Test structure of micro-beam fracture strength based on lateral comb tooth type capacitance

A technology for breaking strength and testing structure, which is applied in the field of testing the breaking strength of micro-electromechanical system microbeams, can solve problems such as product differences, and achieve the effect of achieving breaking strength and testing structure with simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

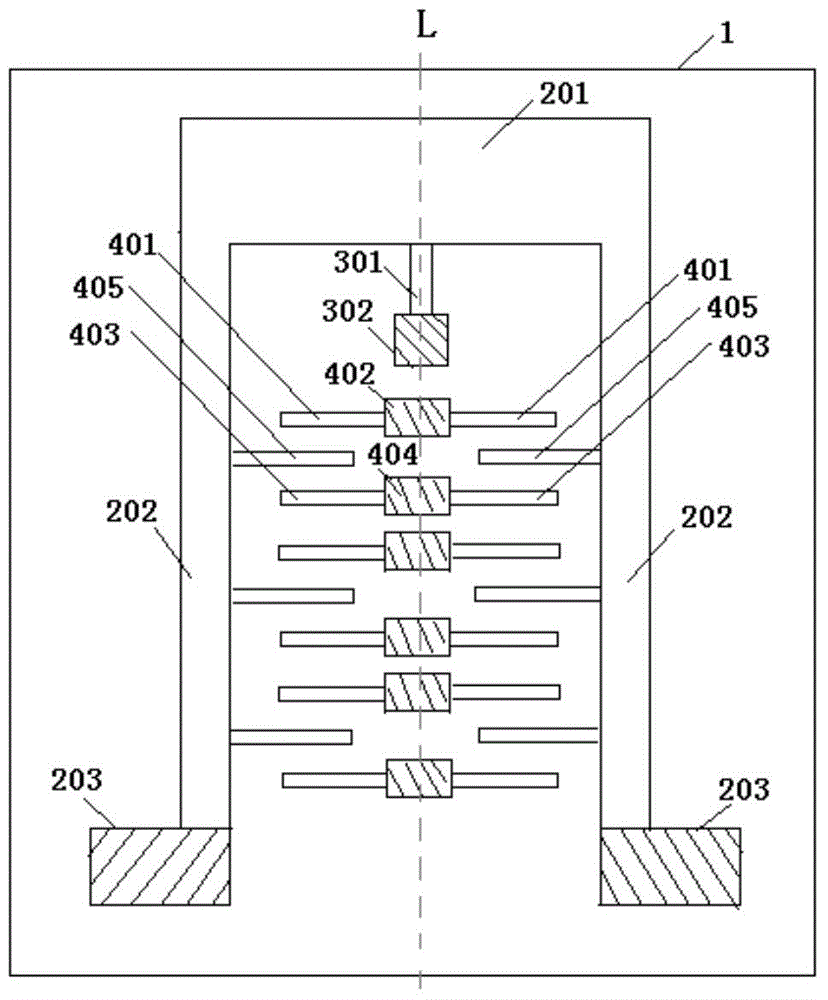

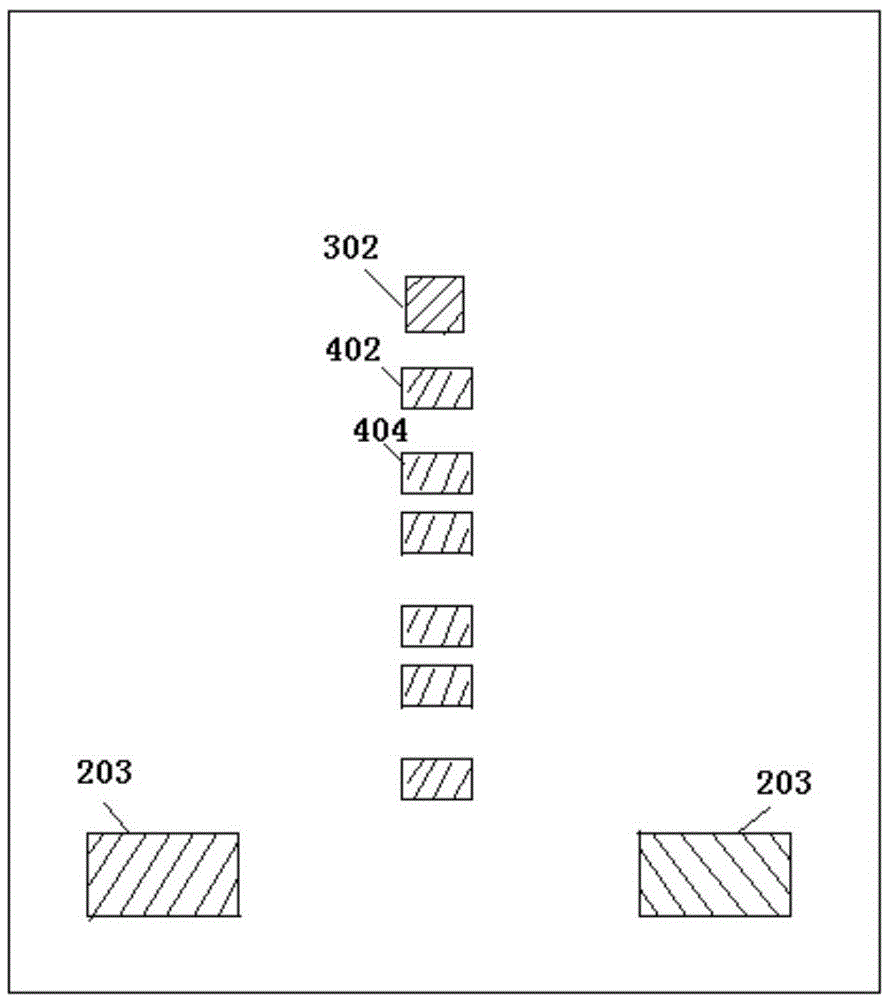

[0016] A test structure for the fracture strength of microbeams based on transverse comb-tooth capacitors of the present invention is composed of three parts: a door-shaped thermal execution structure, a transverse comb-tooth capacitance detection structure, and a microbeam to be tested. The entire structure is about the longitudinal central axis L completely symmetrical. The two longitudinal beams of the door-shaped thermal execution structure are perpendicular to the wide beam, one end is connected to the end of the wide beam, and the other end is connected to the side of an anchor area; the measured micro-beam is parallel to the door-shaped The two longitudinal beams of the thermal executive structure are on the central axis L, one end is connected to the middle of the inner side of the wide beam of the door-shaped thermal executive structure, and the other end is connected to the side of an anchor area; the three groups of identical comb teeth The structure is located in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com