Anti-splitting paster and preparation method thereof

An anti-crack sticker and coating technology, applied in the direction of coating, pavement details, construction, etc., can solve the problems of poor anti-crack waterproof effect, uneven sealing surface, time-consuming and labor-intensive, etc. Deformation, reducing the effect of tensile stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

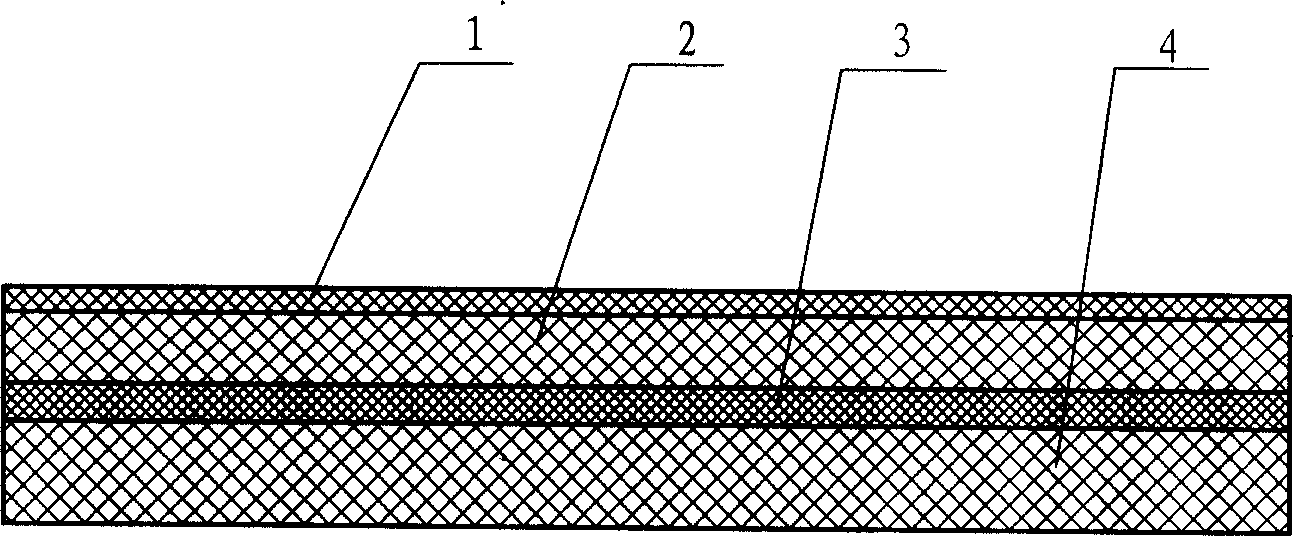

Image

Examples

Embodiment 1

[0022] Example 1: 48% asphalt, 5% SBS, 12% second-line pumping, 6% engine oil, 13% rubber powder, 3% tackifying petroleum resin C7, and 13% talcum powder.

Embodiment 2

[0023] Embodiment 2: asphalt 57%, SBS 10%, pumping three lines 13%, machine oil 4%, rubber powder 9%, tackifying petroleum resin C8 1%, calcium carbonate powder 6%.

Embodiment 3

[0024] Example 3: asphalt 54%, SBS 7%, pumping line 7%, machine oil 8%, rubber powder 11%, tackifying petroleum resin C9 2%, limestone powder 11%.

[0025] The method of preparing the anti-cracking sticker is to spread the tire base in the coating pool, attach the kneaded high-polymer modified asphalt material to both sides of the tire base, so that the high-polymer modified asphalt material can fully penetrate into the tire base so that it is compatible with the tire base. The tire base is firmly bonded, and finally the protective film layer is attached to the high-polymer modified asphalt material layer on one side at 130-150 ° C, and then cooled and cut into rolls. The mixing method of the high-polymer modified asphalt material is as follows: use a heat-conducting oil furnace to heat the storage tank containing the asphalt to melt the asphalt, and add the melted asphalt to the mixing reaction tank at 150-190°C for mixing with other raw materials 1 to 3 hours, and the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com