Method for predicting concrete strength based on hybrid model

A technology of concrete strength and mixed model, applied in the direction of material inspection products, etc., can solve the problems of single modeling method and the difficulty of guaranteeing the robustness of application effect, so as to improve the robustness, overcome the large attribute error and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

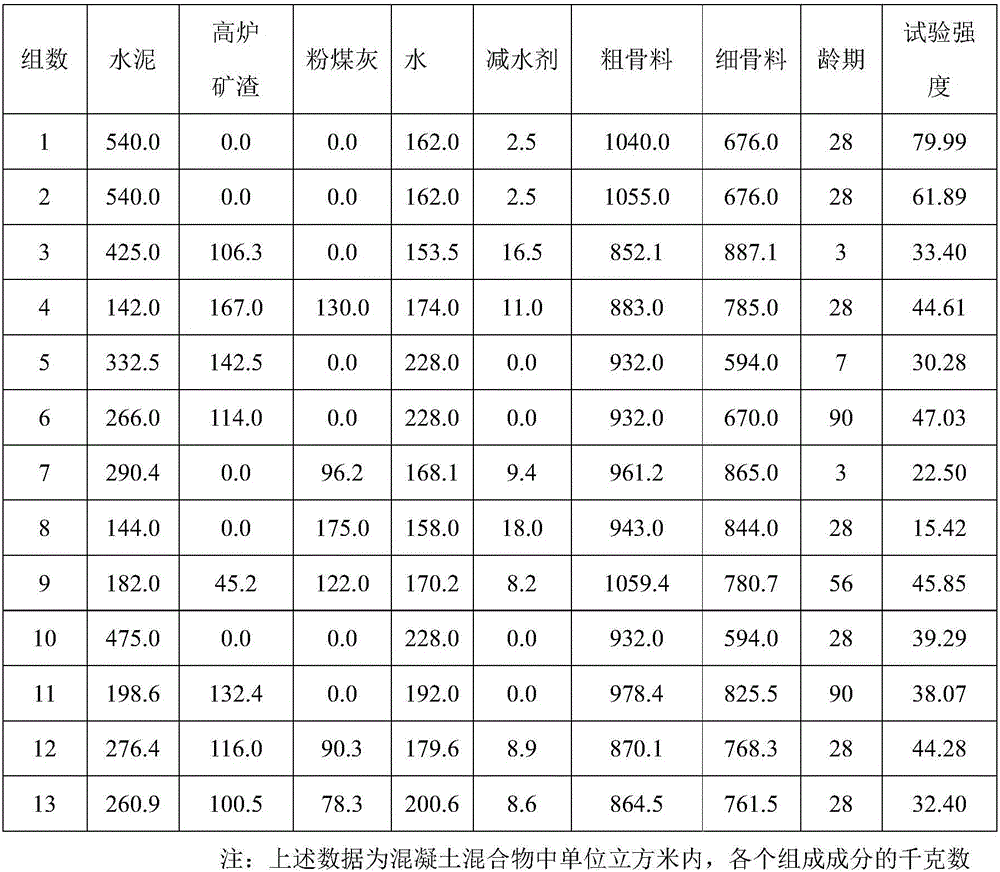

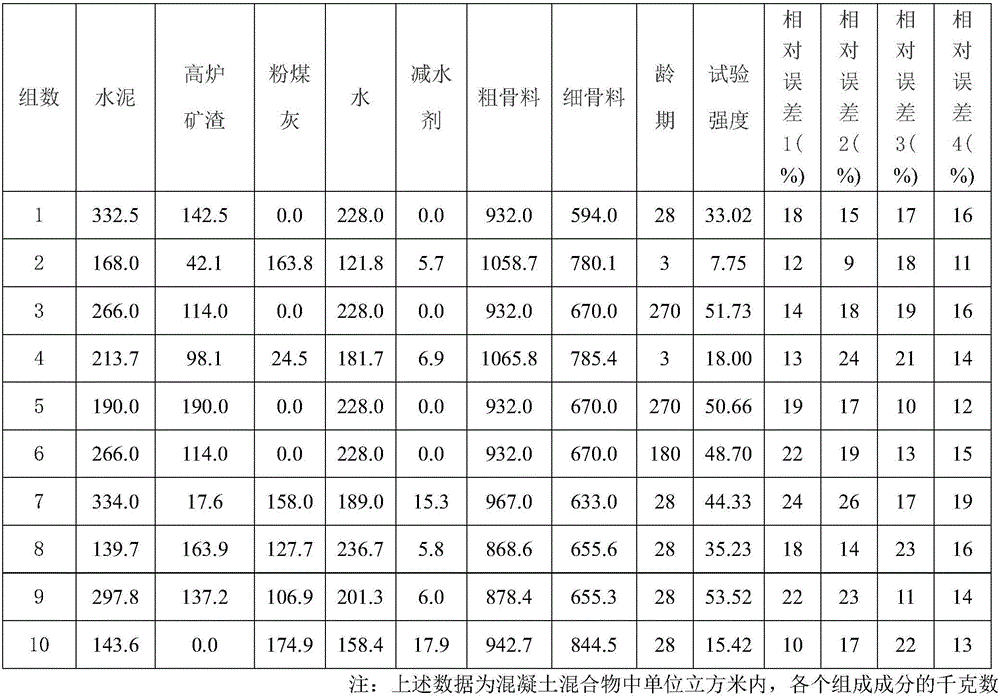

[0038] The invention provides a method of utilizing multiple groups of "cement x 1 , blast furnace slag powder x 2 , fly ash x 3 , water x 4 , water reducer x 5 , coarse aggregate x 6 and fine aggregate x 7 , maintenance age x 8 Concrete component distribution ratio information-concrete strength y” is composed of learning samples to train the mixture model, and to minimize the relative error as the optimization goal to determine the best mixture model. Based on this model, the measured new different concrete Proportioning components, quickly predicting the size of the concrete strength y, used to judge whether the input information of the concrete components meets the engineering design requirements.

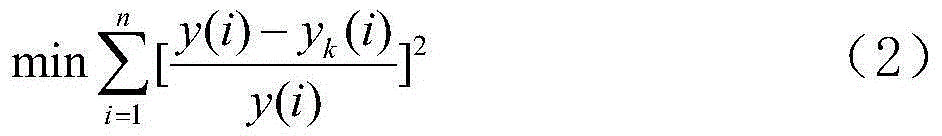

[0039] The present invention uses minimizing the relative error of the predicted output instead of minimizing the sum of squared errors like the conventional least squares method as the optimization target, which is beneficial to overcome the shortcomings of the attribute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com