Method for achieving reverse modeling by using post program

A technology of reverse modeling and programming, applied in the direction of program control, simulator, general control system, etc., can solve the problems of long cycle, digital model cannot be used as the basis for direct processing, and the design process is difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

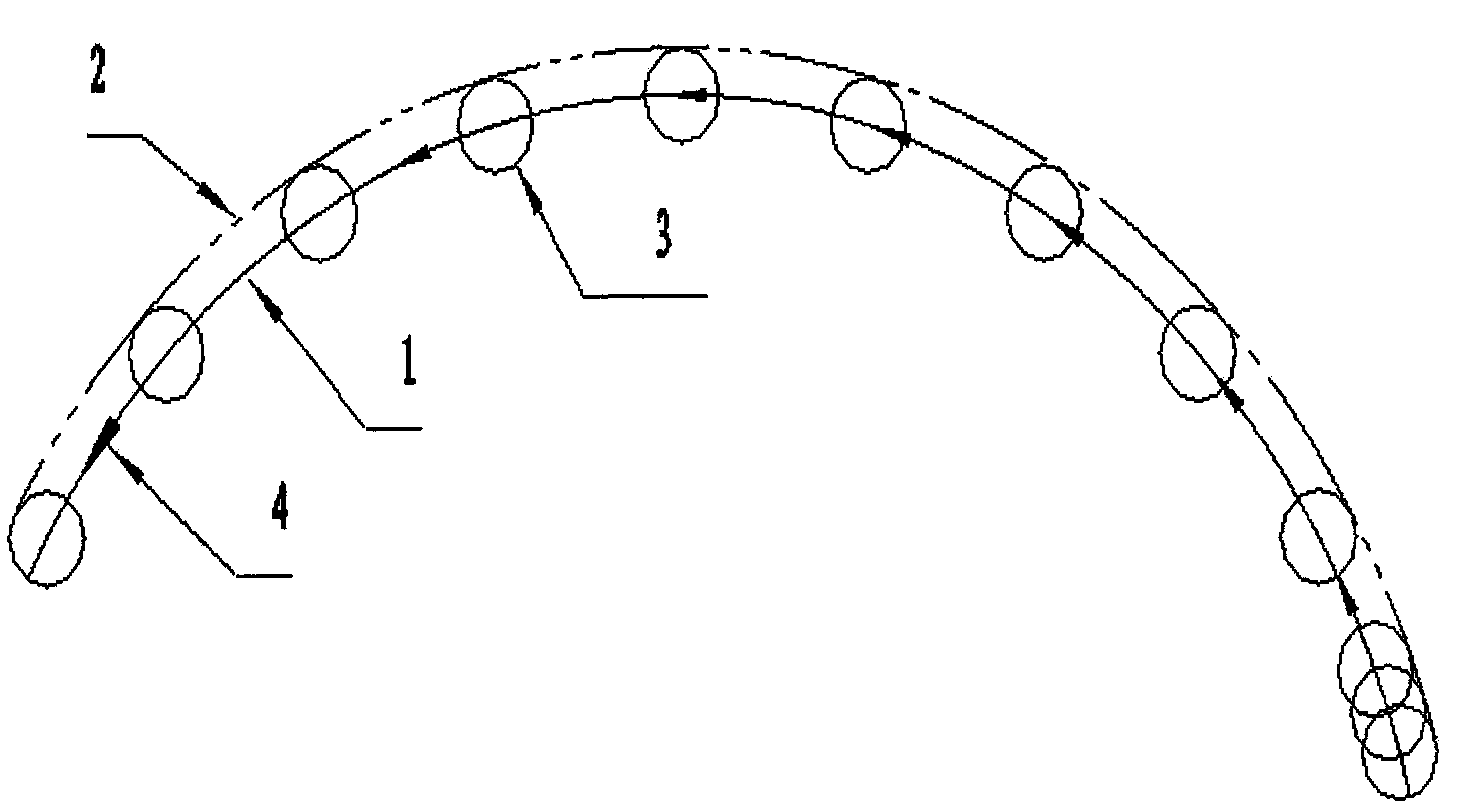

[0013] A method for reverse modeling of an application post-program, comprising the following steps:

[0014] 1) Use the CNC tool measuring instrument to accurately measure the tool and determine the tool parameters, because the post-program is attached to the shape of the tool, only by accurately inputting the tool parameters can the numerical model with the correct value be obtained in the subsequent simulation software;

[0015] 2) Input the measured tool parameters, wool parameters and coordinate system into the post-program, and substitute the post-program into the NC machining simulation system VERICUT software developed by CGTECH in the United States, and perform simulation demonstration through the Export Model function. Use the Export Model function to export the demonstration results to the IGES format file, which can obtain the digital model of the surface patch of the part to be processed;

[0016] 3) Open the IGES format file with Catia V5.0 software, convert the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com