High tensile strength substrate, hot dip galvanizing automobile exterior panel and manufacturing method thereof

A technology with high tensile strength and manufacturing method, applied in hot-dip plating process, chemical instruments and methods, vehicle parts, etc., can solve problems such as time limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

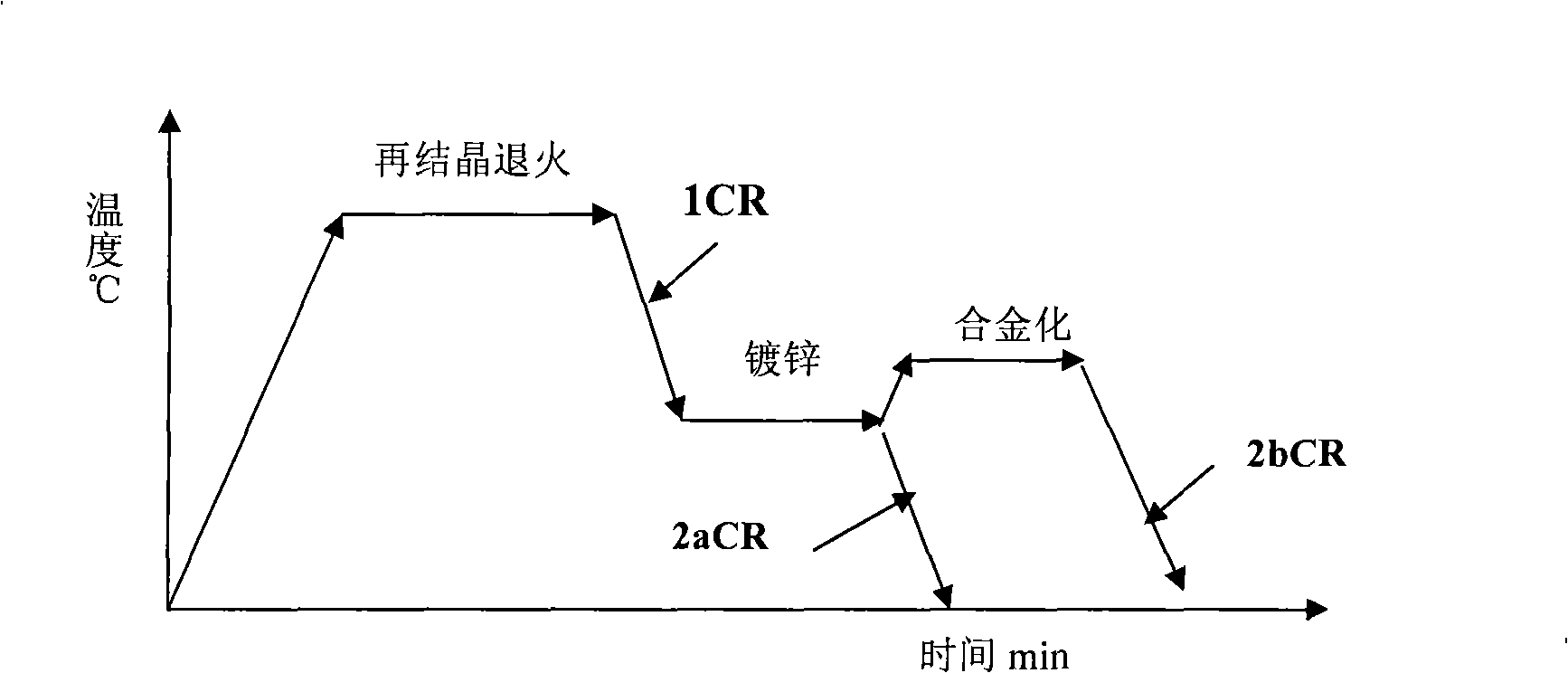

[0064] The present invention is described in detail below through specific examples.

[0065] The composition design and the formulation of the hot-dip galvanizing annealing process of the present invention are simulations of the working conditions of large-scale industrial production, so they can be realized in large-scale industrial production.

[0066] The composition of each embodiment is shown in Table 1.

[0067] Table 1 Chemical composition (wt%) of the present invention

[0068] sample

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com