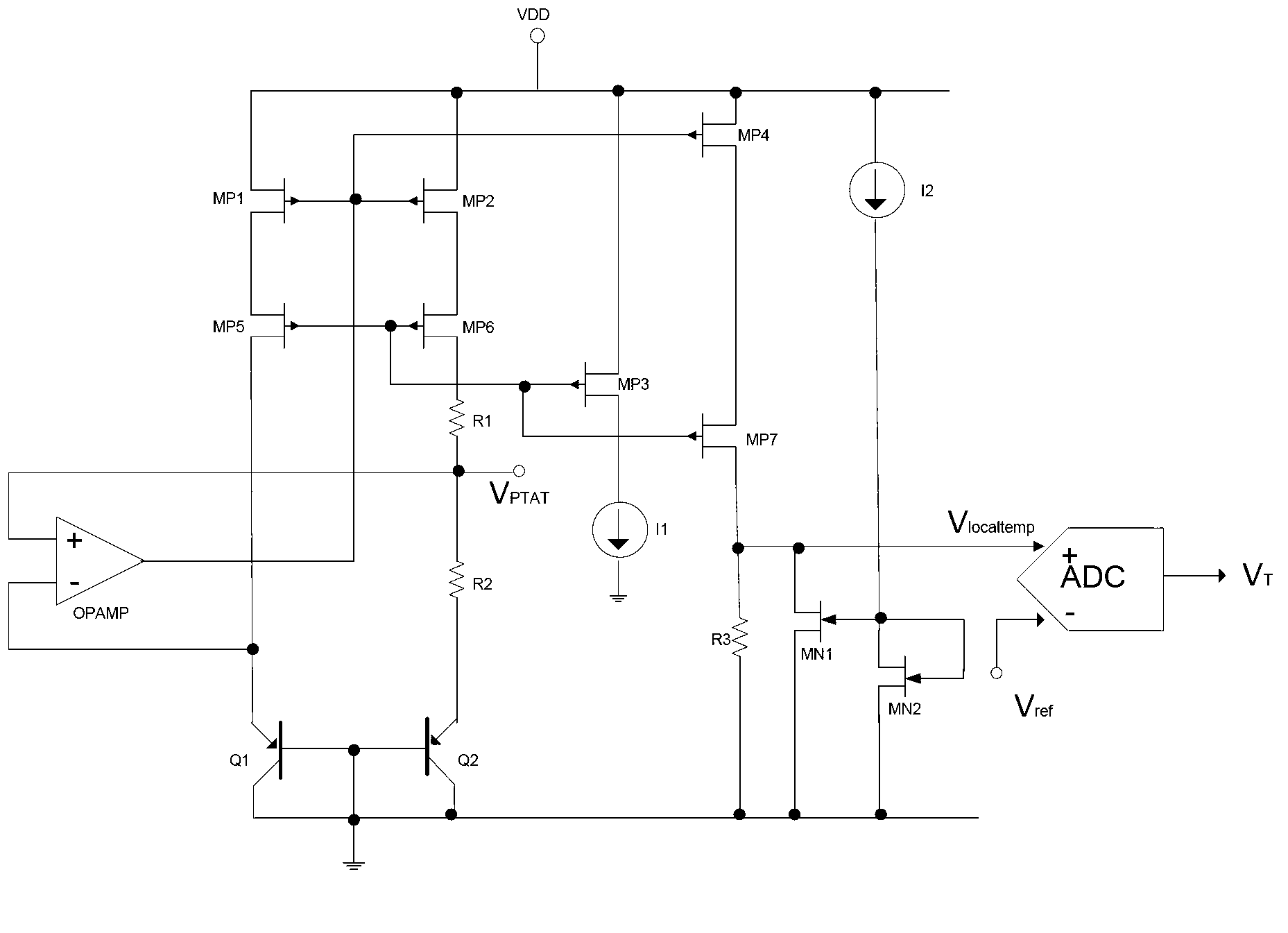

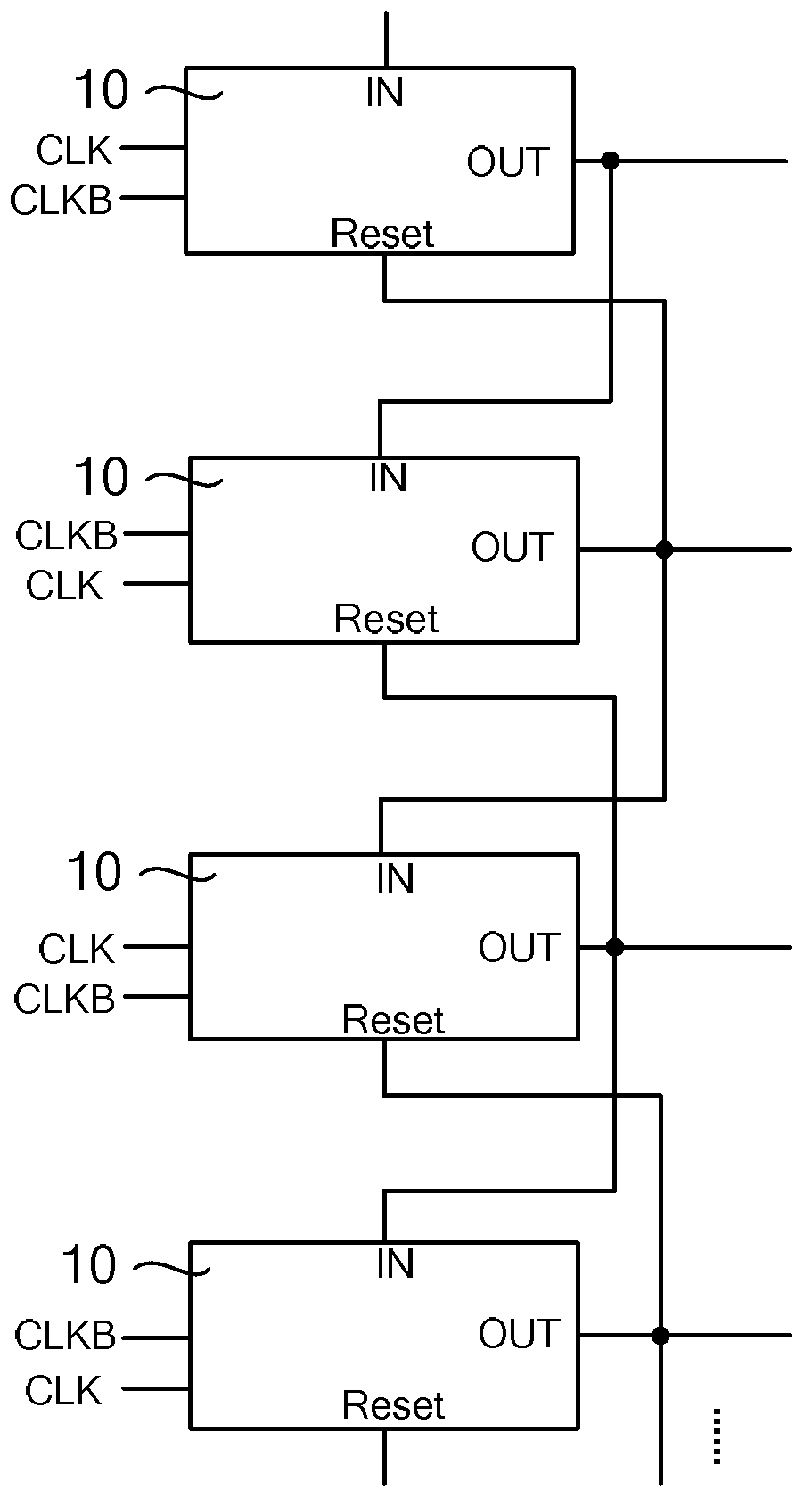

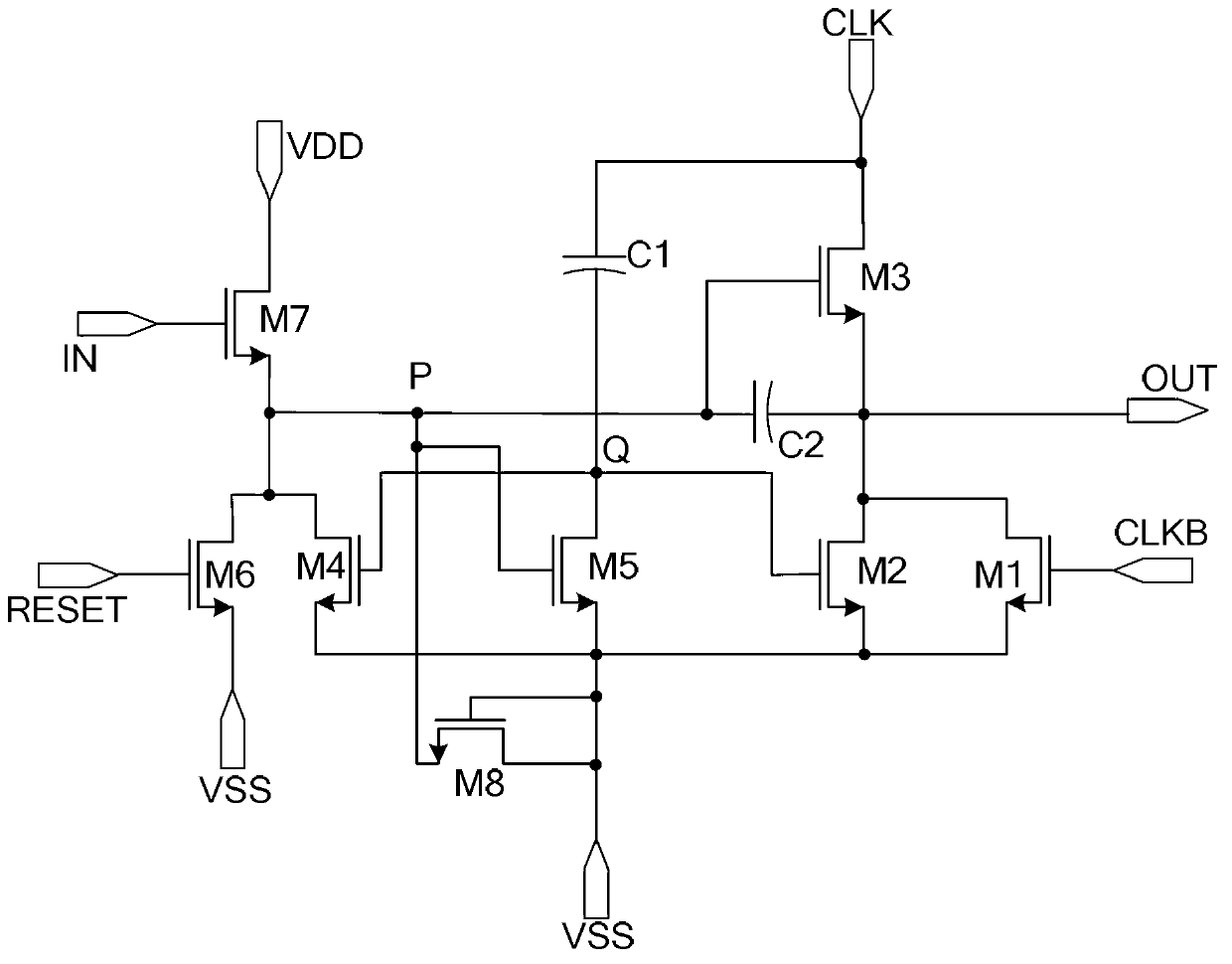

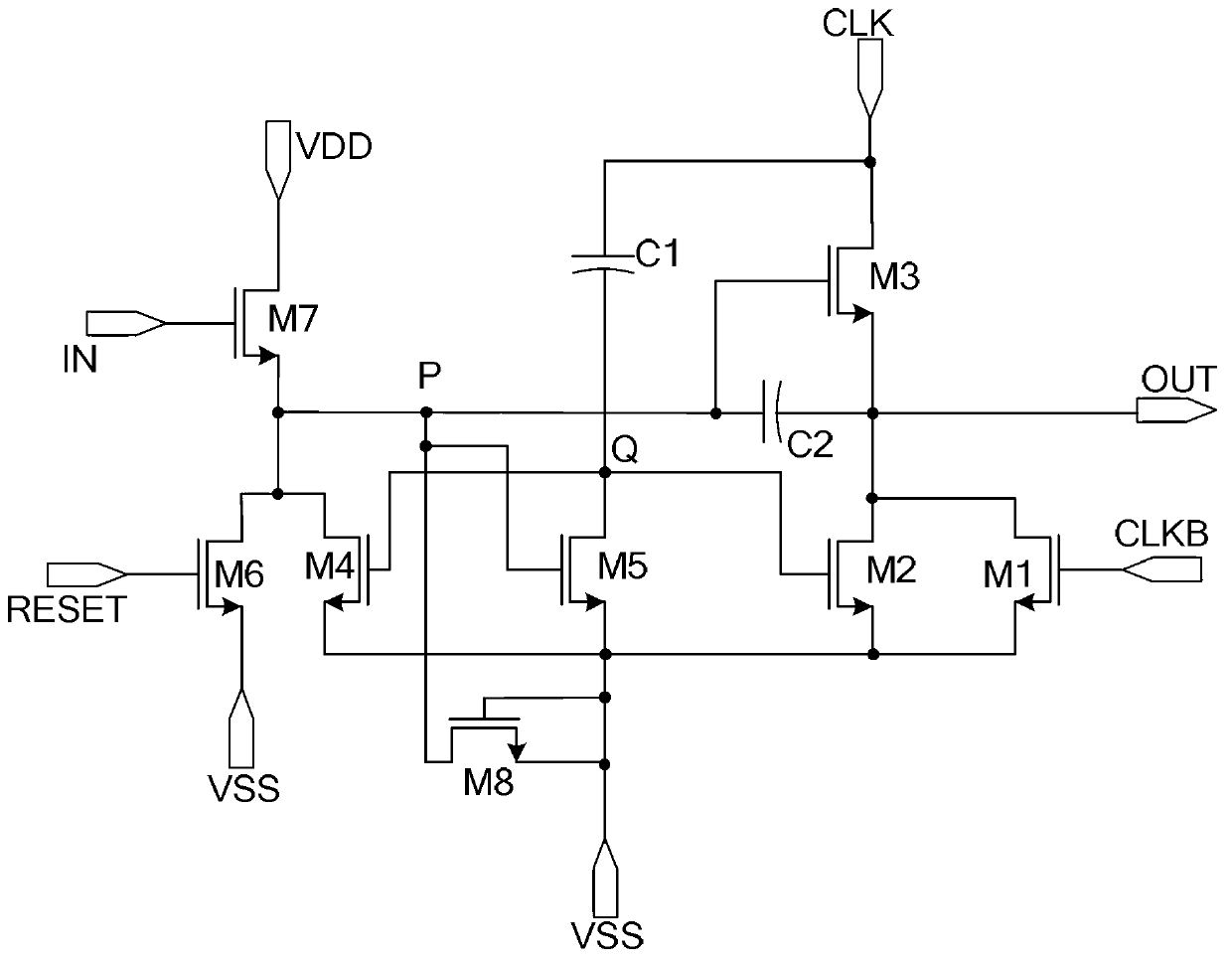

InactiveCN103267775ASimple test structureEasy to manufactureMaterial heat developmentStable stateCMOS

The invention provides a micro-nano-scale material seebeck coefficient online measurement method, which comprises: heating a heat end of a measured thermopile; measuring an open circuit voltage Vout output by the measured thermopile when the measured thermopile achieves a heat stable state; adopting a CMOS temperature measurement circuit arranged on the heat end of the measured thermopile to carry out online measurement of an absolute temperature T2 of the heat end of the measured thermopile, adopting the CMOS temperature measurement circuit output 1 of the heat end to represent a voltage VT2 of the absolute temperature T2, and measuring the VT2 value; adopting another CMOS temperature measurement circuit arranged on a cold end of the measured thermopile to carry out online measurement of an absolute temperature T1 of the cold end of the measured thermopile, adopting the CMOS temperature measurement circuit output 1 of the cold end to represent a voltage VT1 of the absolute temperature T1, and measuring the VT1 value; and calculating a seebeck coefficient S of the measured thermopile, wherein the S meets the following formula: S=Vout / [n(VT2-VT1)]. The method has characteristics of stable test parameter value, and simple and reliable calculation.

Owner:JIANGSU R & D CENTER FOR INTERNET OF THINGS

Shifting register, array substrate and display panel

ActiveCN103295512AFully reflect the performancePoor distinctionStatic indicating devicesDigital storageColor imageShift register

The invention provides a shifting register, an array substrate and a display panel. The shifting register comprises multiple stages of cascade shifting registering circuits, wherein each stage of shifting registering circuit comprises a testing circuit, one end of the testing circuit is connected to a second level end in a coupled mode, the second level end outputs a high level when the shifting register is in a testing mode, and therefore the testing circuit charges the main output end. The array substrate comprises a drive circuit which is composed of the shifting register. The display panel comprises the array substrate and a color-film substrate which is opposite to the array substrate. The shifting register enables all scanning lines of the display panel to be provided with the high level simultaneously, so that direct-current pure-color image detection can be conducted on the display panel, and a traditional liquid crystal cell test is realized. Therefore, a fault caused by an array process and a fault caused by a cell process can be distinguished. In addition, a testing structure is simple, the area of an original shifting register is hardly increased and the manufacturing cost is saved.

Owner:SHANGHAI AVIC OPTOELECTRONICS

Bearing seal ring durability testing device

ActiveCN105547690AAccelerate development cycleImprove and shorten development cycleMachine sealing rings testingDrive shaftEngineering

The invention discloses a bearing seal ring durability testing device which comprises a transmission device and a moving device. The transmission device comprises a servo motor and a transmission shaft arranged on the servo motor, and the transmission shaft is provided with a testing bearing and a bearing seat; the moving device comprises a connecting plate, a support, a fixing plate and an air cylinder, the bearing seat is provided with the connecting plate of the moving device, the connecting plate is connected with the support, the support is connected with the fixing plate, the air cylinder is arranged on the fixing plate, and the testing bearing and the bearing seat move on the transmission shaft through the air cylinder. In this way, the bearing seal ring durability testing device can perform a composite test of rotating friction and axial sliding and a test for testing the seal ring durability under the different conditions.

Owner:SUZHOU DONGWU NEEDLE BEARING

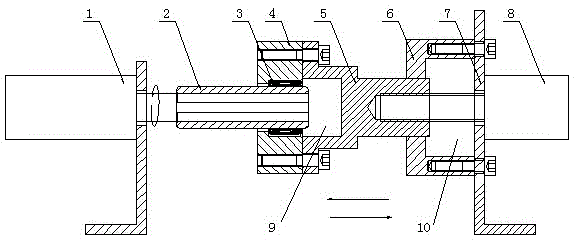

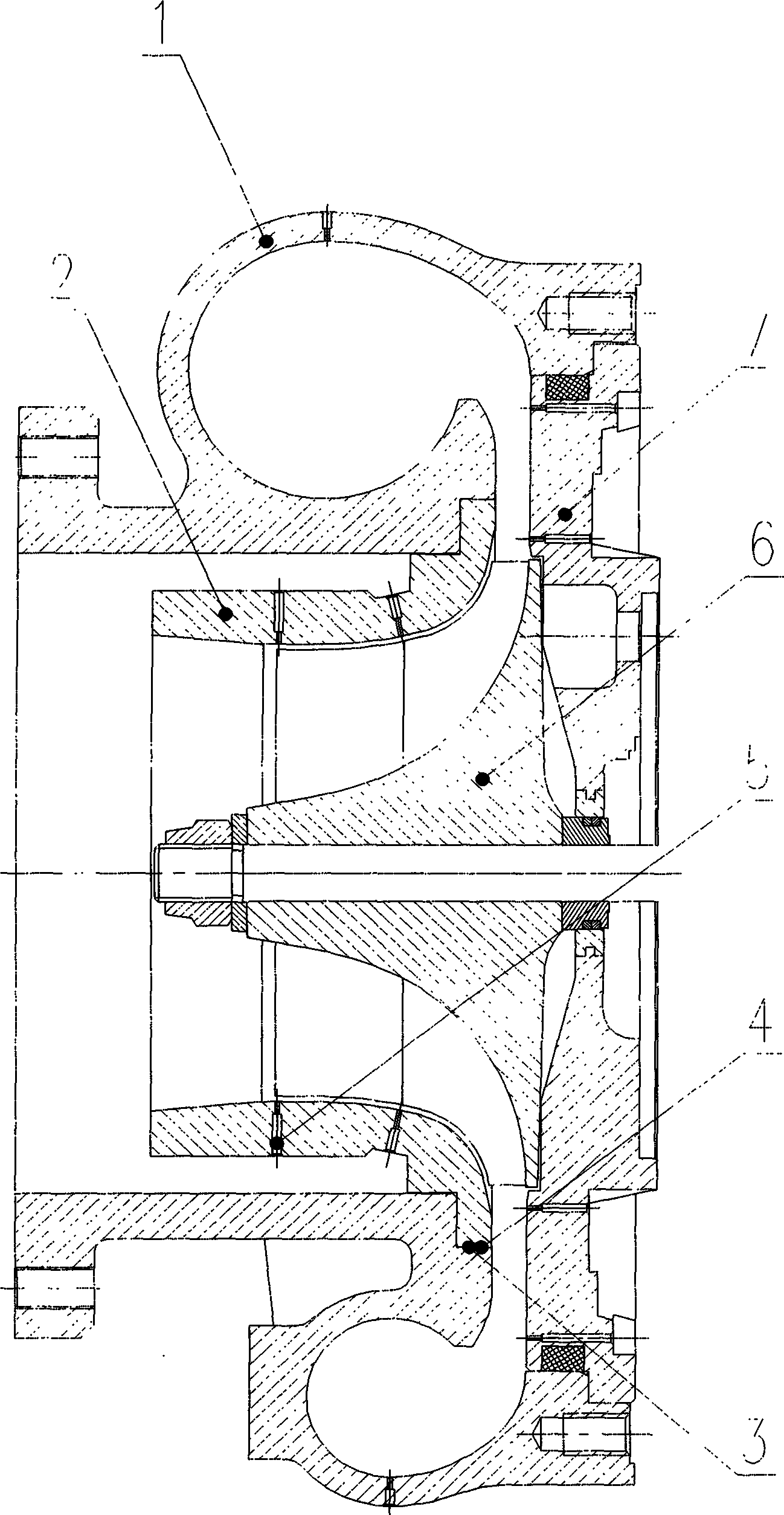

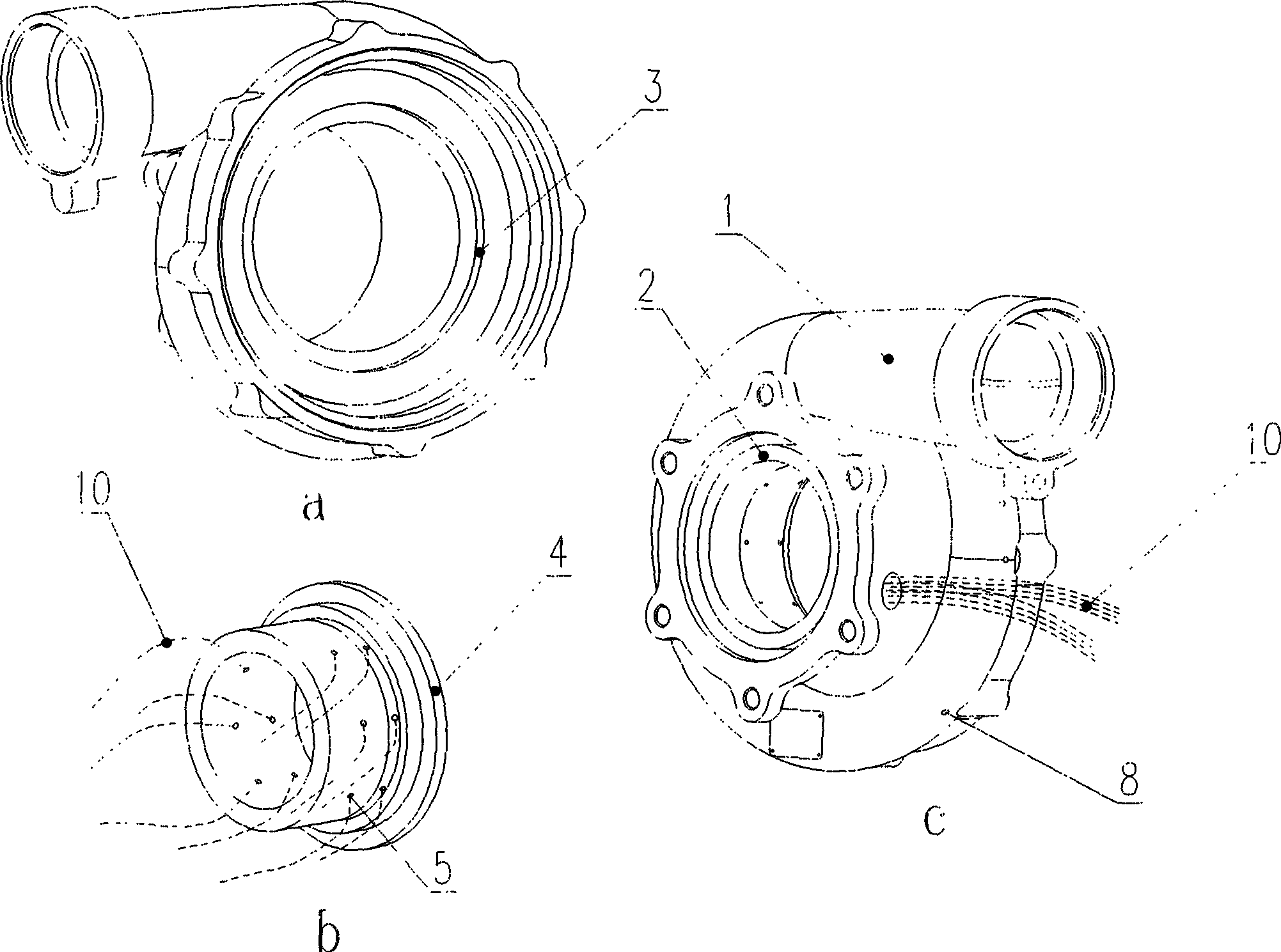

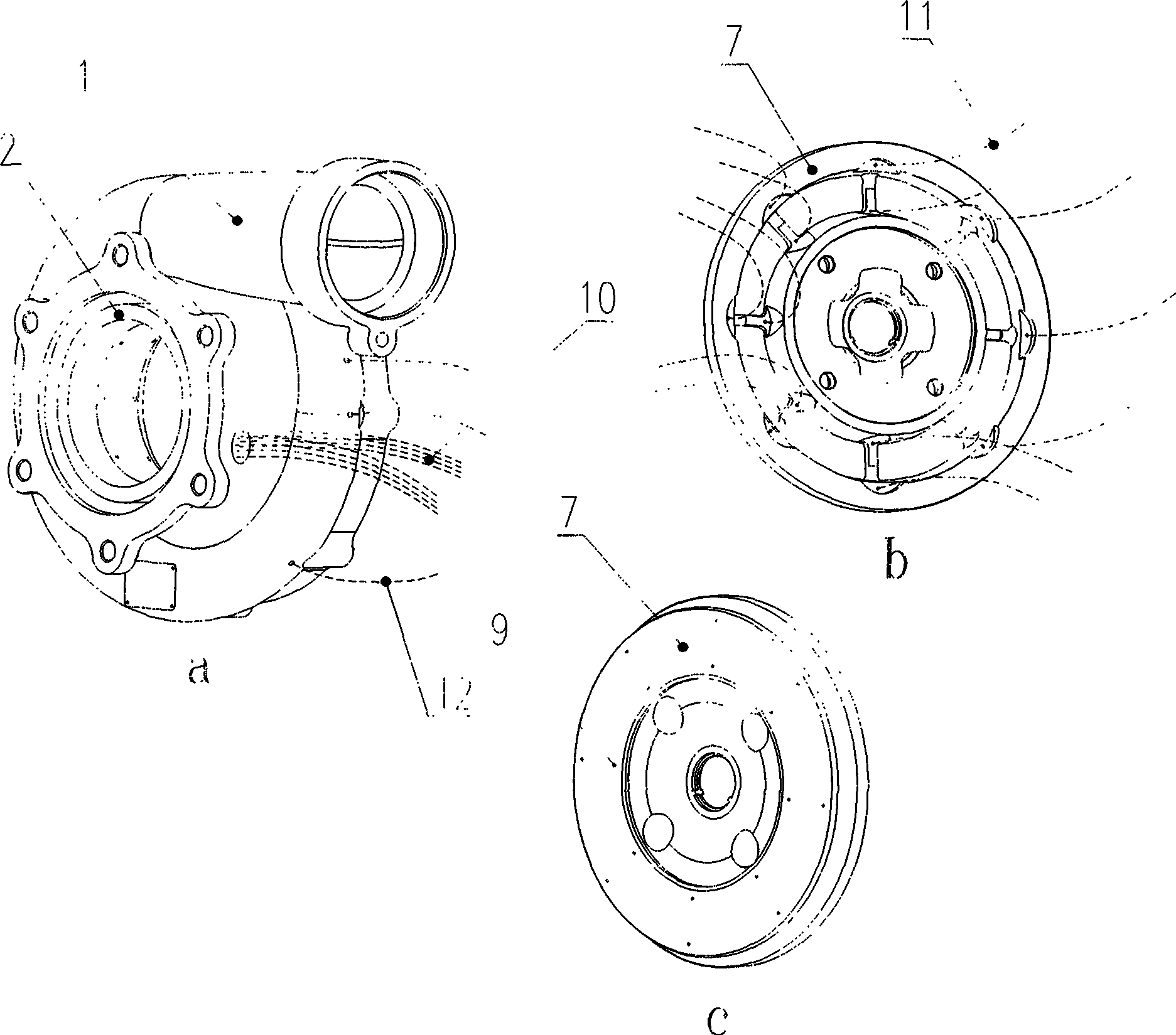

Turbo-charger single-stage prototype centrifugal compressor interstage pressure test structure

InactiveCN101545818ASimple test structureSimple structurePump testingPositive-displacement liquid enginesInternal pressureSingle stage

The invention belongs to turbo-charger technical field, particularly relating to centrifugal compressor interstage pressure test structure, especially a turbo-charger single-stage prototype centrifugal compressor interstage pressure test structure. The test structure includes a compressor spiral casing, a blower impeller and a compressor back disk. The spiral casing is fixed on the compressor back disk through bolts. The blower impeller is fixed on the shaft seal sleeve of the compressor back disk by the shaft end nuts. The compressor spiral casing is divided into a split spiral casing and a sleeve at the position of diameter 180 mm in the middle on the side wall of the compressor spiral casing diffuser. The split spiral casing and the sleeve are fixably connected with the contact surface of the sleeve by the hot charging face of the split spiral casing. The invention measures the inner pressure of the spiral casing and the diffuser on the centrifugal compressor prototype model machine and measures the enclosing cover pressure in the circumferential direction 360 DEG scope. The test structure has simple structure and easy implement based on the prototype model machine.

Owner:CHINA NORTH IND GRP NO 70 RES INST

Test structure and test method of time dependent dielectric breakdown

ActiveCN104345253AEasy to detectSimple test structureTesting dielectric strengthElectric breakdownIntegrated circuit

The invention relates to a test structure and test method of a time dependent dielectric breakdown (TDDB). The test structure includes a test unit, a resistor array unit and a control unit, wherein the test unit is above the resistor array unit and a metal medium layer is arranged between the test unit and the resistor array unit. The resistor array unit and the control unit are serially connected and then arranged in parallel with the test unit between a first connection end and a second connection end. Through application of different voltages between the first connection end and the second connection end, the control unit controls the stress state at work or non-work measurement state of the resistor array unit and through the two kinds of states, effects of joule heat of the resistor array unit on the electric breakdown performance of the metal medium layer are evaluated and the effects of the joule heat of the resistors on the reliability of the metal medium layer in a real integrated circuit are simulated authentically. The test structure and test method solve a defect that TDDB performance, caused by a joule heat effect, cannot be evaluated in the prior art and improve the detection capability of the performance and yield of a device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

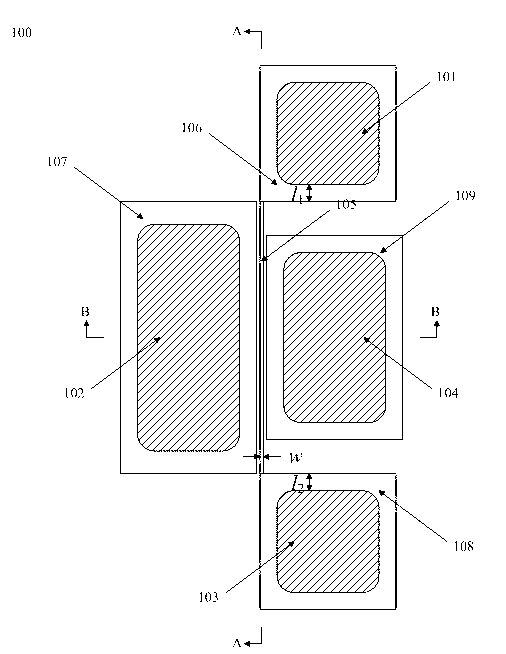

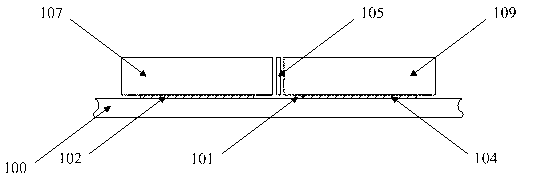

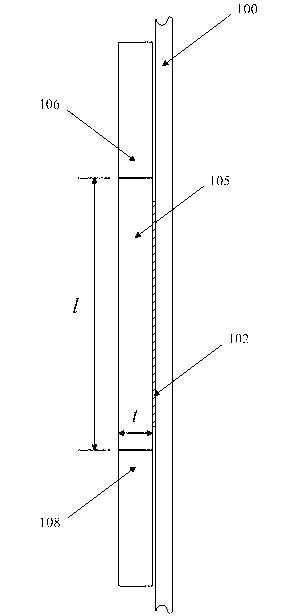

Structure for testing micro-beam breaking strength based on longitudinal comb-tooth-type capacitor

InactiveCN104502193ASimple test structureHigh sensitivityMaterial strength using tensile/compressive forcesUsing electrical meansTest structureCapacitance

The invention discloses a structure for testing the micro-beam breaking strength based on a longitudinal comb-tooth-type capacitor. A bidirectional comb-tooth structure is composed of a bar-shaped anchor region and comb teeth connected to two side surfaces of the anchor region, wherein one row of comb teeth is connected to outer side surfaces of vertical edges of self-seal type rectangular structures, tail ends of two transverse edges vertical to the vertical edges are connected to side surfaces of respective anchor regions; the two self-seal type rectangular structures with the comb teeth are symmetrically distributed at the left side and the right side of the bidirectional comb-tooth structure, comb-tooth ends are alternatively opposite to comb teeth of the bidirectional comb-tooth structure, wherein the comb teeth of the self-seal type rectangular structures are movable teeth, the comb teeth of the bidirectional comb-tooth structure are fixed teeth; one end of a to-be-tested micro beam is connected to the middle of the inner side surface of the vertical edge of one self-seal type rectangular structure, the other end of the to-be-tested micro beam is fixed on the side surface of one anchor region, and the other self-seal type rectangular structure without the to-be-tested micro beam is of a reference structure; the self-seal type rectangular structures, the to-be-tested micro beam and the comb teeth are all positioned on the same plane, and are suspended above a substrate in parallel. The structure is high in sensitivity and convenient and feasible.

Owner:SOUTHEAST UNIV

Structure for testing Young modulus of top silicon layer of silicon-on-insulator

InactiveCN103245579AAvoid influenceSimple test structureTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesIn planeYoung's modulus

The invention discloses a structure for testing the Young modulus of a top silicon layer of a silicon-on-insulator. The structure comprises a substrate formed by a silicon substrate in the silicon-on-insulator, wherein a first insulating region, a second insulating region, a third insulating region, and a fourth insulating region are arranged on the substrate and are formed by insulating layers in the silicon-on-insulator; a first anchor region, a detection electrode, a second anchor region, an exciting electrode which are formed by the top silicon layer in the silicon-on-insulator are respectively arranged on the first insulating region; and a resonance beam formed by a top silicon beam in the silicon-on-insulator is arranged between the detection electrode and the exciting electrode, one end of the resonance beam is connected with the first anchor region, the other end of the resonance beam is connected with the second anchor region, and the resonance beam is arranged above the substrate and is excited by the exciting electrode to generate an in-plane transverse resonance. According to the structure, the accuracy of testing on the Young modulus of the top silicon layer of the silicon-on-insulator can be improved.

Owner:SOUTHEAST UNIV

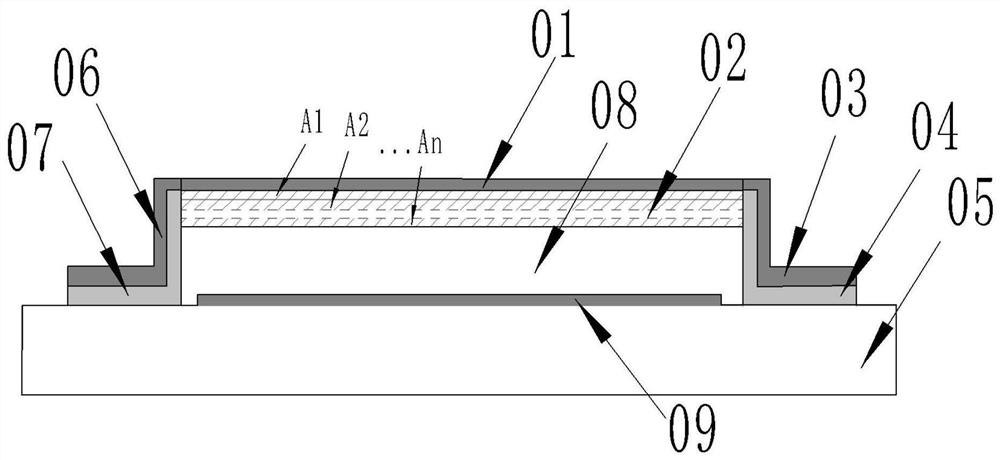

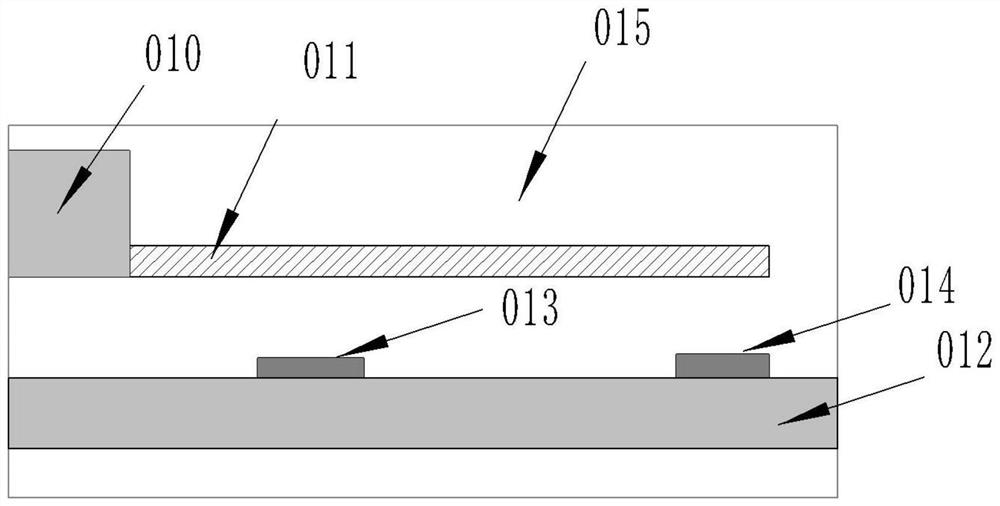

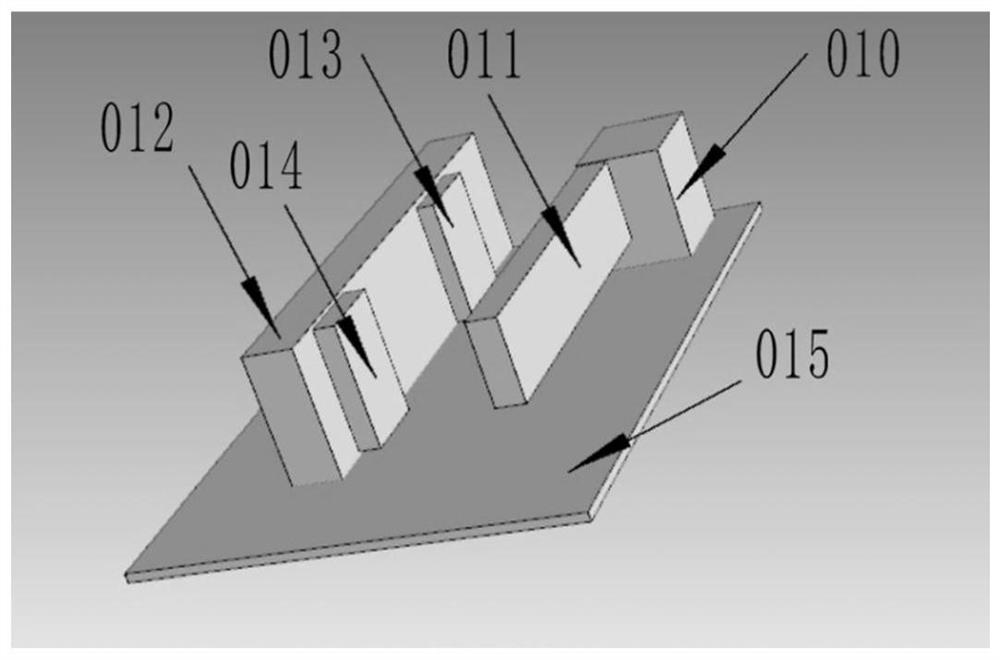

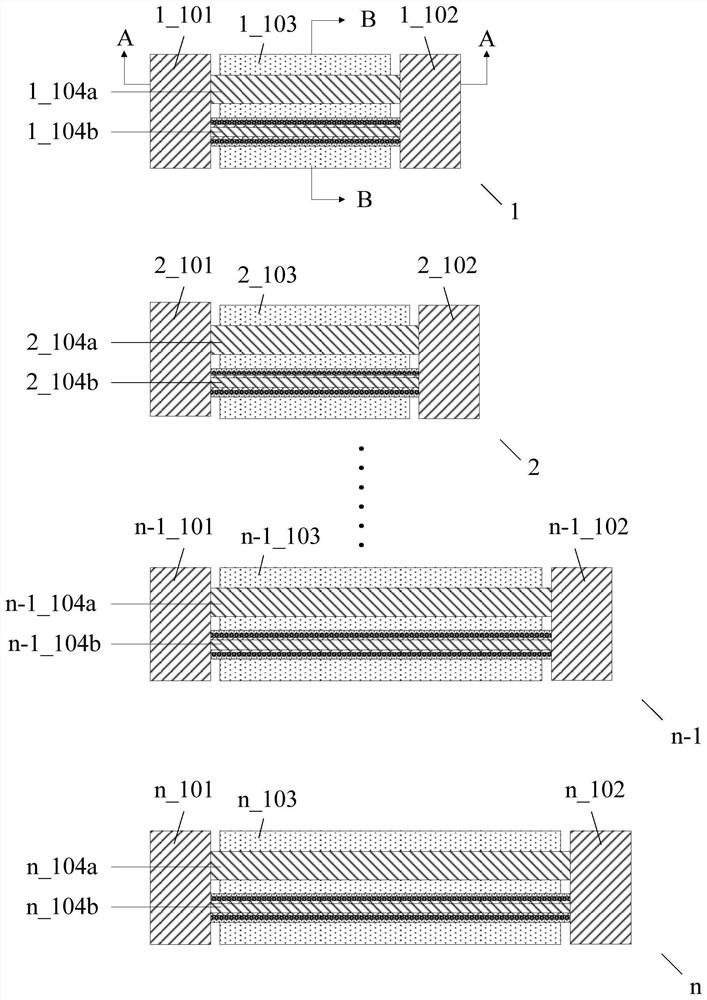

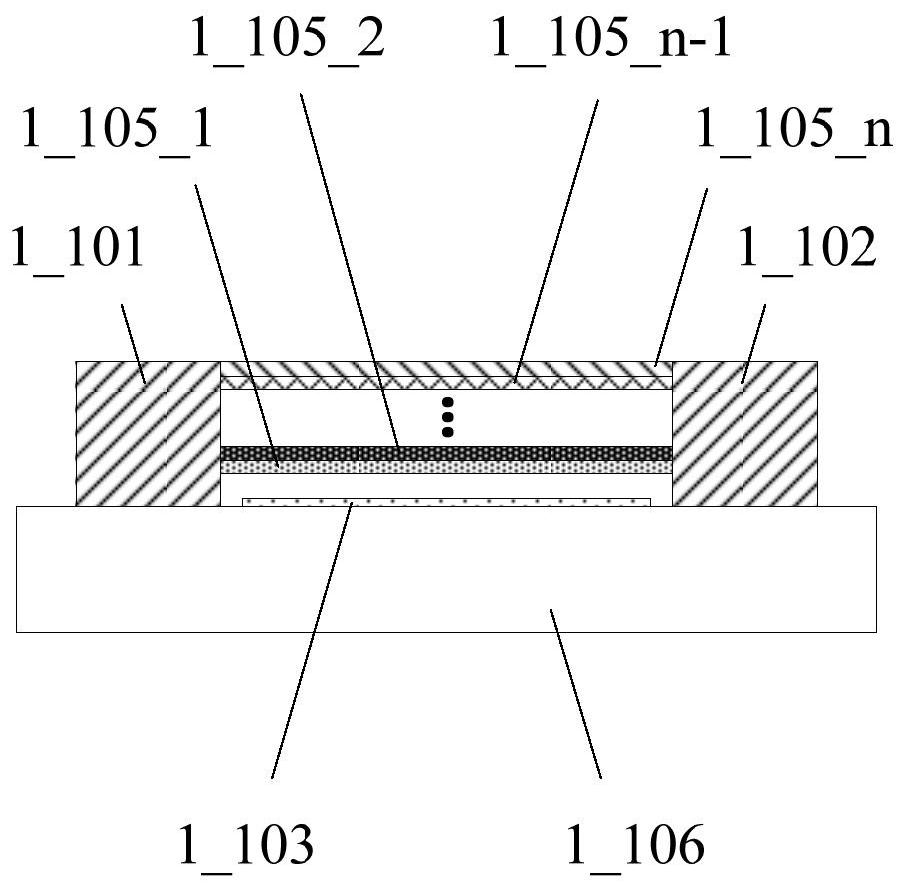

Multi-layer film residual stress and Young modulus on-line test structure for micro-manufacturing and on-line extraction method

ActiveCN112129347ALower requirementMeet the requirements of the online testMeasurement devicesDecorative surface effectsCantilevered beamMicro fabrication

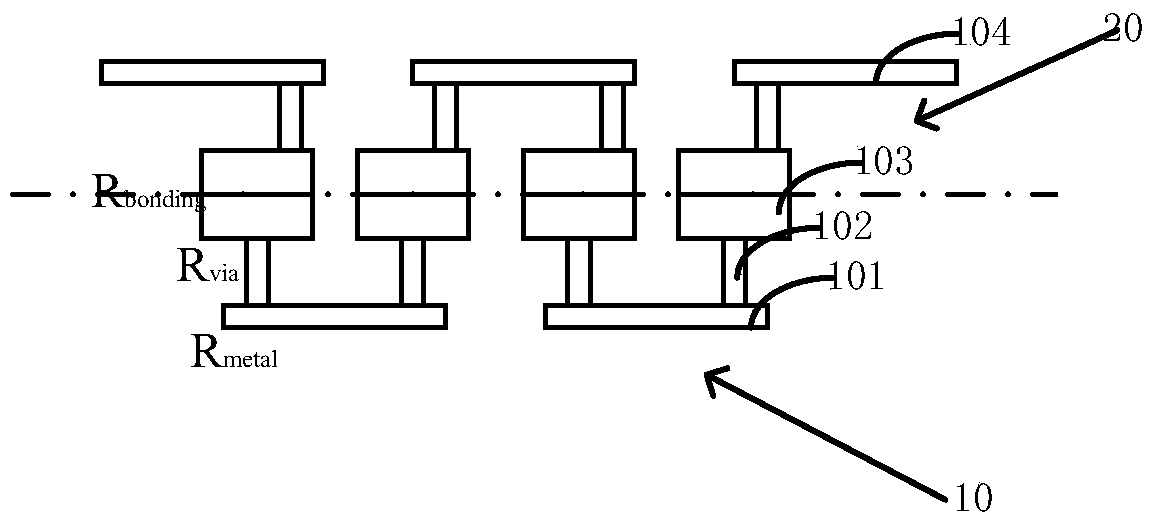

The invention belongs to the technical field of micro electro mechanical systems, and discloses an on-line test structure for Young modulus of a single-layer film and for micro-manufacturing, an on-line test structure for multi-layer film residual stress and Young modulus and an on-line extraction method. The Young modulus test structure of the single-layer film is composed of a set of transversely-pulled cantilever beam structures made of different film materials and contact electrodes. The transversely-pulled cantilever beam structures comprise single-layer films serving as upper electrodesand driving electrodes serving as lower electrodes. The Young modulus and residual stress test structure of the multi-layer film comprises top metal electrodes, multi-layer two-end clamped beam structures and bottom electrodes. As for the multi-layer two-end clamped beam structures of a group of test structures, two-end clamped beams are connected with a substrate through reinforcing anchor areas.The pull-in voltage of each test structure is measured by using electrostatic drive. The contact voltage and the pull-in voltage are sent into an extraction program for calculation to obtain the residual stress and the Young modulus of each layer of film. The testing method is simple, and can meet the precision requirement of on-line testing of a process line.

Owner:SOUTHEAST UNIV

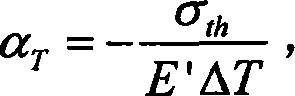

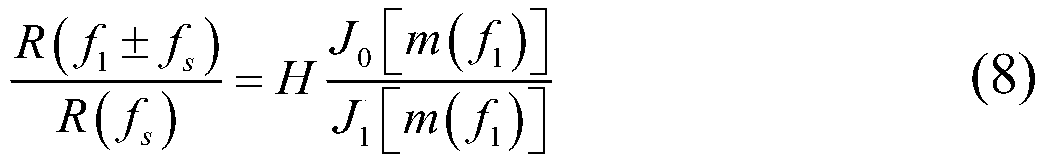

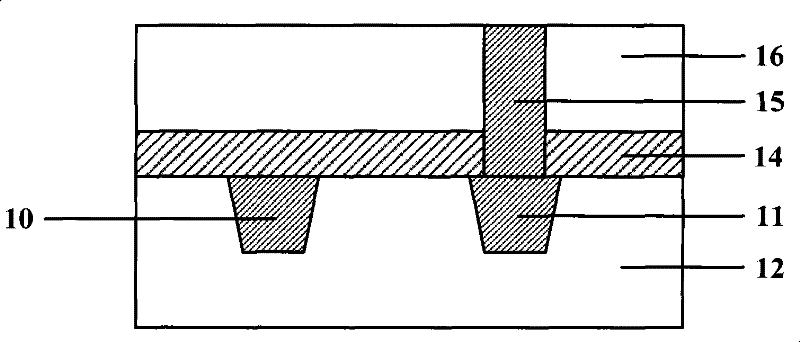

Multilayer film thermal expansion coefficient extraction method

InactiveCN112326721ASimple test structureFast measurementMaterial thermal coefficient of expansionThermal dilatationThin membrane

The invention discloses a method for extracting the thermal expansion coefficient of a multilayer film. The method comprises the following steps: measuring the pull-in voltage of each equal-width multilayer double-end clamped beam at normal temperature; measuring the pull-in voltage of each unequal-width multilayer double-end clamped beam at the normal temperature; calculating the equivalent Youngmodulus and the initial residual stress of an ith layer of film; measuring the pull-in voltage of each equal-width multilayer double-end clamped beam at the temperature T, and calculating the residual stress of the ith layer of film at the temperature T; calculating the thermal expansion coefficient of each layer of film at the temperature T; measuring the pull-in voltage of each equal-width multilayer double-end clamped beam at different temperatures, and calculating the residual stress of the ith layer of film at different temperatures; and calculating the coefficient of thermal expansion of each layer of film at different temperatures. The method for extracting the thermal expansion coefficient of the multilayer film provided by the invention is simple and easy to implement, convenientto operate and low in cost, and the multilayer double-end clamped beam is simple in test structure and high in measurement speed.

Owner:HOHAI UNIV

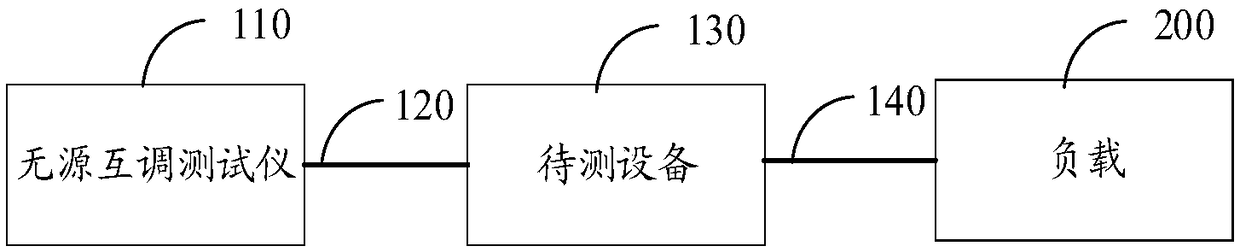

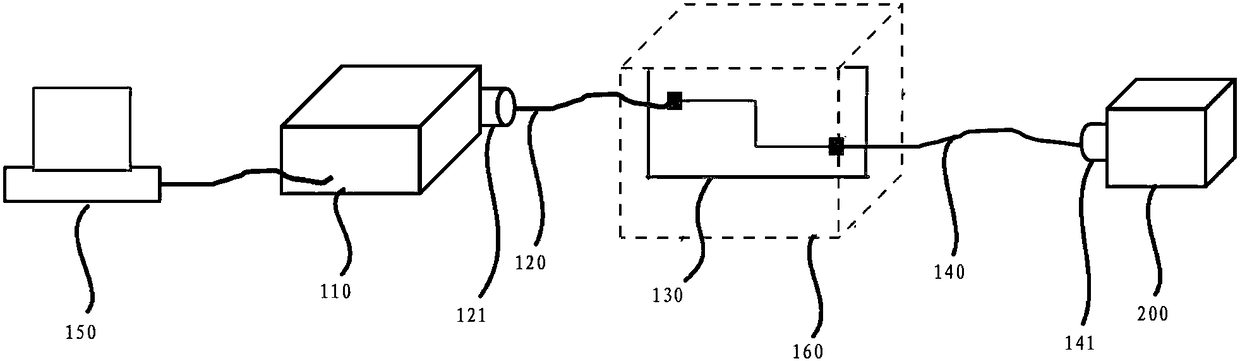

Passive intermodulation testing device

InactiveCN108107345ASmooth transmissionEasy to testRadiofrequency circuit testingCarrier signalEngineering

The invention relates to a passive intermodulation testing device which comprises a passive intermodulation tester and a first transmission line, wherein the passive intermodulation tester is connected with one end of a line of equipment to be tested through a first transmission line, and the other end of the line of the equipment to be tested is connected with a load. The passive intermodulationtester transmits at least two carrier signals and outputs the at least two carrier signals to the equipment to be tested through the first transmission line, and the passive intermodulation tester receives passive intermodulation signals returned by the equipment to be tested through the first transmission line. That is, the equipment to be tested is placed between the passive intermodulation tester and the load, and the passive intermodulation tester is connected with the equipment to be tested through the first transmission line. After the carrier signals are absorbed by the load, the residual intermodulation interference signals can be fed back to the passive intermodulation tester through the first transmission line. The test is convenient, the test structure is simple, and signal forwarding does not need to be carried out through a tedious device. Rapid and stable transmission of signals can be ensured, and fast and stable passive intermodulation testing can be realized.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

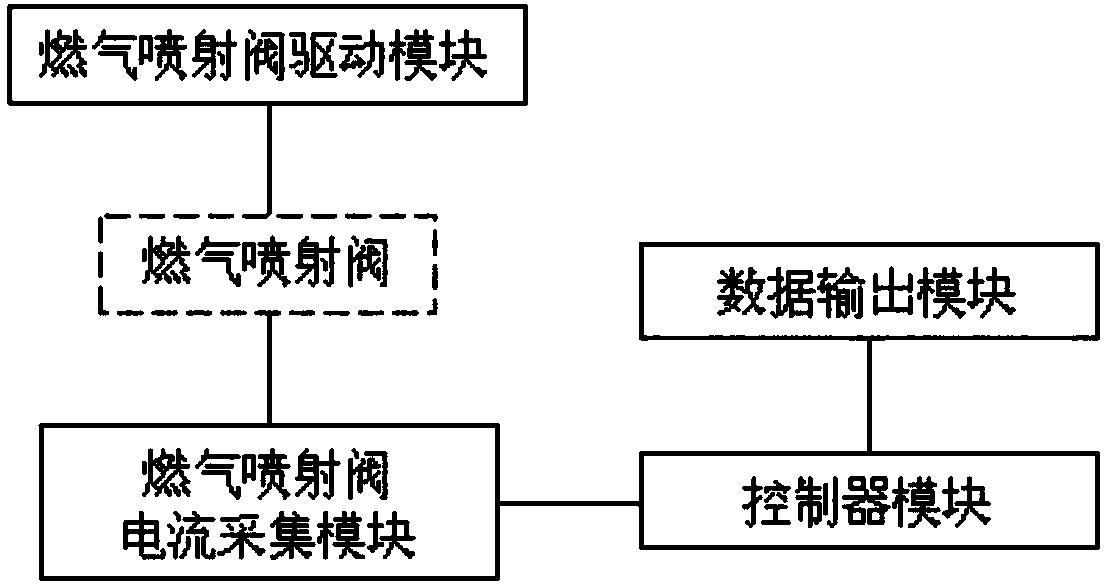

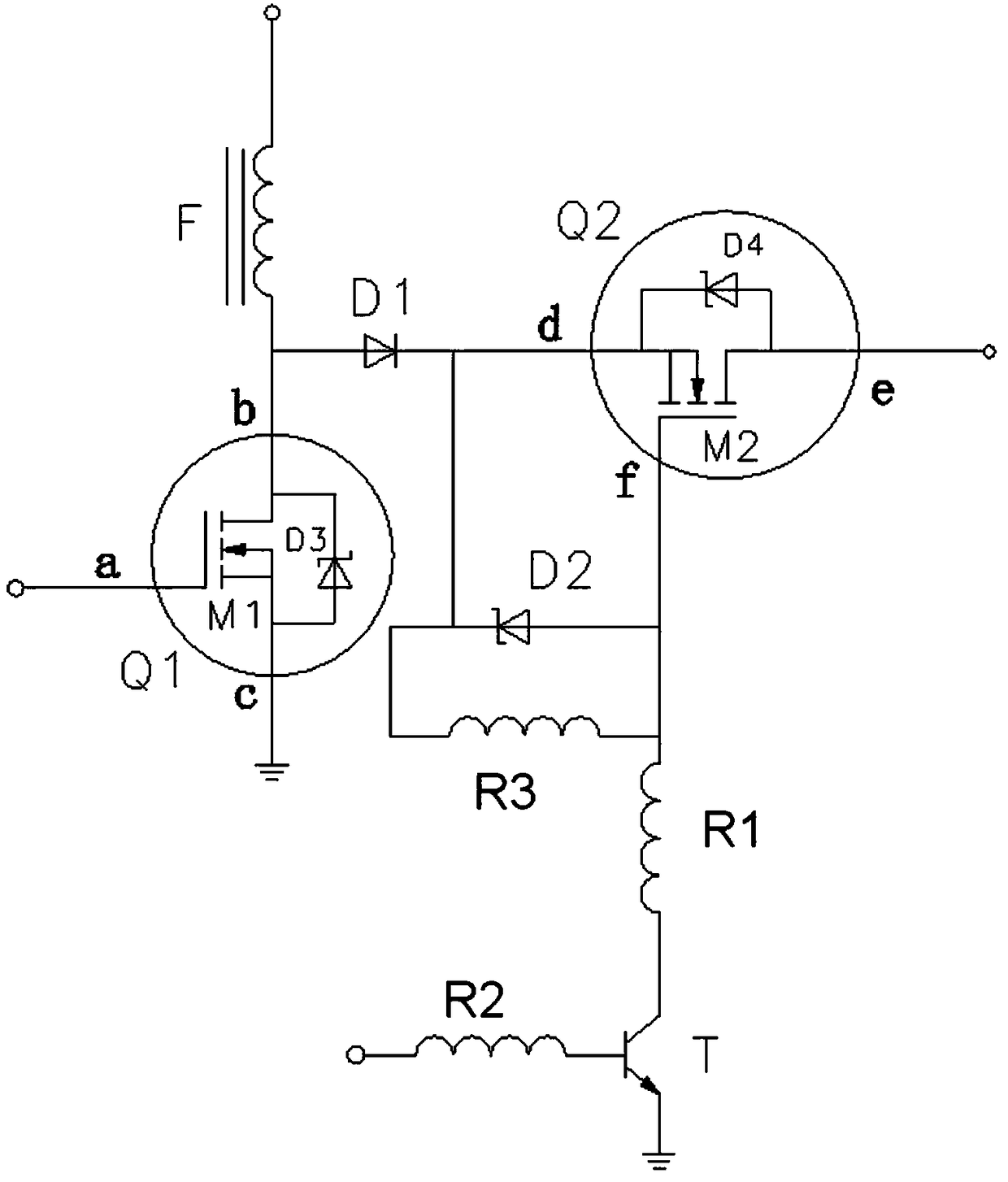

Gas jet valve detection device and method based on current detection

InactiveCN108196147ATruly reflect the basic performanceImprove accuracyElectrical testingFuel gasTest structure

The invention relates to the technical field of jet valve detection and particularly discloses, according to an embodiment, a gas jet valve detection device and method based on current detection. Thegas jet valve detection device comprises a gas jet valve driving module, a gas jet valve current acquisition module and a controller module; the gas jet valve driving module and the gas jet valve current acquisition module are separately connected with a gas jet valve; the controller module is connected with the gas jet valve current acquisition module. The gas jet valve detection device and method have the advantages that a current detection method used herein is to directly detect characteristics of a gas jet valve itself, the accuracy is high, conformity is good, the basic properties of thegas jet valve can be better revealed, the test structure is simple, and normal running of an external drive gas jet valve is just required; the method to reflect gas jet valve characteristics throughcurrent changes allows a uniform experiment standard to be established among the manufacturers more conveniently and is easier to accept by users.

Owner:北京华意乔技术有限公司

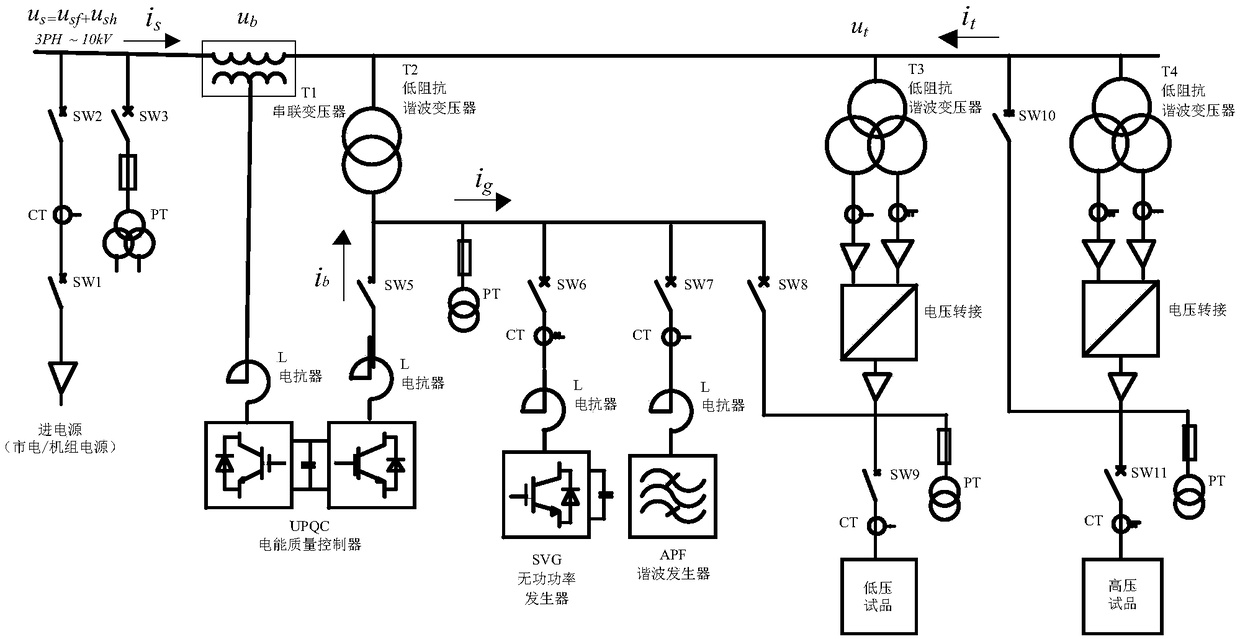

Mining high-low voltage reactive power and harmonic compensation device based on cancellation method

ActiveCN108418224AMeet the test needsImprove static load capacityReactive power adjustment/elimination/compensationReactive power compensationTest efficiencyTransformer

The invention relates to a mining high-low voltage reactive power and harmonic compensation device based on a cancellation method, and belongs to the technical field of electrical test equipment. Themining high-low voltage reactive power and harmonic wave compensation device based on a cancellation method includes a high voltage bus, a bus transformer, an electric energy quality controller, a harmonic transformer T2, a harmonic transformer T3, a harmonic transformer T4, a reactive power generator and a harmonic generator, wherein the low voltage side of the bus transformer is connected with the electric energy quality controller through a reactor I; the electric energy quality controller is connected with the harmonic transformer T2 through a reactor II; the high voltage side of the harmonic transformer T2 is connected with the high voltage bus; the low voltage side of the harmonic transformer T2 is also connected with one end of a reactor III and one end of a reactor IV; the other end of the reactor III and one end of the reactor IV are respectively connected to the reactive power generator and the harmonic generator; and the harmonic transformer T3 and the harmonic transformer T4 are respectively connected with a low voltage test product and a high voltage test product through a voltage adapter and a high voltage adapter. The mining high-low voltage reactive power and harmonic compensation device based on a cancellation method can effectively simplify the test structure, can improve the test efficiency and can reduce the cost.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

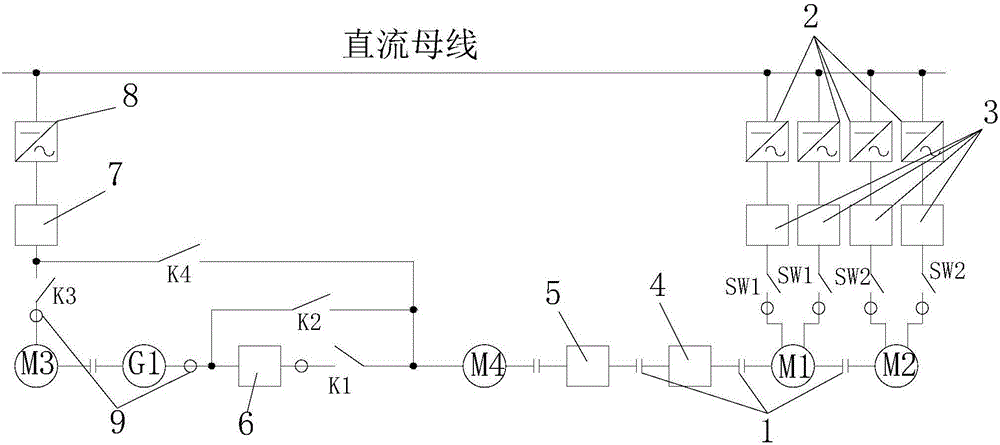

Test system of high power frequency conversion electric drive equipment

InactiveCN106597283AMeet the experimental requirementsTest accurateDynamo-electric machine testingFrequency changerEngineering

The invention provides a test system of high power frequency conversion electric drive equipment. The system comprises a test load feedback unit, a tested motor which is in a transmission connection with the test load feedback unit, a tested frequency converter which is connected to the tested motor, and a test driving feedback unit which is connected to the output end of the tested frequency converter, wherein the power end of the test load feedback unit is connected to a direct current bus, and the power end of the test driving feedback unit is connected to the direct current bus. Through the above structure, the adaptability and transform ability of the system can be effectively improved, the whole can accurately test high voltage frequency conversion drive equipment, a test structure is effectively simplified, frequent disassembly and assembly are not needed, the test efficiency is improved, and the labor intensity and cost are reduced.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

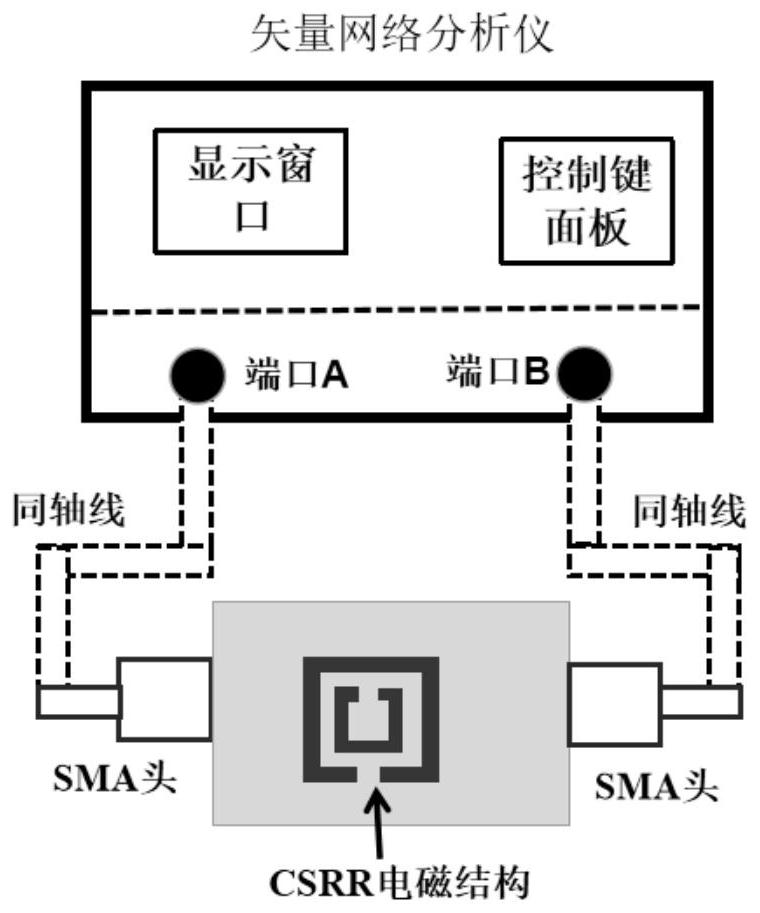

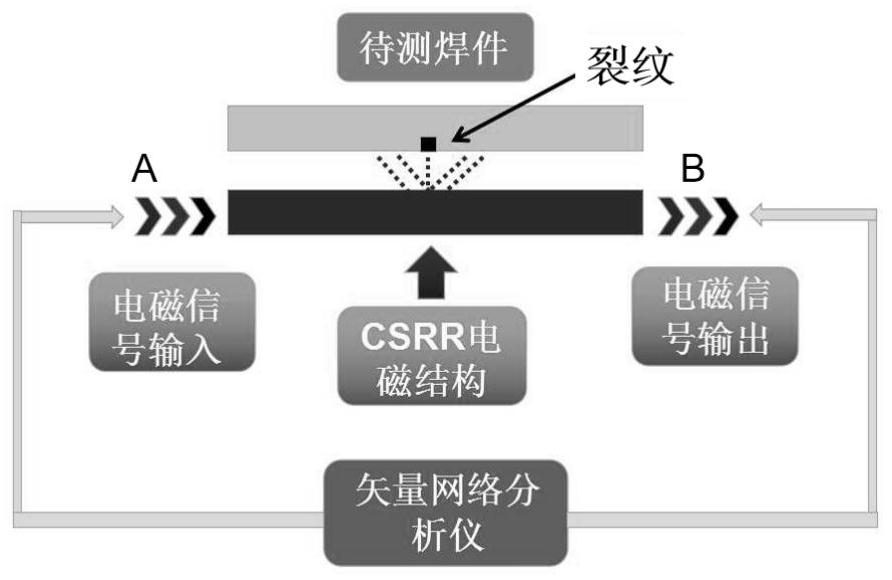

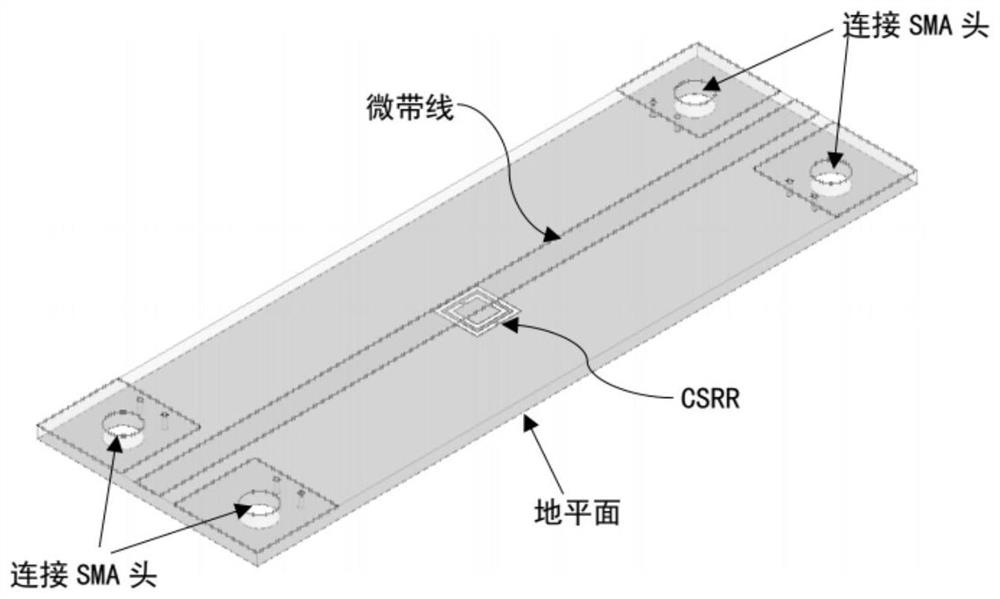

Nondestructive testing method for metal surface welding cracks based on CSRR electromagnetic structure

PendingCN113433209ASimple structureSimple test structureMaterial magnetic variablesStructural engineeringWeld seam

The invention discloses a nondestructive testing method for metal surface welding cracks based on a CSRR electromagnetic structure, and the nondestructive testing method mainly utilizes the sensitivity of the CSRR electromagnetic structure to the metal surface welding cracks to realize the nondestructive testing of the metal surface welding cracks; the vector network analyzer provides a broadband vector signal for the CSRR electromagnetic structure, and the signal is coupled to the CSRR electromagnetic structure through the microstrip line; the CSRR electromagnetic structure is coupled with a welding part with a welding crack right above the CSRR electromagnetic structure, and when the CSRR electromagnetic structure detects that a crack exists in a welding seam, the resonant frequency of the CSRR electromagnetic structure can obviously deviate. In the whole detection process, the CSRR electromagnetic structure is not in contact with the to-be-detected weldment, so that no new defect is introduced to the to-be-detected weldment, and the purpose of nondestructive detection is achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

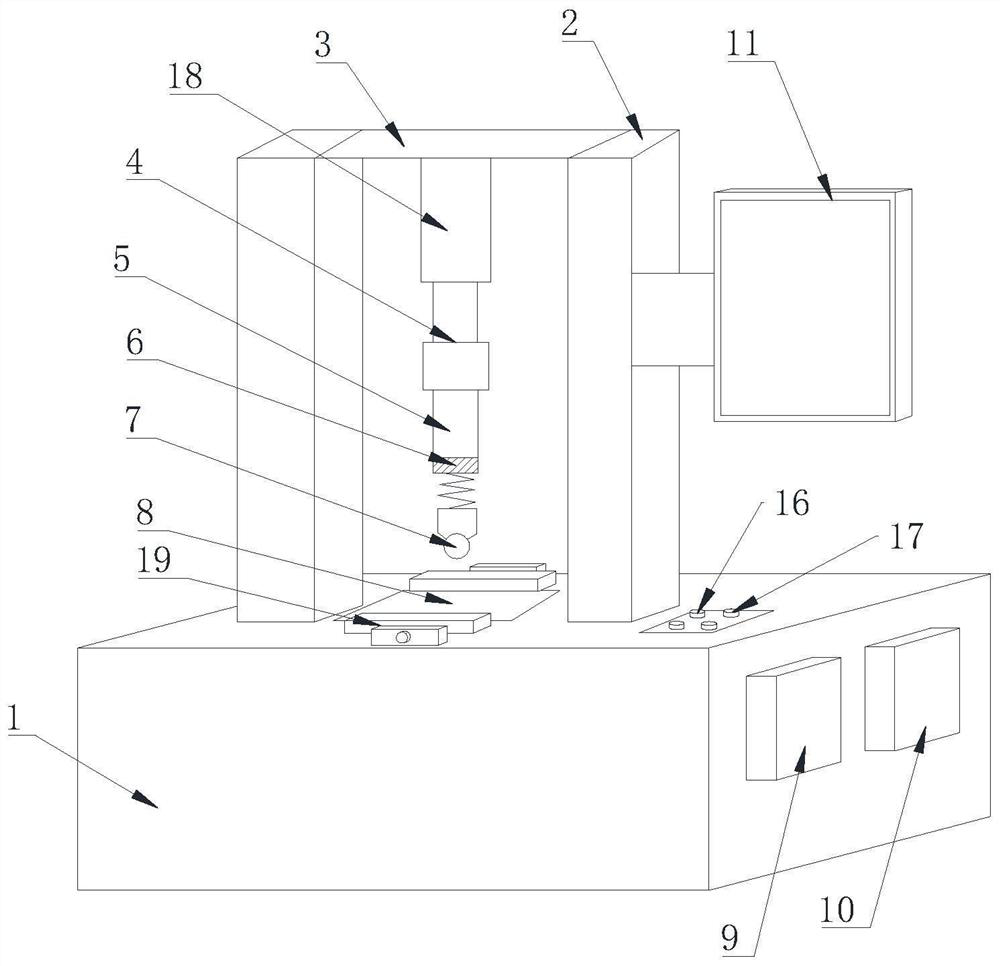

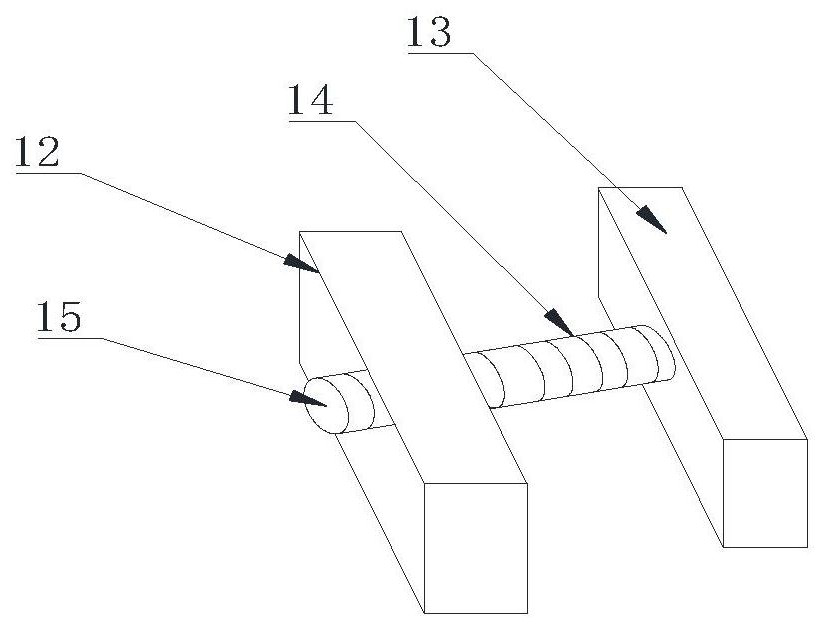

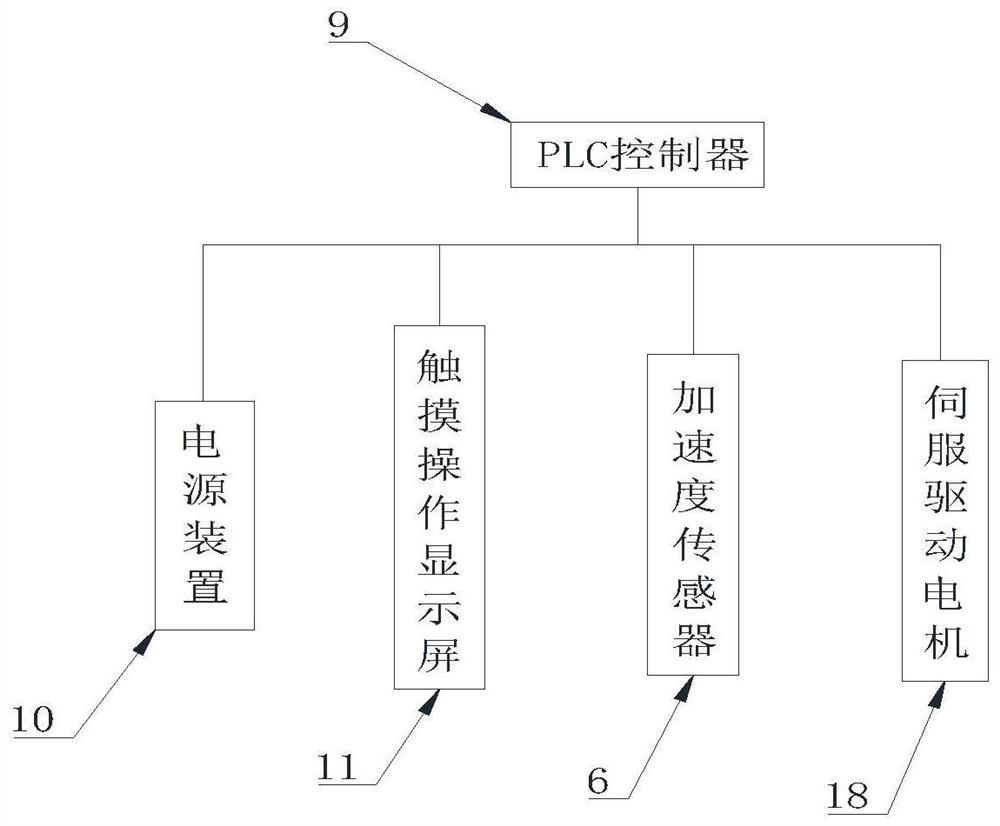

Metal material plastic yield strength detection device

PendingCN111855452AEasy to replaceEasy to fixMaterial strength using repeated/pulsating forcesTest sampleElectric machine

The invention discloses a metal material plastic yield strength detection device, which relates to the technical field of material detection. According to the technical scheme, the device comprises adetection platform, two supporting stand columns, a horizontal cross beam, a servo drive motor, an adjusting telescopic rod, an impact pressure head component, an acceleration sensor, a hard alloy ball and a to-be-tested sample fixing area, wherein the to-be-tested sample fixing area is located between the two supporting stand columns, and the to-be-tested sample fixing area is perpendicular to the central axis of the hard alloy ball; a PLC and a power supply device are arranged on the side wall of the detection platform; a touch operation display screen is detachably connected to the side wall of the supporting stand column. A switch control mechanism is arranged on the top surface of the detection platform; and the servo drive motor, the acceleration sensor and the touch operation display screen are connected with the PLC. According to the device, the yield strength of the metal material is detected by adopting a dynamic load indentation method, the yield strength of the metal material can be rapidly detected, the detection efficiency is high, and the detection result is accurate; meanwhile, the device is simple in test structure and convenient to operate.

Owner:WEIFANG UNIVERSITY

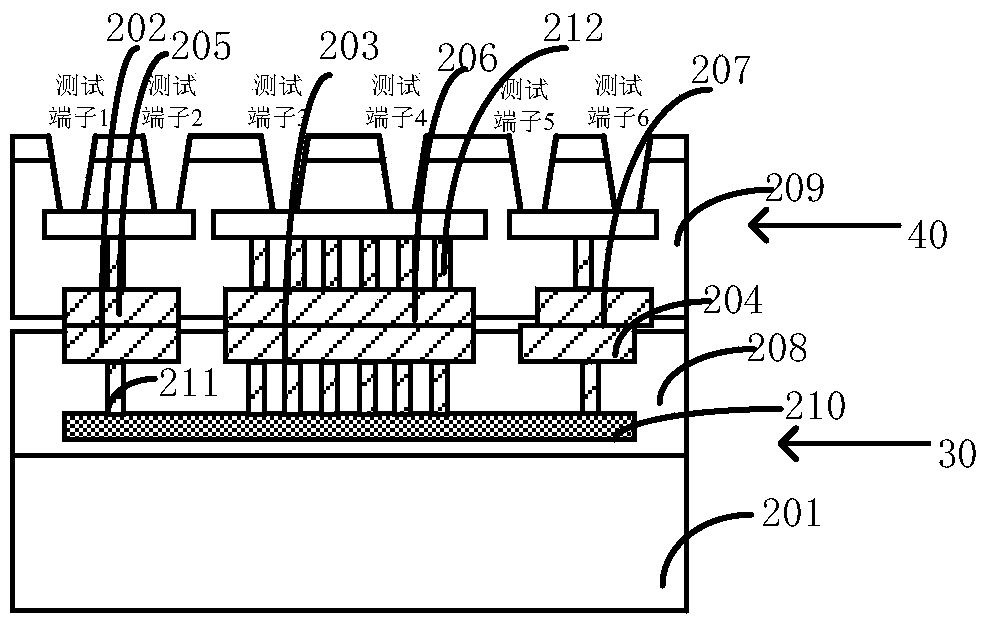

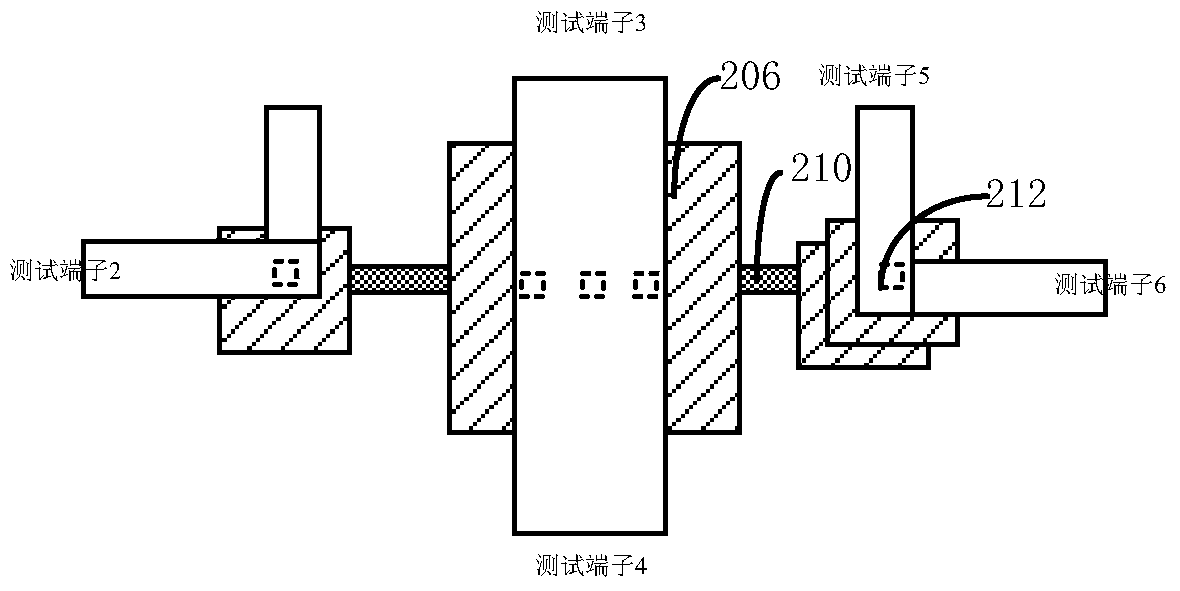

A detection structure and detection method for wafer bonding quality

ActiveCN104779238BSolve problems that cannot be accurately testedSimple test structureSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringWafer bonding

The invention relates to a detection structure and a detection method for detecting the quality of wafer bonding. According to the detection structure, a bottom metal layer, bottom pads, and bottom through holes between the bottom metal layer and the bottom pads of a bottom wafer form an interconnect structure which is used as a lower half part of the test structure; top pads, a top metal layer, and top through holes between the top pads and the top metal layer of a top wafer form an interconnect structure which is used as an upper half part of the test structure; and the top metal layer is used as a test pad, and the opening of the test pad is arranged in the top metal layer of the top wafer after the top wafer is thinned. The test structure is composed of three parts, wherein the left and right test structures are respectively a first test target and a second test target, and the middle structure mainly plays a lead role. The test structure is a symmetrical structure, which enables other additional resistors except the test targets in the circuit to be equal. By adopting the test structure of the invention, the problem that the Cu-Cu bonding resistance Rc in a 3D IC cannot be tested accurately is solved simply and effectively.

Owner:SEMICON MFG INT (SHANGHAI) CORP

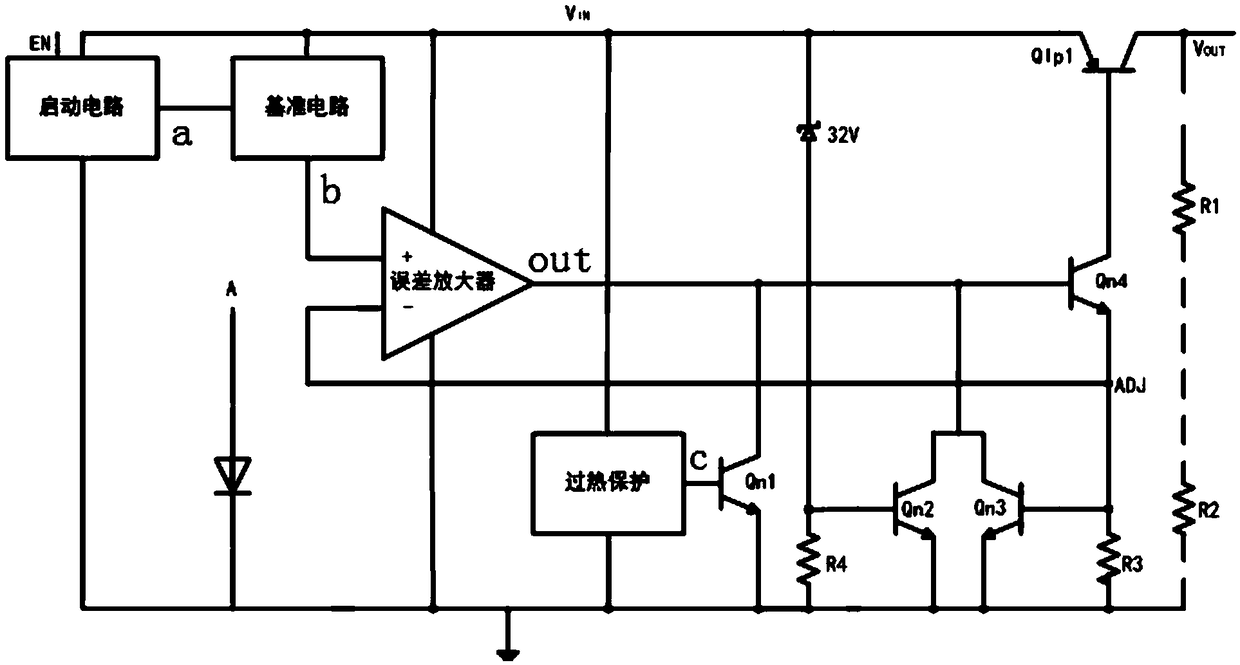

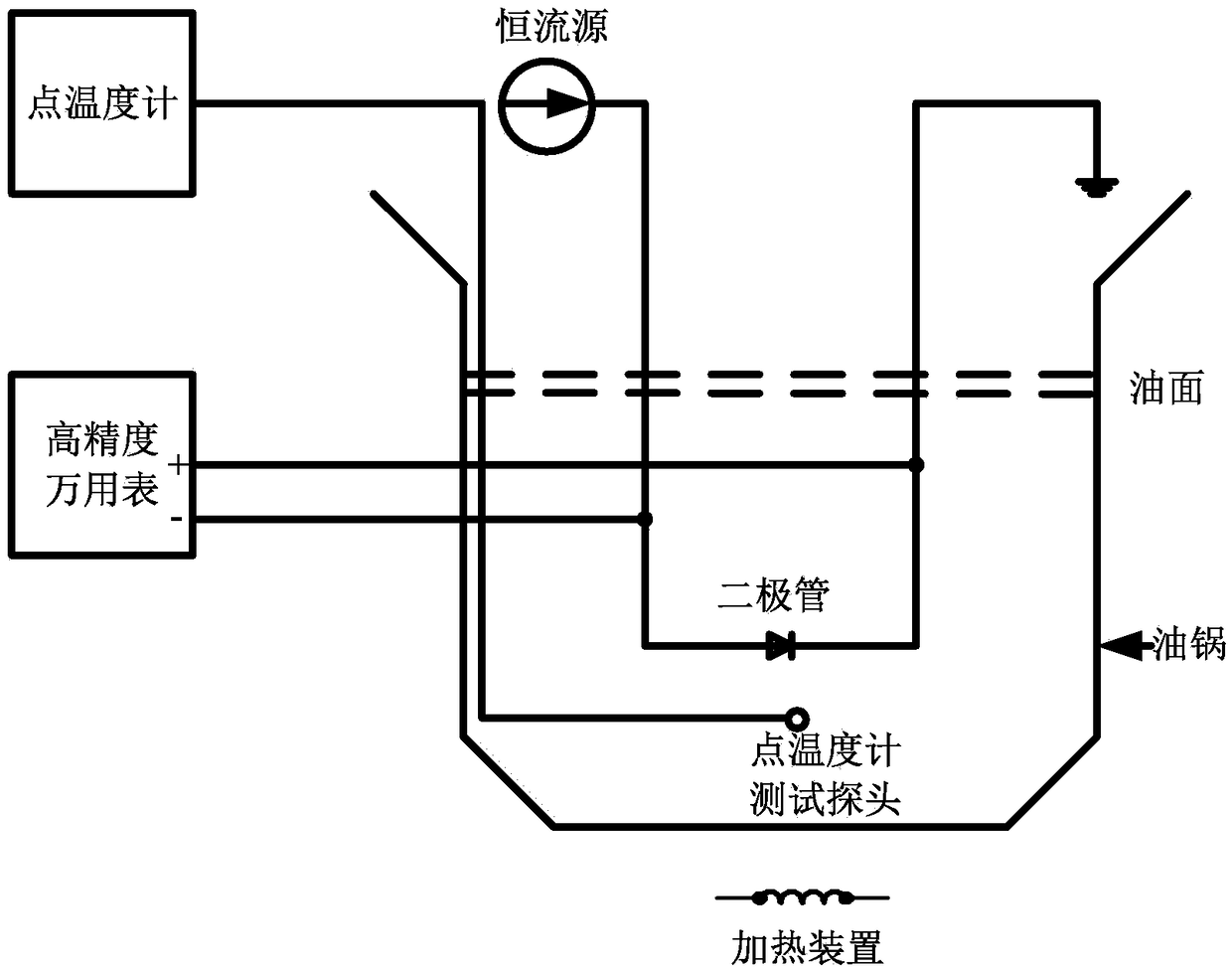

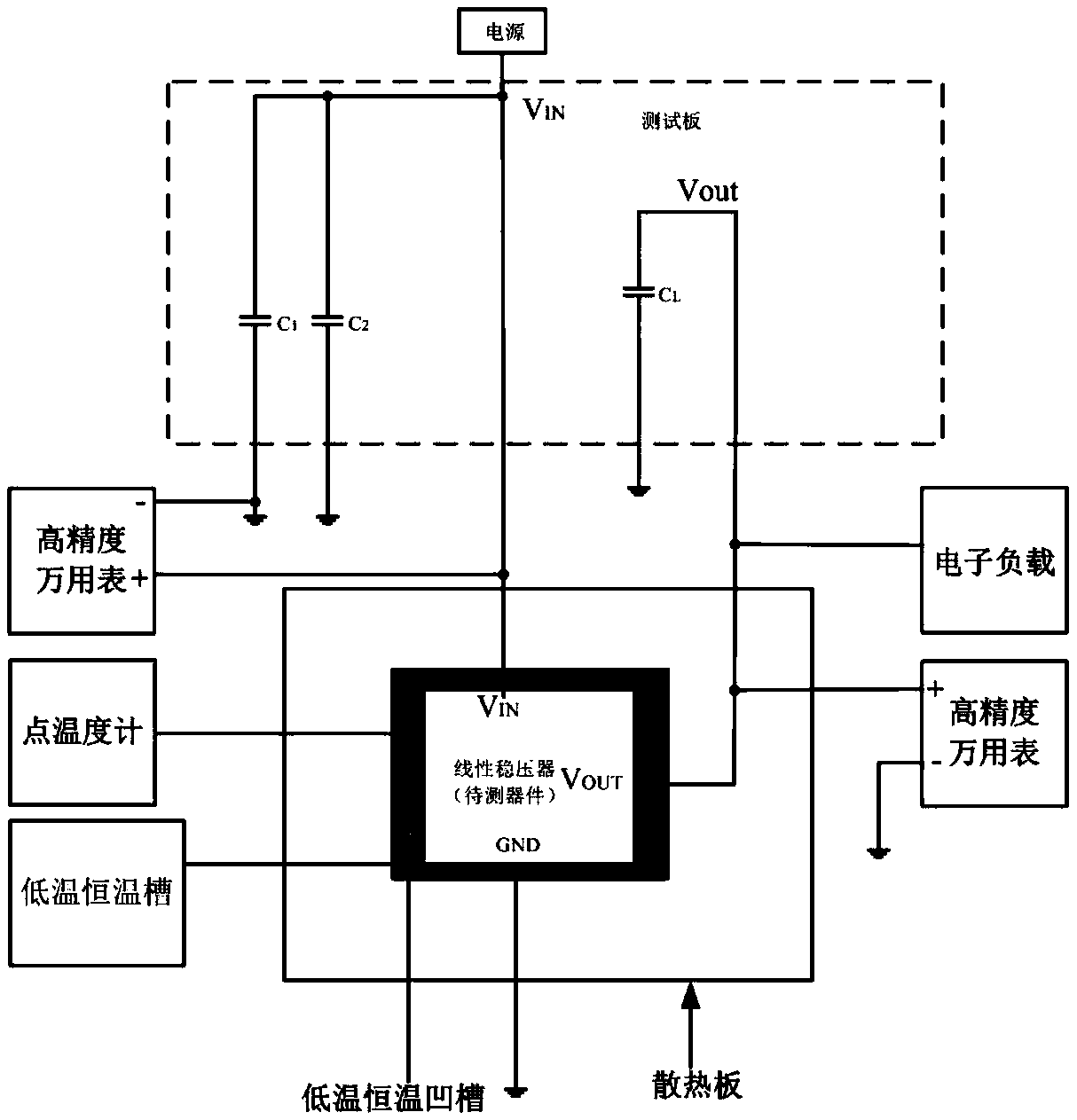

Heat resistance testing method for linear voltage stabilizer

ActiveCN109298316AAccurately characterize junction temperatureSimple and fast operationElectronic circuit testingMaterial heat developmentHeat resistanceJunction temperature

The invention discloses a heat resistance testing method for a linear voltage stabilizer. The heat resistance testing method comprises the steps that a chip junction temperature testing structure of the linear voltage stabilizer is constructed, and the chip junction temperature of the linear voltage stabilizer is tested through an oil bath method; then a junction-to-case heat resistance testing structure of the linear voltage stabilizer is constructed for testing the junction-to-case heat resistance of the linear voltage stabilizer, and the case temperature and the power applied by a device are determined; and finally, the junction-to-case heat resistance of the linear voltage stabilizer is calculated. The heat resistance testing method is easy and convenient to operate, concise in structure, easy to implement and low in cost, the forward voltage drop of a diode is adopted to represent the chip junction temperature, and testing precision is high.

Owner:XIAN MICROELECTRONICS TECH INST

Test structure of breakdown voltage, analytic procedure applying same and wafer

InactiveCN101577265BSimple test structureEasy to implementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsAnalysis methodMetal

The invention discloses a test structure of breakdown voltage, an analytic procedure applying the same and a wafer. The test structure comprises at two comb test circuits with metal connection wires, wherein the distances among metal wires in each comb test circuit are equal, the distances among metal wires of the comb test circuits are not equal, and the distances of the metal wires are the distance between any two adjacent metal wires in the comb test circuits. The analytic procedure comprises the following steps: measuring breakdown voltage of each comb test circuit of a test structure of each chip formed on the wafer; obtaining the change trend of breakdown voltage of each comb test circuit of the each chip along with the distance change among the metal wires; and analyzing the reasonof uneven distribution of breakdown voltage of the wafer according to the change trend of breakdown voltage of each comb test circuit of each chip along with the distance change among the metal wires.The invention can quickly analyze the reason of uneven distribution of breakdown voltage of interlamination media of the wafer.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com