Micro-nano-scale material seebeck coefficient online measurement method

A Seebeck coefficient and measurement method technology, which is applied in the field of thermoelectric performance testing of micro-nano thermoelectric conversion materials, can solve the problems of increasing the complexity of the preparation process and increasing measurement errors, and achieve stable test parameter values, convenient production, and simple and reliable calculations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0025] Such as figure 1 Shown:

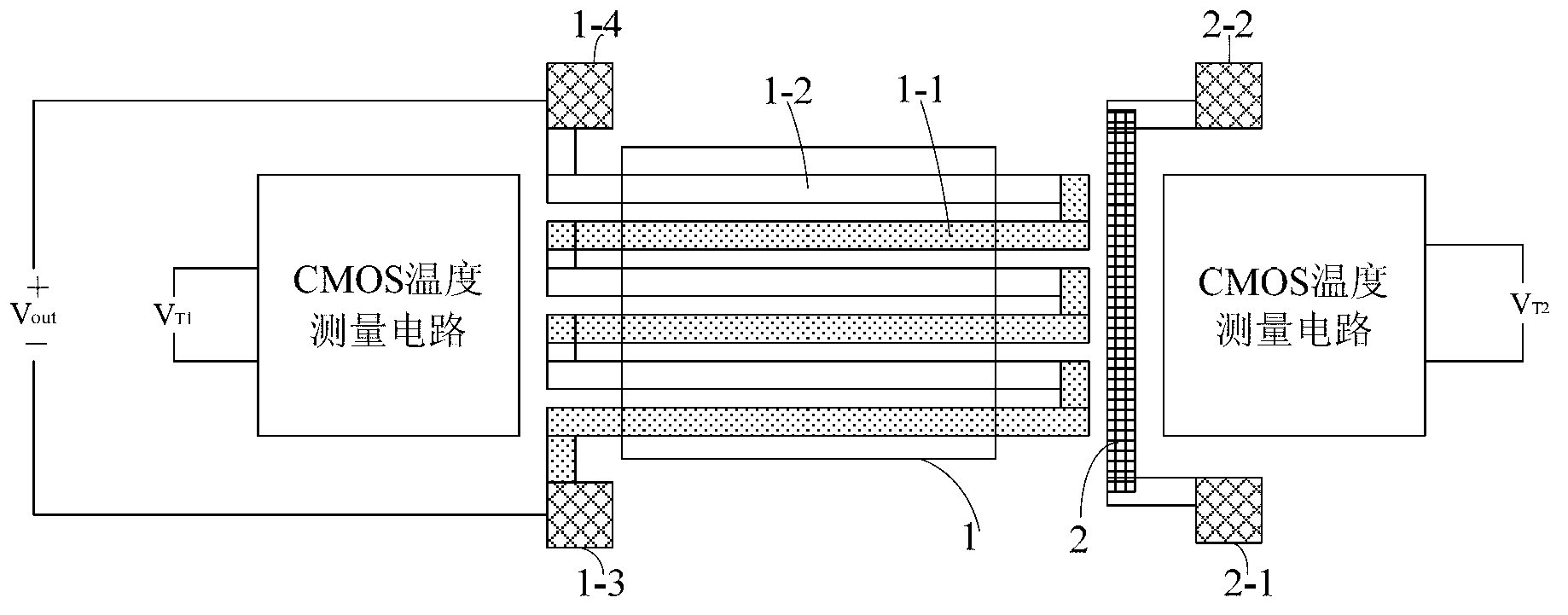

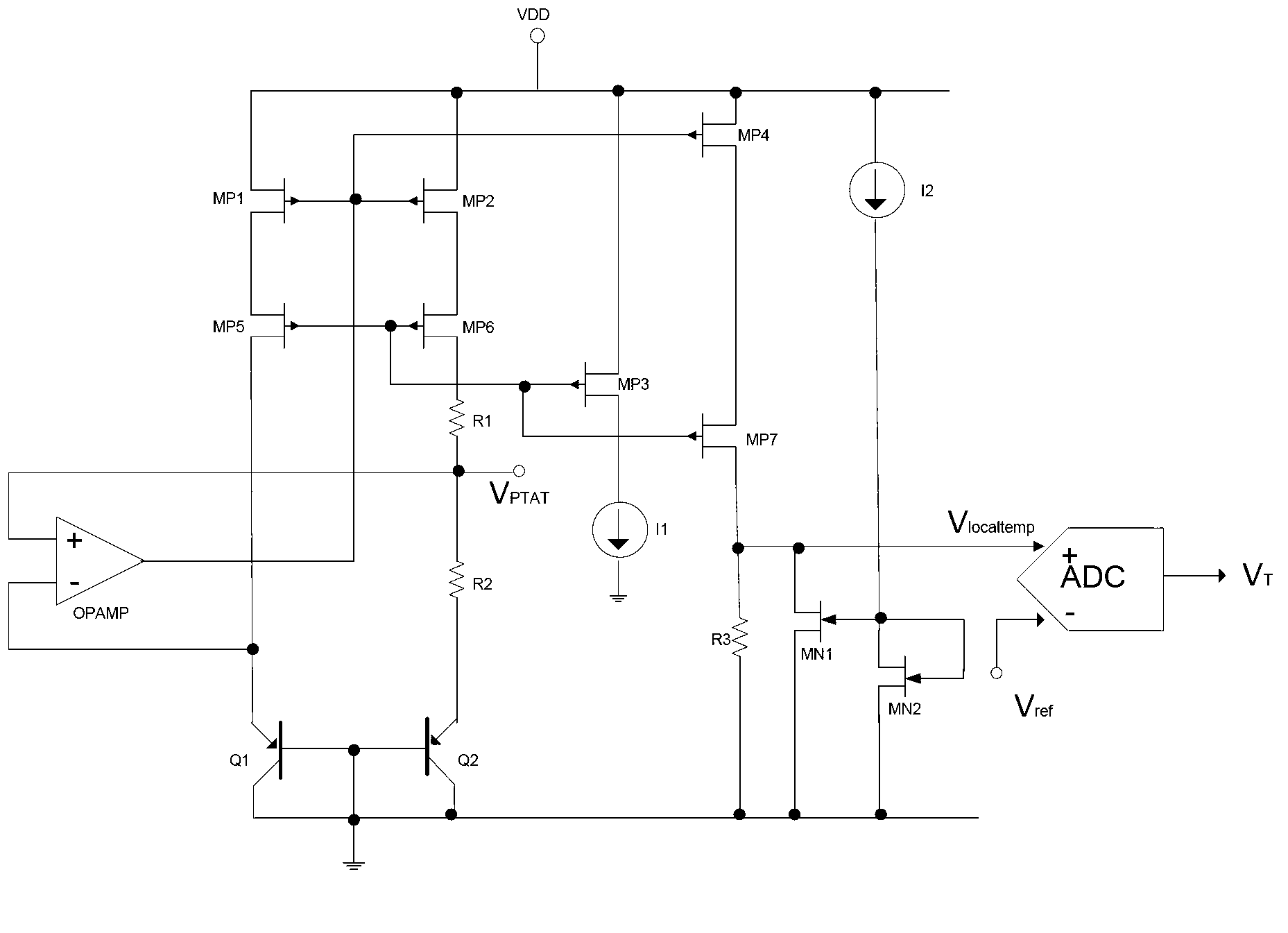

[0026] The measurement structure of this method includes a silicon substrate, a heating resistor 2, a CMOS temperature measurement circuit, and a thermopile 1. In this embodiment, the thermopile 1 includes three pairs of thermocouples arranged in parallel and connected in series. Using multiple pairs of thermocouples can reduce measurement errors. The heating resistor 2 is used to heat the hot end of the thermopile 1, and the CMOS temperature measurement circuit is used to measure the absolute temperature of the hot and cold end of the thermopile 1 online. The thermocouple, heating resistor 2 and CMOS temperature measurement circuit are all located on the silicon substrate.

[0027] Each pair of thermocouples includes thermocouple strips 1-1 and thermocouple strips 1-2 of different micro-nano materials. The materials of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com