Nondestructive testing method for metal surface welding cracks based on CSRR electromagnetic structure

An electromagnetic structure, welding crack technology, applied in the direction of material magnetic variables, etc., can solve the problems of large volume, high cost, complicated operation, etc., and achieve the effects of high detection accuracy, convenient operation and simple test structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

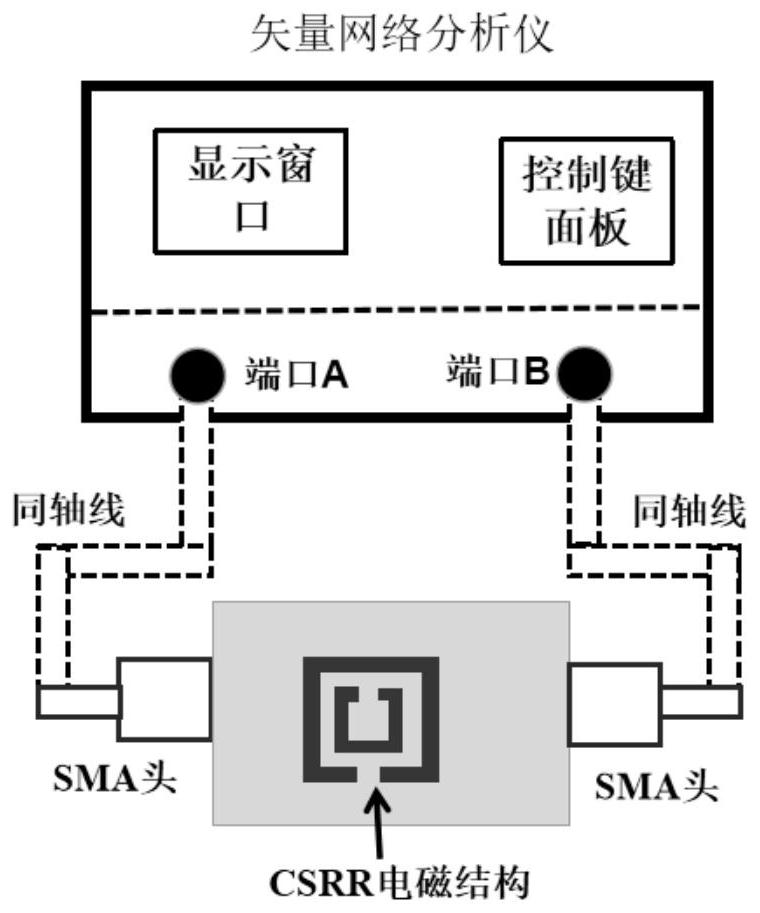

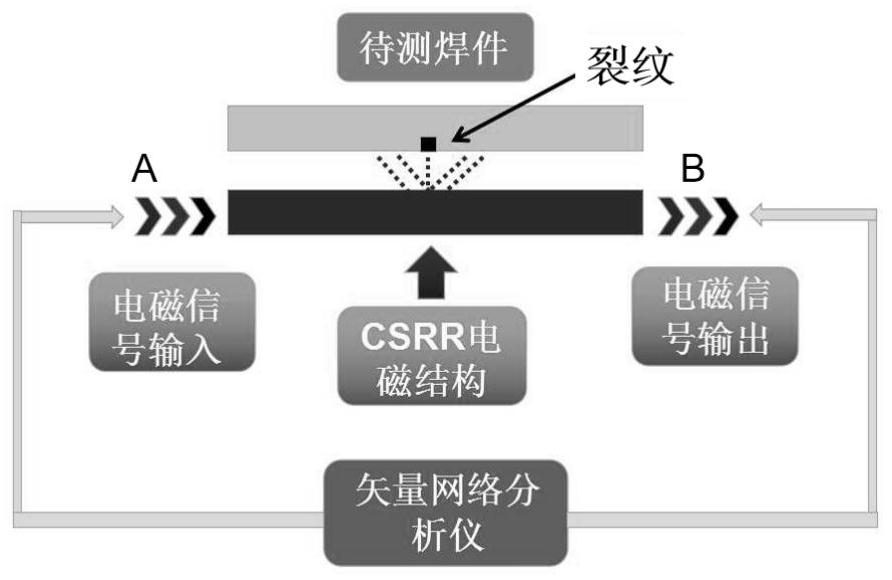

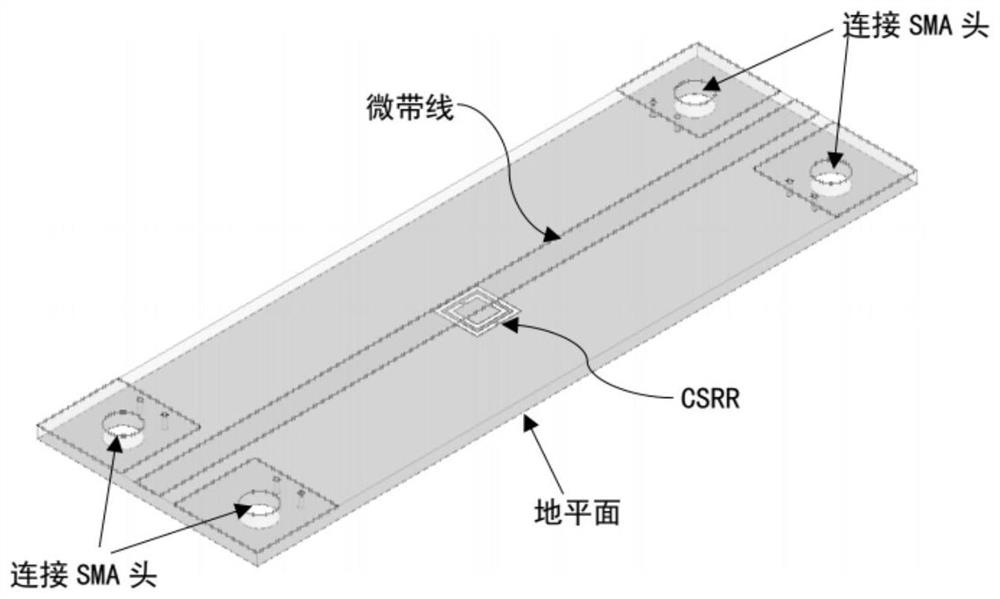

[0024] Non-destructive testing method for metal surface welding cracks based on CSRR electromagnetic structure. This non-destructive testing method mainly uses the sensitivity of CSRR electromagnetic structure to metal surface welding cracks to realize the non-destructive testing of metal surface welding cracks; the main tests used in this detection method The equipment includes: vector network analyzer, CSRR electromagnetic structure, welded parts with welding cracks, and the connection relationship of the detection circuit is as follows figure 1 shown.

[0025] like figure 1 As shown, the A port of the vector network analyzer is connected to the SMA connector of the CSRR electromagnetic structure through the coaxial line to provide excitation electromagnetic signals for the CSRR electromagnetic structure. The excitation electromagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com