Accelerated testing method for prediction of high temperature material creep life

A creep life and accelerated test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of over optimism, high prediction value, and multiple samples, so as to save samples and improve prediction accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

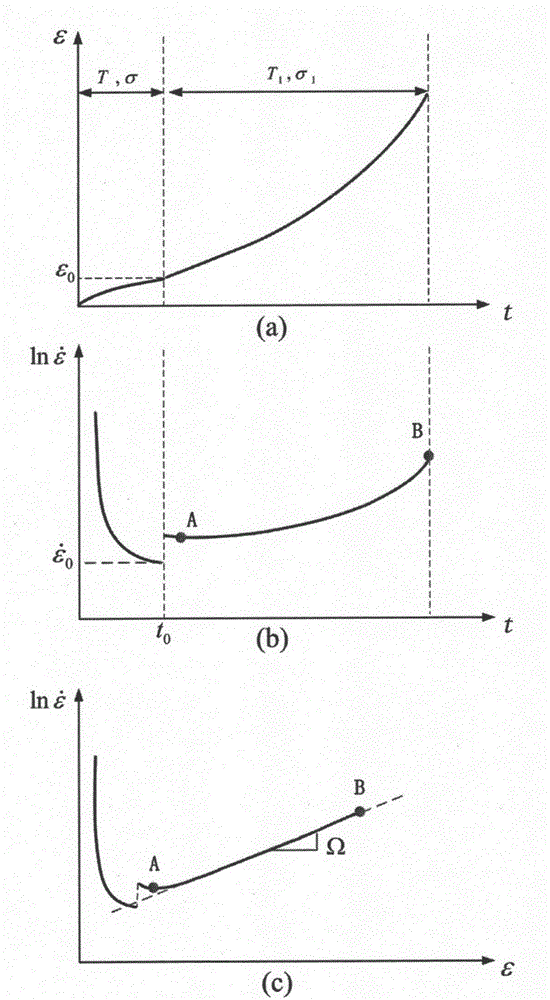

Method used

Image

Examples

Embodiment 1

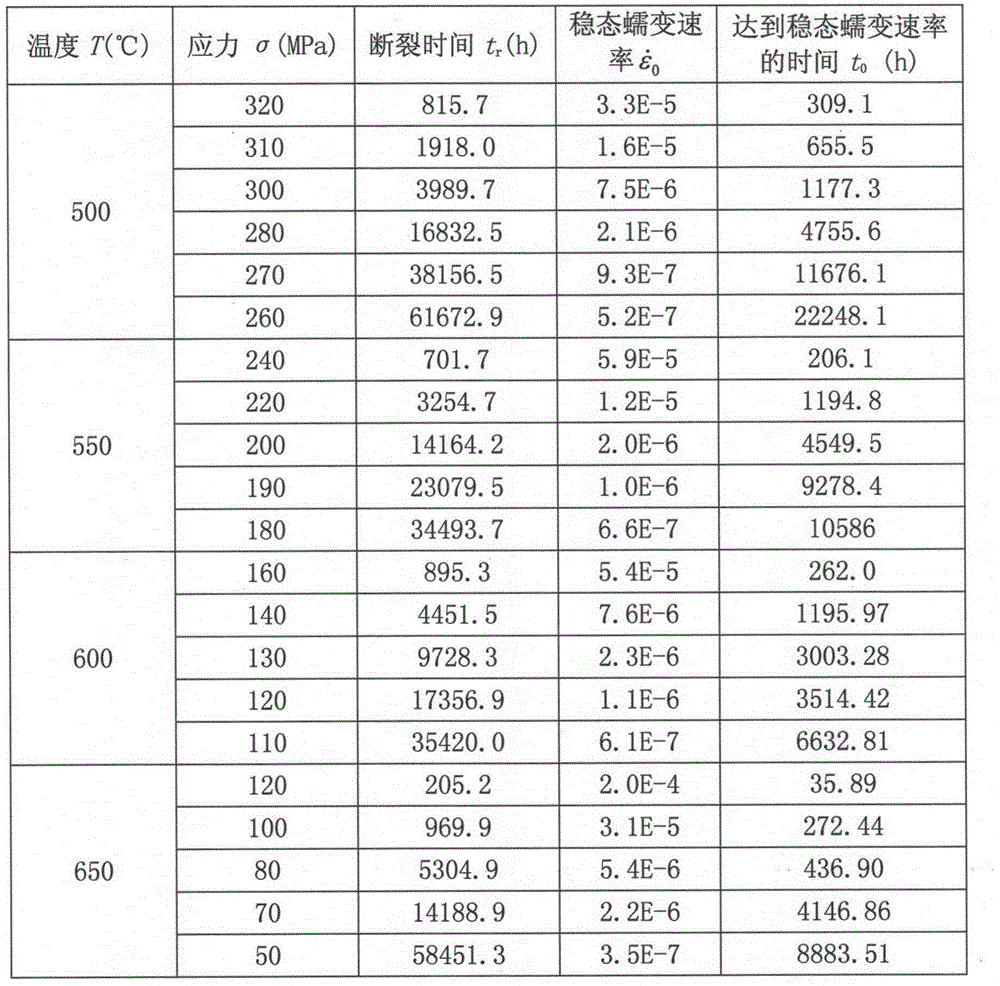

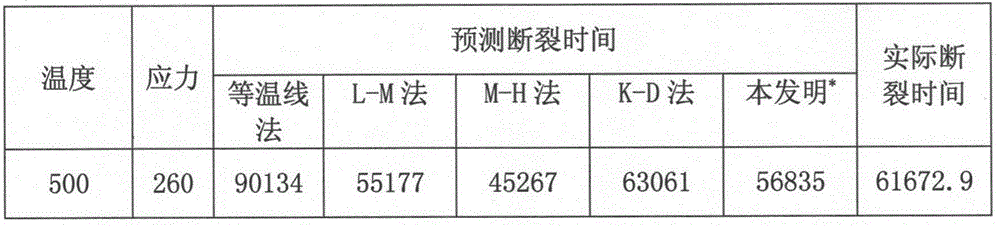

[0031] Japan's NIMS has carried out creep tests on 9Cr-1Mo-V-Nb steel plates under different temperatures and stresses, and published all the data, including creep rupture time, steady-state creep rate, strain-time curve, and strain rate. - time curve, strain rate-strain curve. Table 1 shows the creep durability data of 9Cr-1Mo-V-Nb sheet (MgC). Assuming that the creep rupture time of the minimum stress at each temperature is not known now, and using the data information of the high stress / high temperature area, the existing extrapolation method and this method are used to predict it. Table 2 shows the prediction results obtained by each method. It can be seen that compared with the existing methods, the prediction results of this method are closer to the actual results.

[0032] Table 1 Creep endurance data of 9Cr-1Mo-Nb-V sheet (MgC) published by NIMS in Japan

[0033]

[0034] Table 2. Comparison of the predicted results of each method with the actual results

[0035...

Embodiment 2

[0039] At the end of 2013, the Shanghai Power Generation Equipment Complete Design and Research Institute conducted an anatomical test on a P91 elbow that had been in service in a power plant. At that time, 35 durable samples were taken from the elbow, and the durable fracture test was carried out under different temperatures and loads. The results are shown in Table 3. Using these data, L-M method and M-H method were used to predict the durable fracture time at 540℃ and 105MPa respectively, and the results were 5656.4h and 4535.4h, respectively. In the middle of 2014, 3 durable samples and 4 creep samples were taken from the elbow again. Carry out the endurance test at 540°C and 105MPa on three durable samples to obtain the actual fracture time. So far, one sample has broken for 4041.1 hours, while the other two durable samples have been running synchronously for 2995.5 hours. While carrying out the permanent rupture test, the accelerated test method of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com