Bearing seal ring durability testing device

A durability test and bearing sealing technology, which is applied in the testing of machine sealing rings, measuring devices, and mechanical components, can solve problems such as complex use environments, shorten the development cycle, improve the ability to develop new products, and improve the development cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

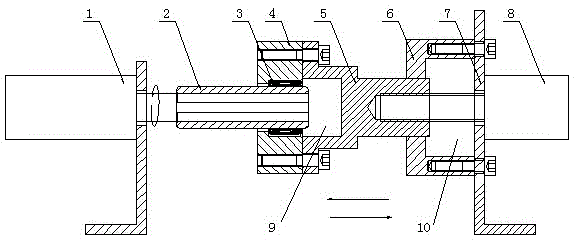

[0012] Such as figure 1 As shown, the bearing seal ring durability test device is characterized in that it includes a transmission device and a moving device, the transmission device includes a servo motor 1 and a transmission shaft 2 arranged on the servo motor, and the transmission shaft 2 is provided with a test bearing 3 and a bearing block 4, the moving device includes a connecting plate 5, a support 6, a fixed plate 7 and a cylinder 8, the connecting plate 5 of the moving device is set on the bearing block 4, and the connecting plate 5 is connected with the support 6, The bracket 6 is connected to the fixed plate 7, the cylinder 8 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com