Metal material plastic yield strength detection device

A technology for plastic yielding and strength testing, which is applied to measuring devices, testing material strength by applying repetitive force/pulsation force, and analyzing materials. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

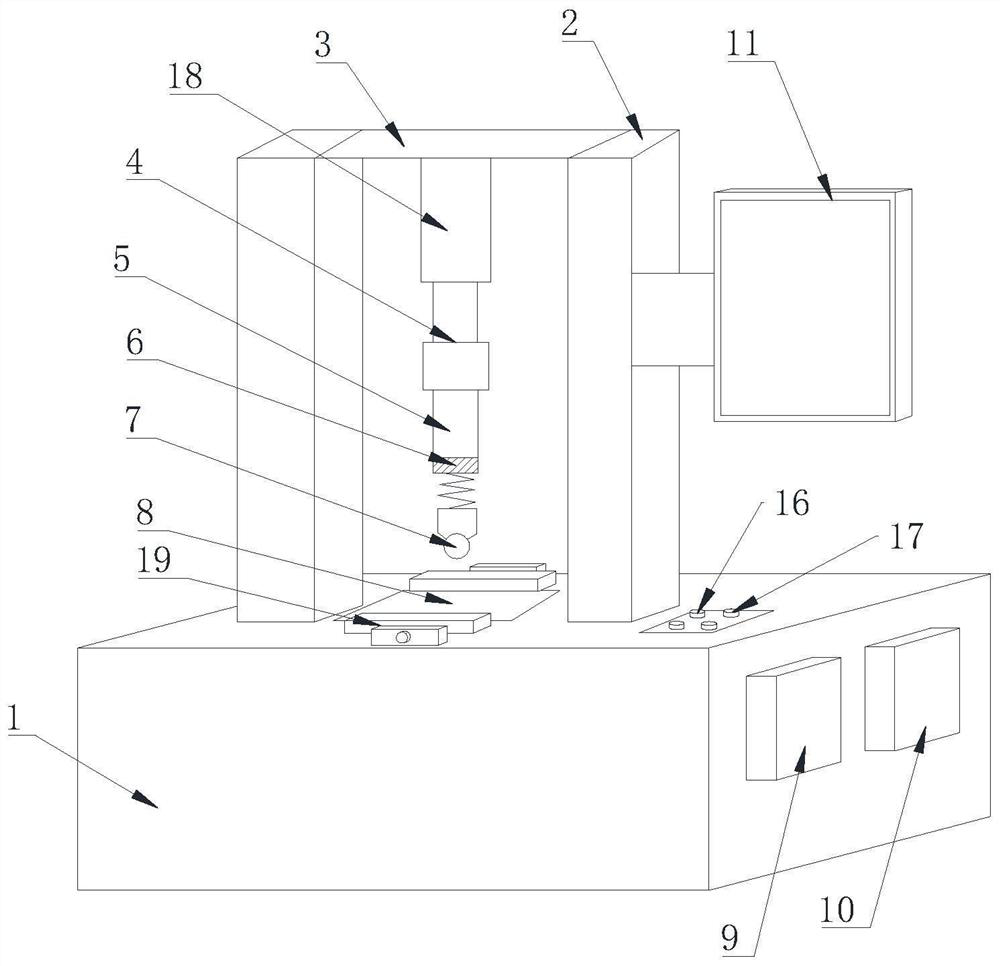

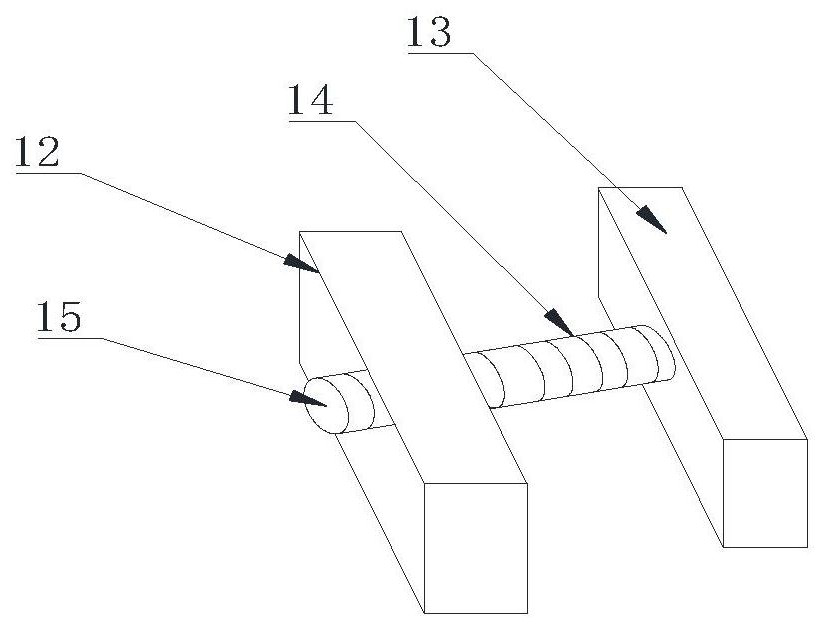

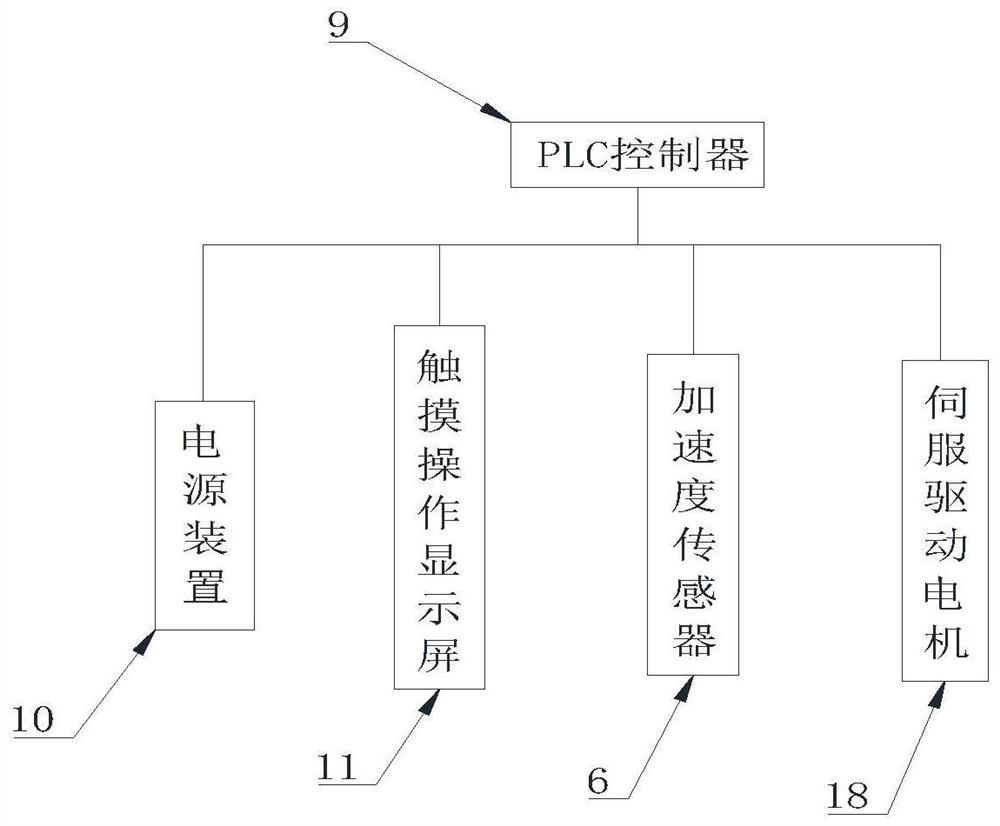

[0025] Embodiment: metal material plasticity yield strength detection device, as figure 1 , figure 2 and image 3 As shown, a detection platform 1 is included, and two support columns 2 are fixed on the top surface of the detection platform 1 at intervals. The tops of the two supporting columns 2 are connected by a horizontal beam 3 . The center of the bottom surface of the horizontal beam 3 is fixedly connected with a servo drive motor 18 . The output end of the servo drive motor 18 is fixedly connected with an adjustable telescopic rod 4 . The bottom end of the adjustable telescopic rod 4 is fixedly connected with an impact pressure head member 5 . An acceleration sensor 6 is fixedly mounted on the inner bottom end of the impact head member 5 . A cemented carbide ball 7 is fixedly connected to the bottom end of the impact head member 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com