Structure for testing micro-beam breaking strength based on longitudinal comb-tooth-type capacitor

A technology of comb structure and test structure, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, using electrical devices, etc., can solve problems such as product differences, and achieve the effect of high sensitivity and simple test structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

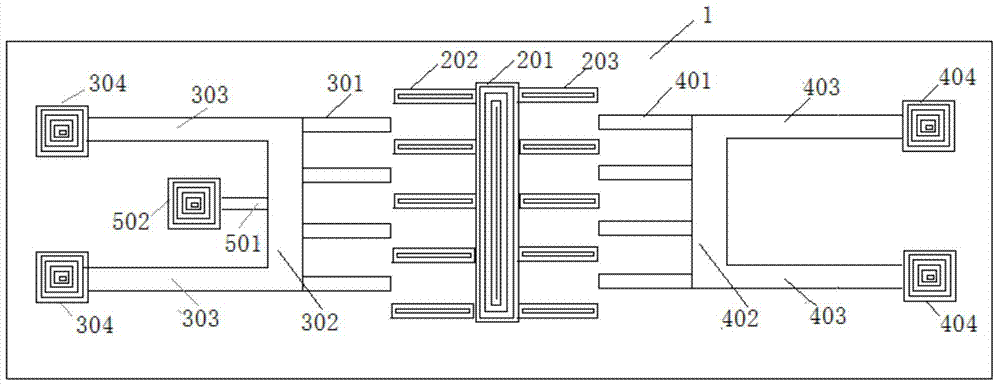

[0015] A test structure of the fracture strength of a microbeam based on a longitudinal comb-tooth capacitor of the present invention includes a substrate, a bidirectional comb-tooth structure, two identical semi-sealed rectangular structures with a single row of comb-tooths, and a quilt Micrometer beam structure. The two-way comb structure is composed of a bar-shaped anchor area and comb teeth connected to both sides of the anchor area; a row of comb teeth is connected to the outer side of the vertical side of the semi-sealed rectangular structure, and two comb teeth perpendicular to the side The ends of the transverse sides are connected to the sides of the respective anchor areas; the two half-sealed rectangular structures with comb teeth are symmetrically distributed on the left and right sides of the two-way comb structure, and the comb ends are connected with the comb teeth of the two-way comb structure. The comb teeth of the semi-closed rectangular structure are movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com