Patents

Literature

208 results about "Strengths based" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

They are about the real attitudes and values that people hold, that shape and influence their way of caring for others a the deepest level of meaning. A true strengths-based approach is one that governs the way we think about people and the way we go about our work on a daily basis for all actions and interactions.

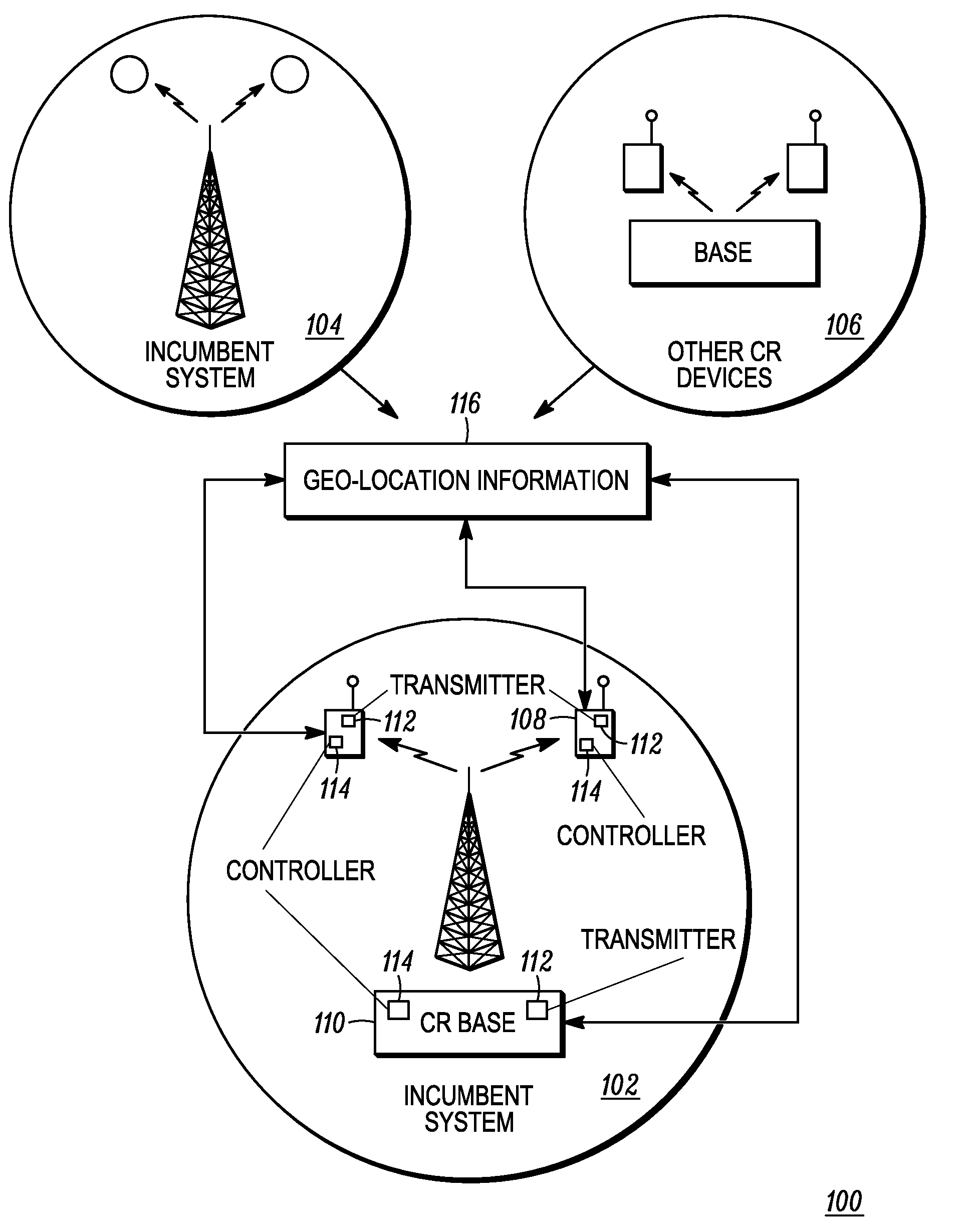

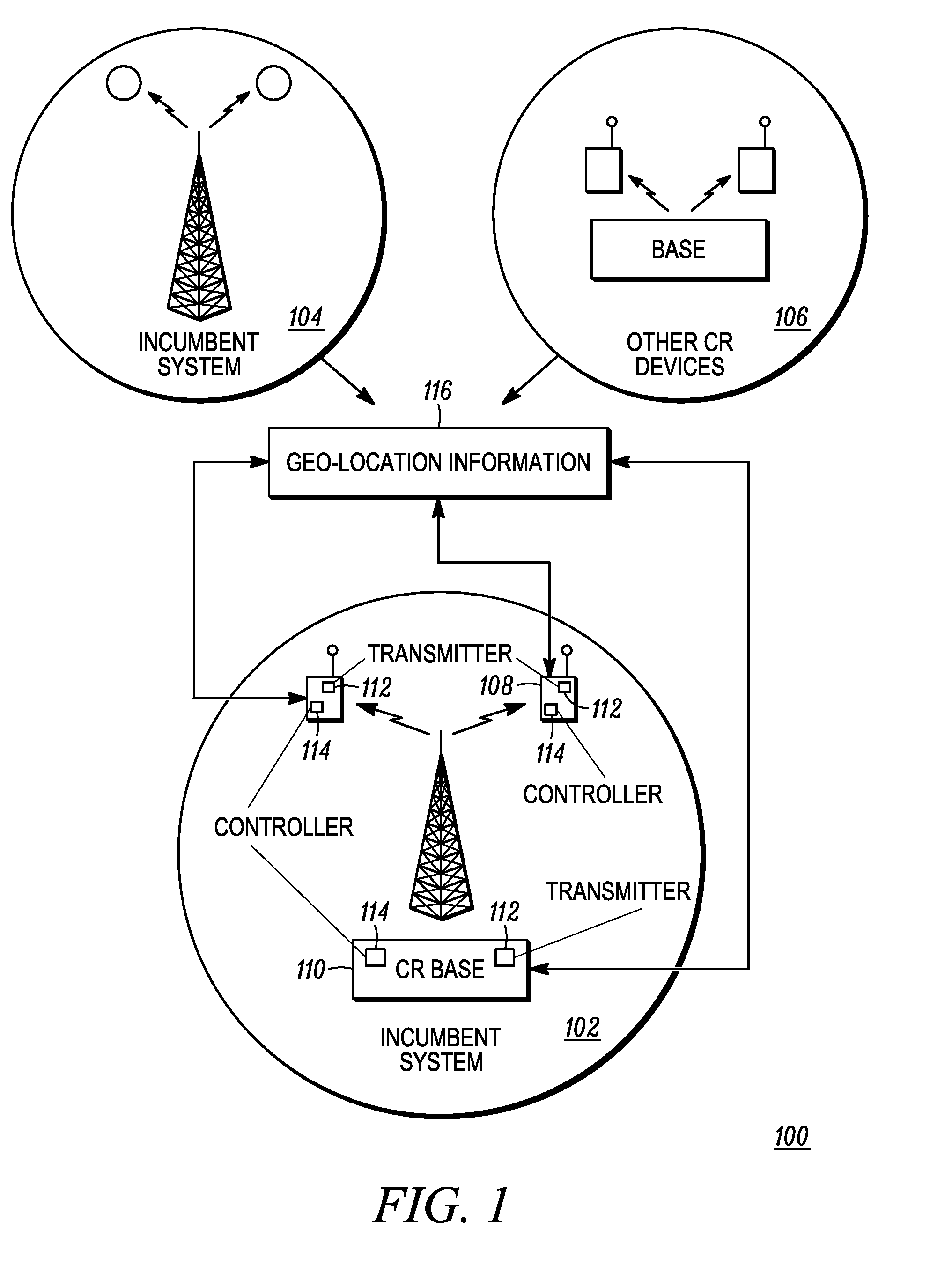

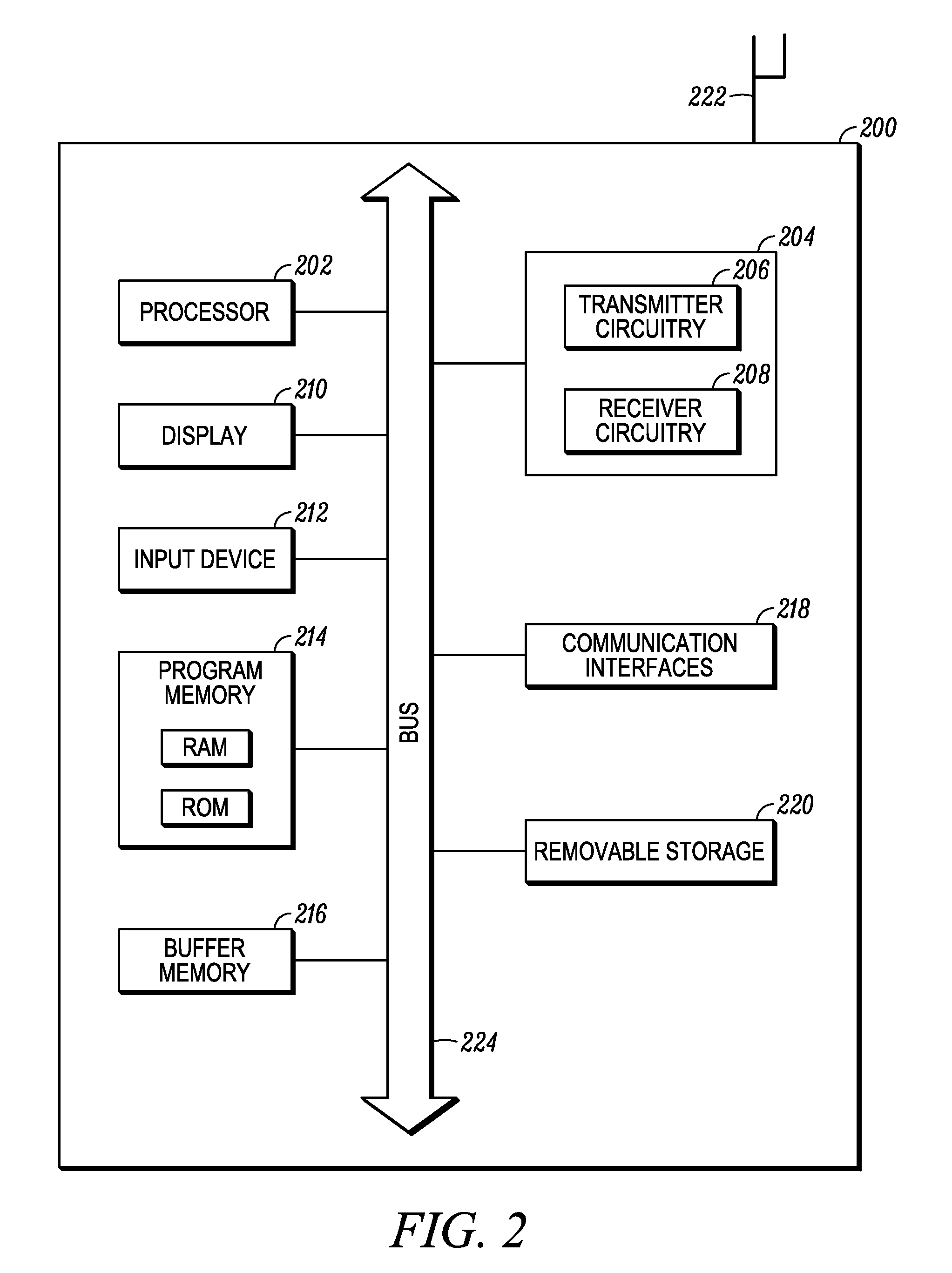

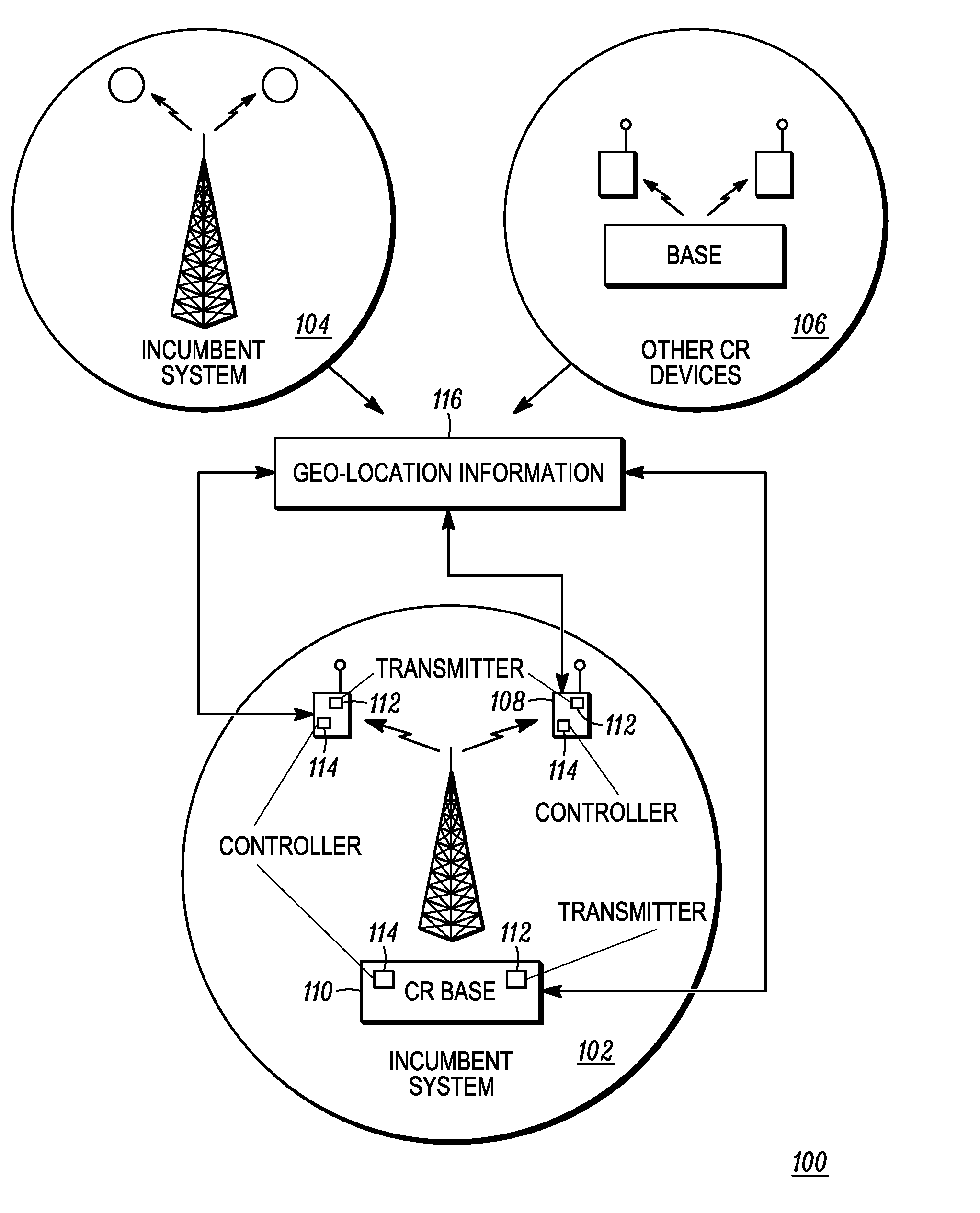

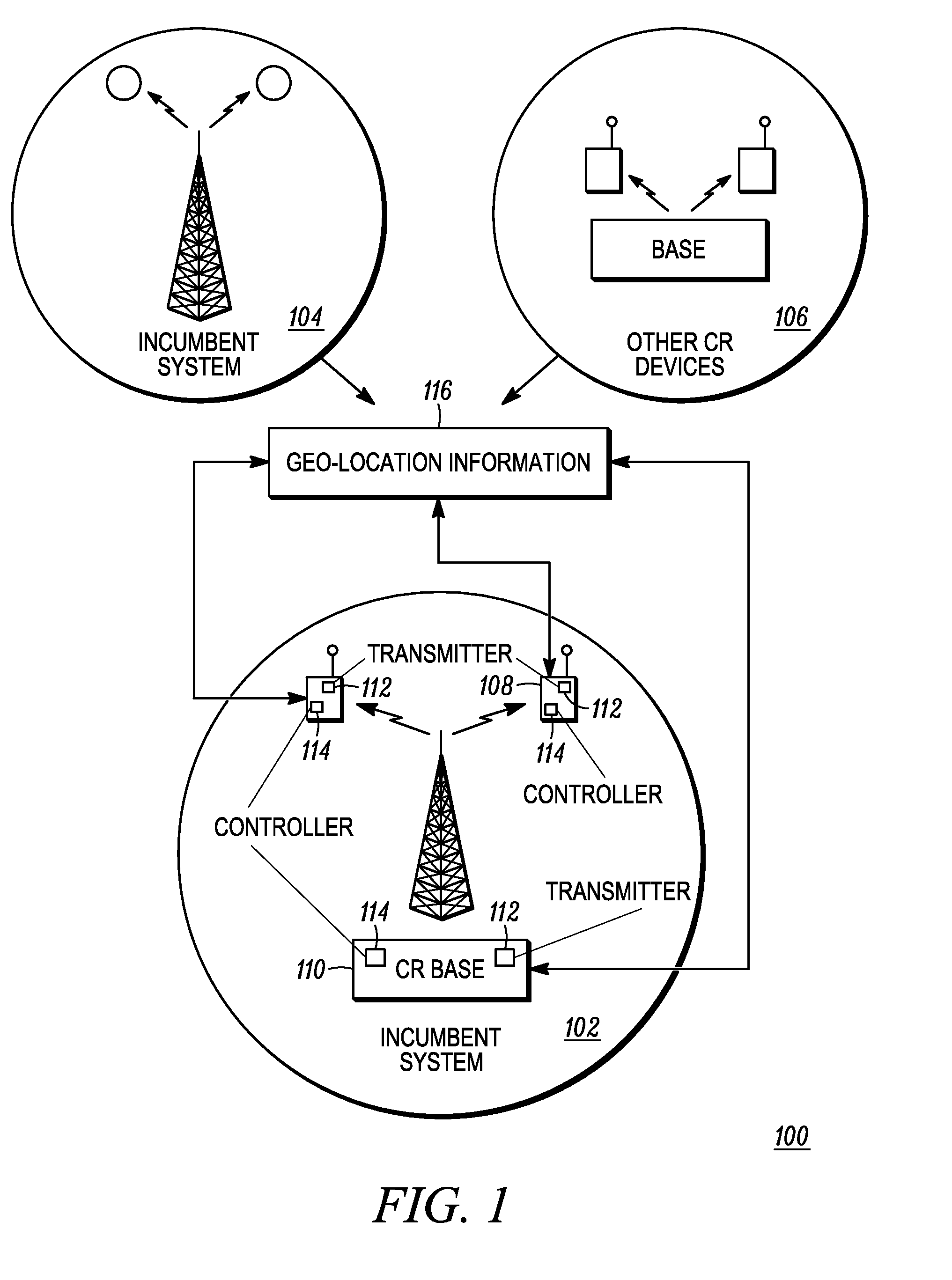

Method for database driven channel quality estimation in a cognitive radio network

ActiveUS20100330919A1Power managementTransmission monitoringCo-channel interferenceGeolocation database

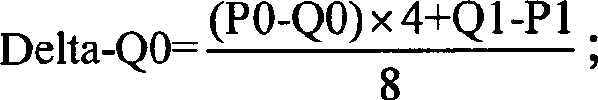

A method of determining operating parameters for a secondary system transmitter is described. The transmitter characteristics, including location and operating frequency band, are provided to a geo-location database. The database determines the maximum allowable transmission power that meets various specifications for different channels and conveys the power and channel(s) to the transmitter. The database estimates channel incumbent signal strengths based on the transmitter location and primary and higher-priority secondary incumbent systems, estimates the splatter levels, determines whether adjacent and co-channel interference protection ratios are met, and adjusts the allowable power level accordingly. The database also estimates aggregate co- and adjacent channel primary and secondary incumbent system interference levels at the transmitter location and predicts channel quality for each allowable channel. The estimated levels are updated using measurements of actual levels at the transmitter location. The database dynamically allocates channels using the secondary system priorities.

Owner:MOTOROLA SOLUTIONS INC +1

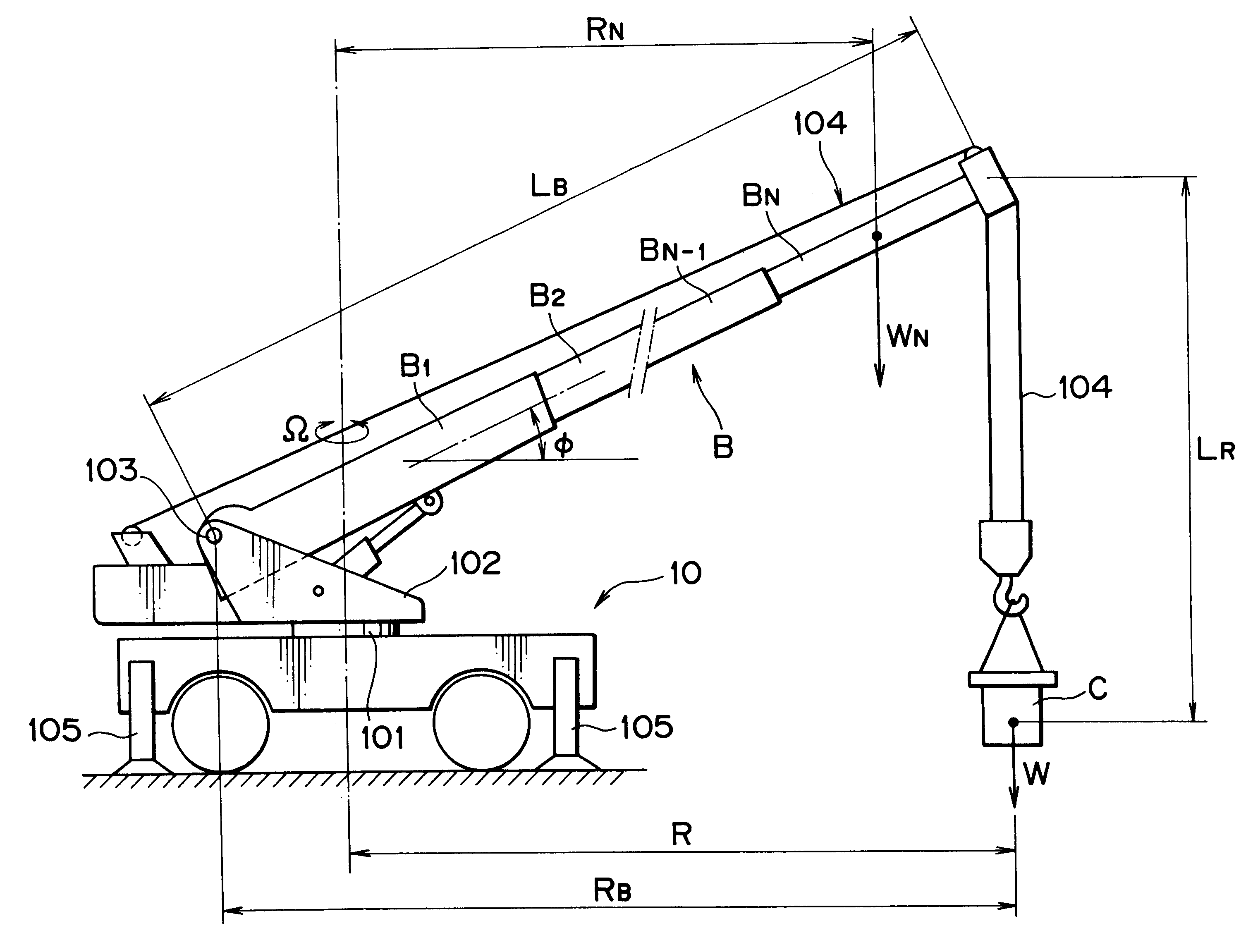

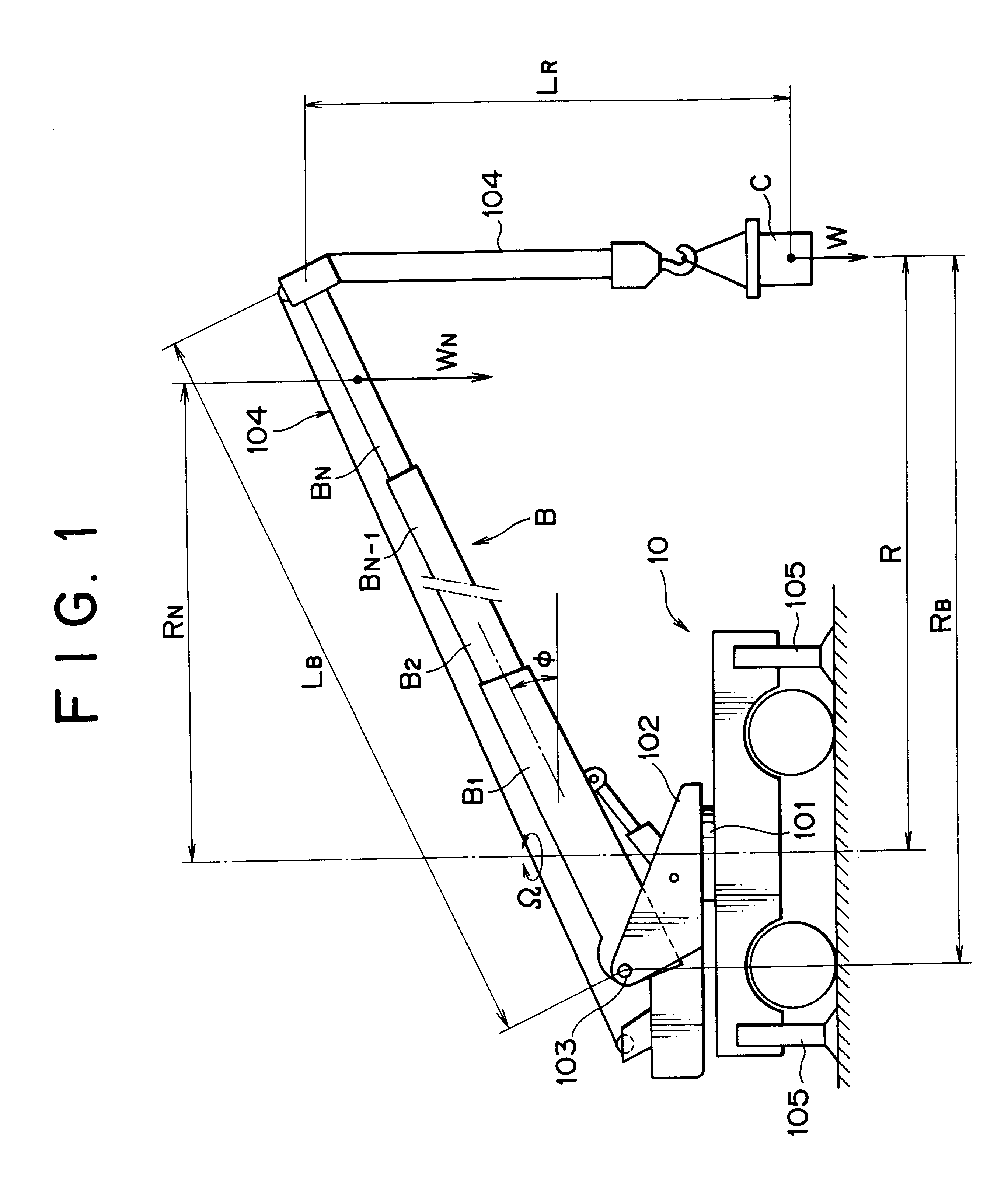

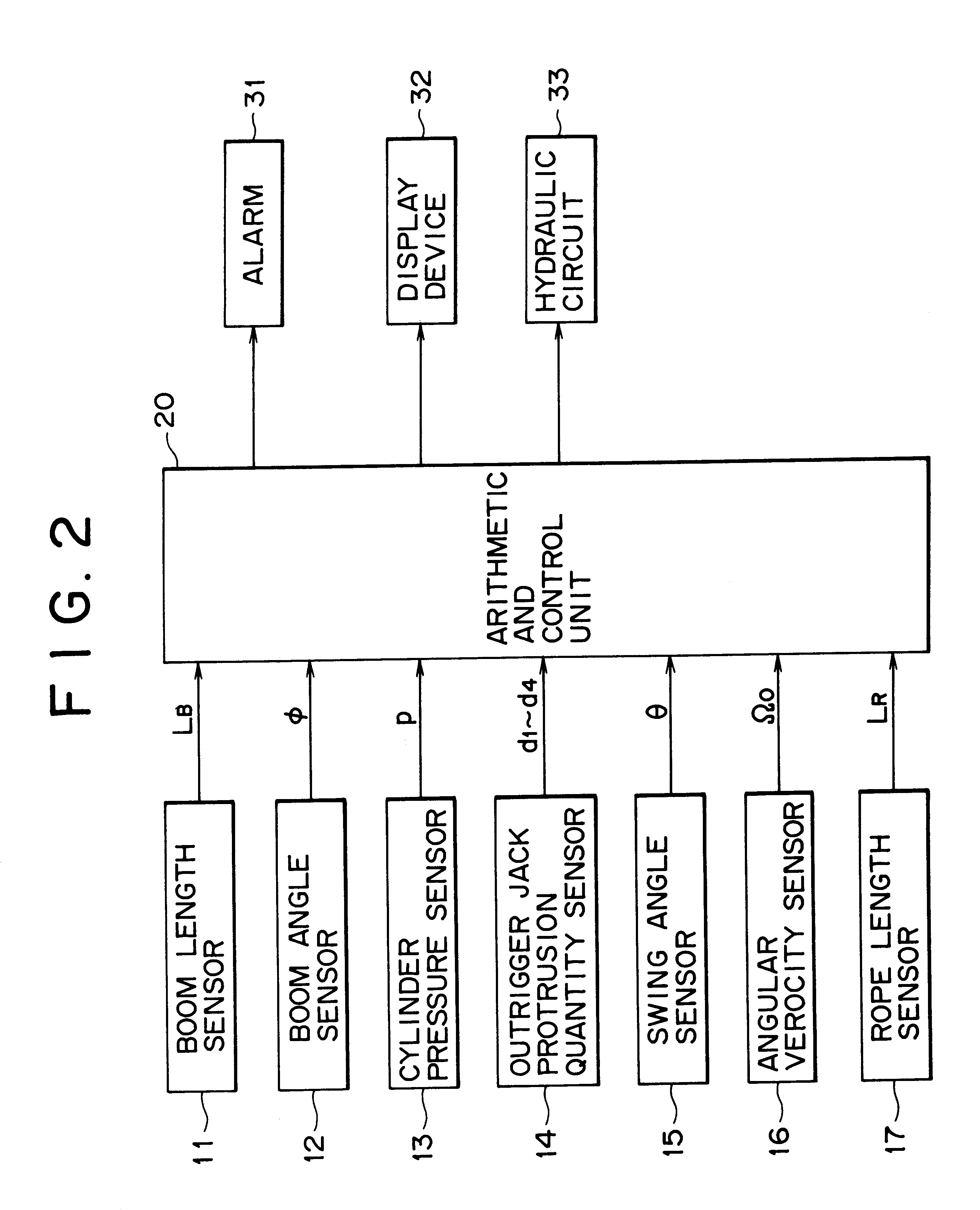

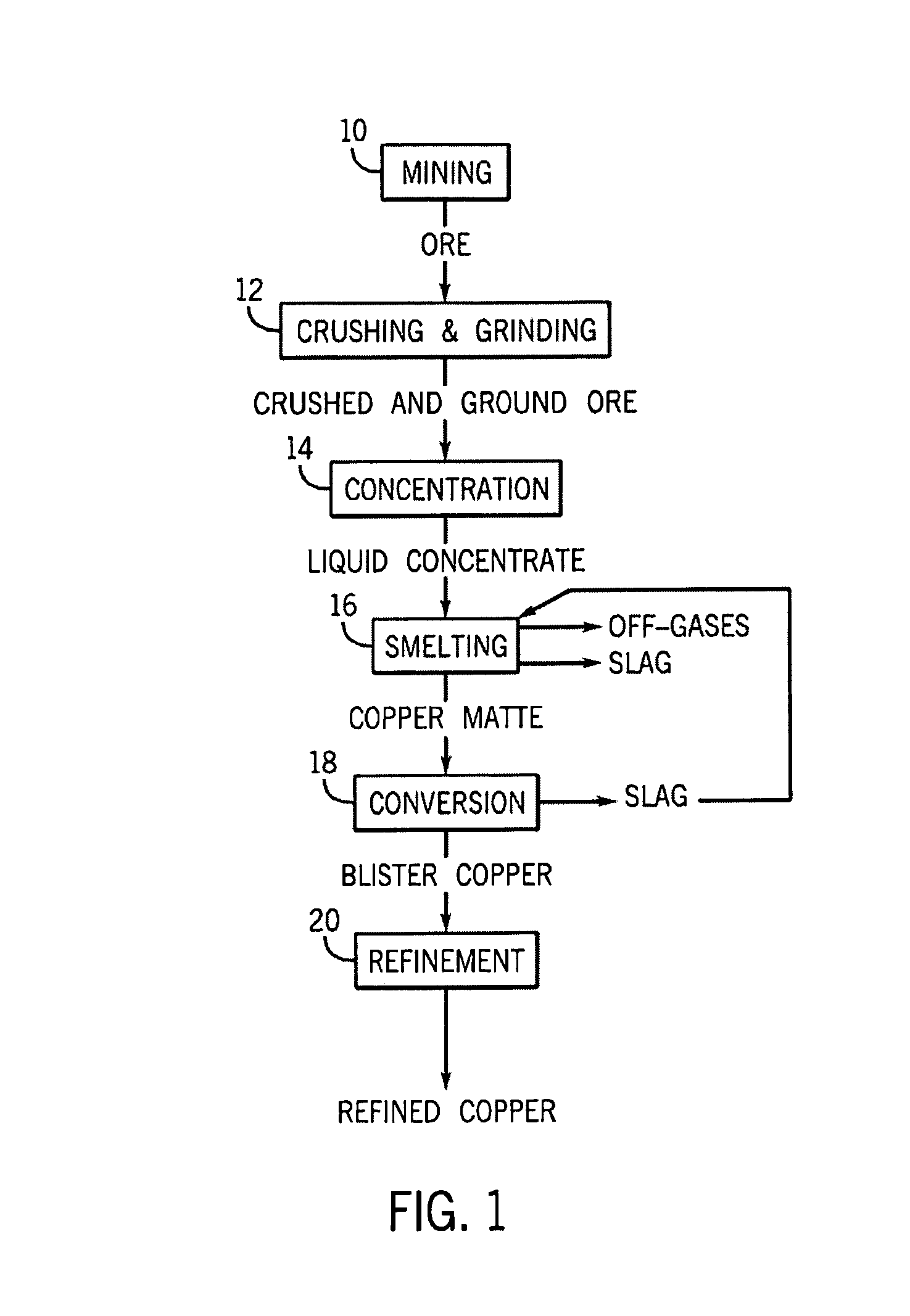

Swing type machine and method for setting a safe work area and a rated load in same

A method for setting a safe work area and a rated load in a swing type work machine, as well as a swing type work machine which utilizes the said method, are disclosed. An area where a strength-based safe work area which is established taking the strength of a swing member into account and a stability-based safe work area which is established taking the stability of the work machine into account overlap each other, is set as a safe work area to be used actually. Likewise, out of a strength-based rated load which is set taking the strength of the swing member into consideration and a stability-based rated load which is set taking the stability of the work machine into consideration, the lower one is set as a rated load to be used actually. Using the safe work area and rated load thus obtained, there are made a safety control and an appropriate display. According to this method, in a swing type work machine such as a crane, it is possible to establish a safe work area and a rated load both matching the actual hoisting capacity of the work machine.

Owner:KOBE STEEL LTD

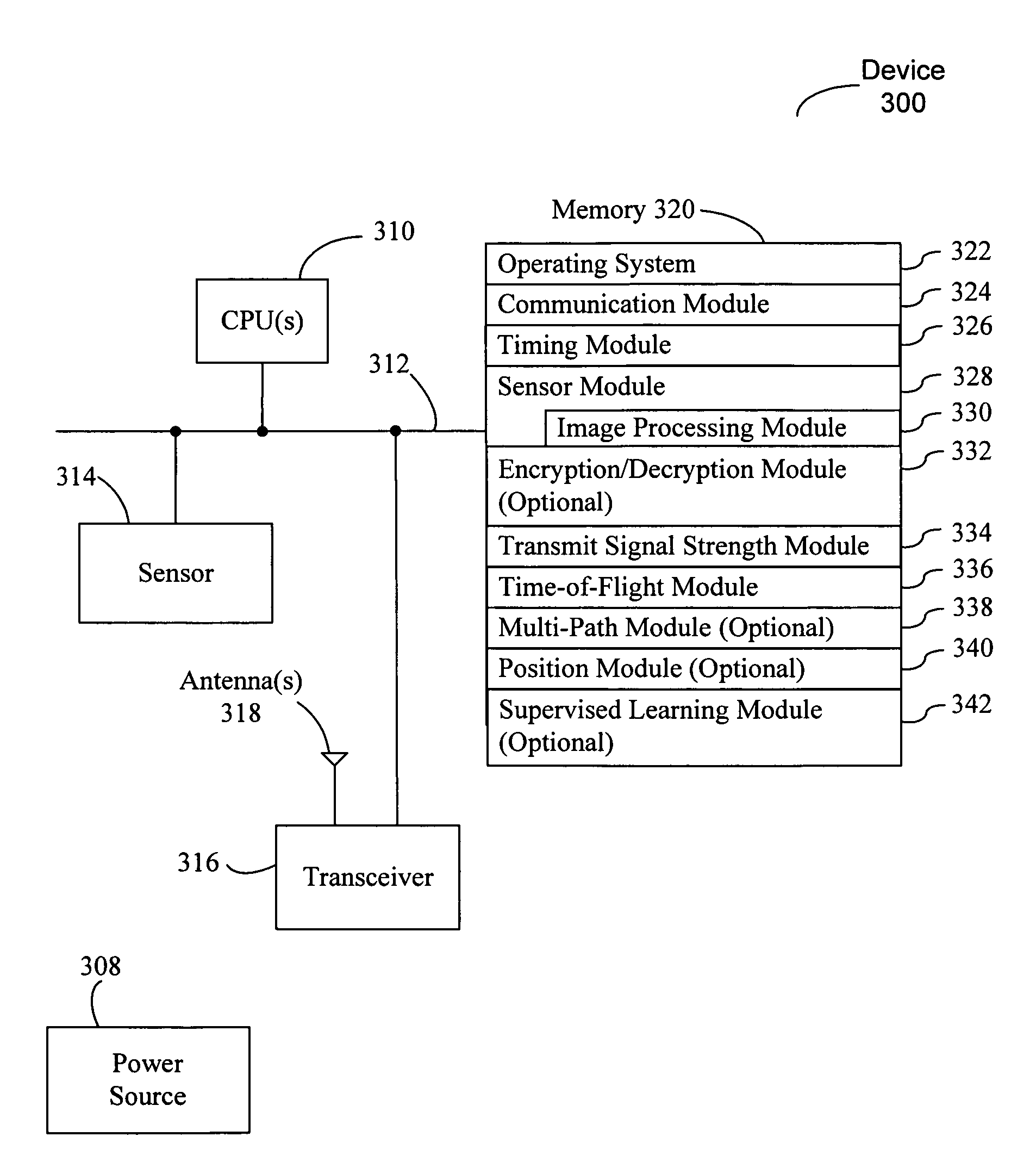

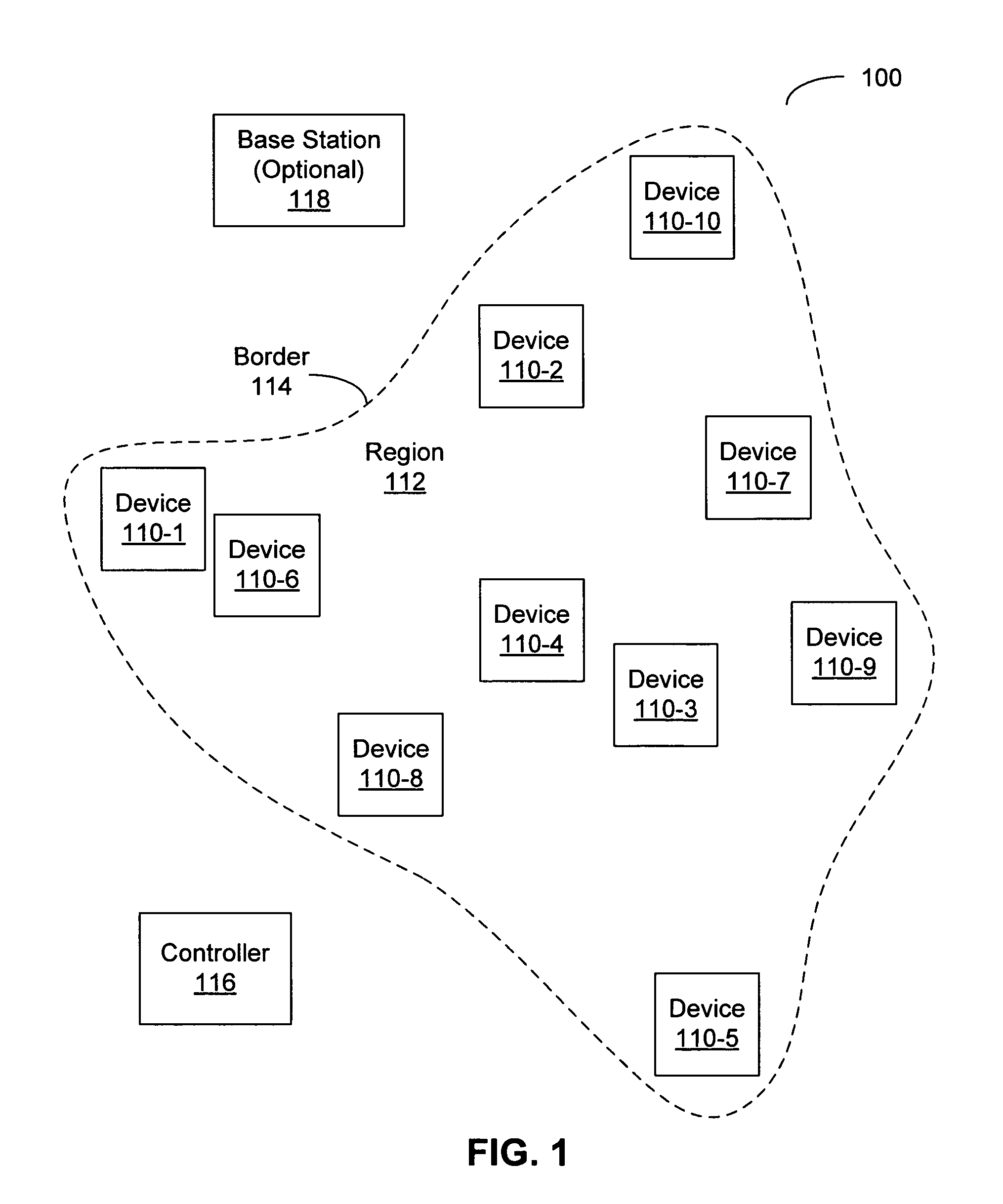

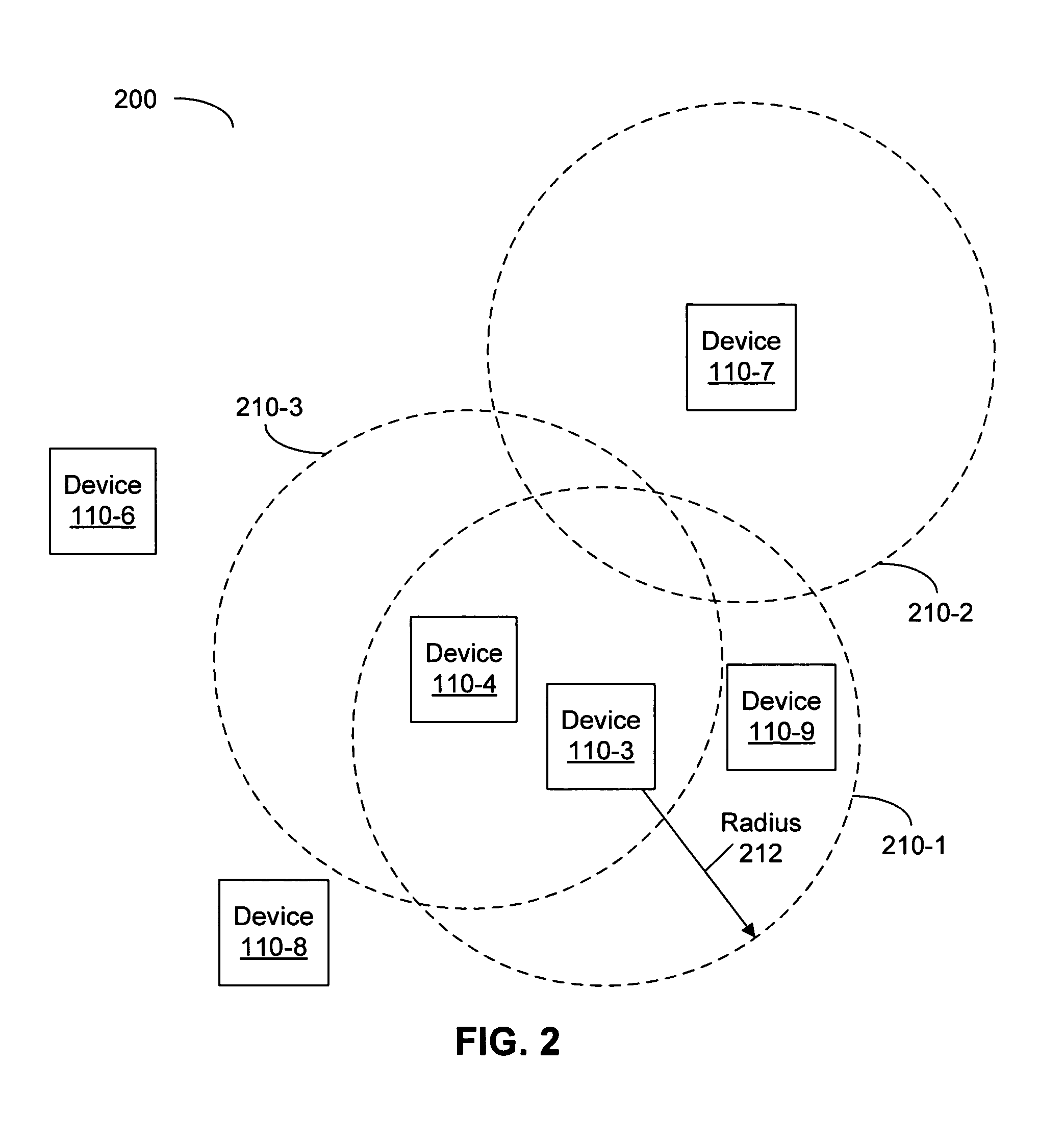

Sensor localization using lateral inhibition

ActiveUS7783457B2Improve spatial resolutionEnhanced inhibitory effectAmplifier modifications to reduce noise influenceComputer controlLateral inhibitionEngineering

A system including multiple devices that each have a sensor and are each configured to communicate with other devices. The system further includes a controller configured to provide command information that specifies a mode of operation of the devices. In a first mode of operation, the devices transmit communication signals and a given device modifies a strength of its communication signal from an initial strength to a final strength based on communication signals it receives from one or more other devices. And in a second mode of operation, the devices transmit communication signals and the given device dynamically adjusts a strength of its communication signal based communication signals it receives from one or more other devices and on measurements performed by the sensor in the given device.

Owner:ORACLE INT CORP

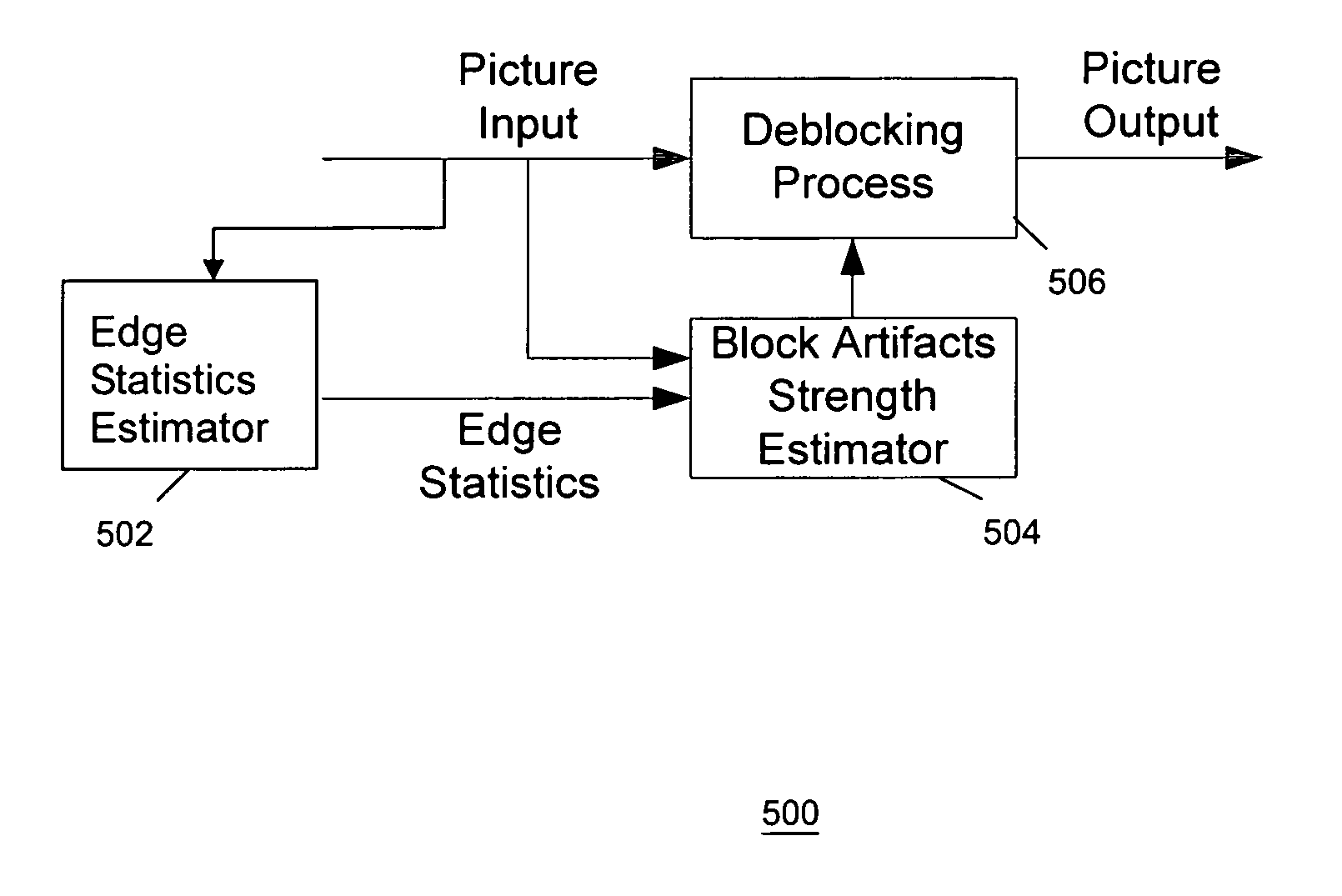

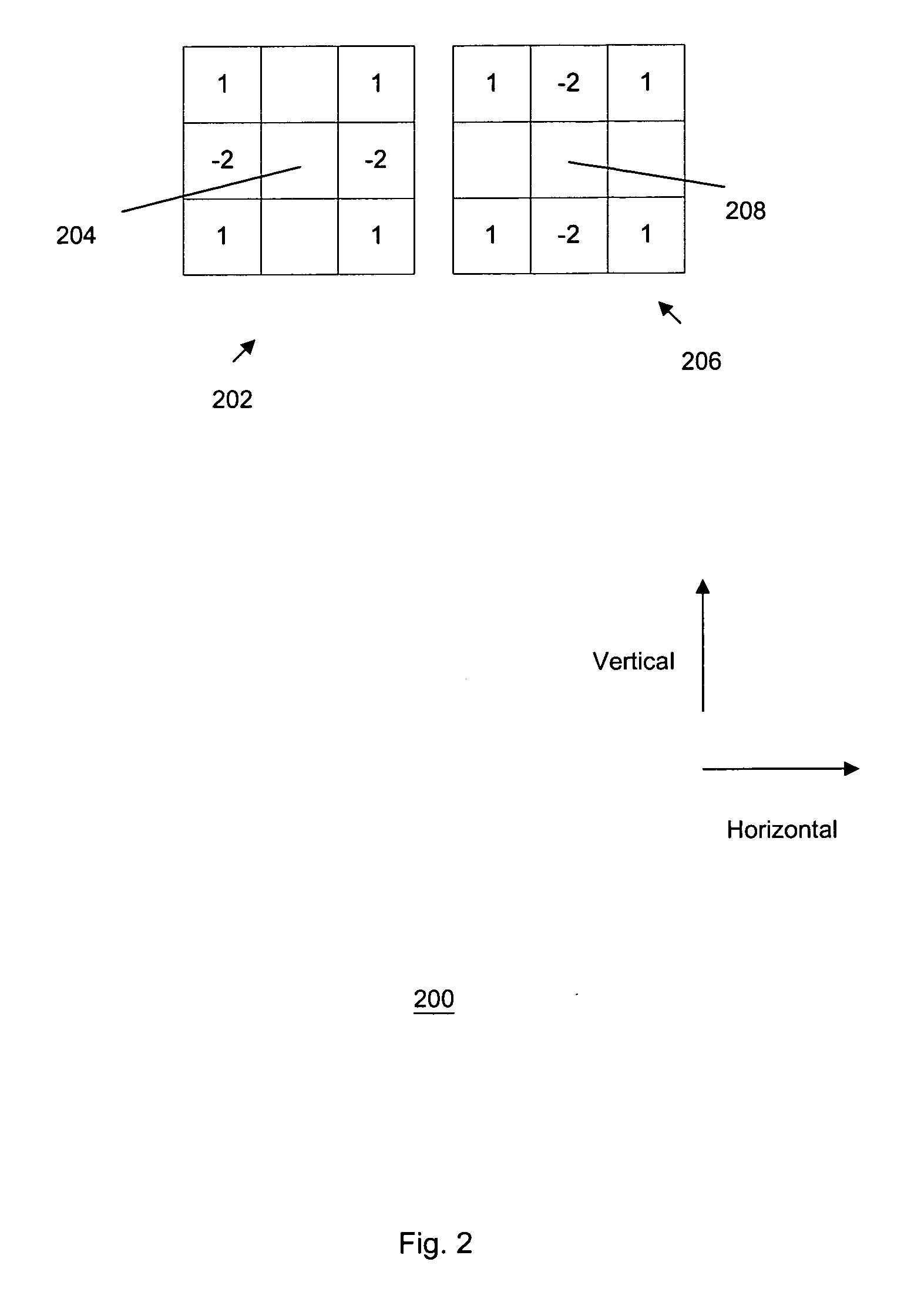

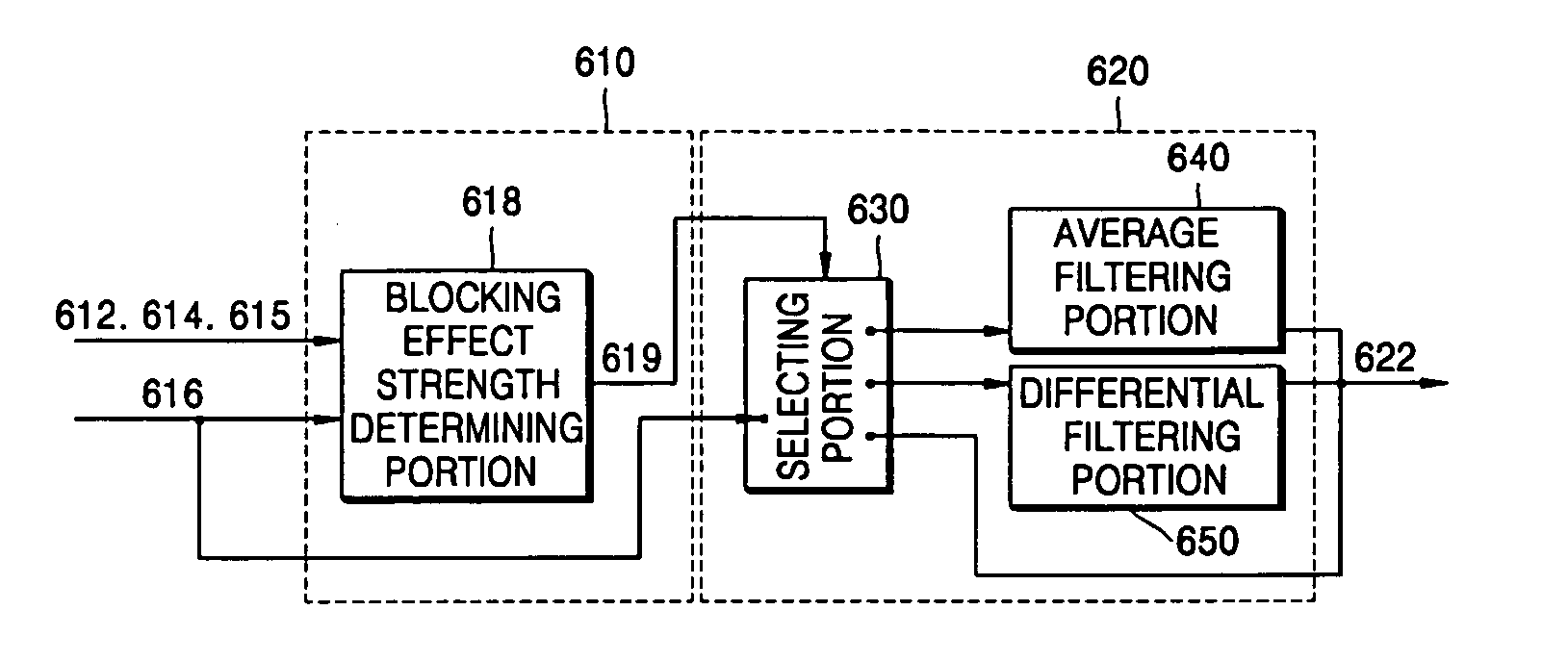

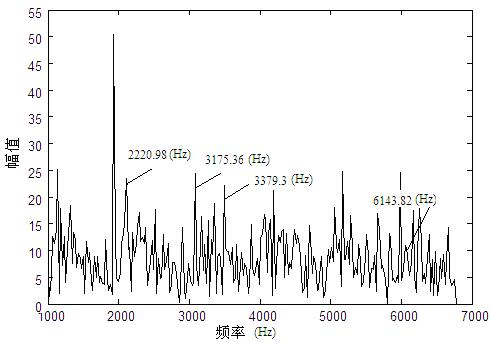

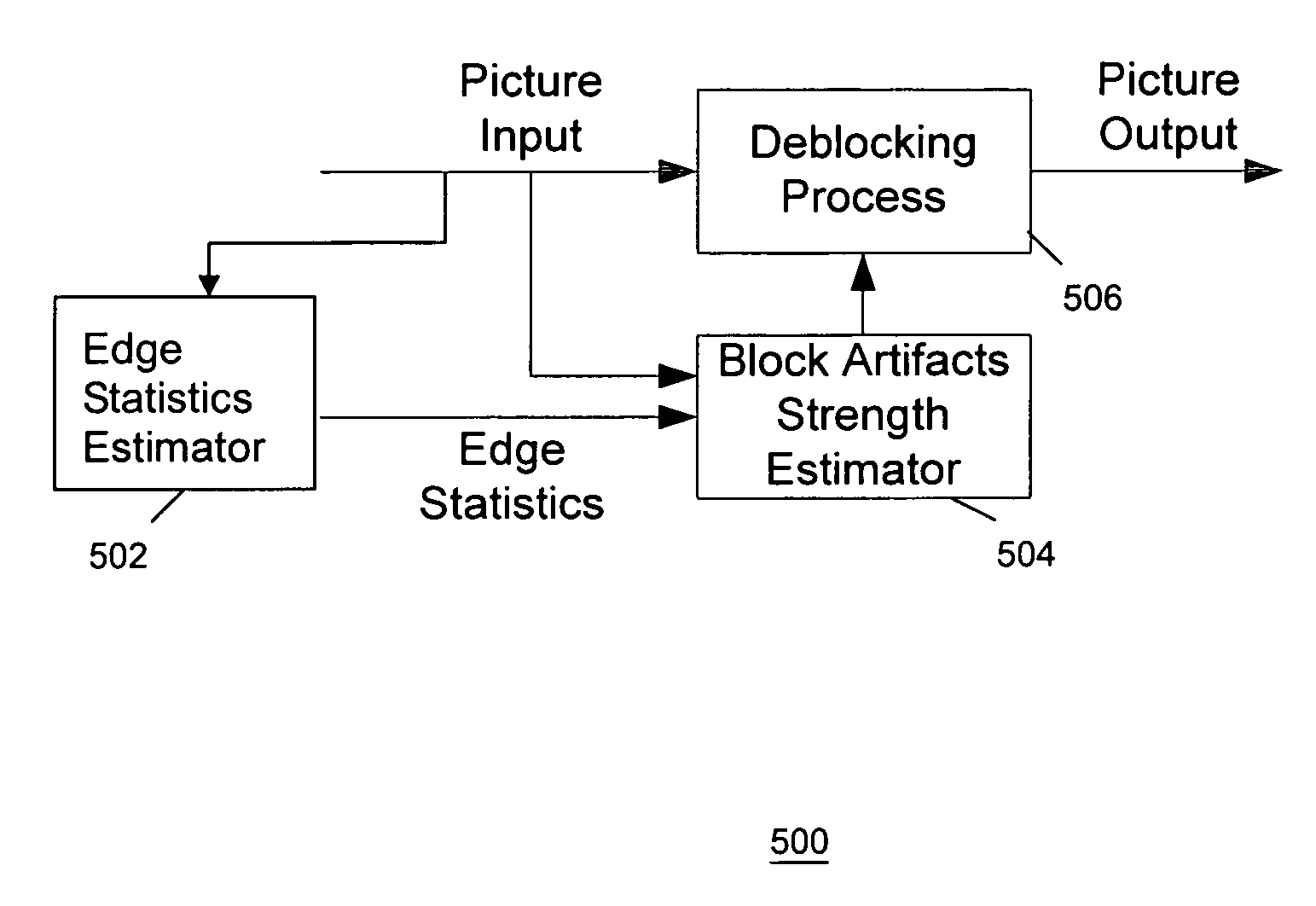

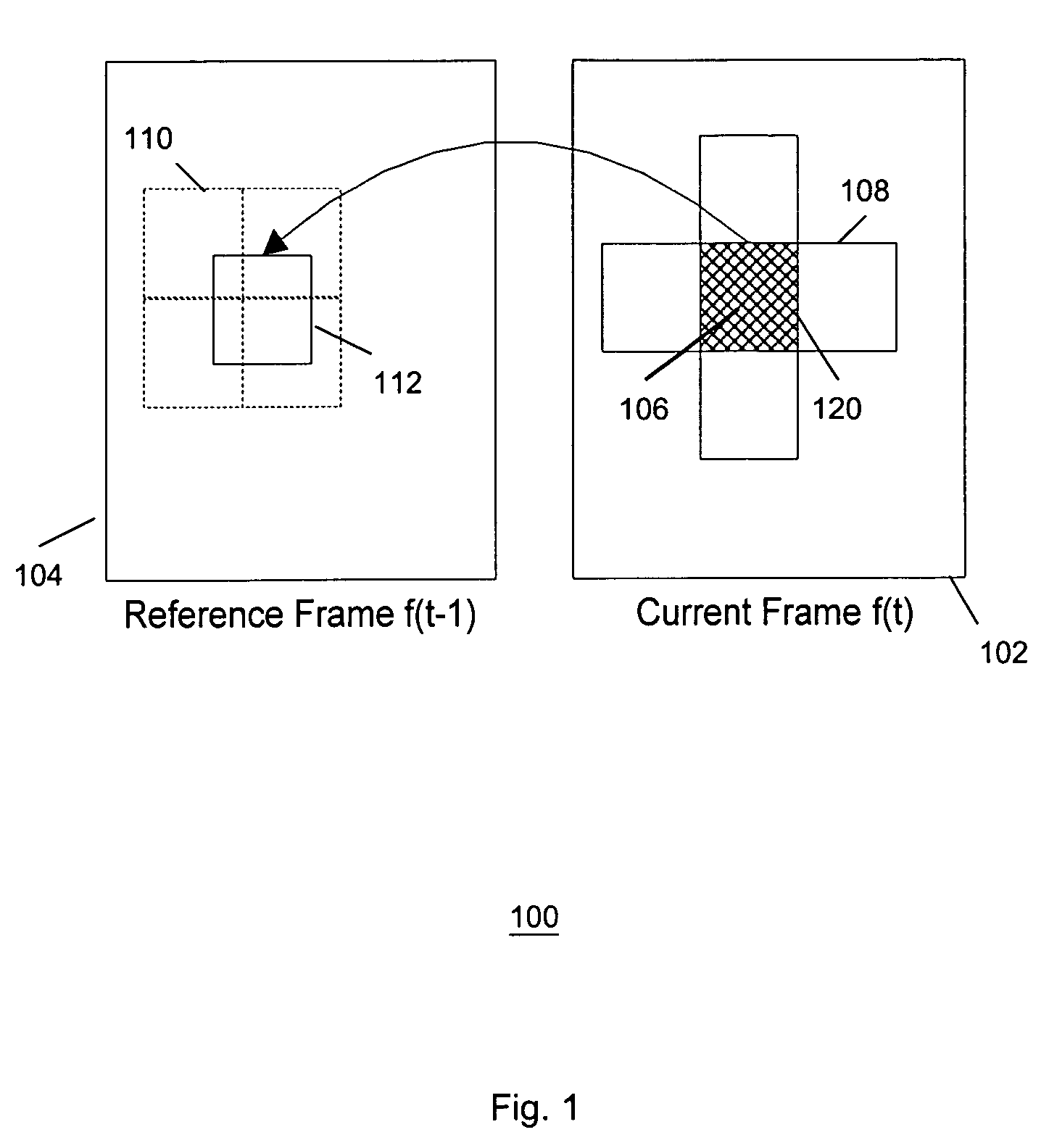

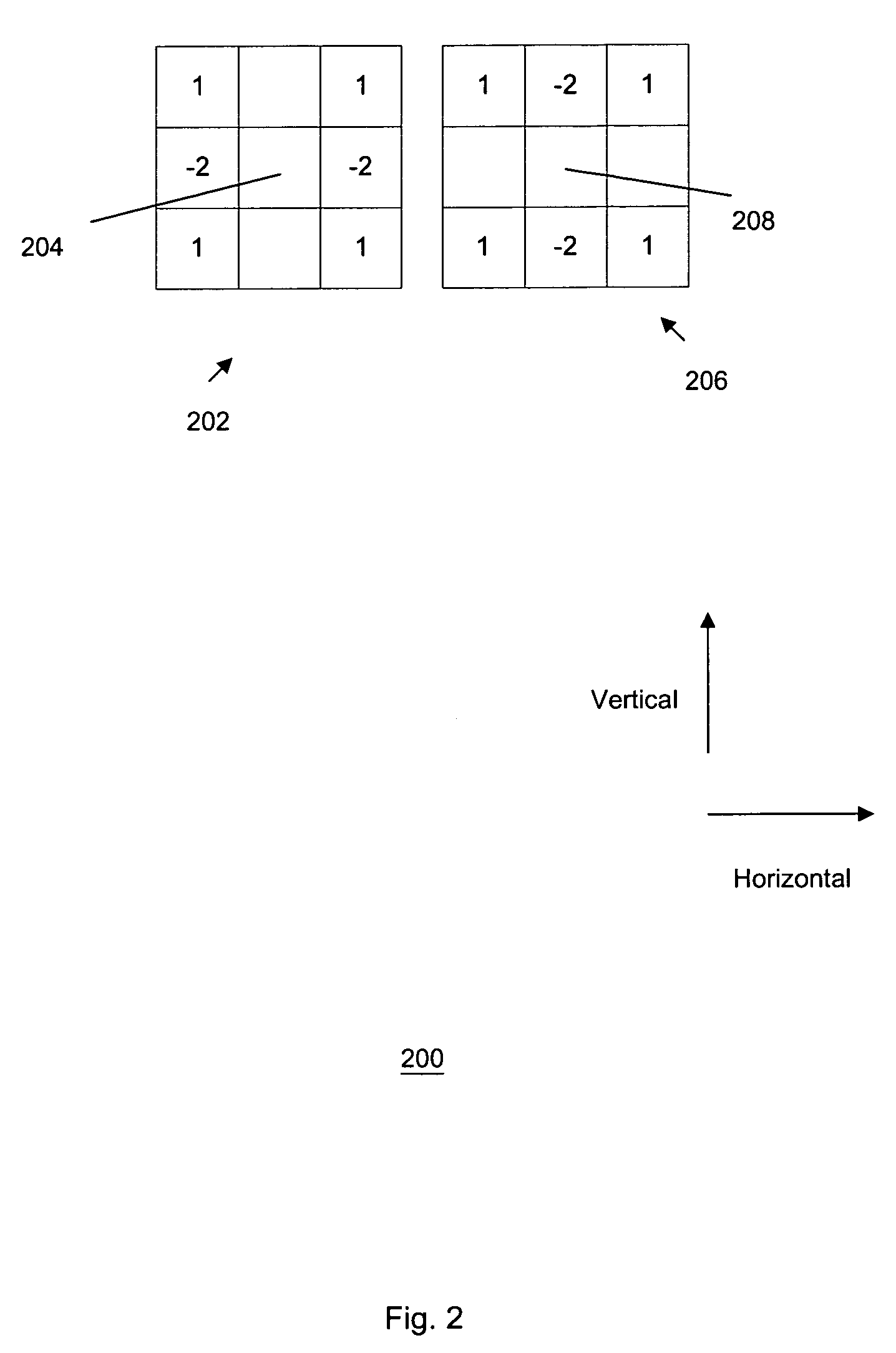

Estimation of block artifact strength based on edge statistics

InactiveUS20070237241A1Reduce removalImprove picture qualityTelevision system detailsPicture reproducers using cathode ray tubesPattern recognitionEdge based

Owner:SAMSUNG ELECTRONICS CO LTD

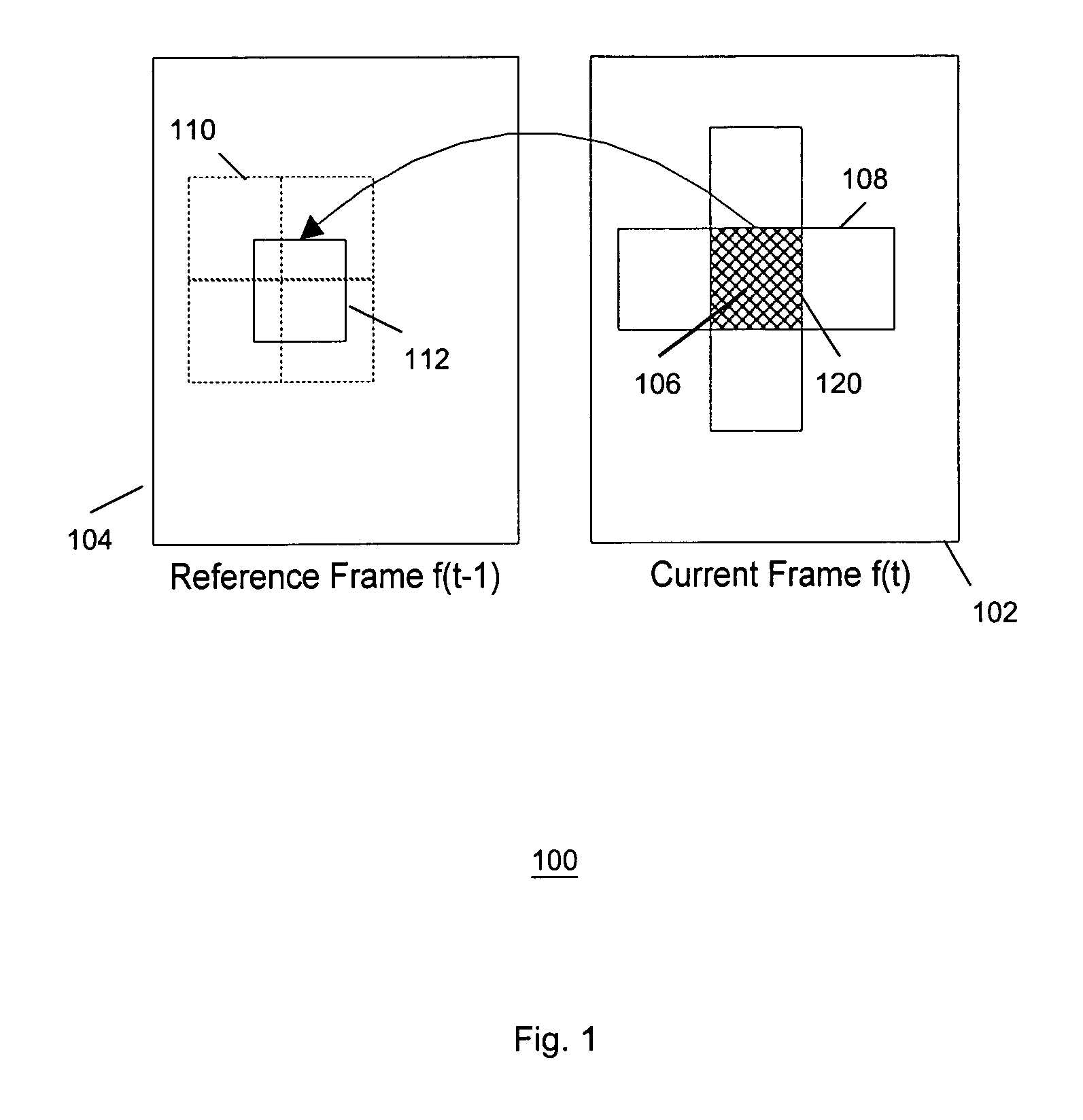

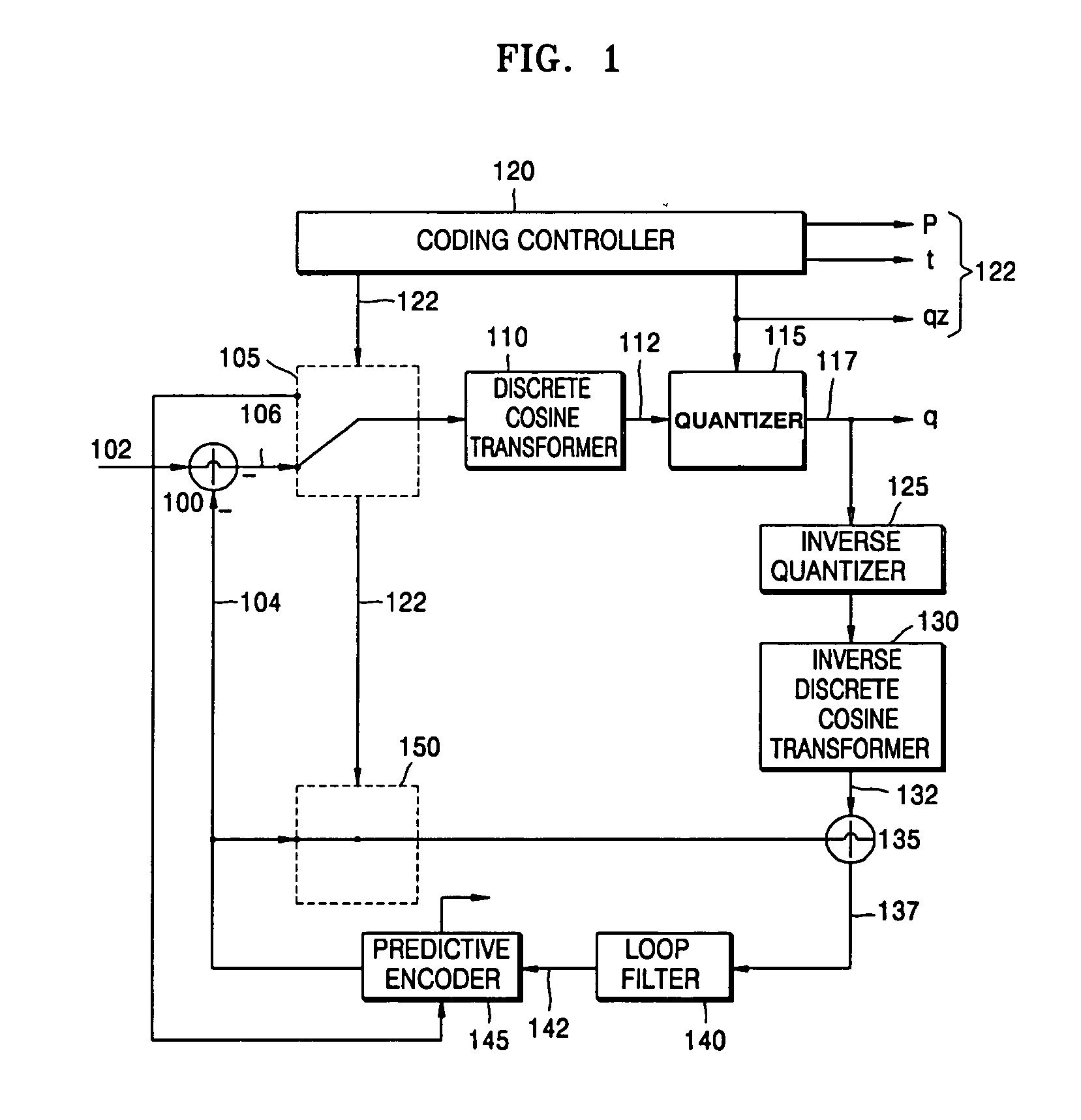

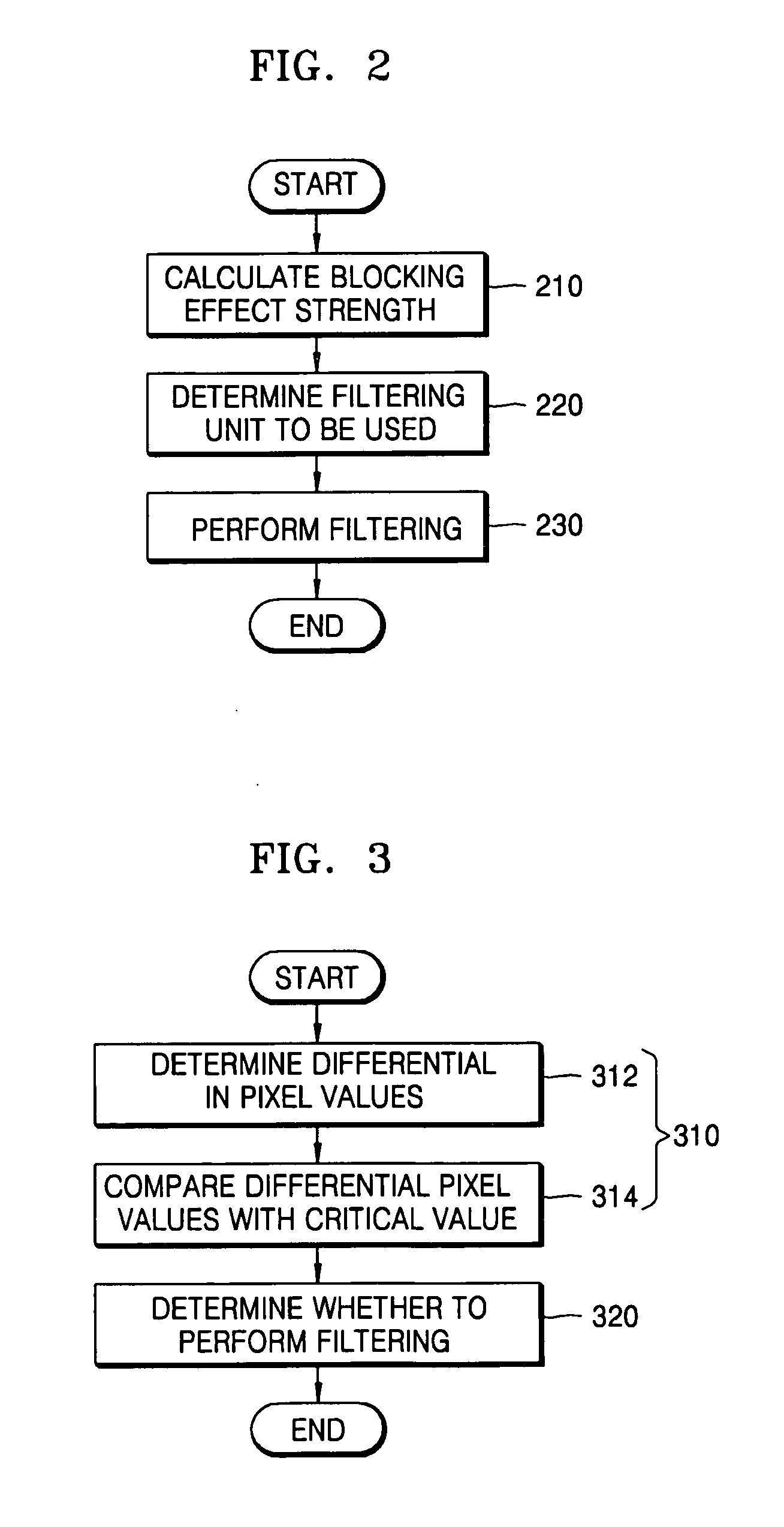

Loop filtering method and apparatus

A loop filtering method and apparatus are provided. The loop filtering method includes: calculating blocking effect strength based on coding type information, which specifies the coding type of a block to be filtered, a motion vector of the block, and reference frame information, which identifies a reference frame; determining a filtering unit to be used for filtering the block based on the calculated blocking effect strength; and performing filtering on the block using the determined filtering unit. Accordingly, it is possible to provide high-quality HDTV images by determining whether to perform loop filtering and adjusting the degree of loop filtering in consideration of the characteristics of HDTV images.

Owner:SAMSUNG ELECTRONICS CO LTD +1

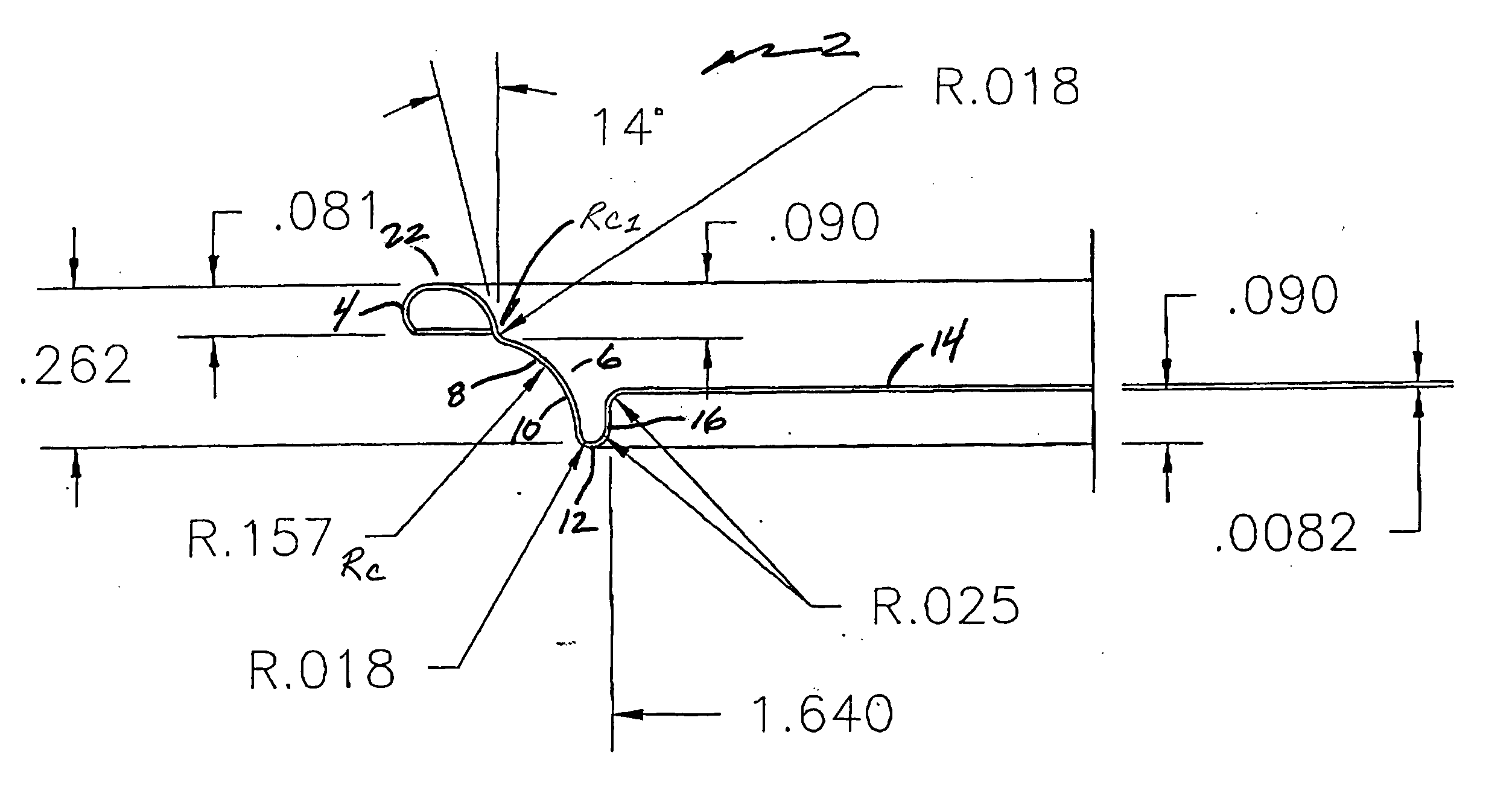

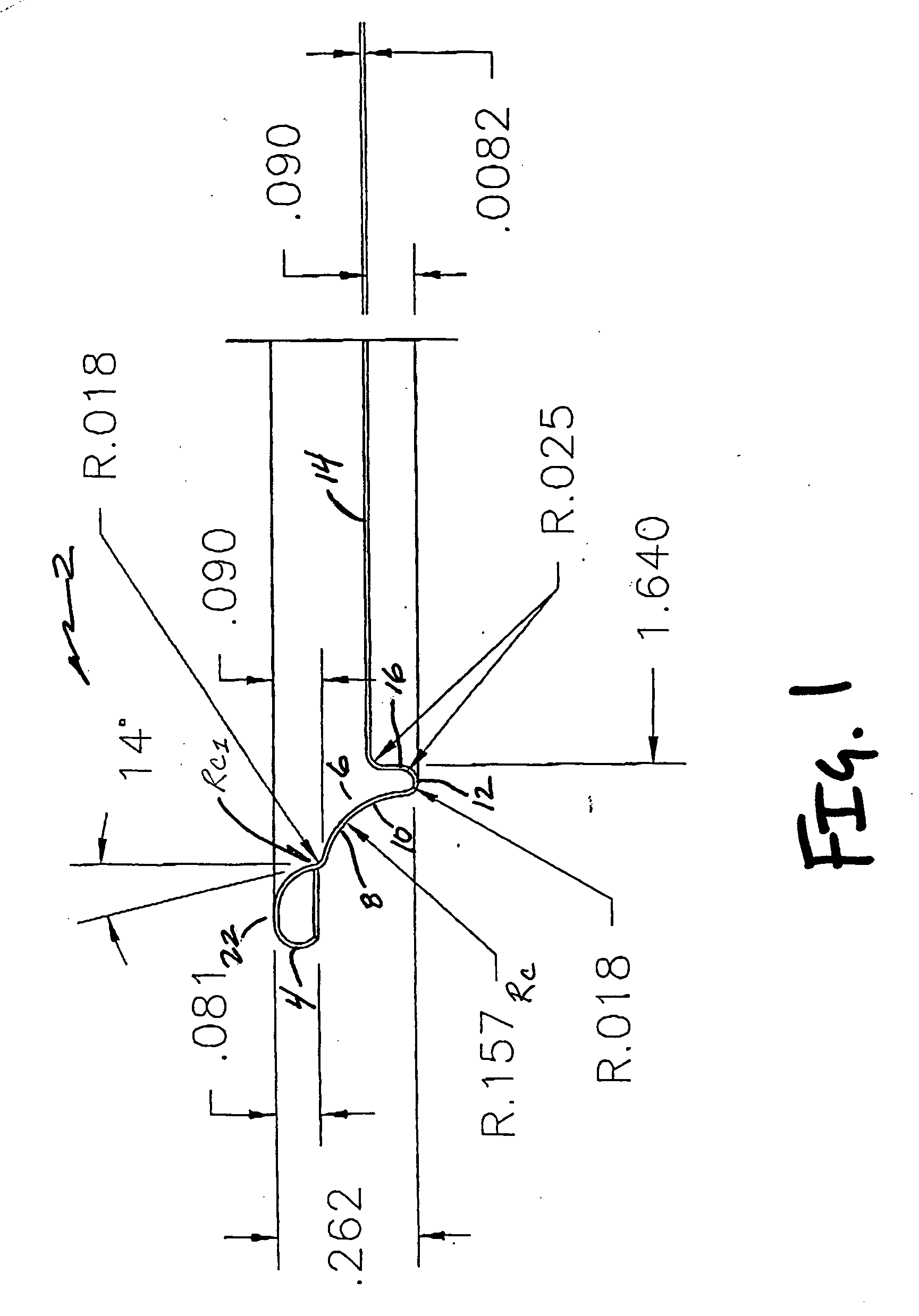

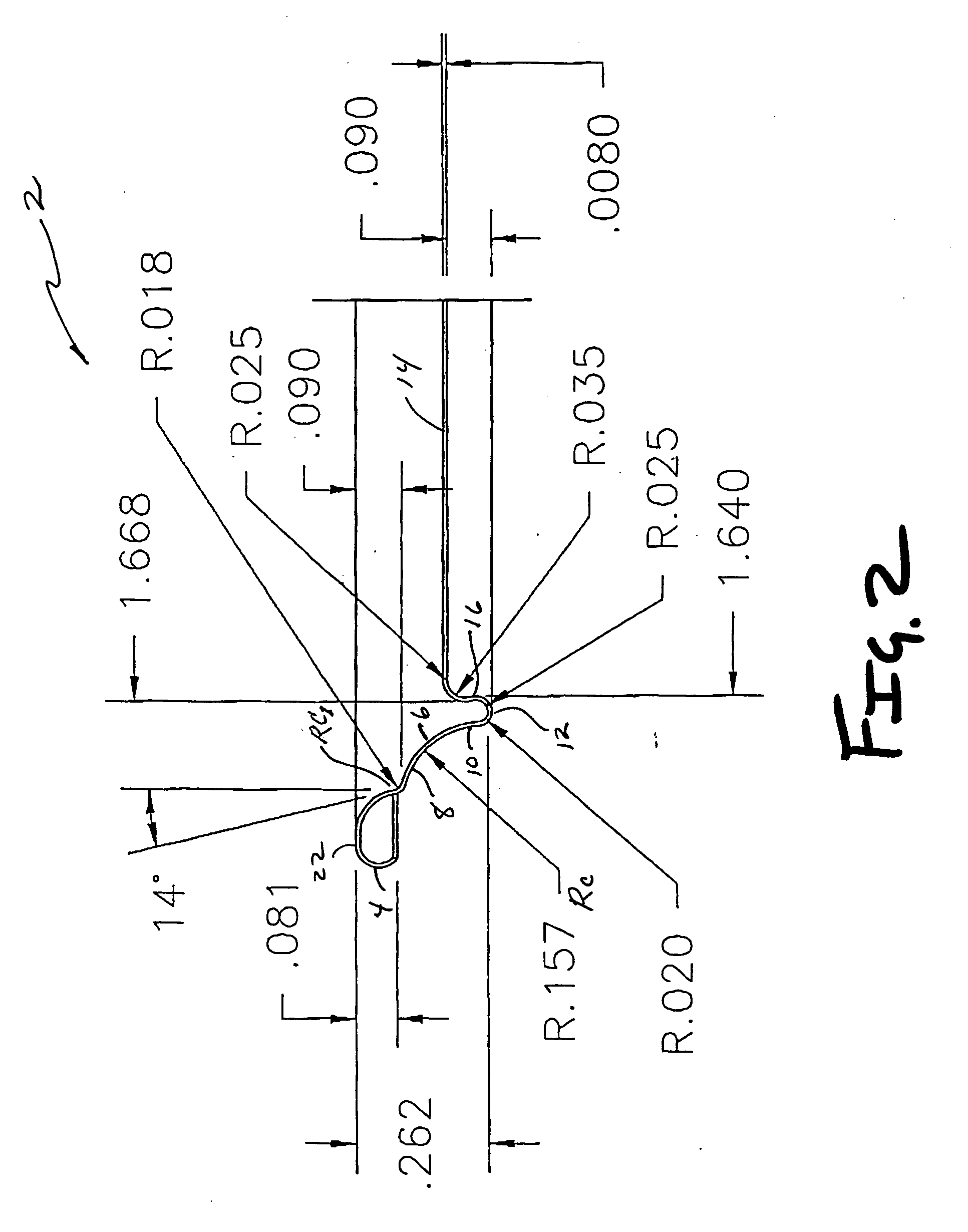

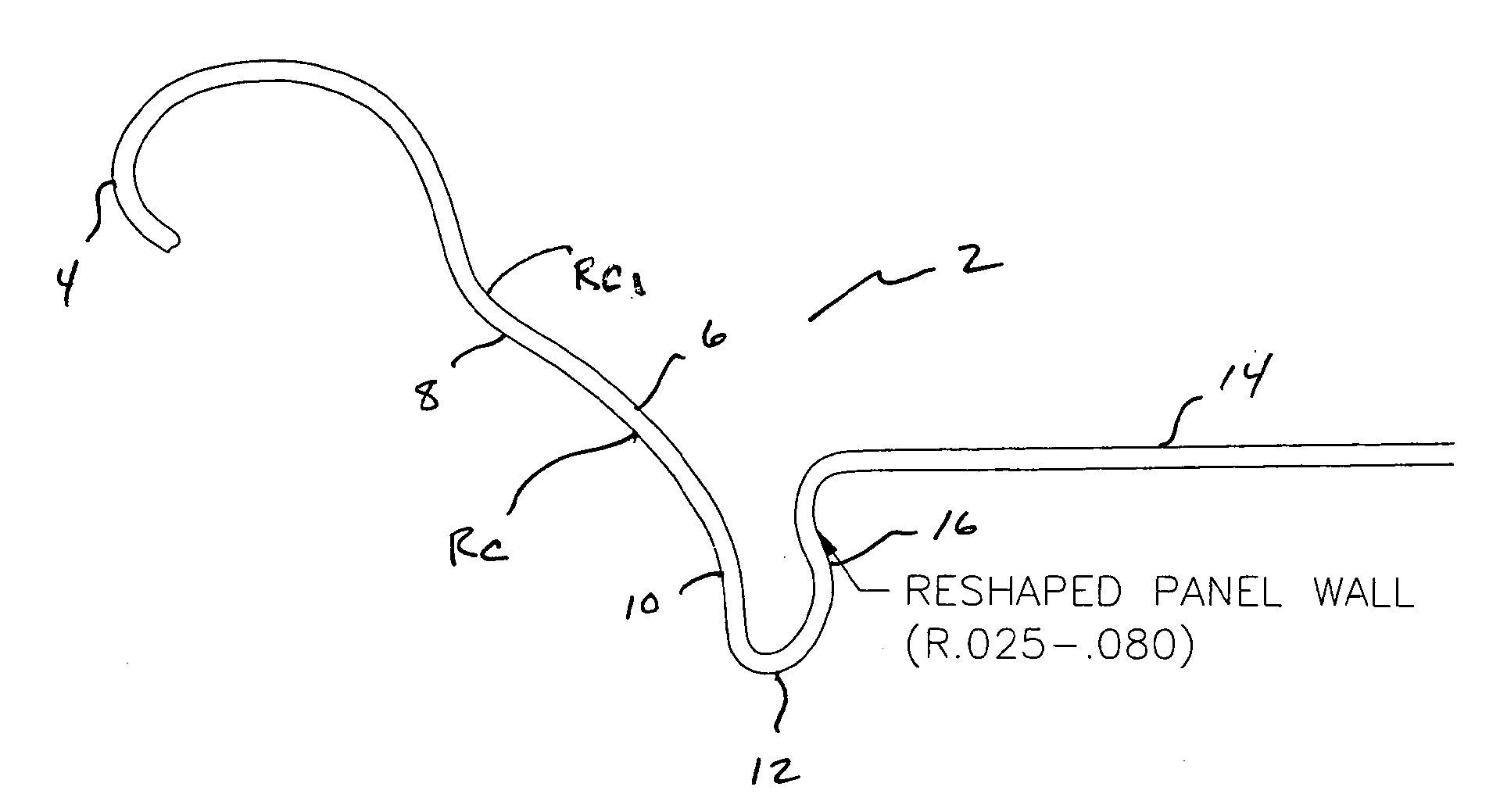

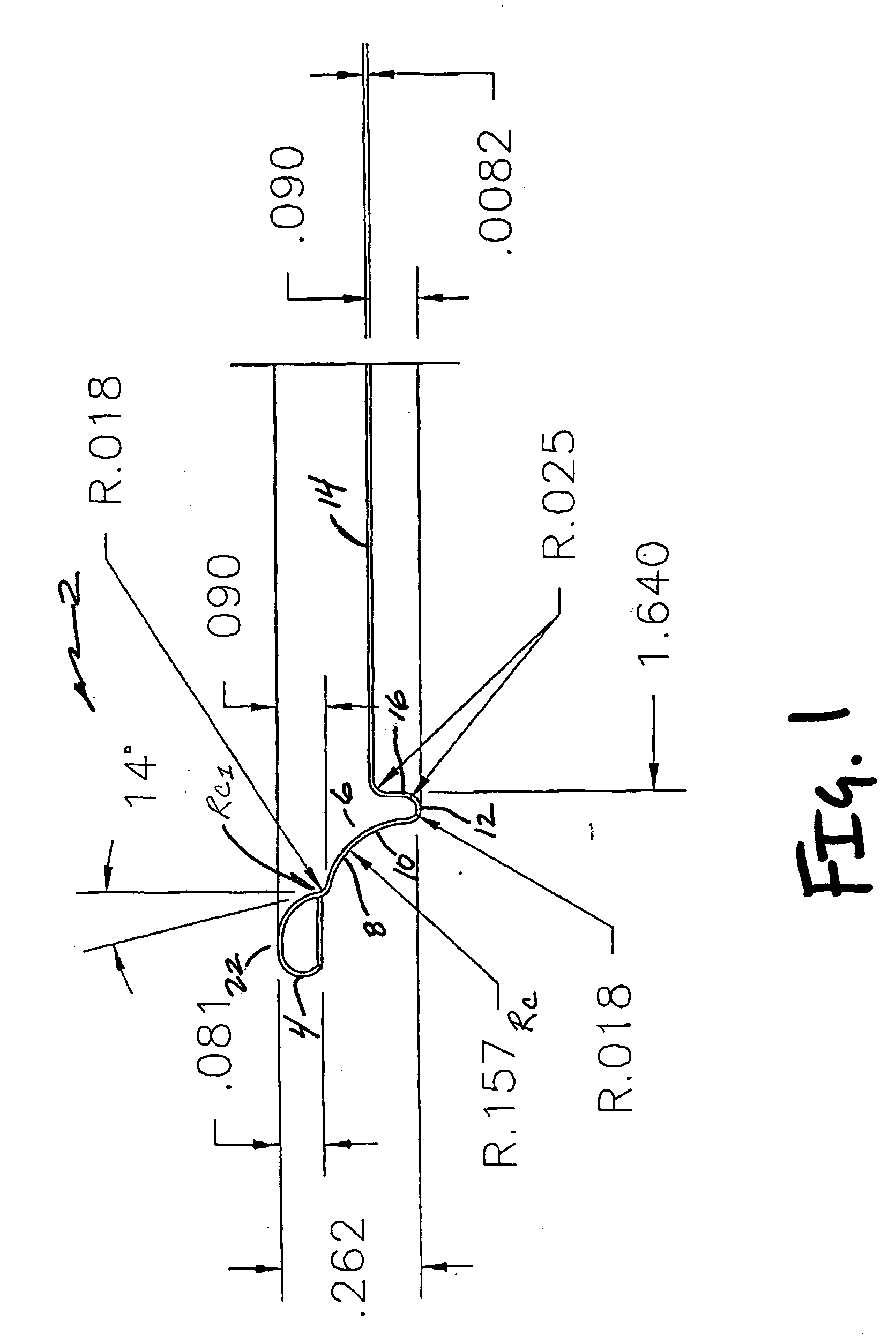

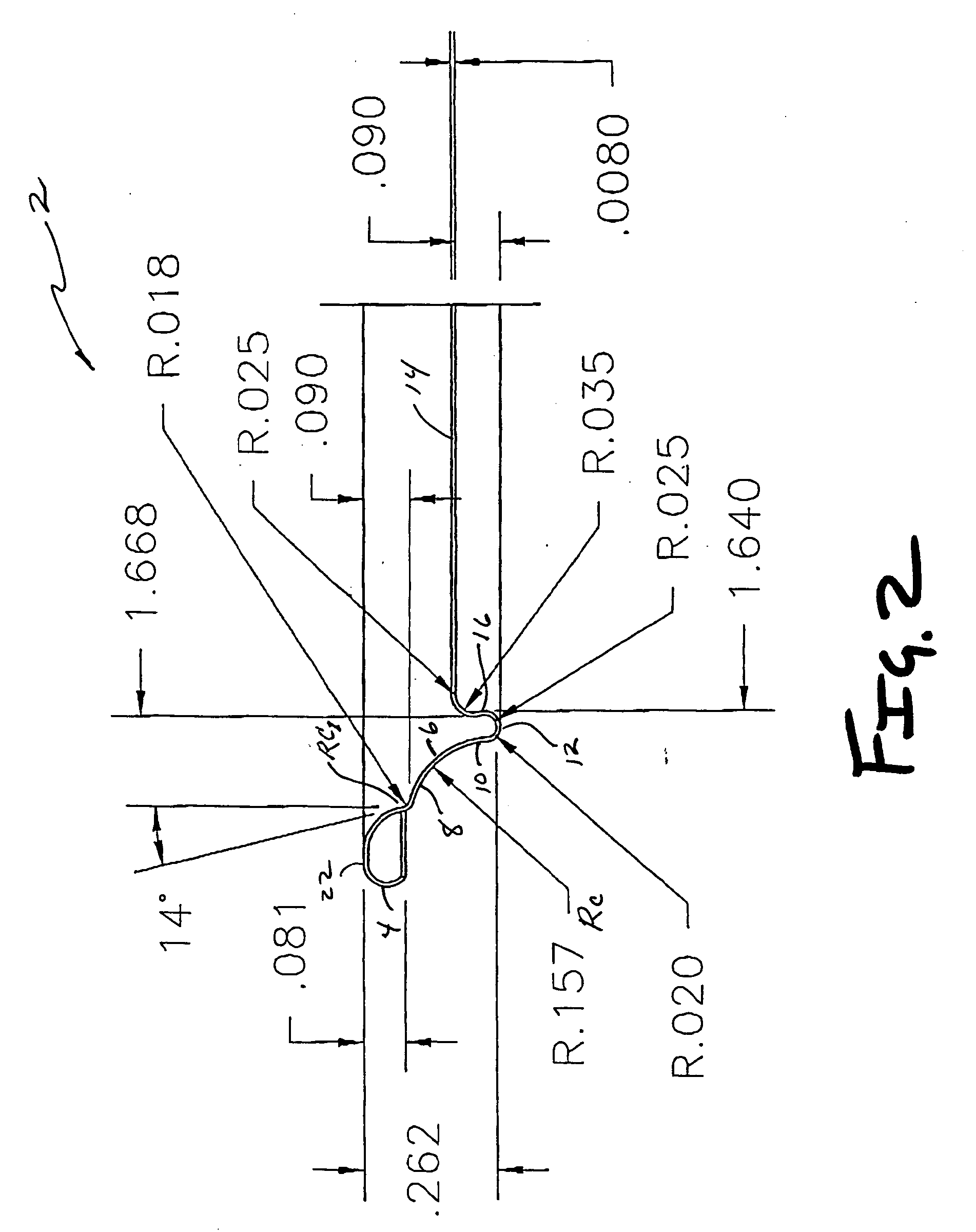

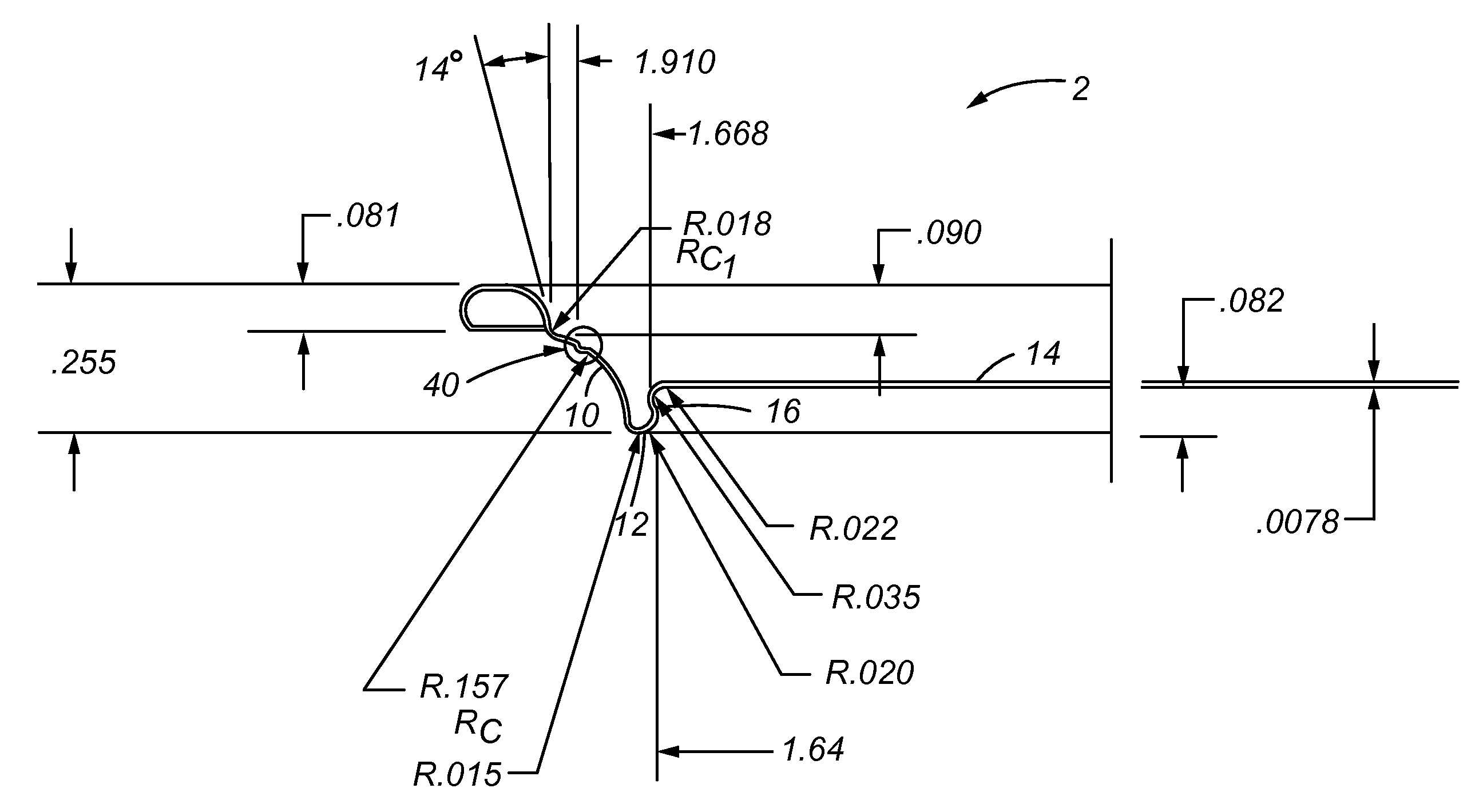

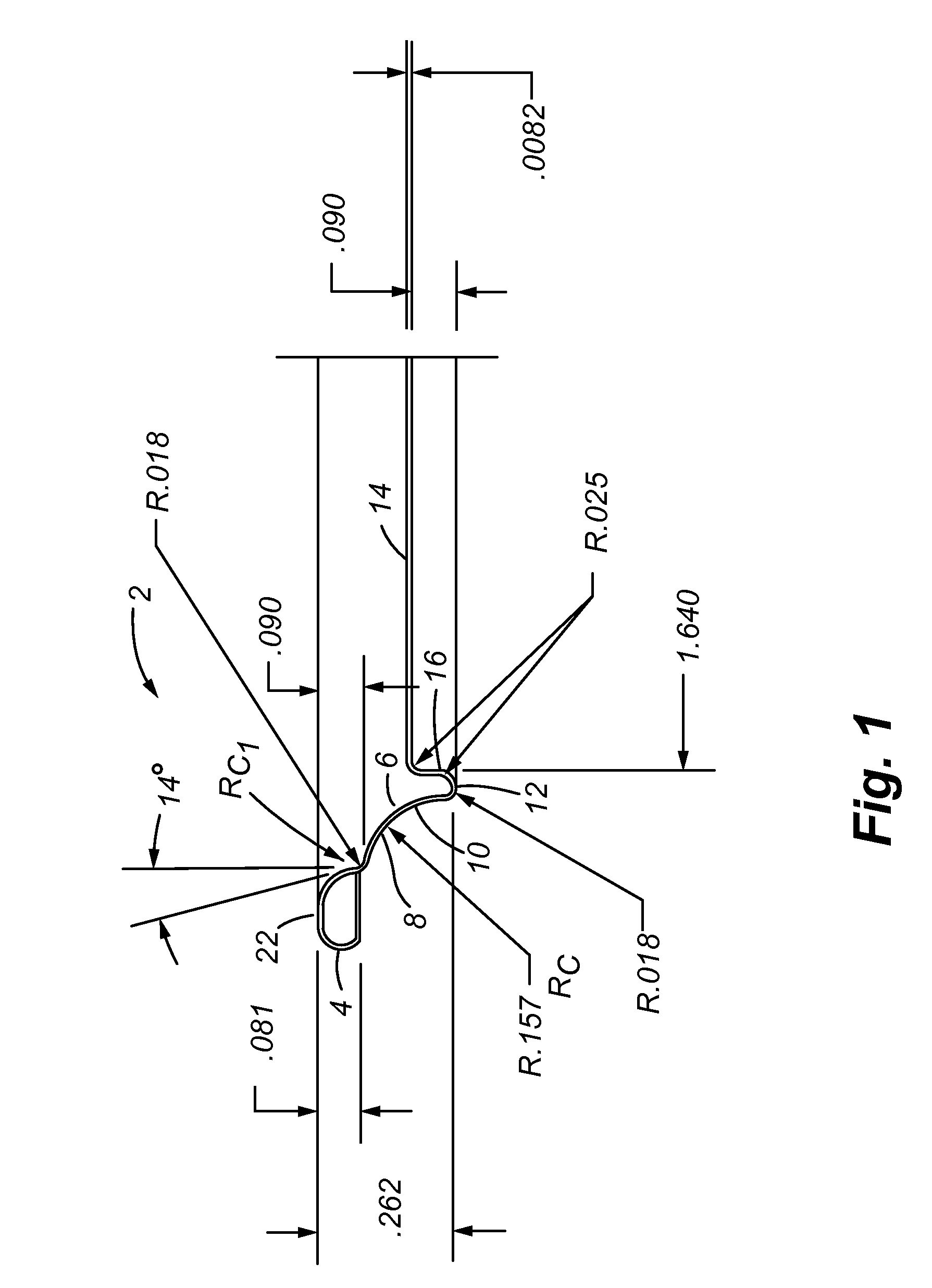

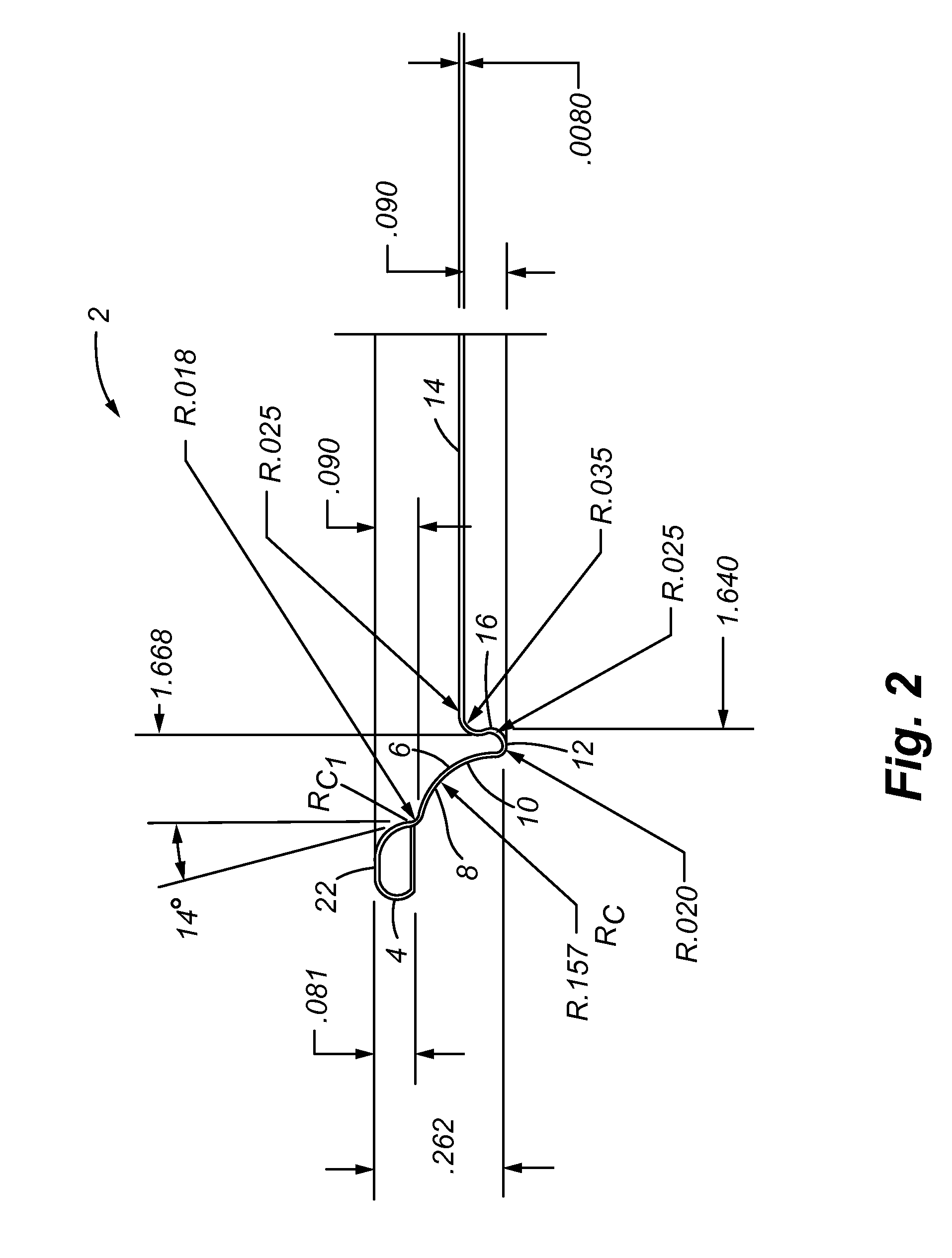

Container end closure with improved chuck wall and countersink

InactiveUS20060071005A1High strengthReduce material costsRefuse receptaclesRigid containersArcuate shapeStrengths based

The present invention describes a beverage can end which utilizes less material and has an improved internal buckle strength based on the geometric configuration of a chuck wall, inner panel wall and central panel, and which, in one embodiment utilizes an arcuate shaped chuck wall with a radius of curvature between about 0.150 inches and 0.250 inches with at least one transition zone positioned between an upper and lower end of the chuck wall.

Owner:BALL CORP

Filtering-wave method of removing blocking-effect in video-frequency picture and loop filter

InactiveCN1816149AQuality improvementReal-time encodingTelevision systemsDigital video signal modificationLoop filterPattern recognition

The method includes two parts: filtering decision and filtering execution. The filtering decision includes steps: based on pixels of received image and coding information to determine whether there is real edge existed on borderline of two adjacent small blocks; determining value of block effect of each two adjacent small blocks; there is one-to-one correspondence between different values of block effect and different filtering strengths. The filtering execution includes steps: not carrying out filtering operation for adjacent small blocks of containing real edge on borderline; carrying out filtering operation for adjacent small blocks of not containing real edge on borderline by using selected filtering method corresponding to filtering strength based on values of block effect. Filtering inputted video images, the disclosed method removes block effect caused by blocked encoding so as to raise quality of video image.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Method for testing tensile strength of fragile material

InactiveCN1621803AMaterial strength using tensile/compressive forcesSpecial data processing applicationsStress distributionDiameter ratio

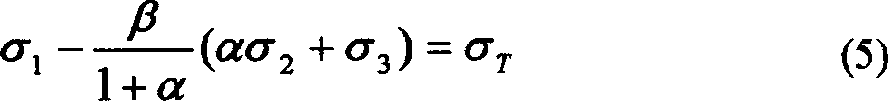

The present invention is platform Brazil sample test method of measuring the tensile strength of fragile material. By means of 3D elastic mechanical number analysis, the stress distribution regulation of the fragile material in different height / diameter ratio and different Poisson's ratio conditions may be obtained. Proper fragile material strength theory is selected and the cracking initiating from the end surface center line of the sample is stipulated as the effective damage, so as to obtain tensile strength calculation formulas for the test under different height / diameter ratio and different Poisson's ratio conditions. Based on the tensile strength calculation formulas, the material tensile strength based on the strength theory may be obtained through measuring the sample sizes, Poisson's ratio, damage load and compression strength.

Owner:喻勇

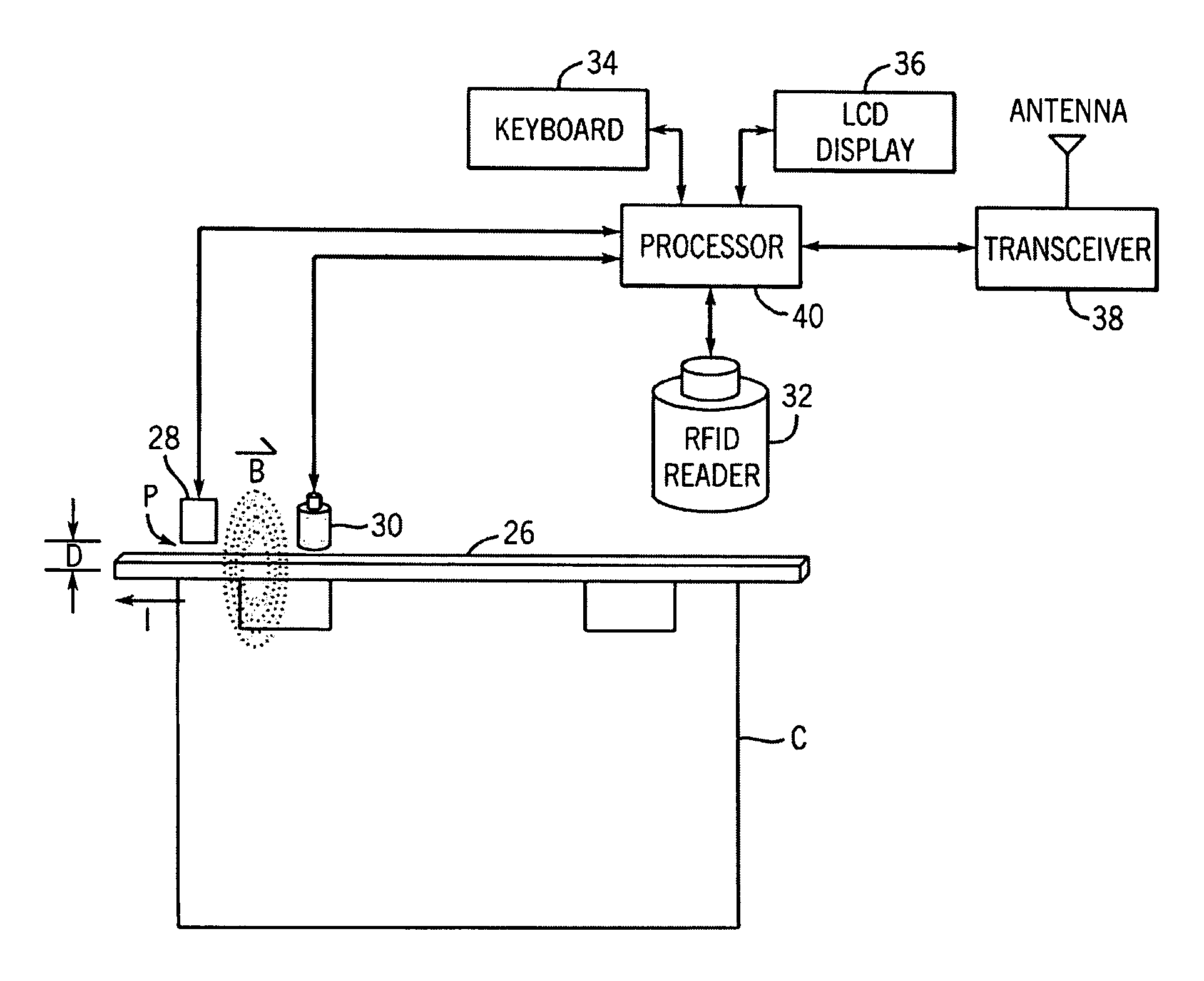

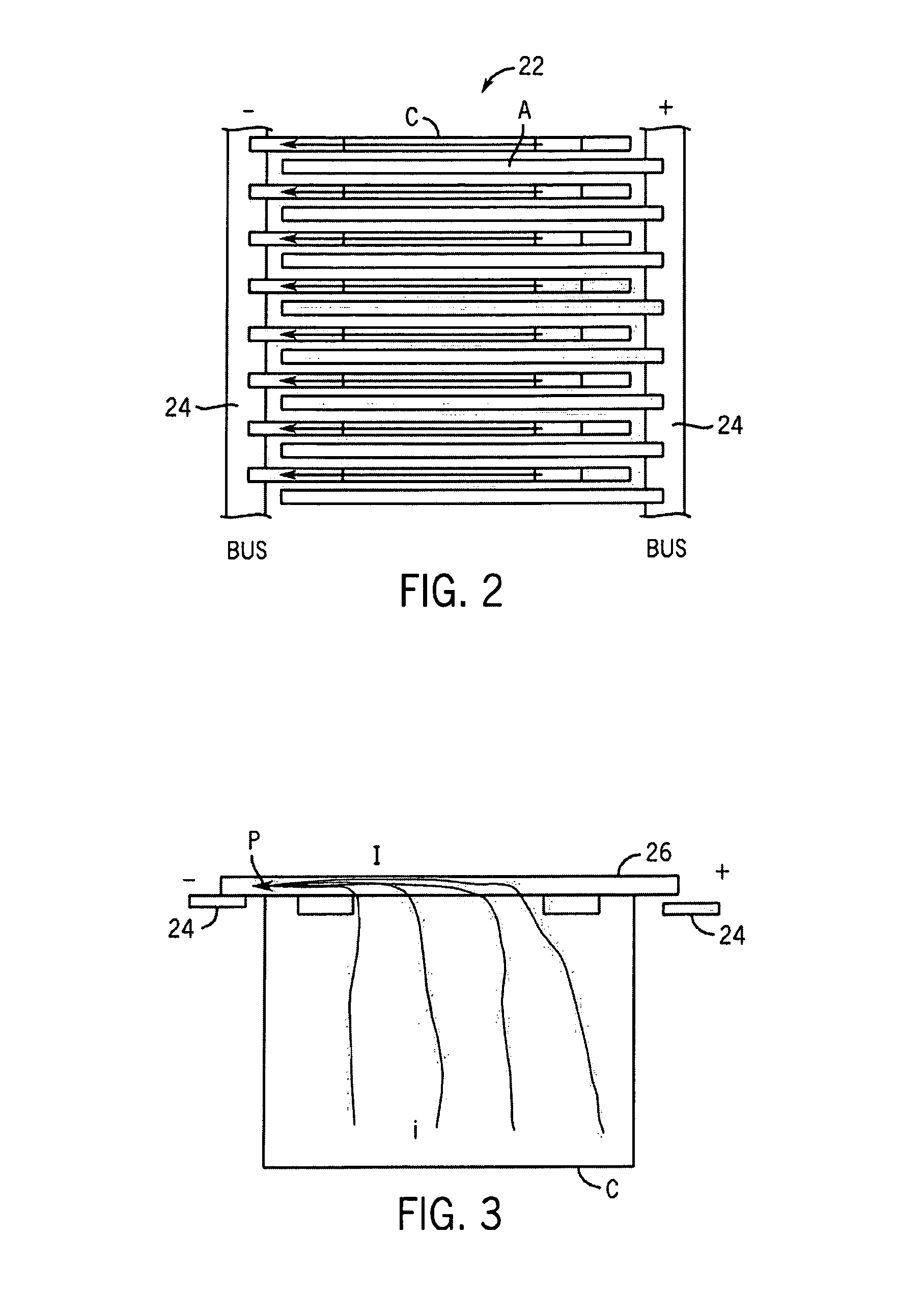

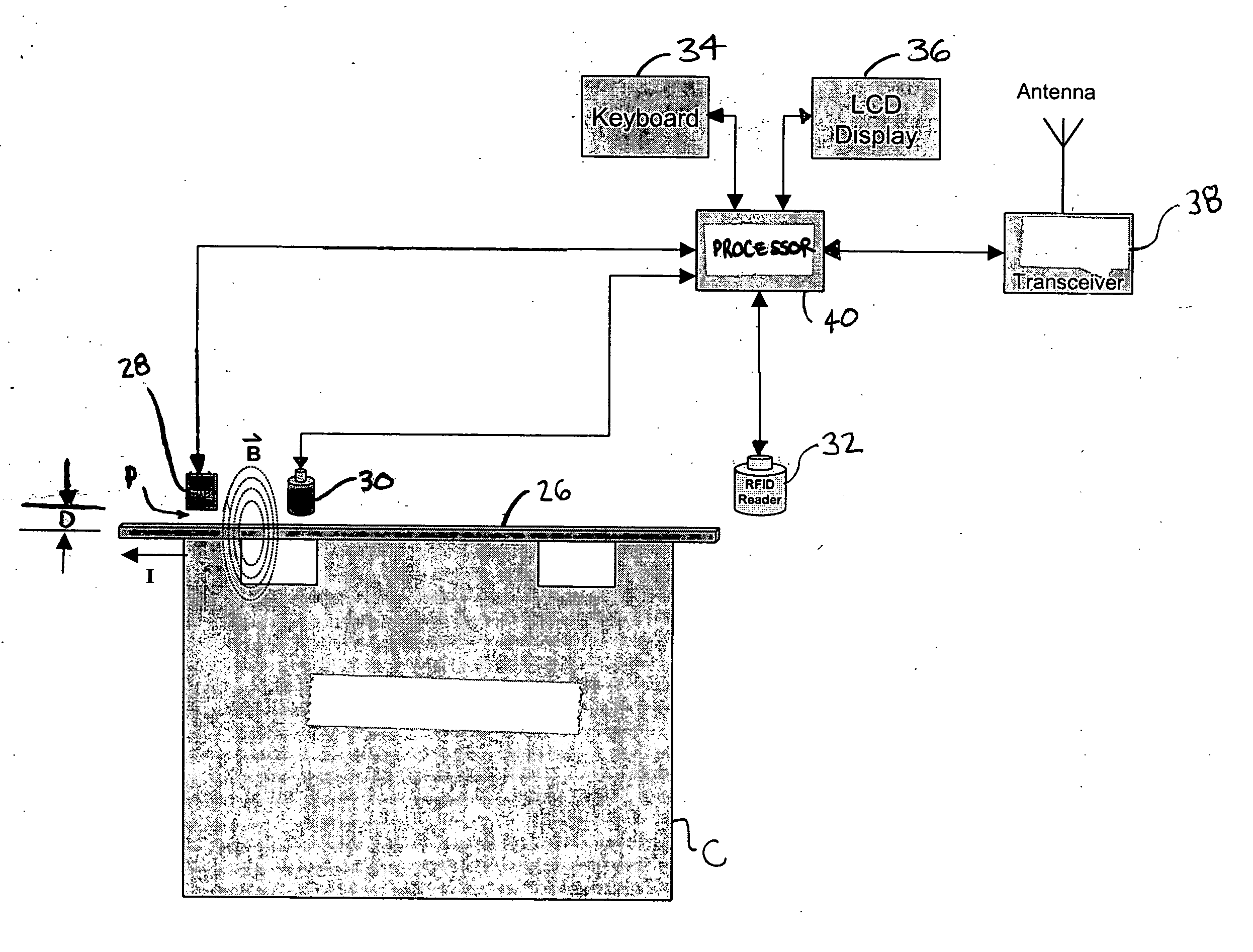

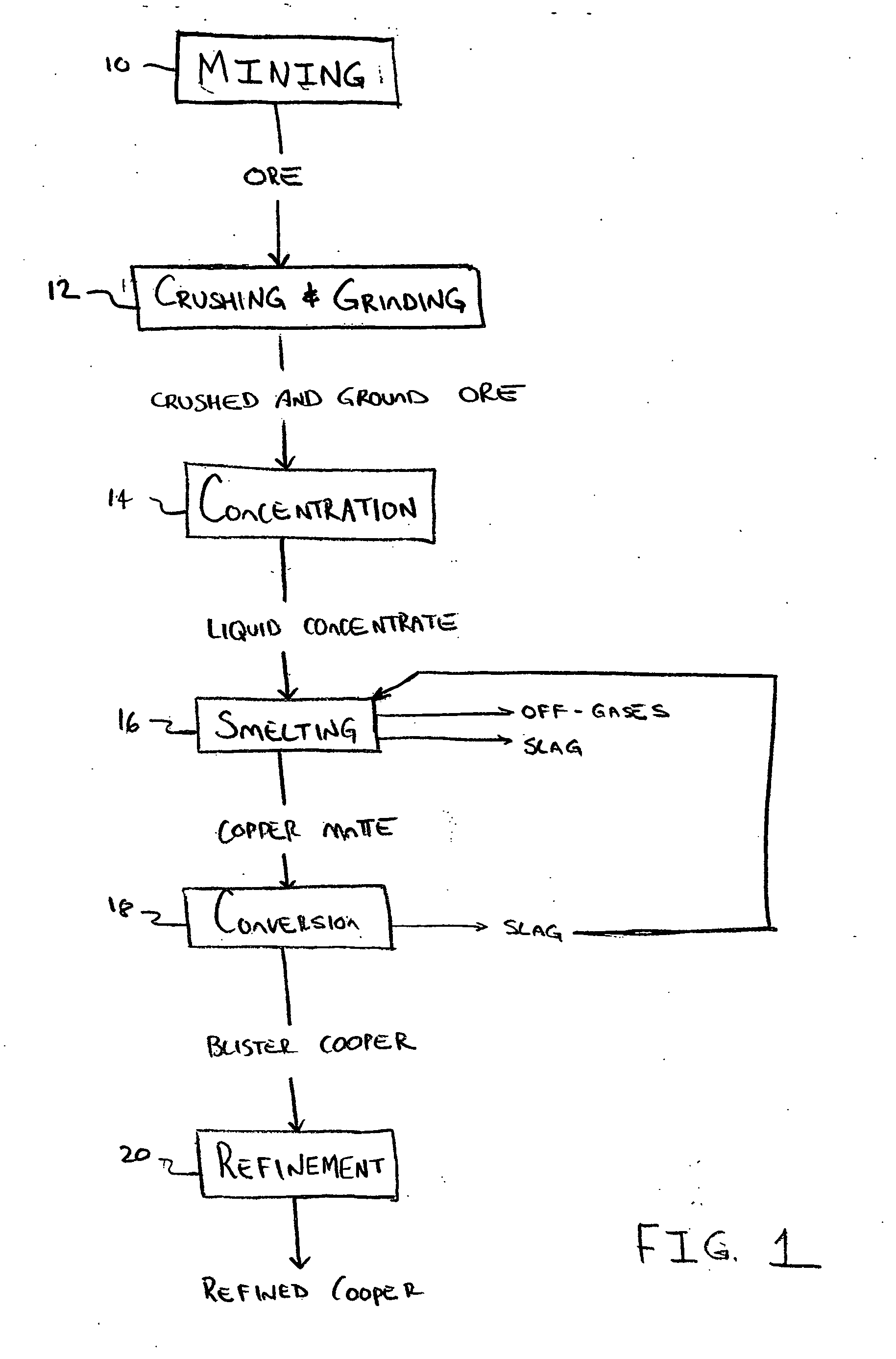

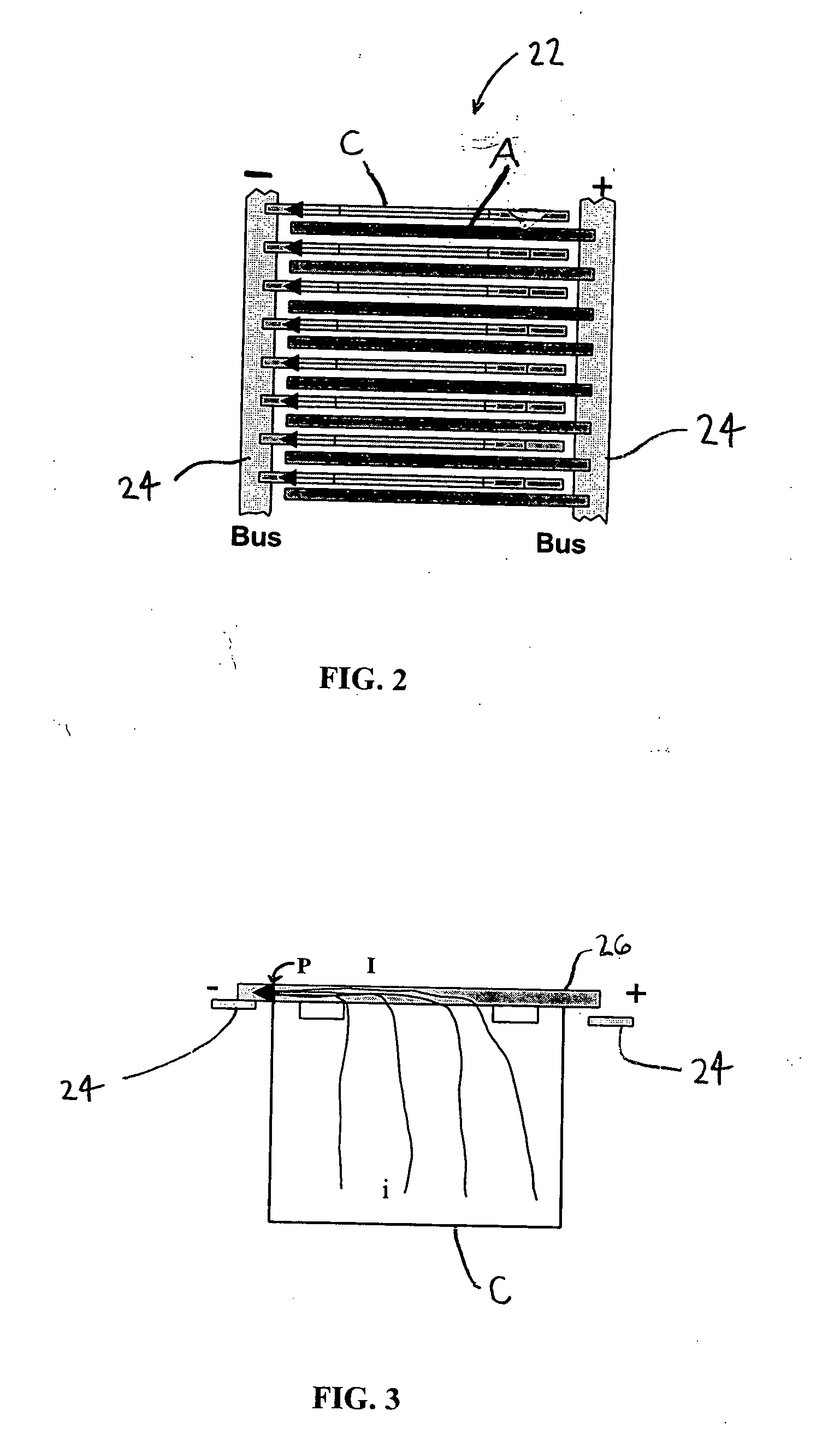

Monitoring electrolytic cell currents

For an electrolytic cell, an apparatus and method are described that use one or more sensors to measure magnetic field strength about a conductor carrying electrical current. A processor is in electrical communication with the sensors and determines a compensated magnetic field strength based on the magnetic fields of other conductors that also carry electrical current to or from the electrolytic cell. The processor uses this compensated magnetic field strength to determine the cathode electrical current carried by the conductor and to identify open and short circuits between the anodes and cathodes of the cell. The described apparatus and method account for interactions between the magnetic fields of the neighboring cathodes.

Owner:KENNECOTT UTAH COPPER

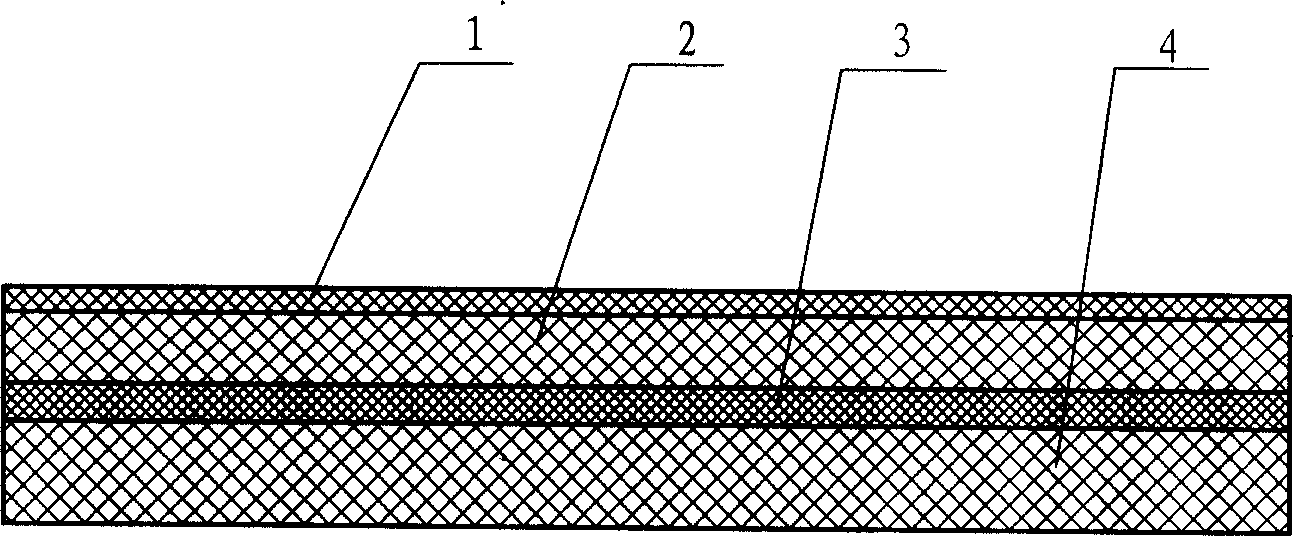

Anti-splitting paster and preparation method thereof

InactiveCN100999893AHigh viscoelasticityLow temperature flexiblePaving detailsRoads maintainencePolymer modifiedBituminous materials

The anticracking patch includes protecting film layer, upper coating layer, high strength base layer and lower coating layer arranged successively from the top to the bottom. Both the upper coating layer and the lower coating layer are made of polymer modified asphalt material comprising asphalt 48-58 wt%, SBS 5-10 wt%, tackifying resin 7-13 wt%, engine oil 4-8 wt%, rubber powder 9-11 wt%, tackifying petroleum resin 1-3 wt% and intensifier 3-13 wt%. The present invention is industrially produced and has excellent anticracking and waterproofing functions.

Owner:BAIHE INT HIGHWAY SCI & TECH HENAN

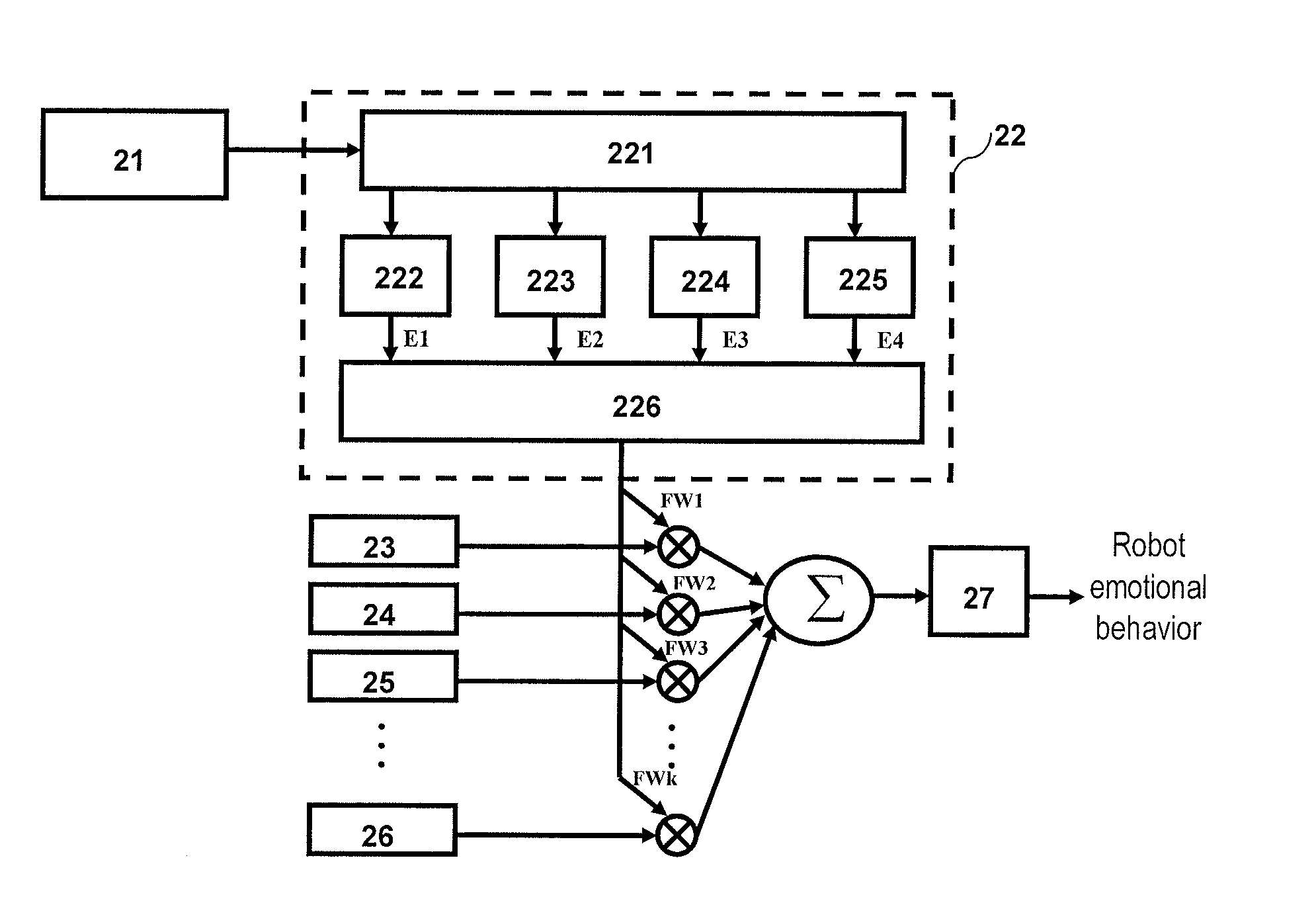

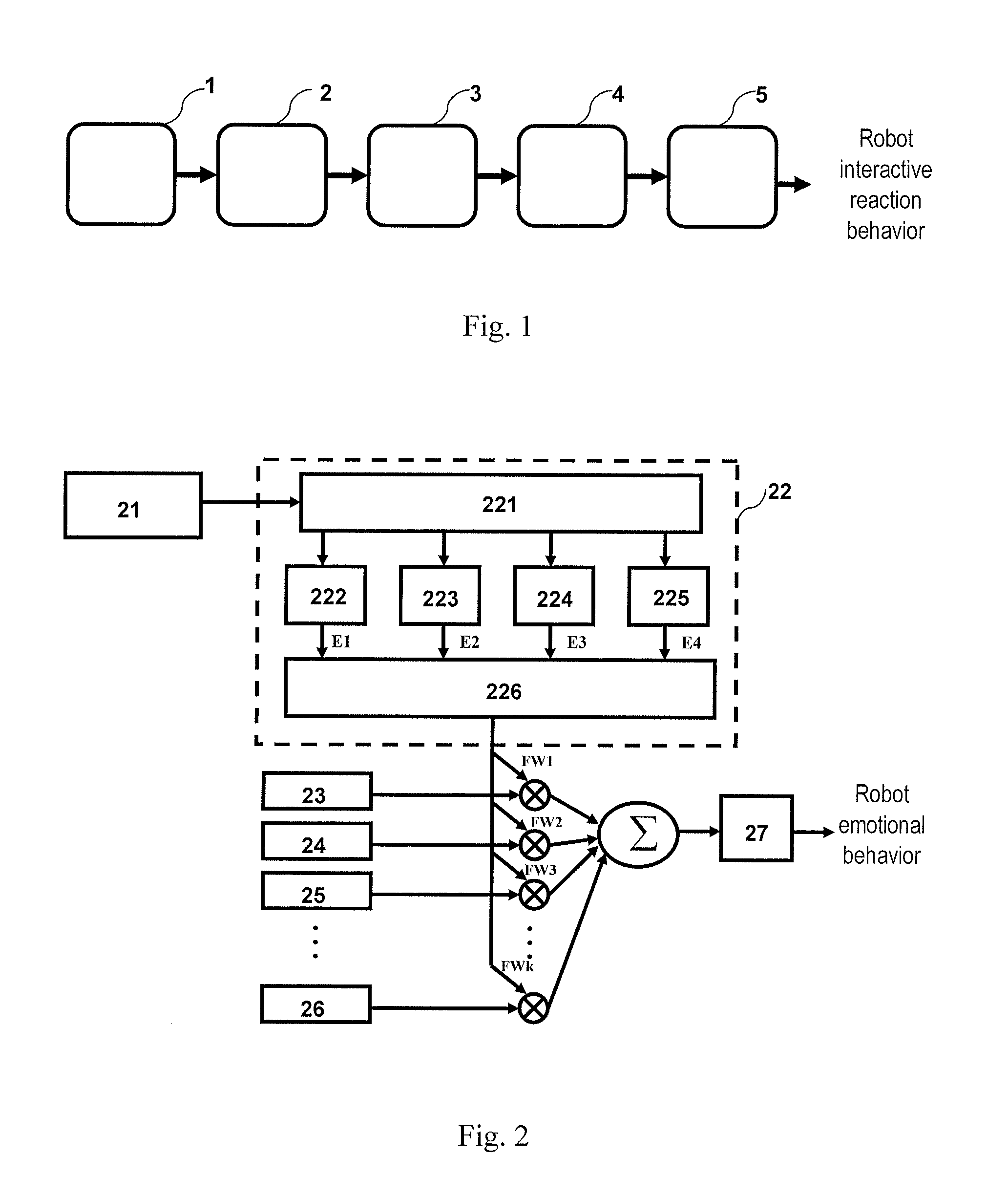

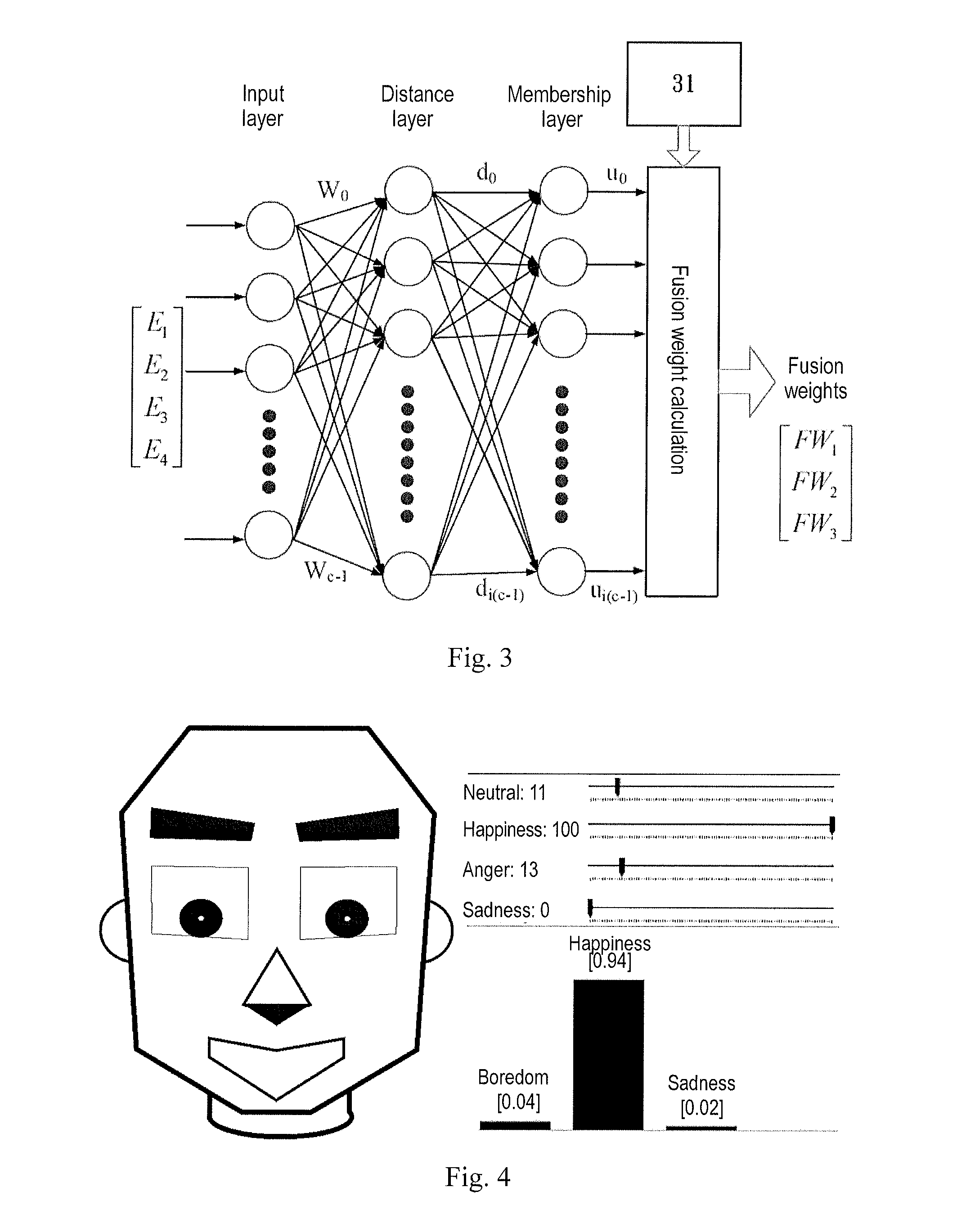

Device and method for expressing robot autonomous emotions

InactiveUS20110144804A1Human-robot interactive effect more decentProgramme-controlled manipulatorComputer controlHuman–computer interactionStrengths based

A device for expressing robot autonomous emotions comprises: a sensing unit; a user emotion recognition unit, recognizing current user emotional states after receiving sensed information from the sensing unit, and calculating user emotional strengths based on the current user emotional states; a robot emotion generation unit, generating robot emotional states based on the user emotional strengths; a behavior fusion unit, calculating a plurality of output behavior weights by a fuzzy-neuro network based on the user emotional strengths and a rule table; and a robot reaction unit, expressing a robot emotional behavior based on the output behavior weights and the robot emotional states.

Owner:NAT CHIAO TUNG UNIV

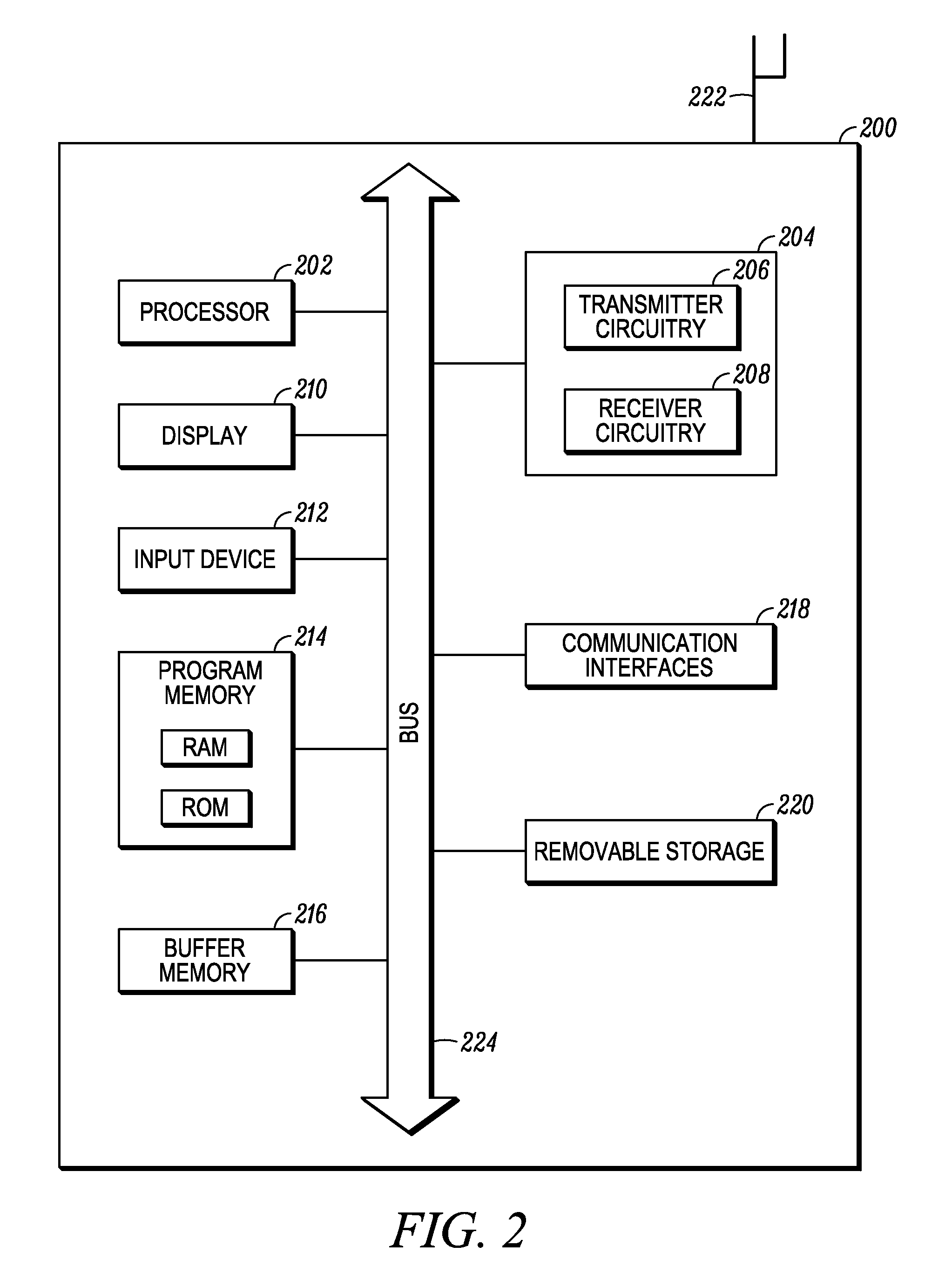

Method for database driven channel quality estimation in a cognitive radio network

A method of determining operating parameters for a secondary system transmitter is described. The transmitter characteristics, including location and operating frequency band, are provided to a geo-location database. The database determines the maximum allowable transmission power that meets various specifications for different channels and conveys the power and channel(s) to the transmitter. The database estimates channel incumbent signal strengths based on the transmitter location and primary and higher-priority secondary incumbent systems, estimates the splatter levels, determines whether adjacent and co-channel interference protection ratios are met, and adjusts the allowable power level accordingly. The database also estimates aggregate co- and adjacent channel primary and secondary incumbent system interference levels at the transmitter location and predicts channel quality for each allowable channel. The estimated levels are updated using measurements of actual levels at the transmitter location. The database dynamically allocates channels using the secondary system priorities.

Owner:MOTOROLA SOLUTIONS INC +1

Monitoring electrolytic cell currents

For an electrolytic cell, an apparatus and method are described that use one or more sensors to measure magnetic field strength about a conductor carrying electrical current. A processor is in electrical communication with the sensors and determines a compensated magnetic field strength based on the magnetic fields of other conductors that also carry electrical current to or from the electrolytic cell. The processor uses this compensated magnetic field strength to determine the cathode electrical current carried by the conductor and to identify open and short circuits between the anodes and cathodes of the cell. The described apparatus and method account for interactions between the magnetic fields of the neighboring cathodes.

Owner:KENNECOTT UTAH COPPER

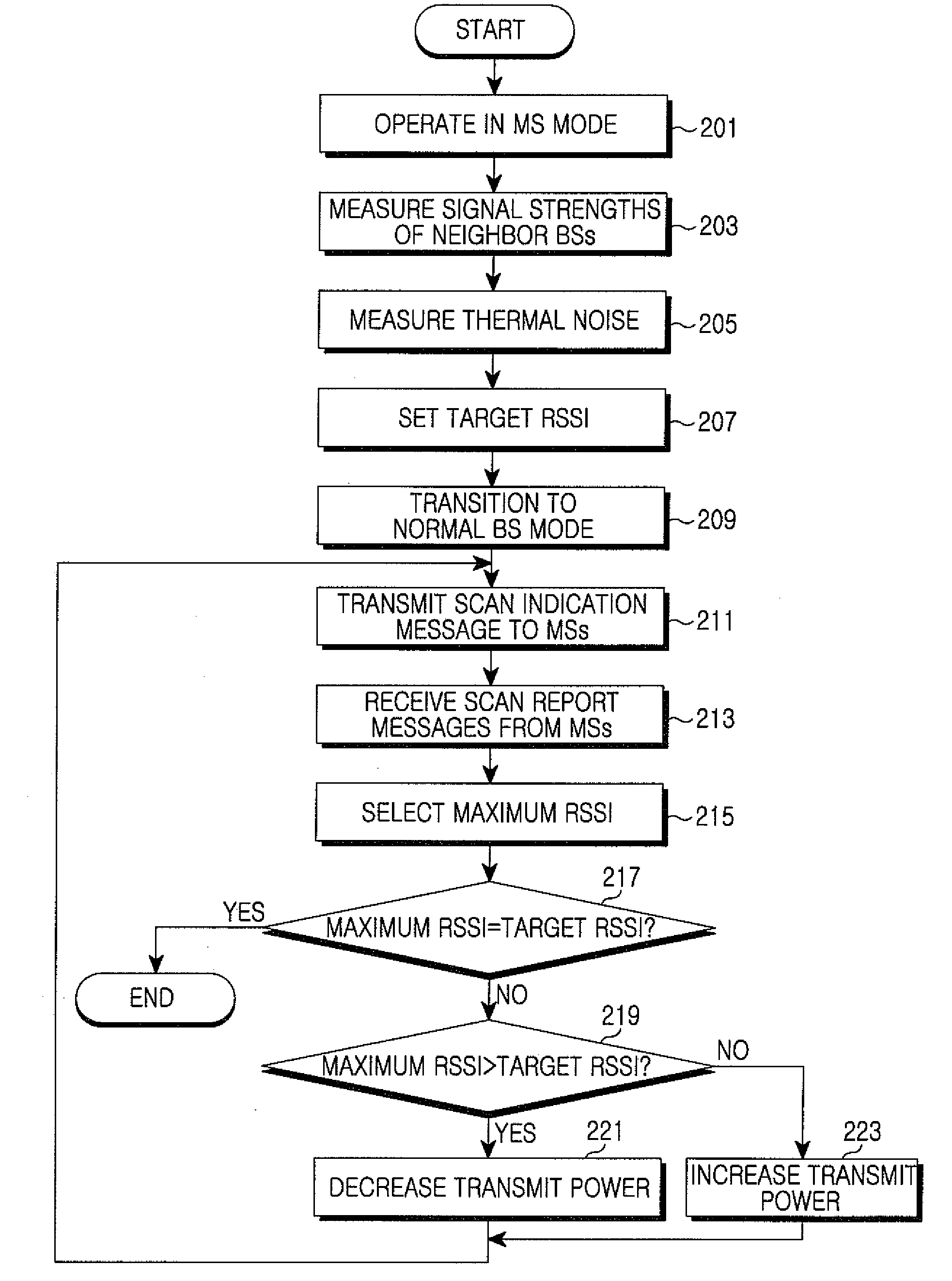

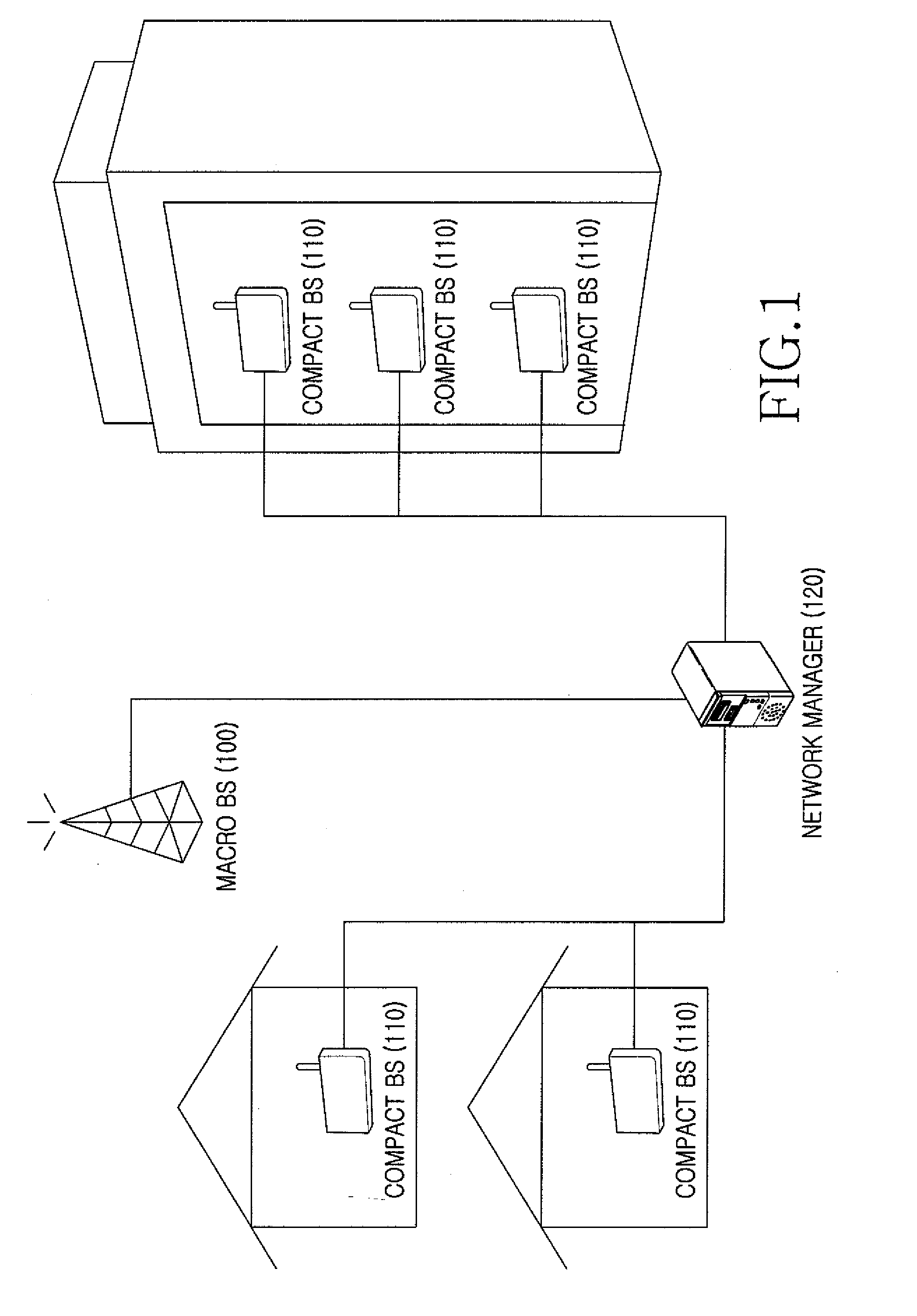

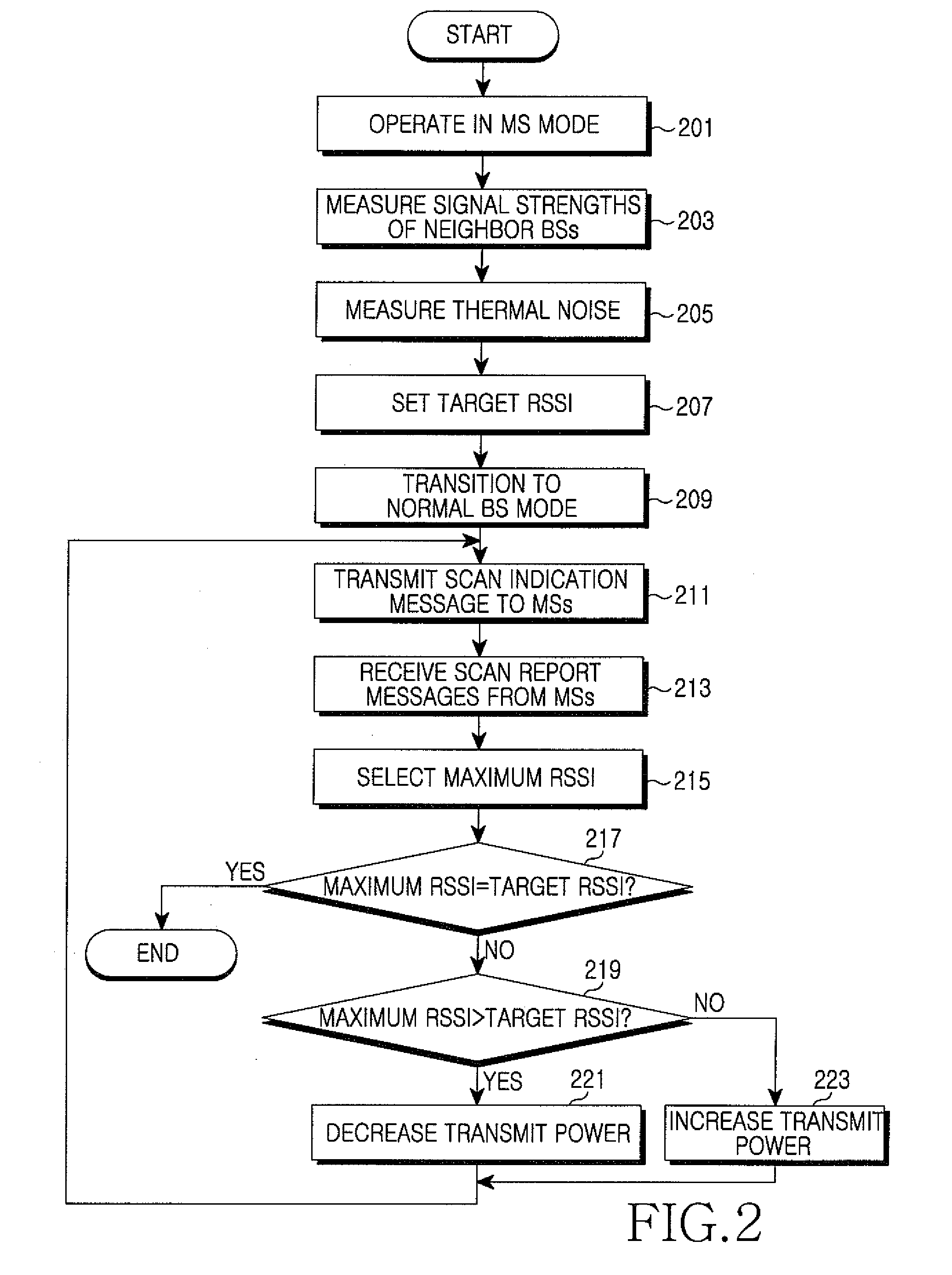

Apparatus and method for setting transmit power of a compact base station in a wireless communication system

ActiveUS20090005105A1Efficient settingsPower managementRadio transmissionCommunications systemTransmitted power

An apparatus and method for setting transmit power of a compact Base Station (BS) in a wireless communication system are provided. In the apparatus and method a measurer measures a signal strength corresponding to each of one or more neighbor BSs while operating in a Mobile Station (MS) mode, a receiver receives a signal strength corresponding to each of the one or more neighbor BSs measured by one or more MSs from the corresponding one or more MSs, and a self-configuration controller sets a target signal strength based on the signal strength corresponding to each of the one or more neighbor BSs measured in the MS mode and controls a transmit power so that the signal strength corresponding to each of the one or more neighbor BSs measured by the one or more MSs substantially reaches the target signal strength.

Owner:SAMSUNG ELECTRONICS CO LTD

Container End Closure With Improved Chuck Wall and Countersink

ActiveUS20090020543A1Eliminate needQuickly and effectively initiate the productionClosuresRefuse receptaclesArcuate shapeUltimate tensile strength

Owner:BALL CORP

Fight simulation system generating military strength based on computer and simulation method

InactiveCN106682351ADesign optimisation/simulationSpecial data processing applicationsTerrainHuman behavior

The invention provides a fight simulation system generating military strength based on a computer and a simulation method and relates to the technical field of simulative training in battlefields. The fight simulation system comprises a data inputting module, a data analysis module and an output evaluation module. The flight simulation method comprises the following steps that during system initialization, path planning of different scenes, tactics strategies and character and terrain cooperating relation are input, and a planning algorithm and information of an operator are input; after initialization data is input, an experimental data analysis and system modeling stage is executed; after data modeling, the data is output to evaluate the model, earnings and price are calculated to ratiocinate whether the proportion of the earnings to the price is reasonable or not, and results are output. By conducting enough modeling on human behaviors, a CGF can automatically make response on events and states in a simulative battlefield environment without human interaction, and possible results in real fights can be simulated.

Owner:北京捷安申谋军工科技有限公司

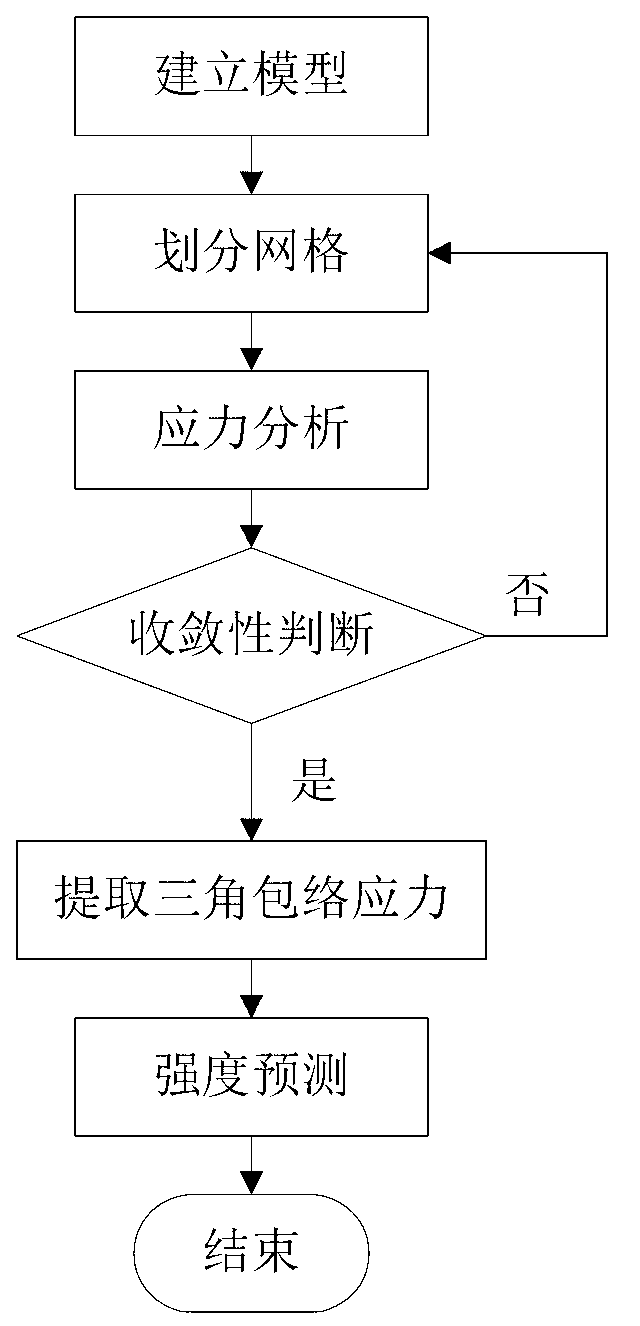

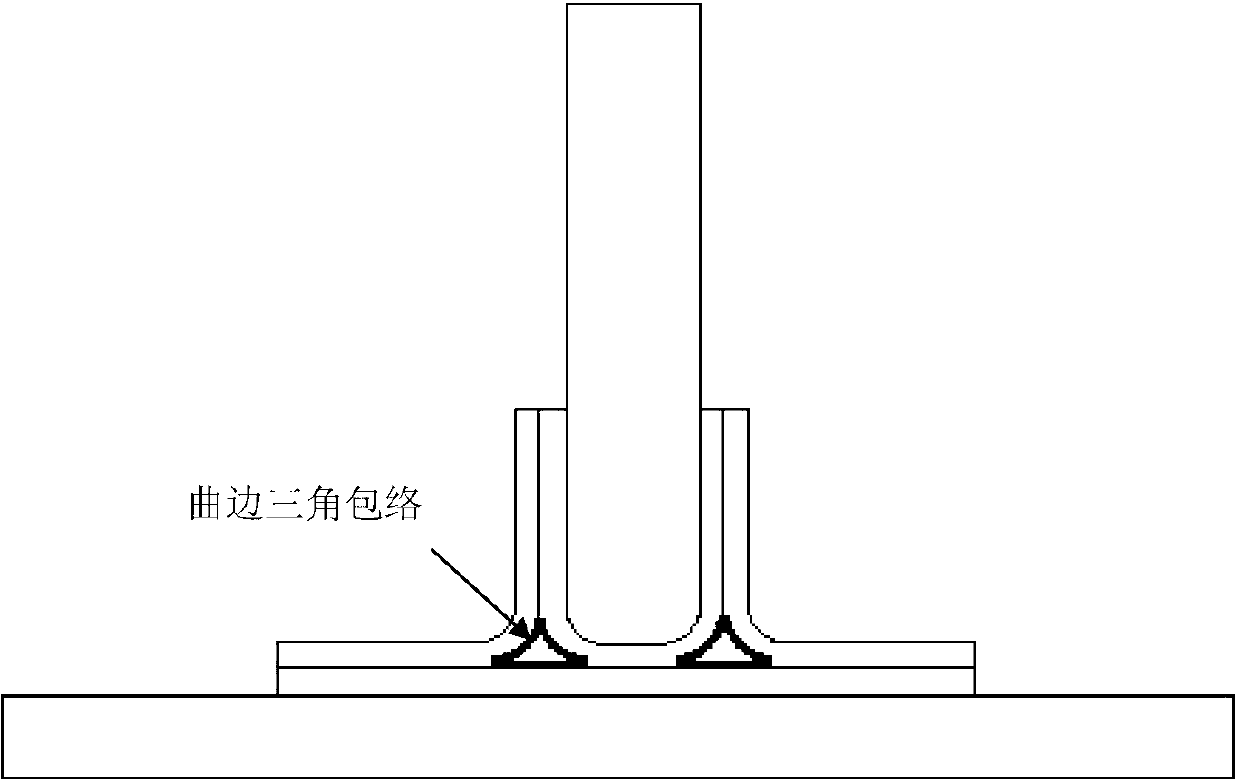

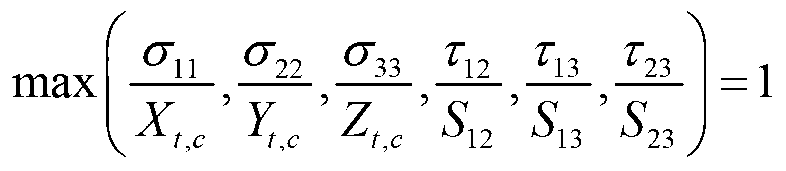

Method for predicating composite material Pi-shaped non-planar glue joint strength based on triangular envelopes

InactiveCN103345545AImprove consistencyGuaranteed prediction accuracySpecial data processing applicationsElement modelPredictive methods

The invention relates to a method for predicating composite material Pi-shaped non-planar glue joint strength based on triangular envelopes. The method includes the following steps that (1), according to parameters of a composite material Pi-shaped non-planar glue joint structure, a geometrical model is established; (2), according to actual working conditions of the composite material structure, loads and boundary conditions of the Pi joint geometrical model are determined; (3), grid partition is performed on the joint geometrical model, and a Pi joint three-dimensional finite element model is obtained; (4), on the basis of the Pi joint three-dimensional finite element model, a finite element stress analysis is performed; (5), according to the linear finite element stress analysis result, a curved edge triangular envelope route of a Pi negative moment steel padding region is set on the basis of the Pi joint three-dimensional finite element model, all stress component values on the curved edge triangular envelope route are extracted, and the average value of the stress component values is calculated and substituted to the failure criterion for predicating the strength. The method for predicating the composite material Pi-shaped non-planar glue joint strength based on the triangular envelopes is suitable for engineering application and can obviously shorten a development cycle and reduce experimentation cost.

Owner:BEIHANG UNIV

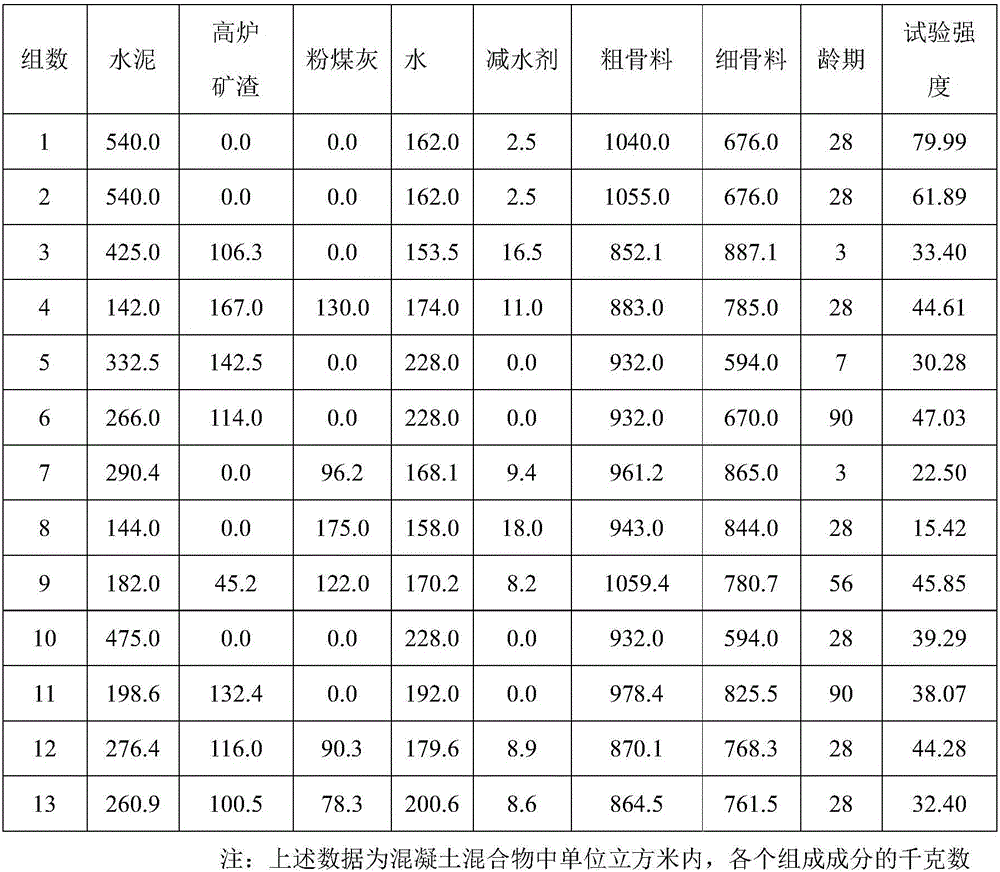

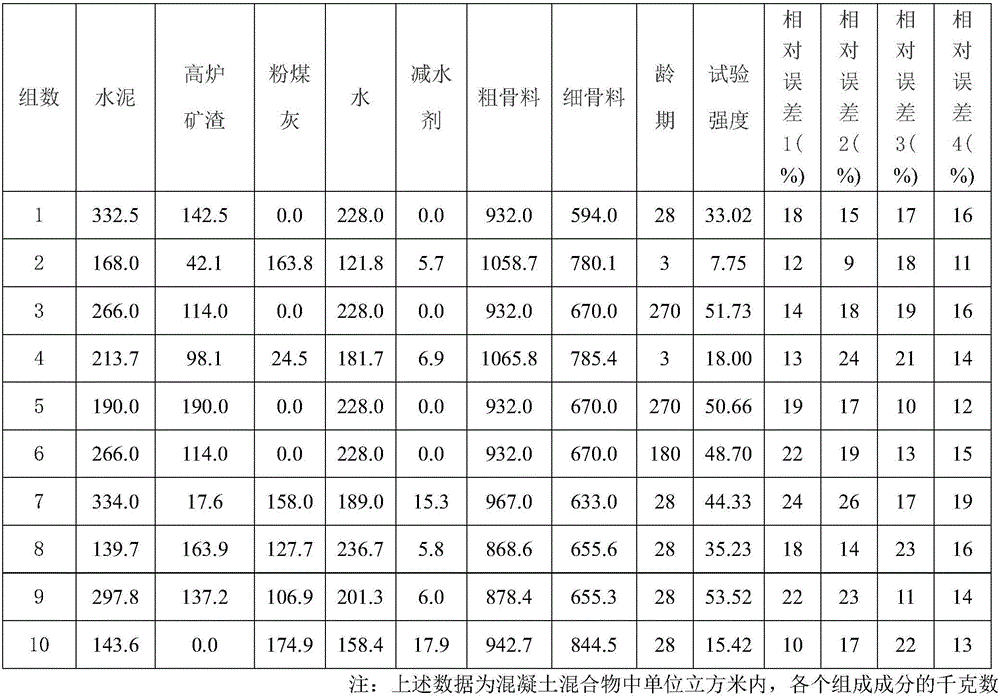

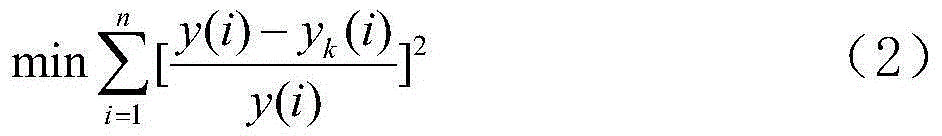

Method for predicting concrete strength based on hybrid model

ActiveCN104991051ASolve the problem that strength testing requires cumbersome, time-consuming, labor-intensive, and labor-intensive manual testingSolve the problem of cumbersome and time-consuming consumables and labor-intensive manual test detectionMaterial testing goodsSlagMixing ratio

The invention discloses a method for predicting the concrete strength based on a hybrid model. The method comprises the following steps: conducting strength experiments on concrete at different mixing ratios on site according to a standard concrete strength detection method, thereby obtaining a plurality of learning samples about the function relationships between cement x1, blast-furnace slag powder x2, fly ash x3, water x4, a water reducing agent x5, a coarse aggregate x6, a fine aggregate x7, a curing period x8 and other concrete component mixing information as well as the concrete strength y; training extreme learning machines, artificial neural networks and support vector machines in the hybrid model, and confirming the optimal extreme learning machine, artificial neural network and support vector machine according to the optimization goal of minimized relative errors; on the basis of the optimal extreme learning machine, artificial neural network and support vector machine, confirming the optimally predicted concrete strength y with a decision function based on adaptive weight according to the predicted values of three modeling methods, wherein the optimally predicted concrete strength y can be utilized for judging whether concrete component input information meets the engineering design requirements or not. Through adoption of the method, the advantages of the three modeling methods are enhanced while the disadvantages of the three modeling methods are avoided, and the comprehensive predicting effect is better, so that the adaptability to different actual work conditions, namely the robustness, can be improved, and important significance is provided for rapid mixing ratio design and quality control for concrete.

Owner:HUAQIAO UNIVERSITY

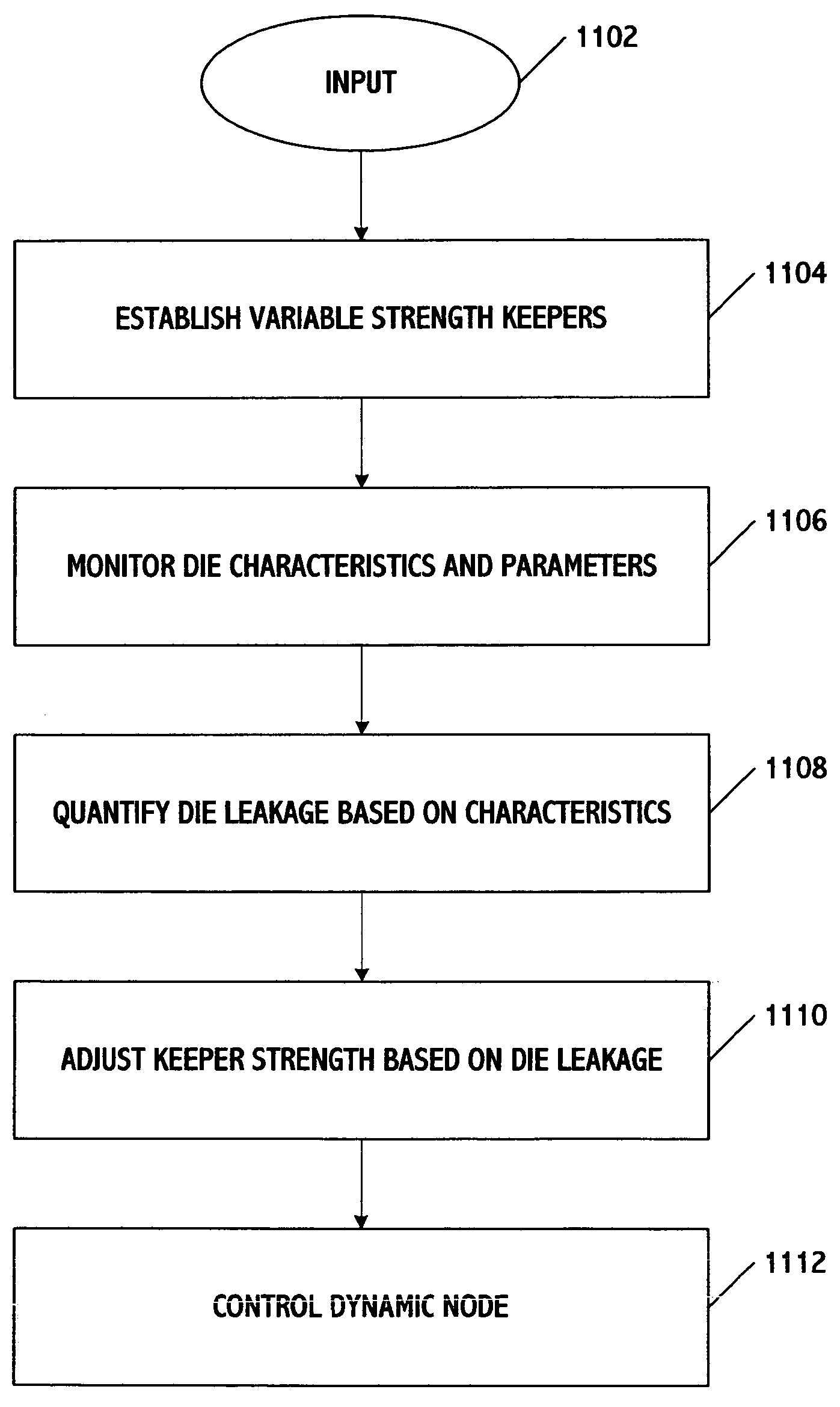

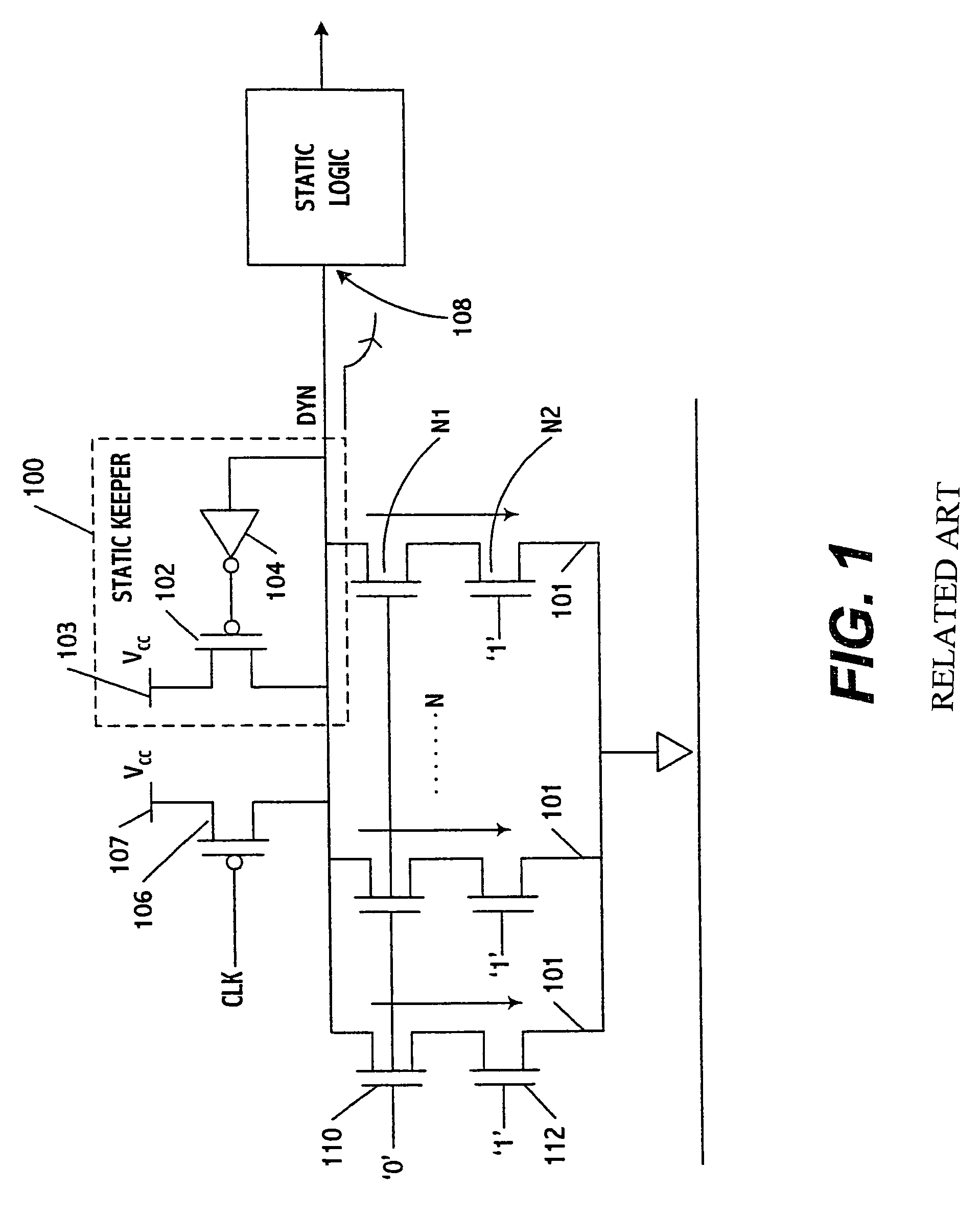

Robust variable keeper strength process-compensated dynamic circuit and method

InactiveUS7002375B2Reliability increasing modificationsLogic circuits characterised by logic functionRobustificationIntrinsics

A variable keeper strength based process-compensated dynamic circuit and method provides a robust digital way to overcome the intrinsic parameter variation present in manufactured die. Using a process-compensated dynamic circuit, the wide robustness and delay distribution becomes narrower which improves performance without sacrificing worst-case robustness. The strength of the keeper is programmed depending on the amount of die leakage. The keeper will have an optimal strength for the best and worst case leakage, allowing better performance with improved worst-case robustness.

Owner:TAHOE RES LTD

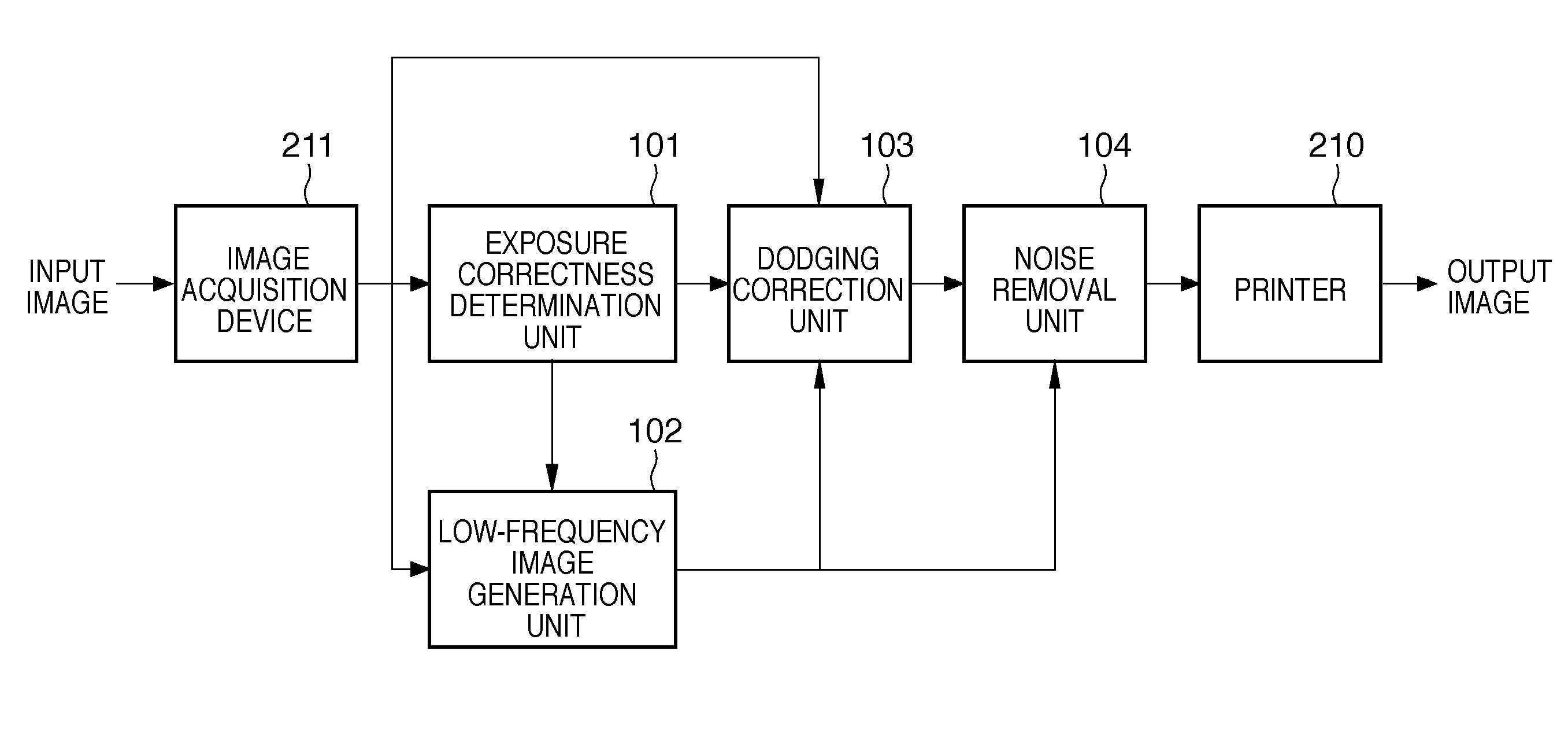

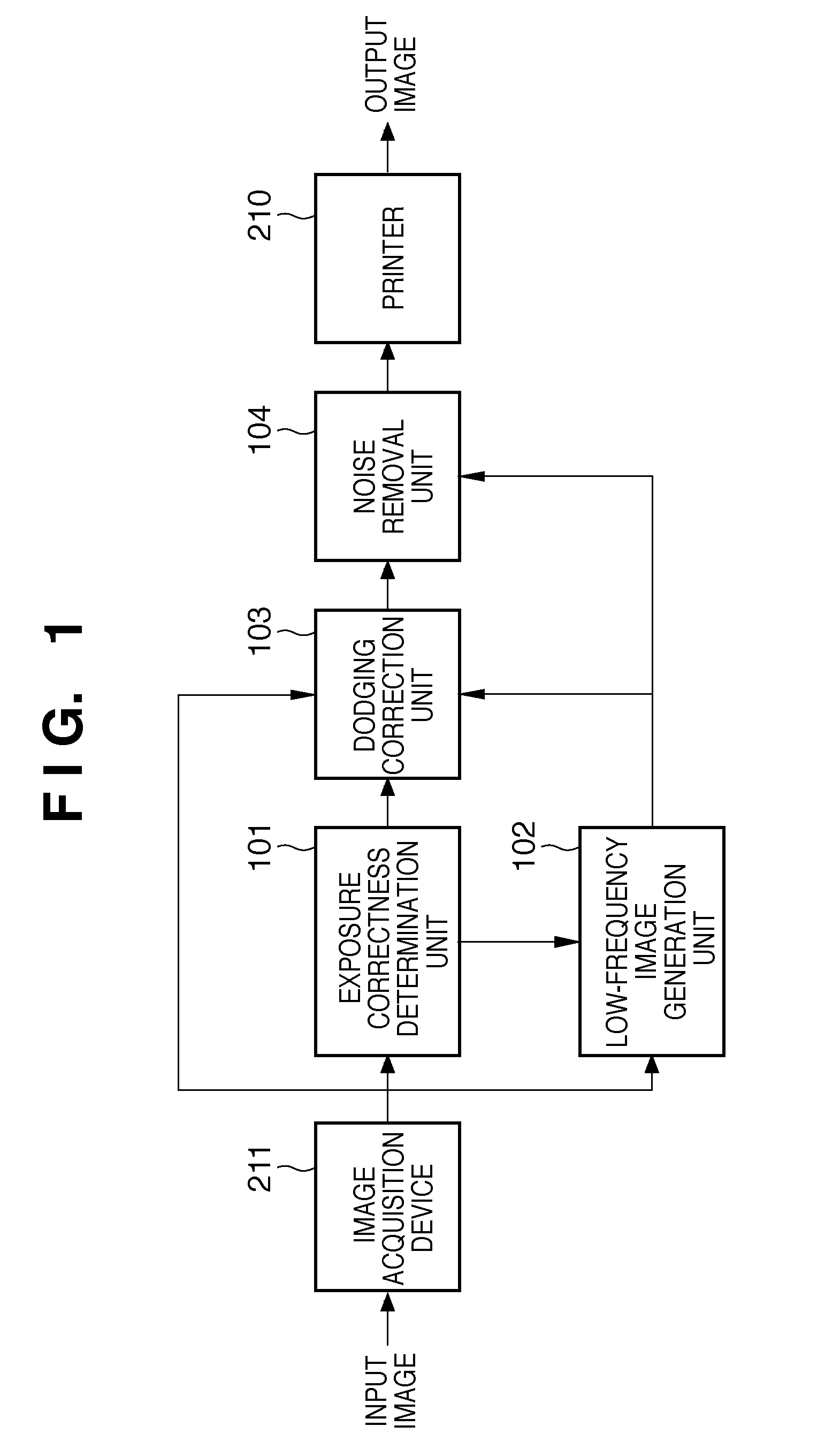

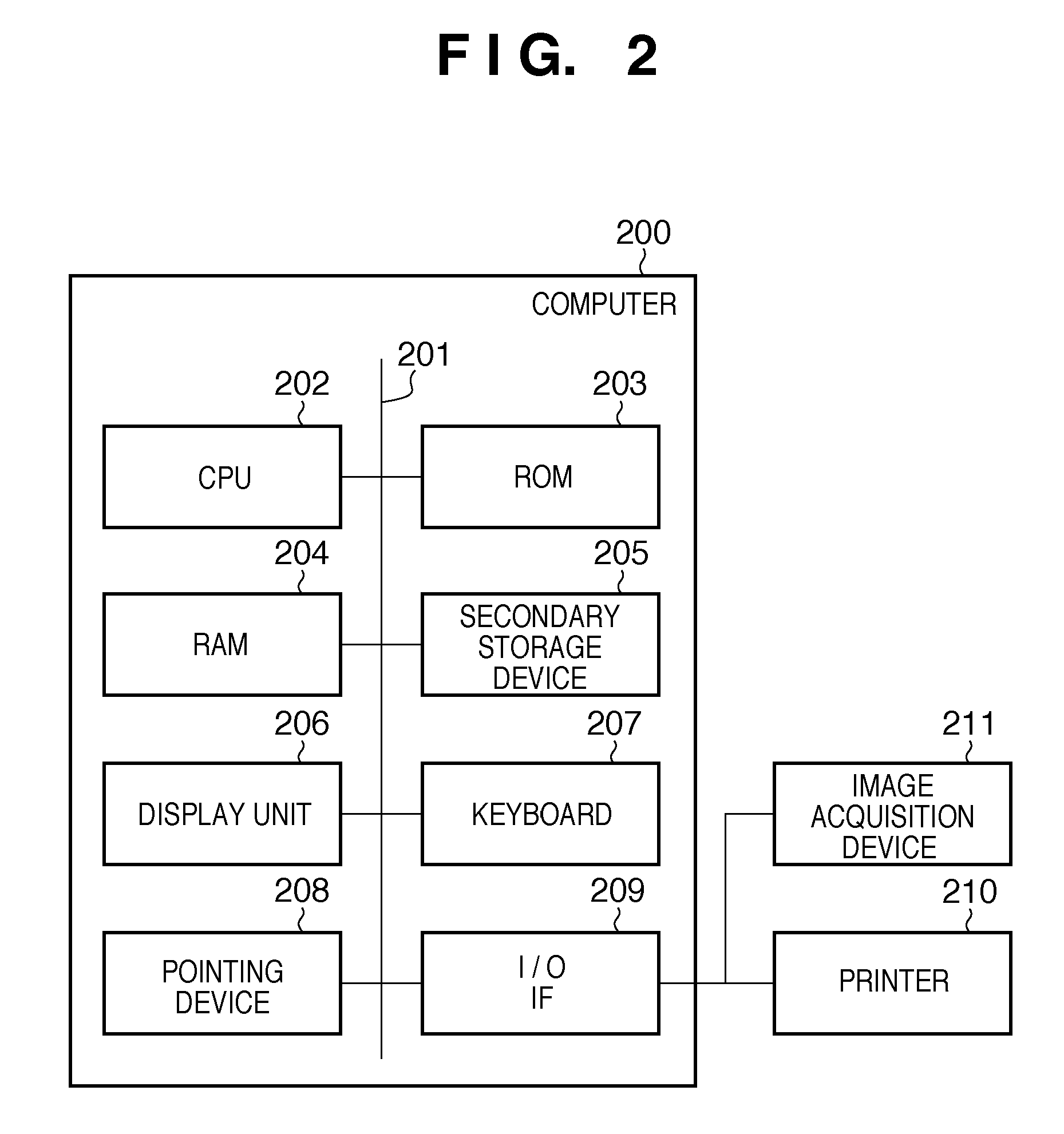

Image processing apparatus, image processing method, and computer-readable medium

InactiveUS20110285871A1Reducing sense of blurring of overall imageWorsen noiseImage enhancementTelevision system detailsImaging processingBand-pass filter

An image processing apparatus comprises a determination unit which determines whether exposure of an input image is correct; a generation unit which generates a low-frequency image for locally changing a correction amount of brightness for the input image when the determination unit determines that the exposure of the input image is incorrect; a correction unit which corrects brightness of the input image by using the low-frequency image; a holding unit which holds a plurality of filters including at least a low-pass filter and a high-pass filter; and a filter processing unit which performs filter processing for a target pixel of an image corrected by the correction unit while locally changing at least types of the plurality of filters or a correction strength based on a correction amount of brightness using the low-frequency image.

Owner:CANON KK

Container end closure having improved chuck wall with strengthening bead and countersink

ActiveUS7938290B2Eliminate needQuickly and effectively initiate the productionClosuresRefuse receptaclesArcuate shapeUltimate tensile strength

The present invention describes a beverage can end which utilizes less material and has an improved internal buckle strength based on the geometric configuration of a chuck wall, inner panel wall and central panel, and which, in one embodiment utilizes an arcuate shaped chuck wall with a radius of curvature between about 0.150 inches and 0.250 inches with at least one transition zone positioned between an upper and lower end of the chuck wall.

Owner:BALL CORP

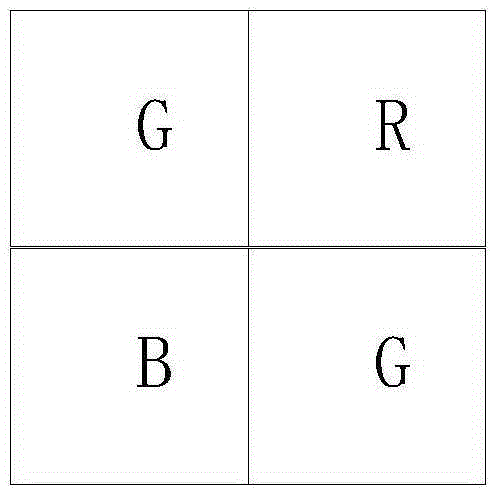

Method and device for dead pixel detection and correction of image sensor

The invention discloses a method and a device for dead pixel detection and correction of an image sensor. The device comprises an image sensor data input unit, a gain compensation unit, a dead pixel judgment unit, a dead pixel deletion strength control unit, a dead pixel correction unit and a dead pixel deletion data output unit. The method comprises the steps of regarding data generated by various arrangements of four filter lenses with the period of 2*2 as input data, establishing an M*N data window by regarding each point of the input data as a center and performing gain calculation and gain compensation; judging a dead pixel condition in each direction of each point of the input data to obtain dead pixel information; providing a variance / brightness model and determining a dead pixel deletion strength based on texture information of each point; and correcting the dead pixel by utilizing the dead pixel information and the dead pixel deletion strength and outputting corrected data. According to the method and a device for dead pixel detection and correction of the image sensor, dead pixel detection and correction of the data format of the image sensor of various arrangement modes of four filter lenses with the period of 2*2 are satisfied, and dead pixel detection and correction can be carried out automatically and efficiently.

Owner:SHANGHAI FULLHAN MICROELECTRONICS

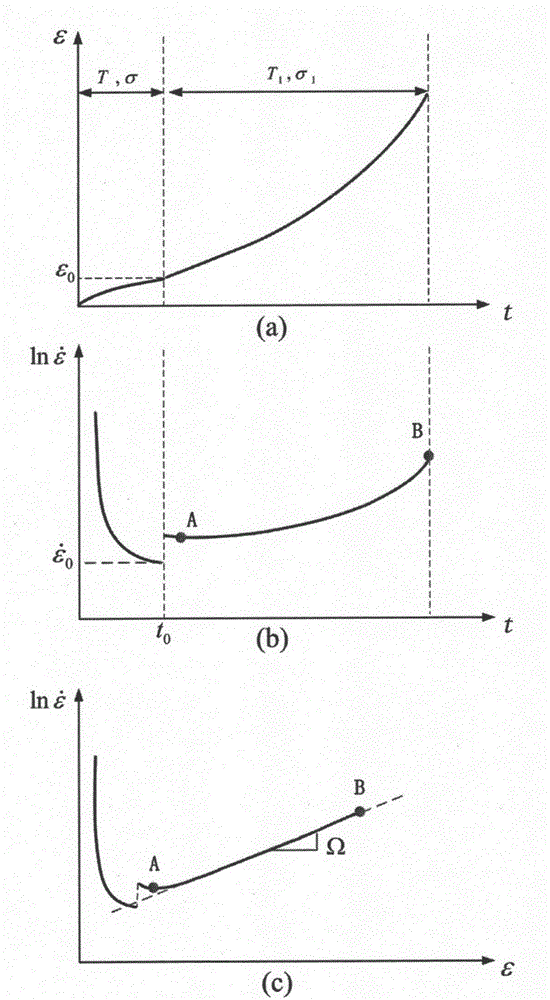

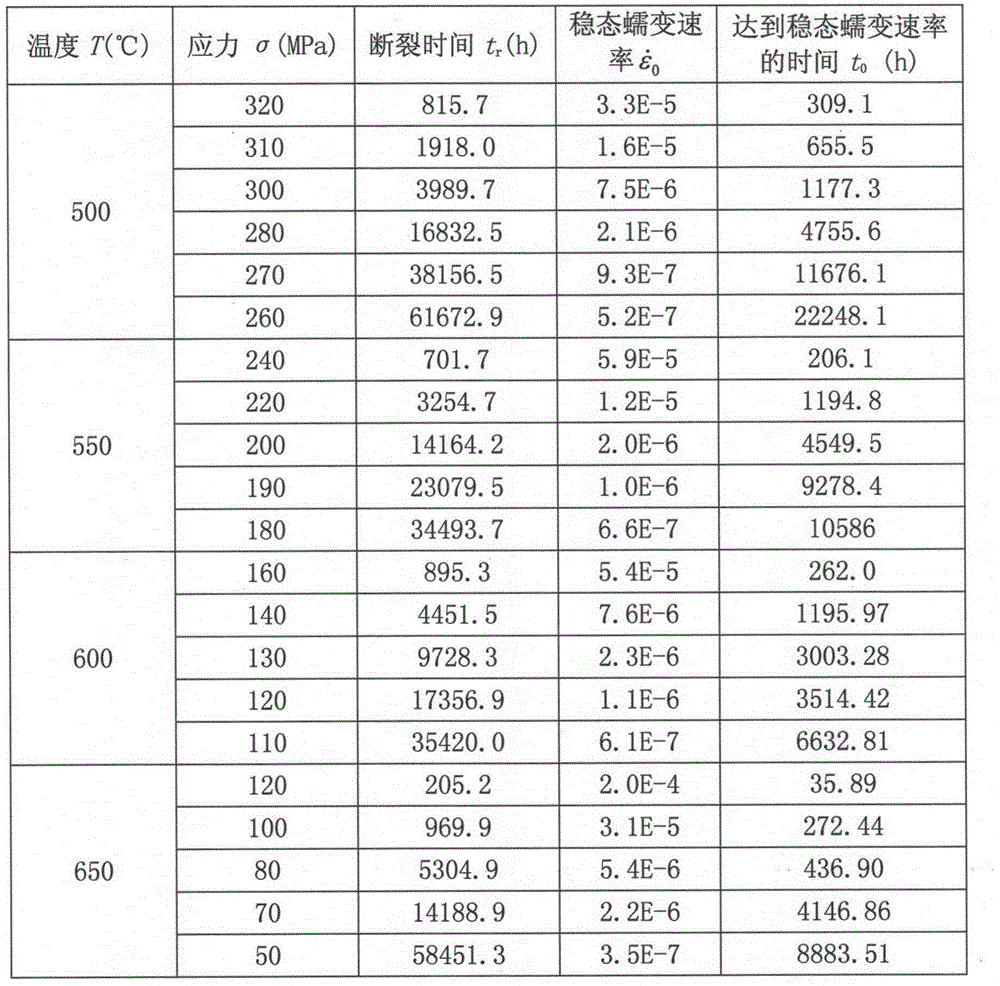

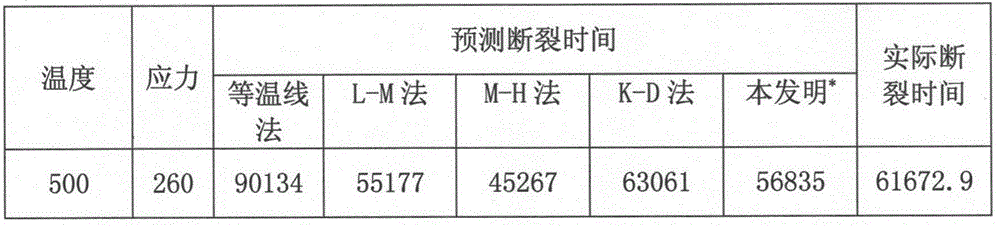

Accelerated testing method for prediction of high temperature material creep life

ActiveCN105158080AEasy to operateImprove forecast accuracyMaterial strength using tensile/compressive forcesHigh pressureUltimate tensile strength

The invention provides an accelerated testing method for prediction of a high temperature material creep life. The accelerated testing method can be operated simply. Based on known temperature T and stress sigma in life prediction, only one creep sample is accelerated in an inconspicuously changed parameter scope of a creep damage mechanism, and through creep deformation data in short time, creep rupture time tr at the prediction temperature T under stress sigma is predicted. The accelerated testing method is very suitable for prediction of a residual creep life of a part in service at a high temperature under high pressure, greatly saves a sample, and has prediction accuracy higher than that of the existing lasting strength-based life prediction method.

Owner:SHANGHAI POWER EQUIP RES INST

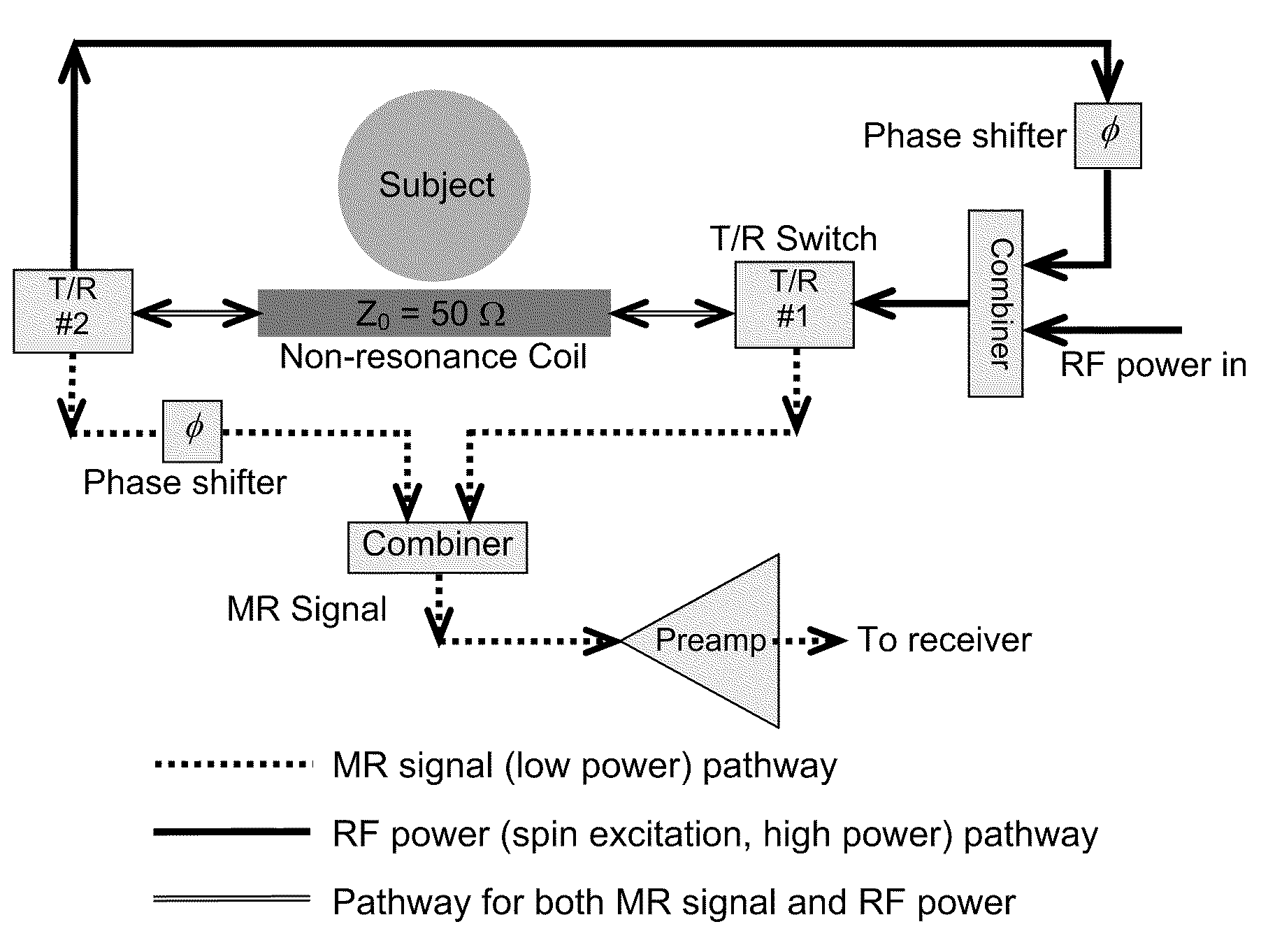

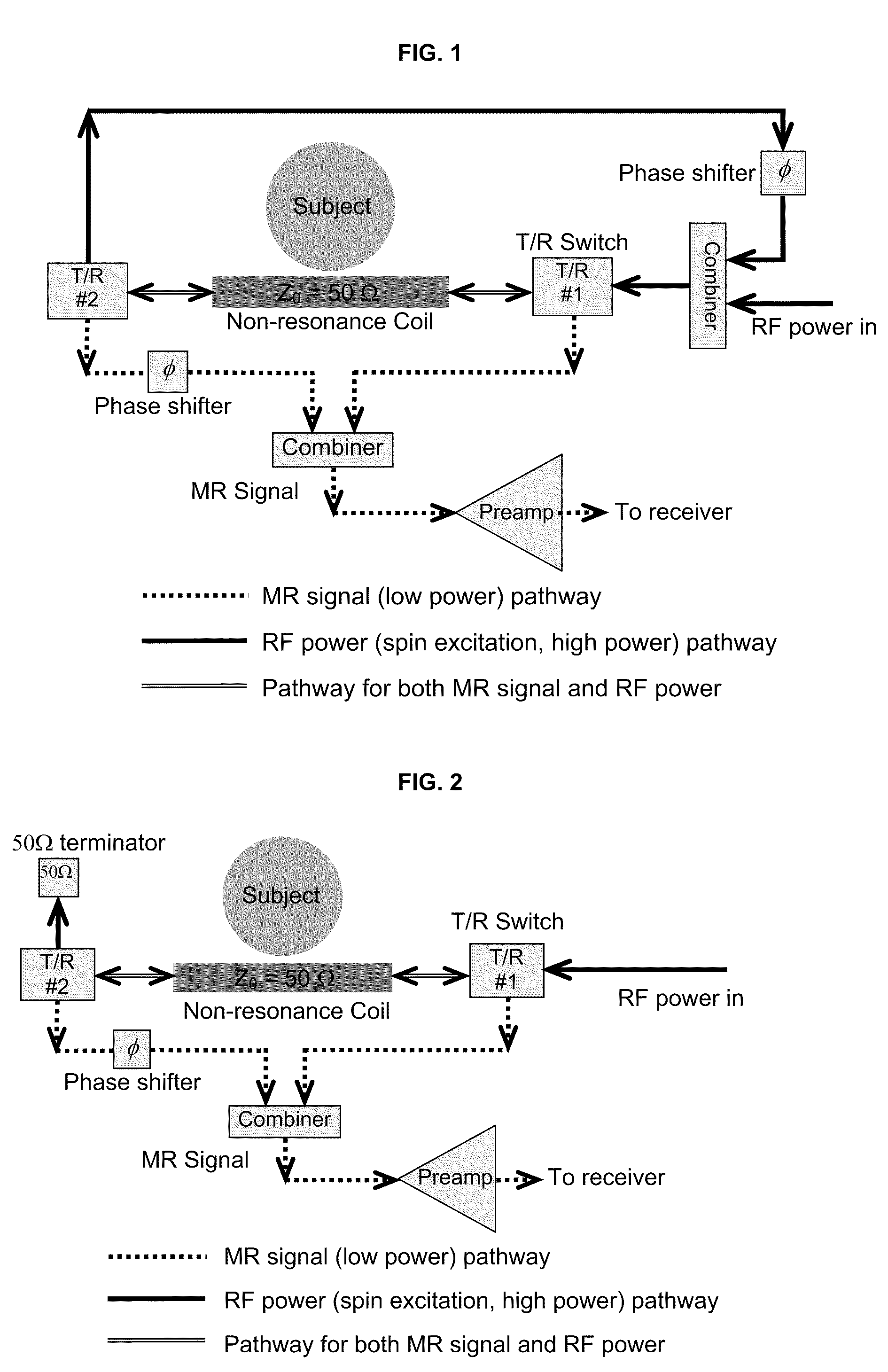

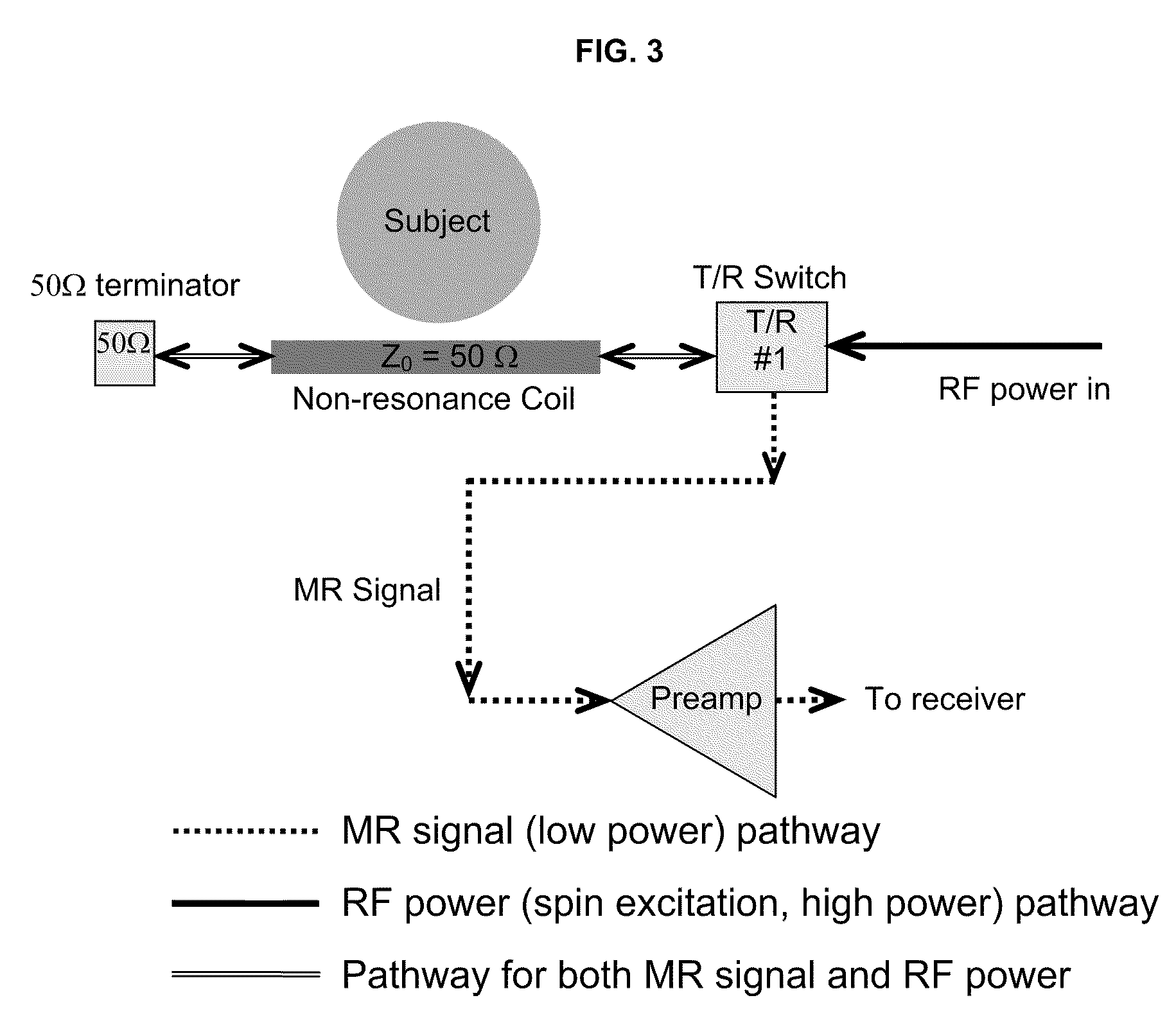

Method and apparatus for MRI signal excitation and reception using non-resonance RF method (NORM)

A system for MR signal excitation and reception and method which uses a non-resonant device or transmission line to perform MR imaging and spectroscopy. The system with non-resonant device is advantageous to parallel imaging due to the improved decoupling performance. Because the non-resonant RF coil is not generally sensitive to frequency, a MR system with the non-resonant RF coil is capable of multinuclear MR operation at varied magnetic field strength. The system comprises a non-resonant RF coil for connecting to an MR system, the conductor being configured to have a characteristic impedance matched to the MR system. The RF coil is configured to produce electromagnetic fields of differing strengths based on the constant characteristic impedance maintained in the system for exciting and receiving MR signals.

Owner:RGT UNIV OF CALIFORNIA

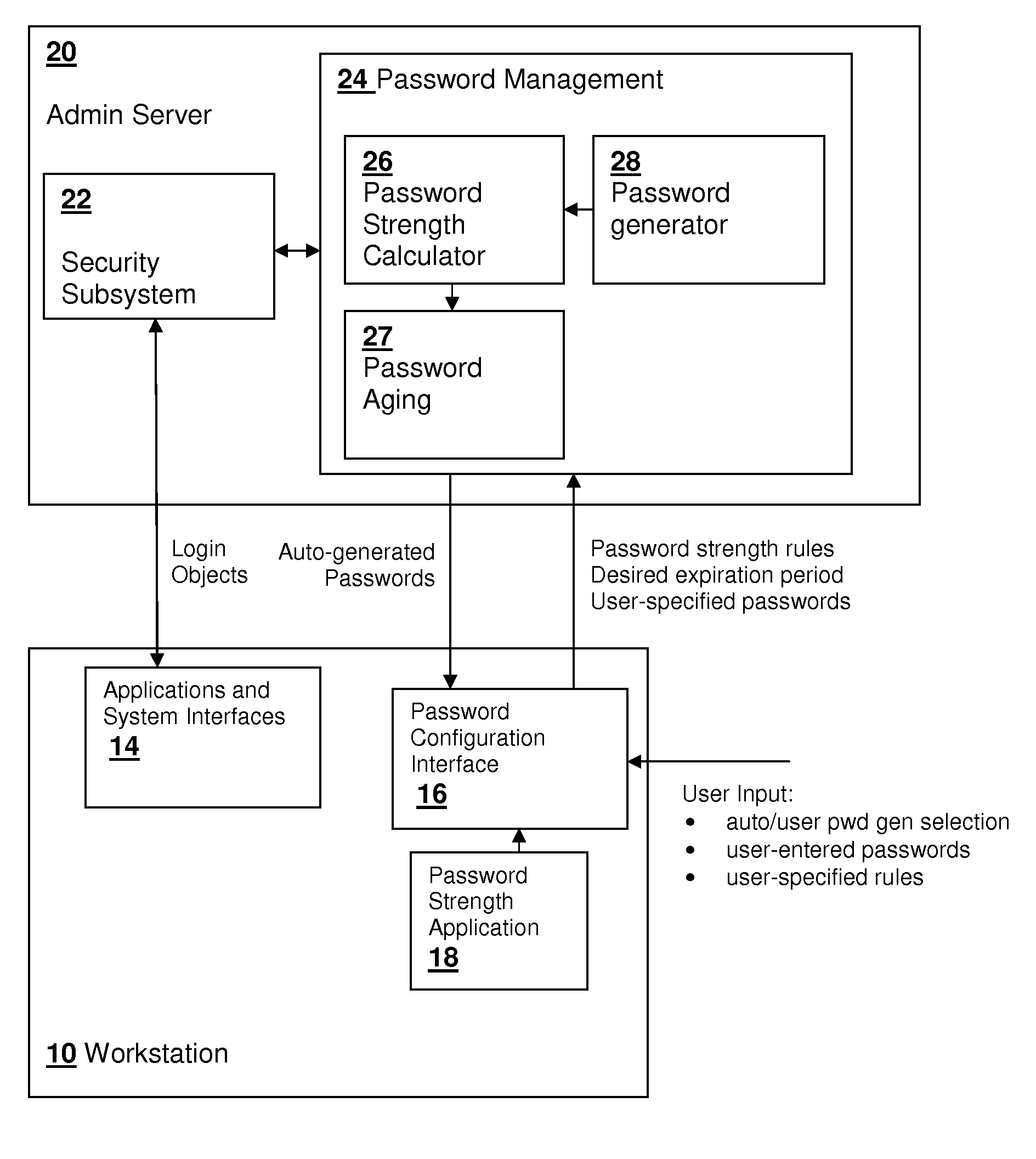

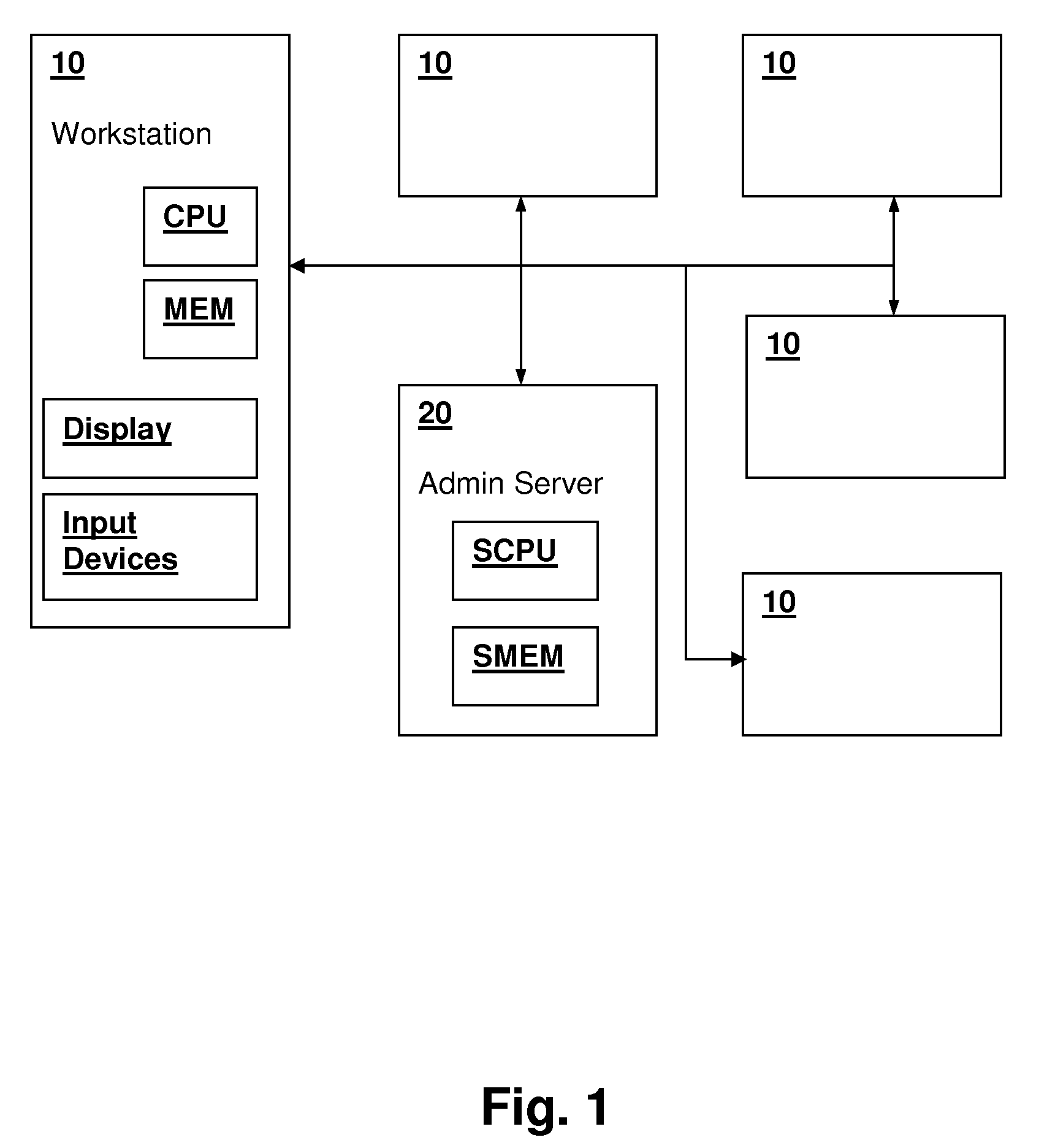

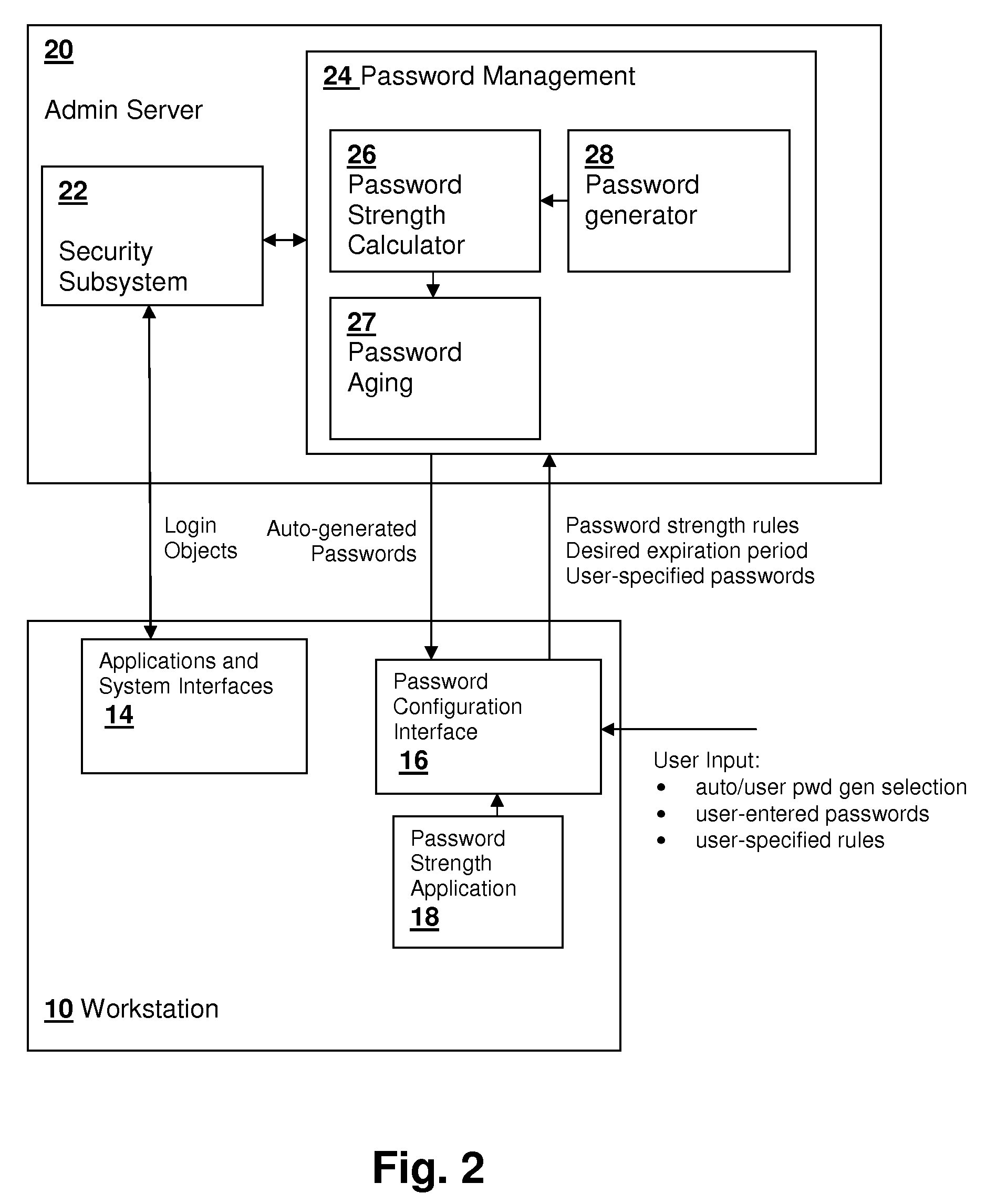

User policy manageable strength-based password aging

InactiveUS8370925B2Digital data processing detailsUnauthorized memory use protectionPasswordLookup table

Password aging based on the strength of the password provides an incentive for users to generate and / or memorize more complex passwords. The strength of the password is computed from a formula that relates the length of the password and the types of characters contained in the password to a strength value, which can be performed using a lookup table having values for different characteristics of the password, determining partial strength values corresponding to the ranges in which the characteristics fall, and then adding the partial strength values. Alternatively, a separate password strength application may be used to provide the strength value, which is entered by the user or administrator generating a new password. Alternatively, the password may be generated based on a specified desired expiration period, with the strength computation performed to ensure that the strength is sufficient to merit the desired expiration period.

Owner:IBM CORP

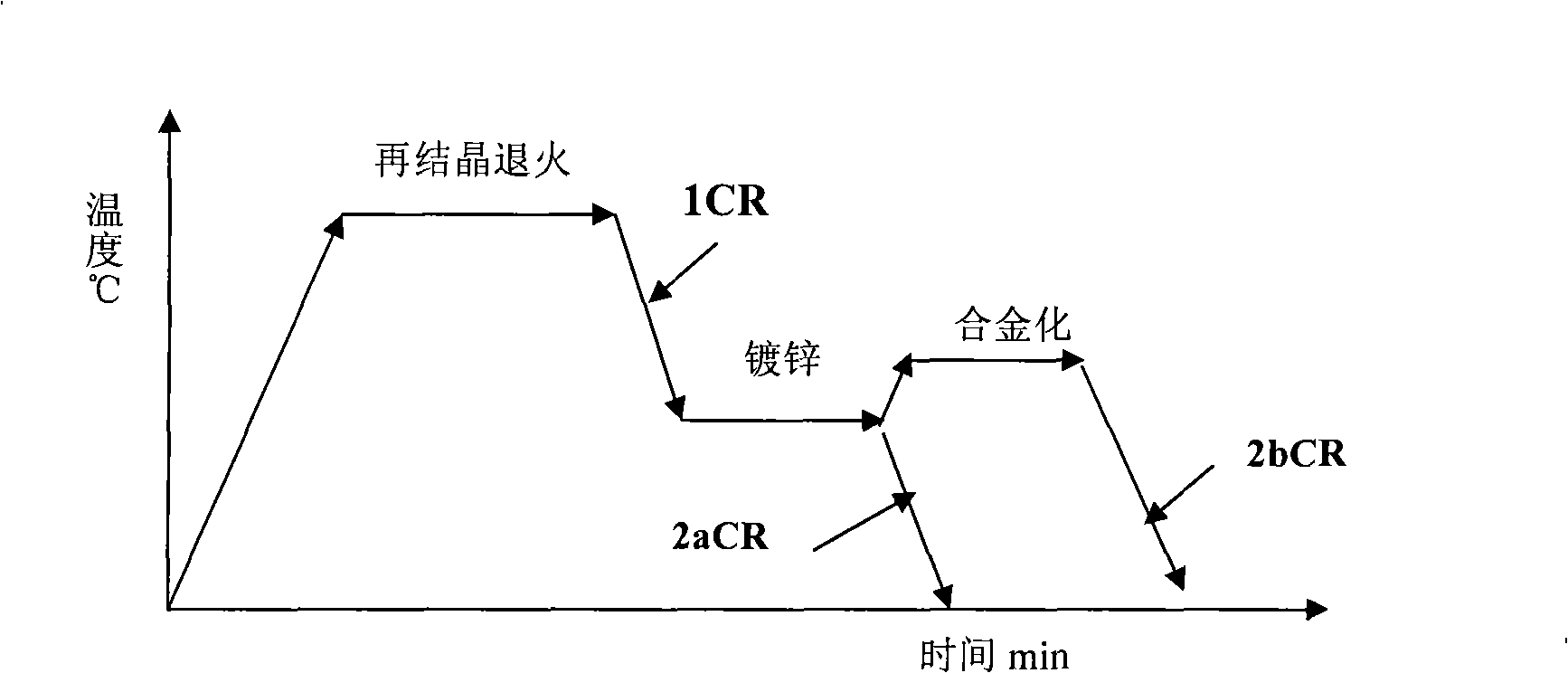

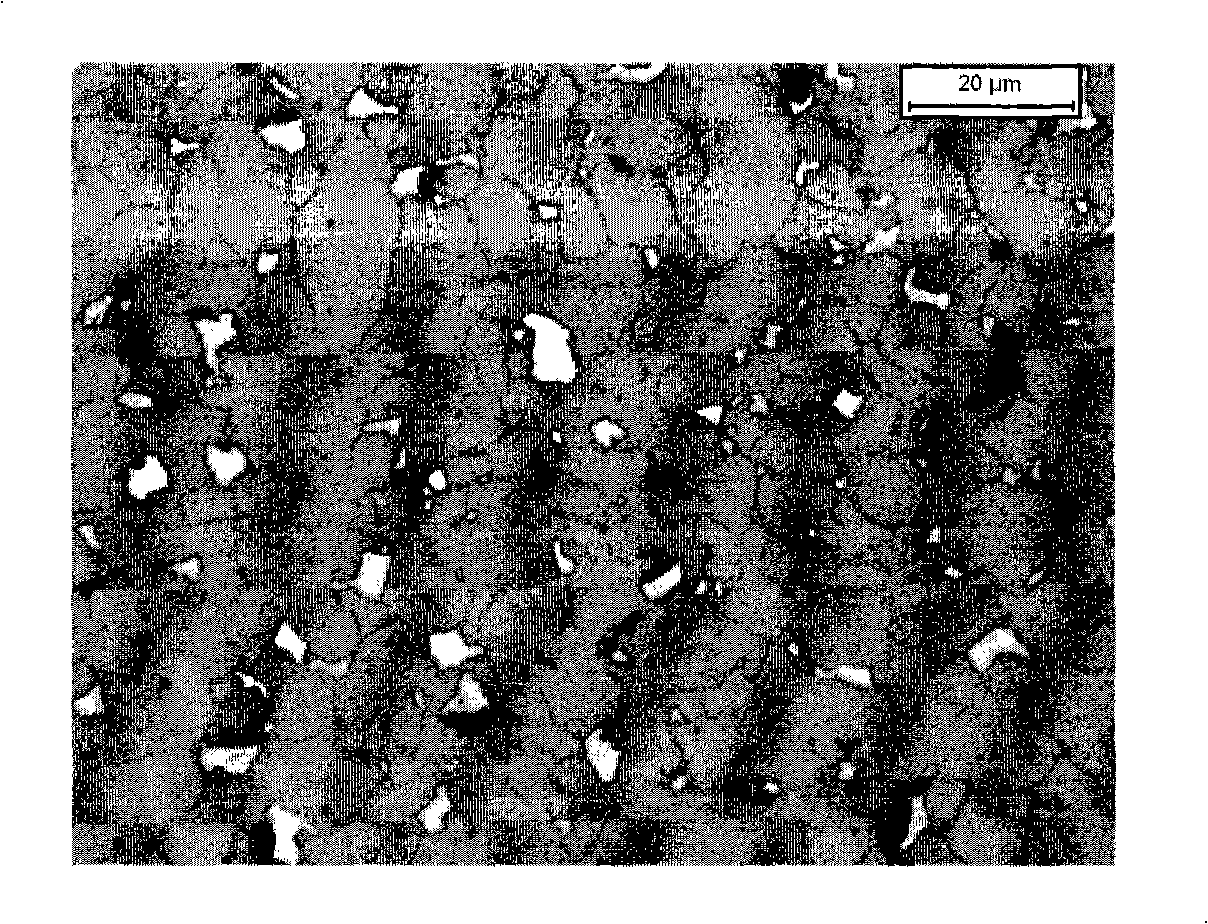

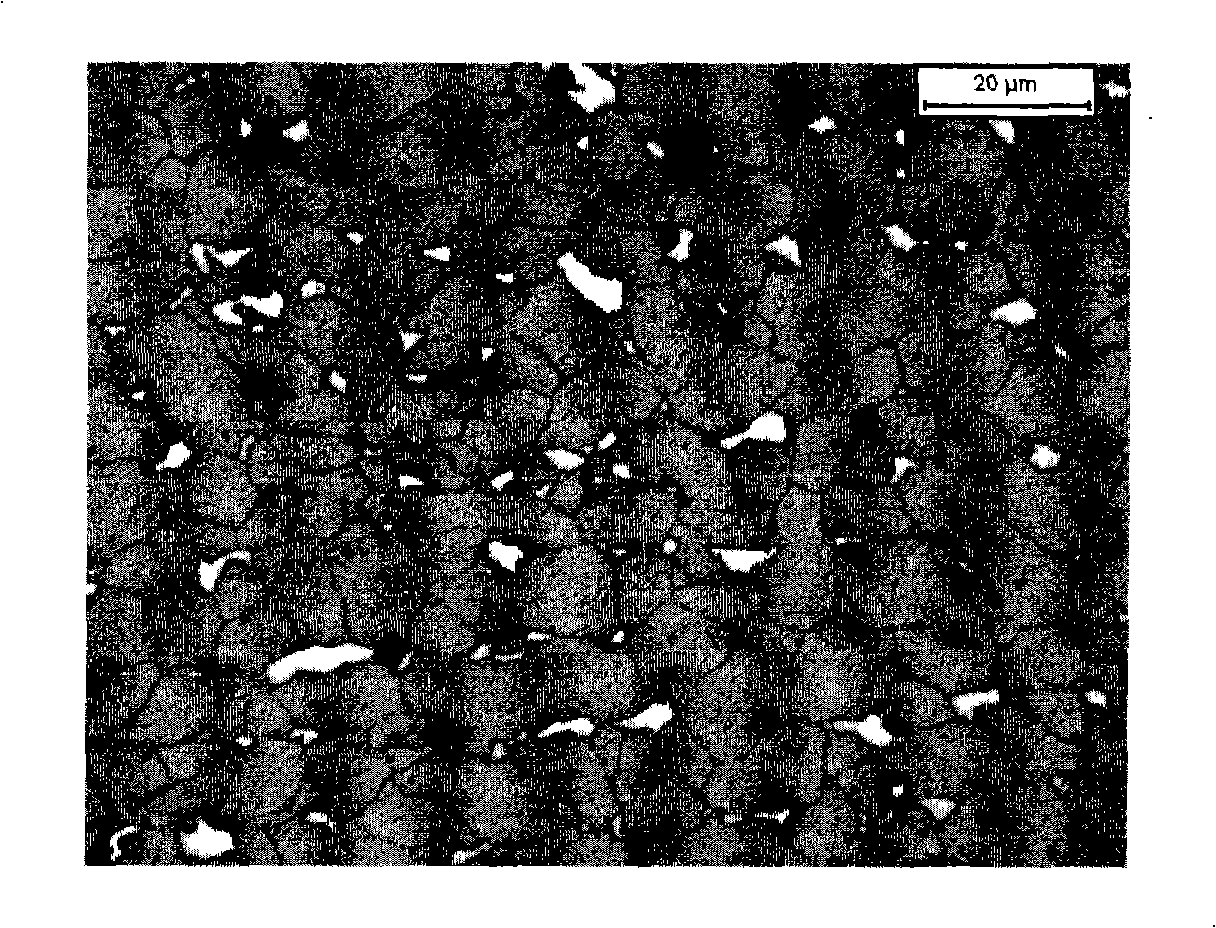

High tensile strength substrate, hot dip galvanizing automobile exterior panel and manufacturing method thereof

ActiveCN101353755AHigh strengthImprove stamping effectHot-dipping/immersion processesMetal layered productsChemical compositionPearlite

The invention relates to a high tensile strength base plate, the chemical compositions (weight percent) of which are: C: 0.01 to 0.08 percent, Si: less than or equal to 0.1 percent, Mn: 0.8 to 1.8 percent, Cr: less than or equal to 1.0 percent, Mo: less than or equal to 0.5 percent, TAl: 0.02 to 0.08 percent, N: less than or equal to 0.006 percent, P+2S: less than or equal to 0.12 percent, Mn+3Cr+2Mo: more than or equal to 1.6 percent and less than or equal to 3.8 percent, and the rest is Fe. A high tensile strength hot galvanizing automobile outside plate adopting the high tensile strength base plate and a preparation method thereof comprise the following steps of: casting the components into blank plates by smelting, refining and continuous casting; hot rolling which adopts high temperature curling at 650 to 680 DEG C to obtain normal pearlite and ferrite original tissue, and then continuous casting with normal cool acid; hot galvanizing annealing with the critical re-crystallization annealing temperature at 800 to 860 DEG C; the cooling speed from the annealing temperature to a zinc pool is 5 to 16 DEG C / s; and entering into the zinc pool with the temperature of 450 to 465 DEG C and finishing galvanization treatment.

Owner:BAOSHAN IRON & STEEL CO LTD

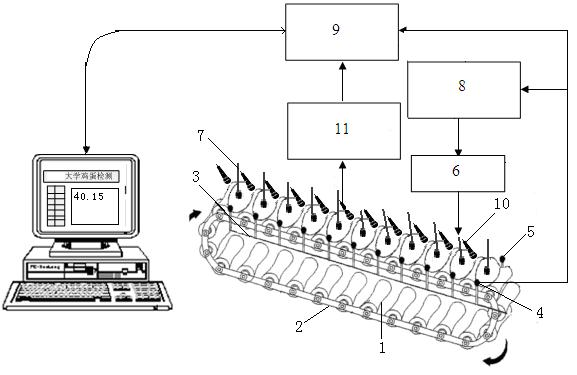

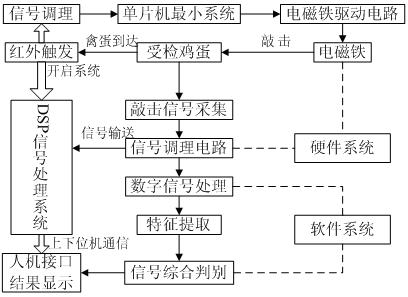

On-line nondestructive detection method and device for eggshell strength

ActiveCN102156169ASpeed up the automated inspection processAutomatic detection and classificationAnalysing solids using sonic/ultrasonic/infrasonic wavesNon-electrical signal transmission systemsEggshellSoftware system

The invention relates to the field of detection of eggshell strength, in particular to an on-line quick nondestructive detection method and an on-line quick nondestructive detection device for eggshell strength based on knocking response signal analysis. The device consists of an egg knocking response signal acquisition and processing hardware system and a signal analysis software system; and an egg is placed on a supporting roller and rolls and advances together with a high-speed running and horizontal conveying production line, four rails on a conveyor belt bracket finish mechanical knocking on the detected egg, a permanent electromagnet drives a knocking bar to execute the knocking command so as to realize mechanical knocking on the detected egg when the egg passes through every knocking rail, the response signals are acquired by a microphone and processed and analyzed by a digital signal processor (DSP) system, and on-line detection results of the eggshell strength are acquired through a standard library model. The eggshell knocking response signals can be comprehensively acquired and analyzed, automatic and quick detection and grading of the eggshell strength are realized, and automatic detection in the production processing and circulation processes of the eggs is quickened.

Owner:JIANGSU UNIV

Estimation of block artifact strength based on edge statistics

InactiveUS7911538B2Improve picture qualityReducing/removing block artifactsTelevision system detailsPicture reproducers using cathode ray tubesPattern recognitionEdge based

Owner:SAMSUNG ELECTRONICS CO LTD

Braze welding method for hard alloy and low-alloy and high-strength steel

ActiveCN103071878AImprove mechanical propertiesUniform tissueWelding/cutting media/materialsSoldering mediaAlloyFiller metal

The invention discloses a braze welding process for a hard alloy and low-alloy and high-strength steel, which belongs to a braze welding method for high-strength base steel. The method comprises the following steps of: preparing the low-alloy and high-strength steel, the hard alloy and a manganese brass flaky brazing filler metal qualified in raw material inspection; removing oxide layers on the surfaces of the low-alloy and high-strength steel, the hard alloy and the manganese brass flaky brazing filler metal with sand paper; coating a soldering flux QJ-302 on the two faces of the brazing filler metal; placing the brazing filler metal between the low-alloy and high-strength steel and the hard alloy; fixing by using a clamp; placing into a KSL-1100X box type furnace; setting the heating speed at 10 DEG C per minute; heating till the solidus temperature of the brazing filler metal is 909 DEG C, and preserving heat for 30 minutes; setting a heating speed at 9 DEG C per minute; heating to 960 DEG C, and preserving heat for 10 minutes; cooling to 300 DEG C, and preserving heat for 30 minutes; and performing furnace cooling to the room temperature to obtain a weldment. The hard alloy is welded on the surface of the low-alloy and high-strength steel, so that the surface hardness and wear resistance of the low-alloy and high-strength steel can be enhanced, the mechanical property and mechanical performance are improved, and the application fields of the low-alloy and high-strength steel and the hard alloy are expanded.

Owner:CHINA UNIV OF MINING & TECH

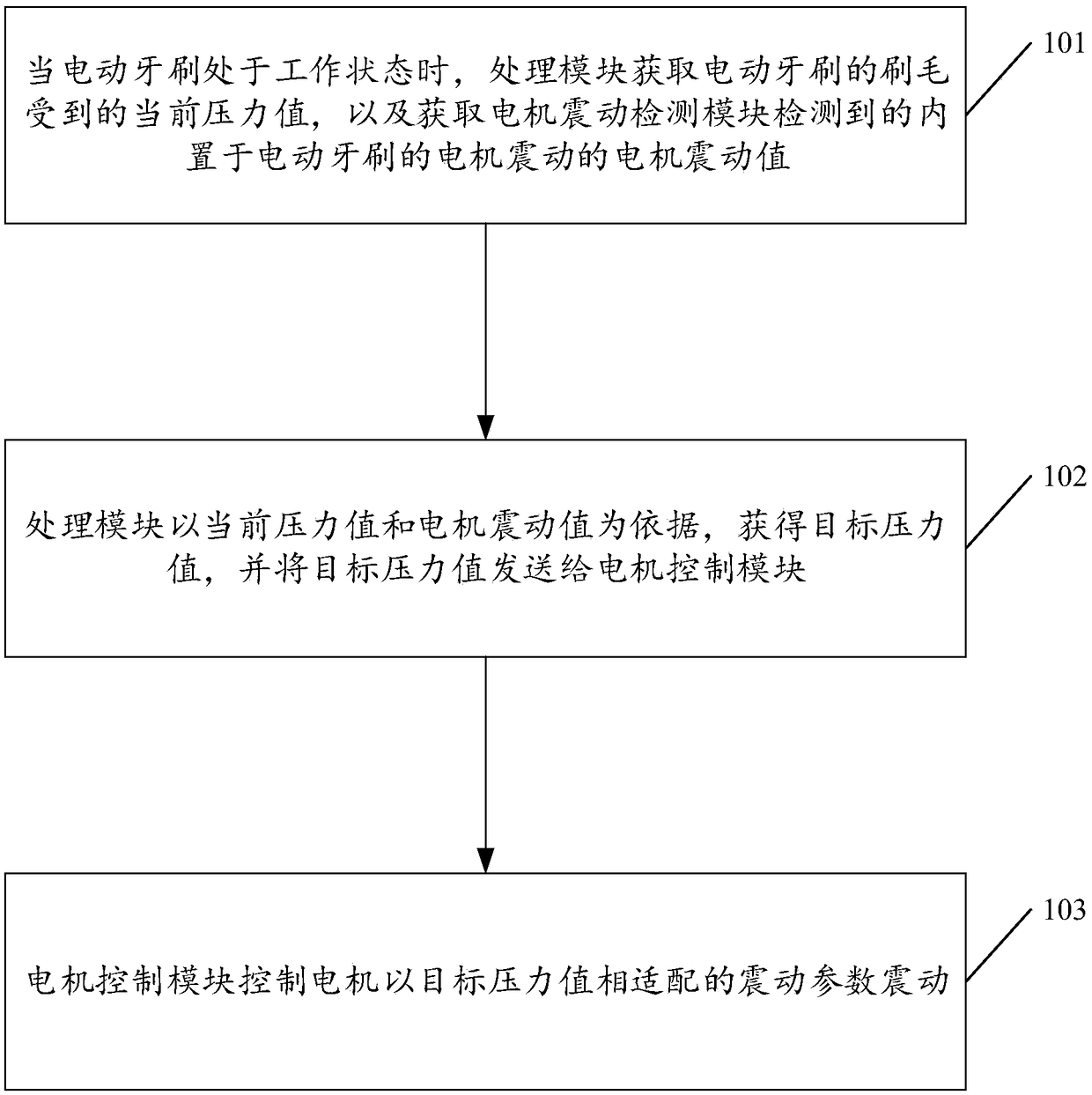

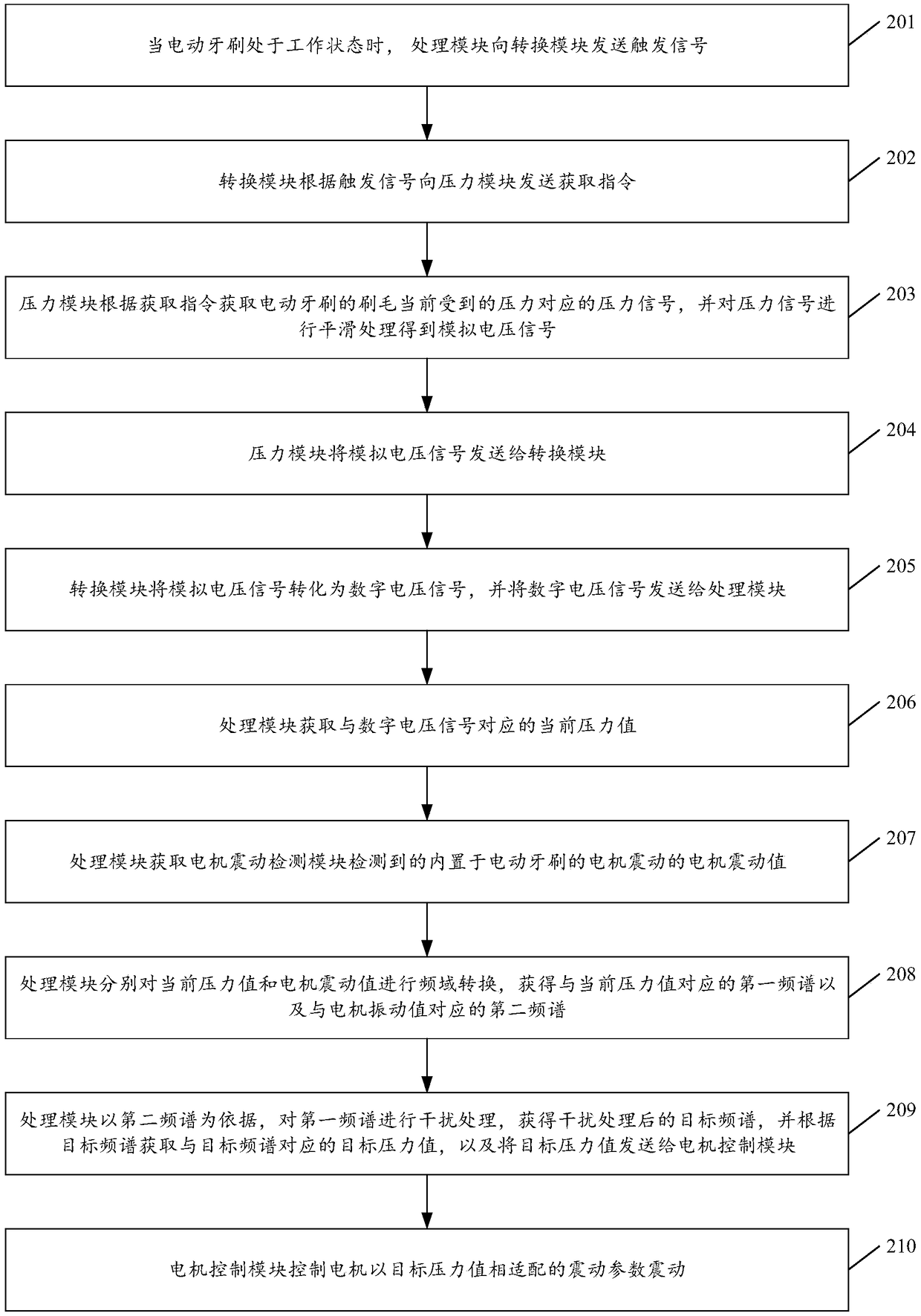

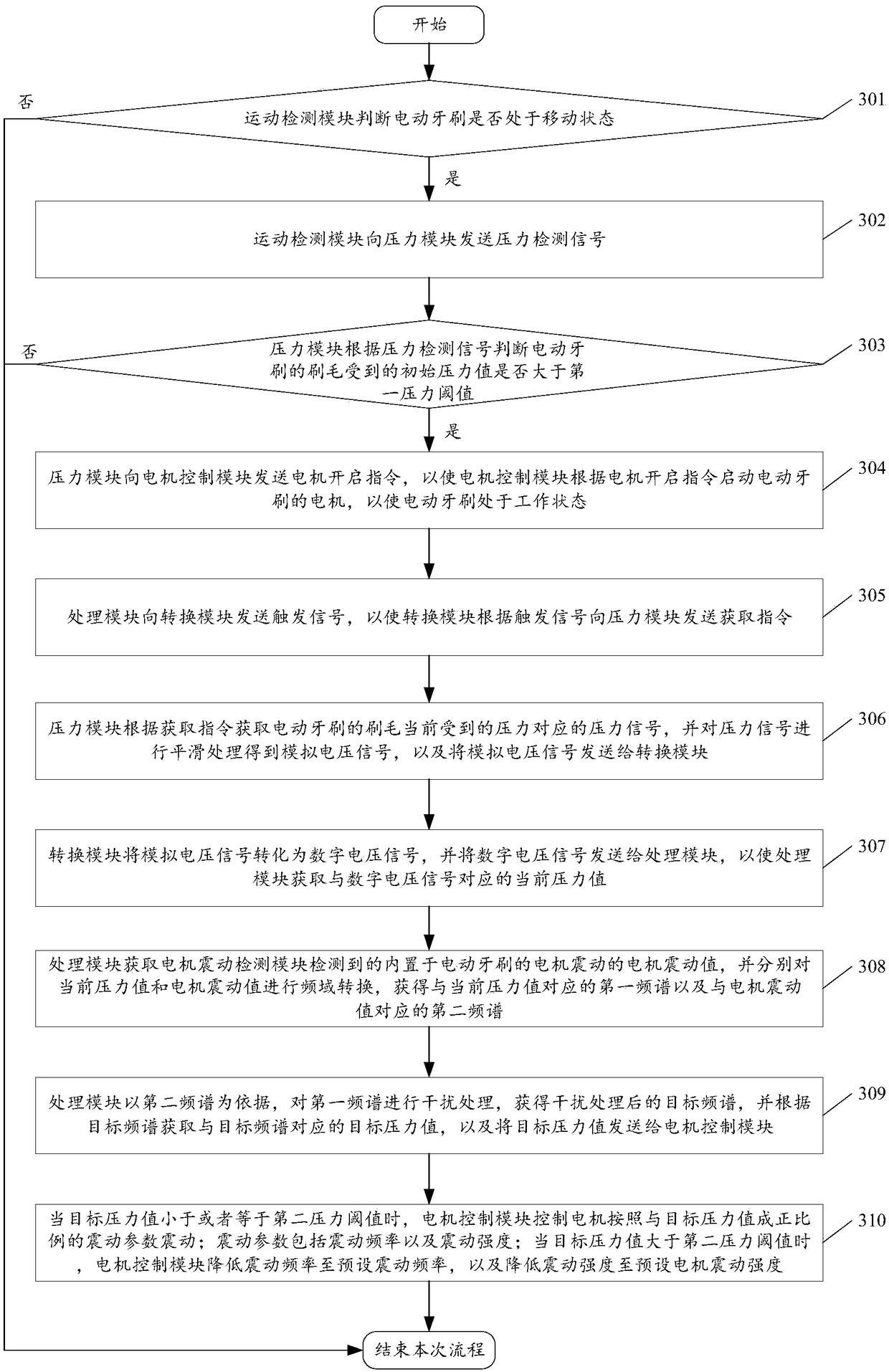

Method for controlling tooth brushing strength based on pressure detection and electric toothbrush

ActiveCN108852546ASolve unhealthy problemsFilter out noiseApparatus for force/torque/work measurementTooth cleaningAutomatic controlBristle

The invention relates to a method for controlling tooth brushing strength based on pressure detection and an electric toothbrush. The method is applied into the electric toothbrushes. The electric toothbrush comprises a motor vibration detection module, a processing module and a motor control module, wherein the processing module is electrically connected with the motor vibration detection module,and is electrically connected with the motor control module. When the electric toothbrush is set in the working state, the processing module is used for obtaining the current pressure value on bristles of the electric toothbrush, and obtaining the motor vibration value of the motor in the electric toothbrush detected by the motor vibration detection module; the processing module is used for obtaining a target pressure value according to the current pressure value and the motor vibration value, and sending the target pressure value to the motor control module; the motor control module is usedfor controlling the motor to vibrate according to the vibration parameters matched with the target pressure value. The method and the electric toothbrush have the advantage that the tooth brushing strength is automatically controlled within the proper range, so as to solve the problem of unhealth of teeth due to overhigh or overlow tooth brushing strength.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com