Test structure of breakdown voltage, analytic procedure applying same and wafer

A technology of breakdown voltage and test structure, which is applied in the field of reliability testing of semiconductor technology, can solve problems such as uneven distribution of dielectric breakdown voltage between layers, and achieve the effect of easy and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

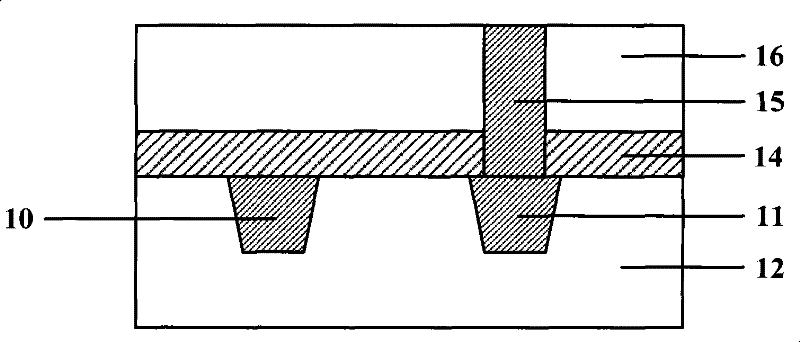

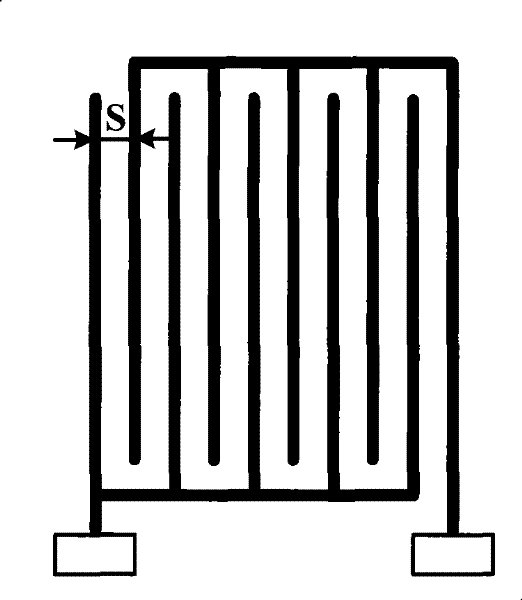

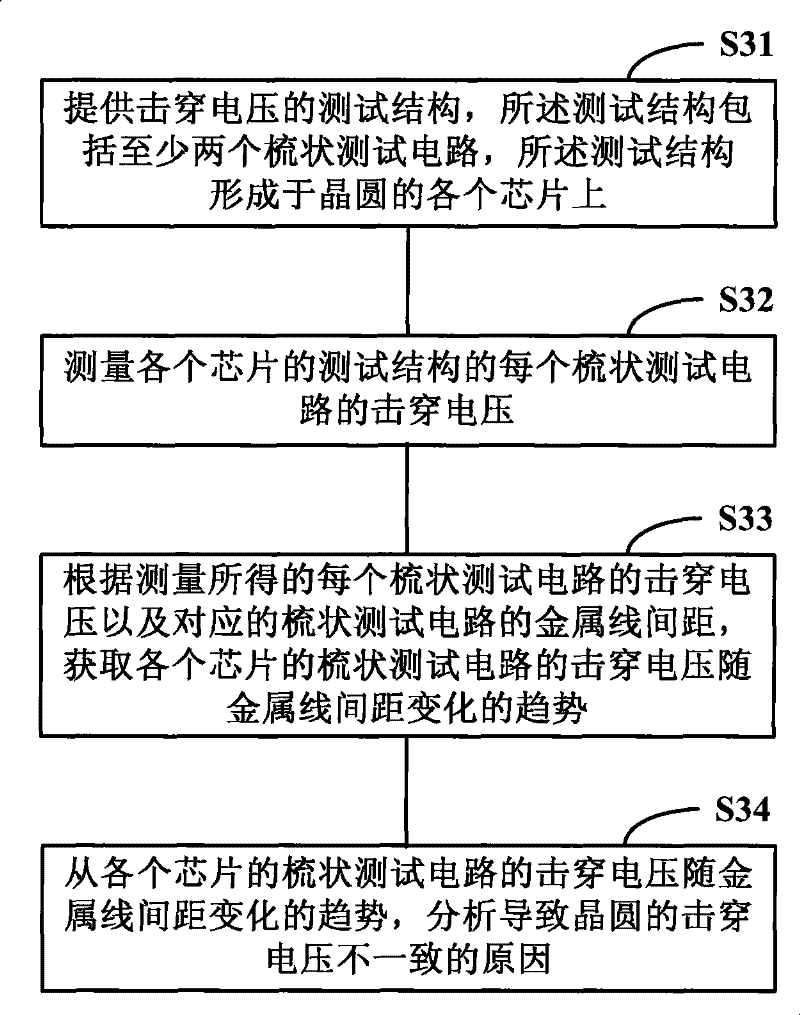

[0028] The breakdown voltage test structure provided by the embodiment of the present invention includes at least two comb-shaped test circuits of metal interconnection lines, wherein the distance between the metal lines in each comb-shaped test circuit is equal, and the metal lines of each comb-shaped test circuit The distances are not equal to each other, and the distance between the metal lines is the distance between any two adjacent metal lines in the comb test circuit. In the embodiment of the present invention, by adding comb-shaped test circuits with different metal line spacings, and measuring the breakdown voltage of each comb-shaped test circuit, it can be analyzed from the trend of the breakdown voltage changing with the metal line spacing that the distribution of the breakdown voltage is different. uniform cause. The specific implementation manners of the present invention will be described in detail below in conjunction with the drawings and embodiments.

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com