Vehicle air throttle air inflow test system and testing method

A throttle body and testing system technology, applied in mass flow measurement devices, indirect mass flow meters, fluid flow detection using thermal effects, etc., can solve problems such as uneconomical and inconvenient, high process requirements, complex structure, etc., and achieve convenience The effect of low purchase and comprehensive cost and simple test structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

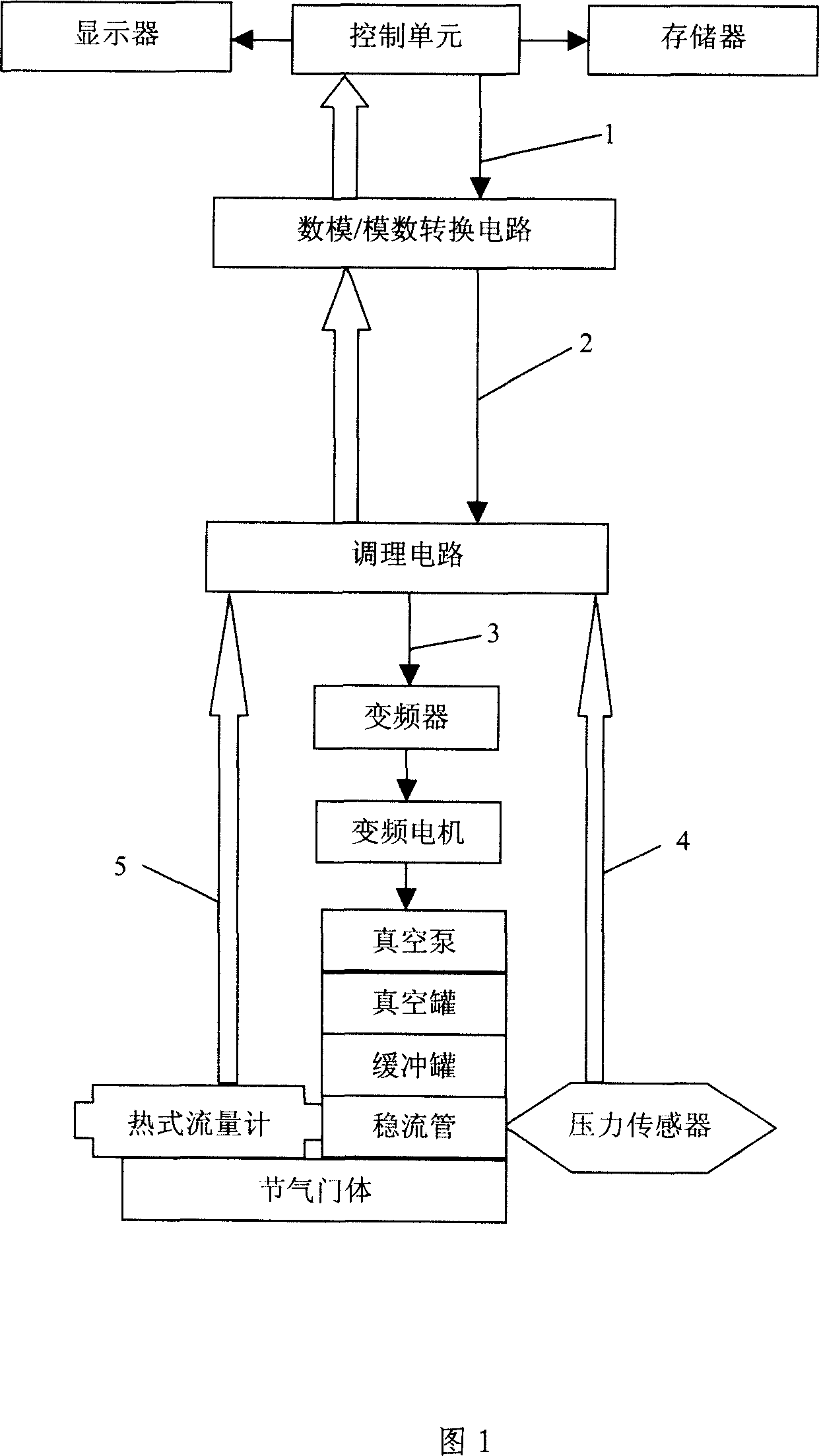

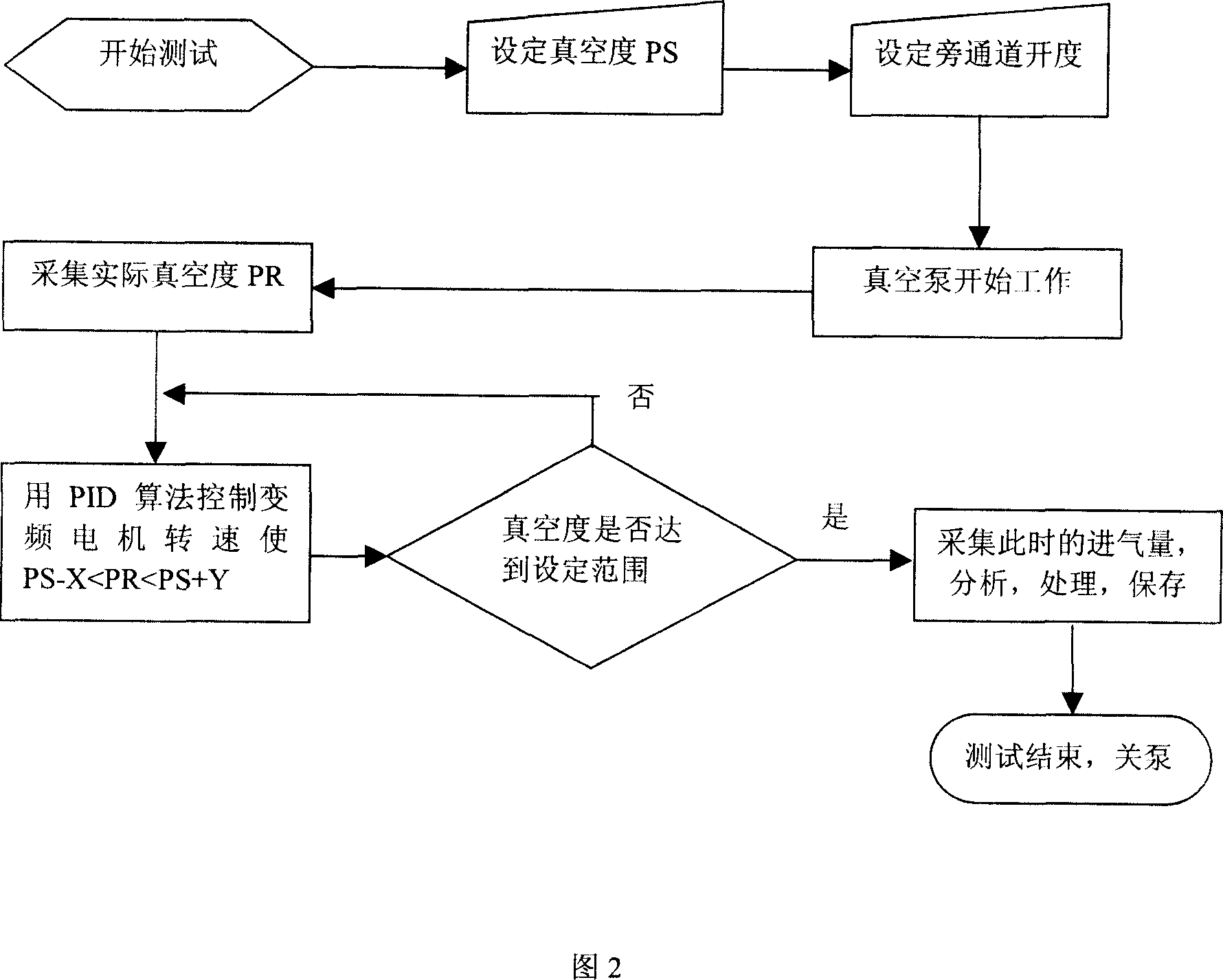

[0030] Specific embodiment one, as shown in Fig. 1, this testing system comprises vacuum source, pressure sensor, thermal gas flowmeter, also comprises the conditioning circuit connected in sequence, analog-to-digital / digital-to-analog conversion circuit and control unit, and vacuum source comprises gas Guide chamber, vacuum pump, variable frequency motor and frequency converter. The gas diversion cavity is connected with the air outlet of the throttle body, the frequency converter is electrically connected with the conditioning circuit, and responds to the control signal of the control unit. . The function of the conditioning circuit is to amplify and filter the passed analog signal. The pressure sensor and the thermal gas flowmeter are also respectively electrically connected to the conditioning circuit. The pressure sensor is arranged in the gas guiding cavity and is used for measuring the vacuum degree in the gas guiding cavity. The thermal gas flowmeter is also arrange...

specific Embodiment 2

[0053] Specific embodiment two, different from embodiment one, is that it is difficult to stabilize the actual vacuum degree when the vacuum degree adjustment is around the set vacuum degree and fluctuates greatly, it may be considered to add a buffer tank in the gas diversion chamber, A buffer tank is connected between the tank and the steady flow tube. The buffer tank is conducive to stabilizing the vacuum degree in the gas diversion chamber within the error range of the set vacuum degree. The buffer tank can be one or connected in series one by one. Multiple, until the vacuum degree in the steady flow tube can be stabilized within the error range of the set vacuum degree.

[0054] The present invention can not only be used for testing the gas mass flow rate of different opening degrees of the bypass channel of the automobile throttle body, but also can test the gas mass flow rate of different opening degrees of the main channel. In addition to detecting the intake air volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com