Structure for testing Young modulus of top silicon layer of silicon-on-insulator

An on-insulating substrate, Young's modulus technology, applied in the application of repetitive force/pulsation force to test the strength of materials, coupling of optical waveguides, components of TV systems, etc. Excessive corrosion of the oxide layer, occupying a large area, etc., to achieve the effect of simple signal loading and measurement, simple fundamental frequency method, and stable and accurate calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

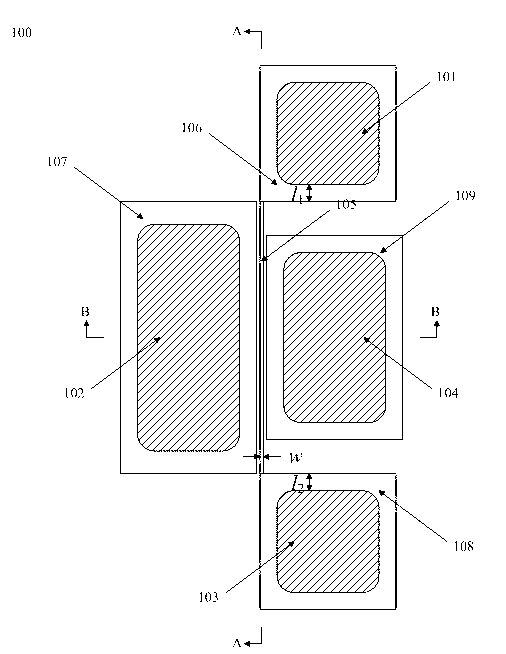

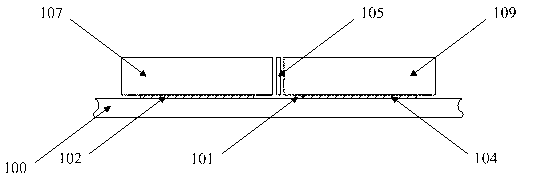

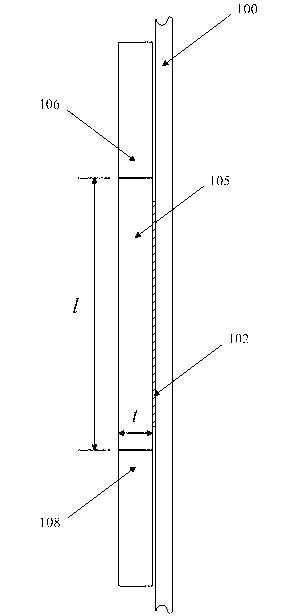

[0016] A test structure of the Young's modulus of the silicon material top silicon layer on an insulating substrate, comprising: a substrate 100 formed by a silicon substrate in the silicon material on an insulating substrate, on which an insulating The first insulating region 101, the second insulating region 102, the third insulating region 103 and the fourth insulating region 104 formed by the insulating layer in the silicon material on the substrate, in the first insulating region 101, the second insulating region 102, the fourth insulating region The first anchor region 106, the detection electrode 107, the second anchor region 108 and the excitation electrode 109 formed by the top silicon layer in the silicon material on the insulating substrate are respectively provided on the third insulating region 103 and the fourth insulating region 104. Between the detection electrode 107 and the excitation electrode 109 is provided a resonant beam 105 formed by the top silicon laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com