Test system of high power frequency conversion electric drive equipment

A test system and transmission equipment technology, applied in the direction of motor generator test, measuring instrument, measuring device, etc., can solve the problems of weak adaptability and convertibility, low test efficiency, high cost, etc., to improve adaptability and reliability The effect of changing ability, reducing labor intensity and cost, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

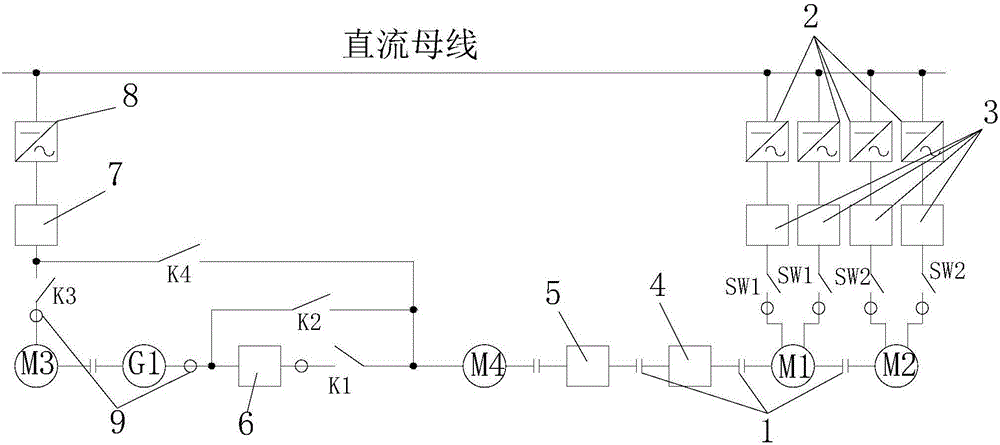

[0028] figure 1 It is the principle diagram of the present invention, as shown in the figure, a high-power variable frequency electric drive equipment testing system provided by the present invention includes a test loading feedback unit, a motor under test connected to the test loading feedback unit, and a tested The frequency converter under test connected to the motor, and the test drive feedback unit connected to the output end of the frequency converter under test, the power end of the test load feedback unit is connected to the DC bus, and the power end of the test drive feedback unit is connected to the DC bus. The busbar connection, through the above structure, can effectively improve the adaptability and transformability of the system, and can meet the requirements of modern mining, and the whole system can accurately test the high-voltage frequency conversion transmission equipment, and effectively simplify the test structure, without frequent disassembly and assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com