Experimental apparatus and method for preparing natural gas hydrate rock sample via two-step process

An experimental device and hydrate technology, applied in the preparation of test samples, gas fuel, petroleum industry, etc., can solve the problems of large differences in synthesis conditions, complex deposition environment, and difficulty in accurately controlling hydrate saturation, and achieve economic savings Equipment cost, meet the experimental requirements, and calculate the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

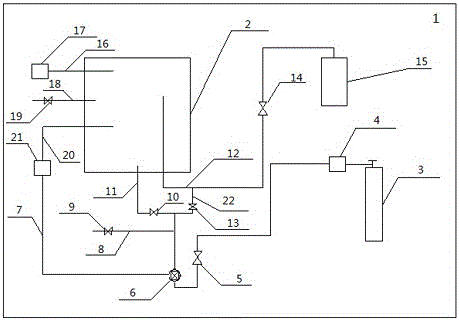

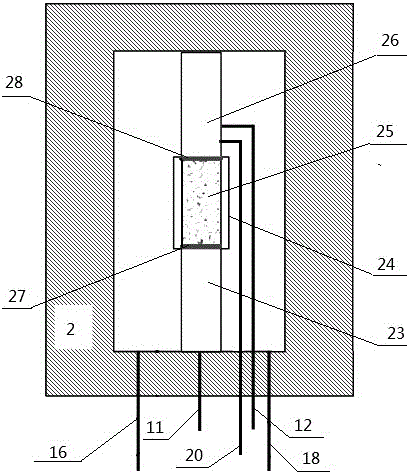

[0043] Such as figure 1 As shown, the experimental device for preparing natural gas hydrate rock samples by the two-step method includes installing a reaction kettle 2, a methane cylinder 3, a gas flow meter 6, a recovery air bag 15, a confining pressure pump 17, a computer data acquisition system 21, and The first vent valve 14, the second vent valve 19 and so on.

[0044] The methane cylinder is connected to the reaction kettle 2 through the first high-pressure pipeline 11 after the pressure reducing valve 4, and is used to provide methane for the generation of hydrate in the sample;

[0045] The confining pressure pump 17 is connected to the reactor 2 through the second high-pressure pipeline 16, and is used for applying confining pressure to the sample in the reactor 2;

[0046] Cold storage 1 can realize temperature control from -20°C to room temperature, and all experimental equipment and experimental processes are carried out in the cold storage;

[0047] The first ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com