Noise reduction PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy material and preparation method thereof

An alloy material and noise reduction technology, which is applied in the field of polymers, can solve the problems of inability to reduce noise and silence, and achieve the effects of good appearance, simple preparation process, and improved impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0033] Examples 1-5 PC / ABS alloy material for noise reduction and sound elimination, the components and contents of the PC / ABS alloy material are shown in Table 1; wherein, the weight-average molecular weight of the PC resin is 22000g / mol and the glass transition temperature is 140°C; the relative weight-average molecular weight of ABS resin is 125,000g / mol, wherein the weight percentage content of butadiene is 25%, the weight percentage content of acrylonitrile is 25%, and the weight percentage content of styrene is 50%; the weight percentage of high damping silicone rubber The average molecular weight is 140000g / mol, the rubber particle size is 400-500nm, and the damping coefficient is 1.4; the antioxidant is Irganox 168 of Ciba Company; the lubricant is commercially available N,N-ethylene bisstearic acid amide.

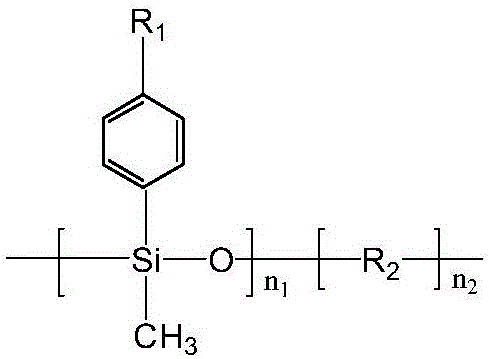

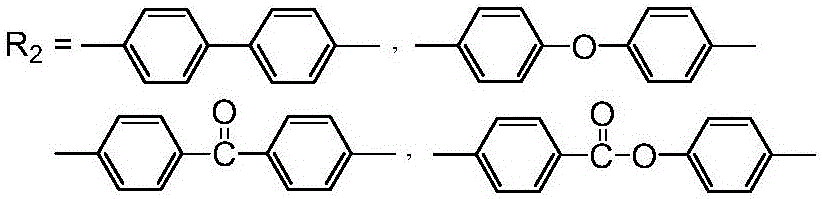

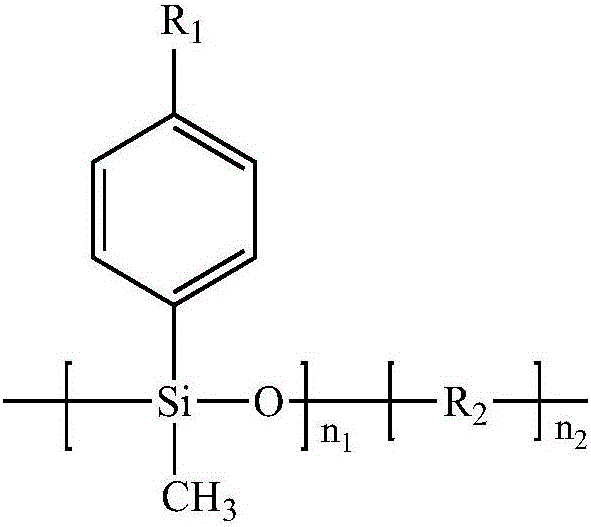

[0034] High damping silicone rubber is to put silicone rubber, damping agent polybutanone oxime silane, and white carbon black in the internal mixer at a weight rat...

Embodiment 6

[0047] This embodiment relates to a noise-reducing and sound-absorbing PC / ABS alloy material, and its preparation method is as follows:

[0048]a. Take the corresponding raw materials according to the following components and weight:

[0049]

[0050] b. First mix PC resin, ABS resin, high damping silicone rubber, antioxidant and lubricant in a mixing mixer;

[0051] c. Then, the mixture is blended and granulated by a twin-screw extruder to obtain noise-reducing and sound-absorbing PC / ABS alloy particles. The barrel temperature of the extruder is 220-270° C., and the screw speed is 300-700 rpm.

[0052] The relative molecular weight of PC resin is 18000g / mol, and its glass transition temperature is 140°C. It is a PC resin synthesized by transesterification method;

[0053] The relative molecular weight of the ABS resin is 120000g / mol, wherein the weight percentage content of butadiene is 20%, the weight percentage content of acrylonitrile is 26%, and the styrene weight per...

Embodiment 7

[0063] This embodiment relates to a noise-reducing and sound-absorbing PC / ABS alloy material, the preparation method of which is the same as that of Embodiment 6, except that:

[0064] Prepare materials according to the following components and parts by weight:

[0065]

[0066] The relative molecular weight of PC resin is 32000g / mol, and its glass transition temperature is 150°C. It is a PC resin synthesized by phosgene method;

[0067] ABS resin is a graft copolymer composed of acrylonitrile-butadiene-styrene, and its relative molecular weight is 185000g / mol, wherein the weight percentage content of butadiene is 30%, the weight percentage content of acrylonitrile is 25%, and the weight percentage content of styrene The percentage content is 45%;

[0068] High damping silicone rubber molecular weight is 200000g / mol, rubber particle size is 800-1000nm, damping coefficient is 0.8, and preparation method is identical with embodiment 7;

[0069] Antioxidant is the compound o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Relative weight average molecular weight | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com