Bogie hanging system parameter testing device and method

The technology of a suspension system and test method is applied in the field of test of bogie suspension parameters to achieve the effects of overcoming friction and blocking force interference, improving test accuracy and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

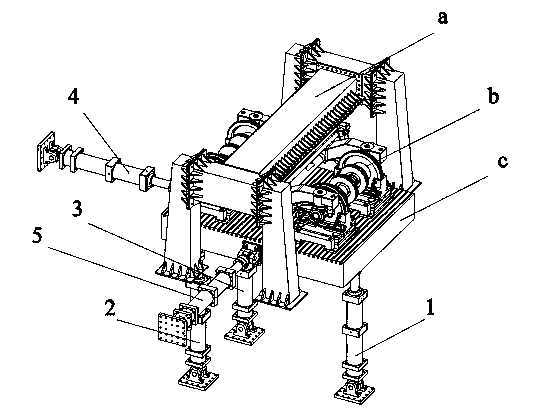

[0067] Taking CRH380 series bogie as an example

[0068] 1. Take the static vertical stiffness test as an example, according to the above test process:

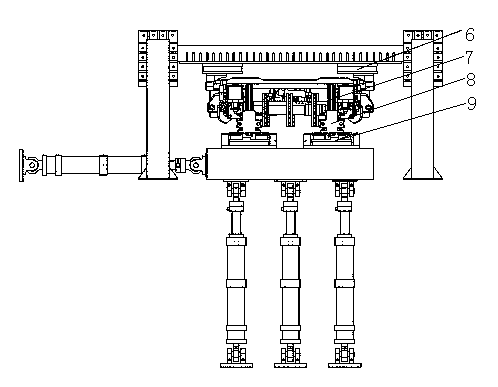

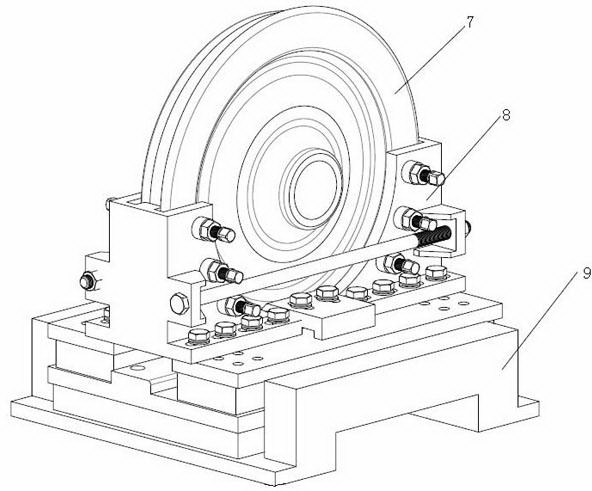

[0069] A. Install the bogie on the test platform, refer to figure 2 , the wheel pair 7 is installed on the wheel pair fixture 8, the wheel pair fixture is installed on the lower three-dimensional force measuring platform 9, and the lower three-dimensional force measuring platform is fixed on the motion platform;

[0070] B. By adjusting the appropriate height of the motion platform, connect the upper three-dimensional force measuring platform on the bogie bolster and the gantry frame, and fix the upper part of the bogie;

[0071] C. By raising and lowering the motion platform, the collected force value of the lower three-dimensional force measuring platform is the same as the test force value given in the test program, and then the initial height position of the motion platform is determined;

[0072] D. After the bogie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com