Online measuring structure of residual strain of polysilicon film and testing method

A polysilicon thin film, residual strain technology, applied in the direction of electric/magnetic solid deformation measurement, measuring device, electromagnetic measuring device, etc., can solve the problems of unfavorable thin film residual strain on-line detection, slow test speed, difficult to re-detect, etc., to achieve the test method Simple and easy to implement, test the effect of simple structure and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

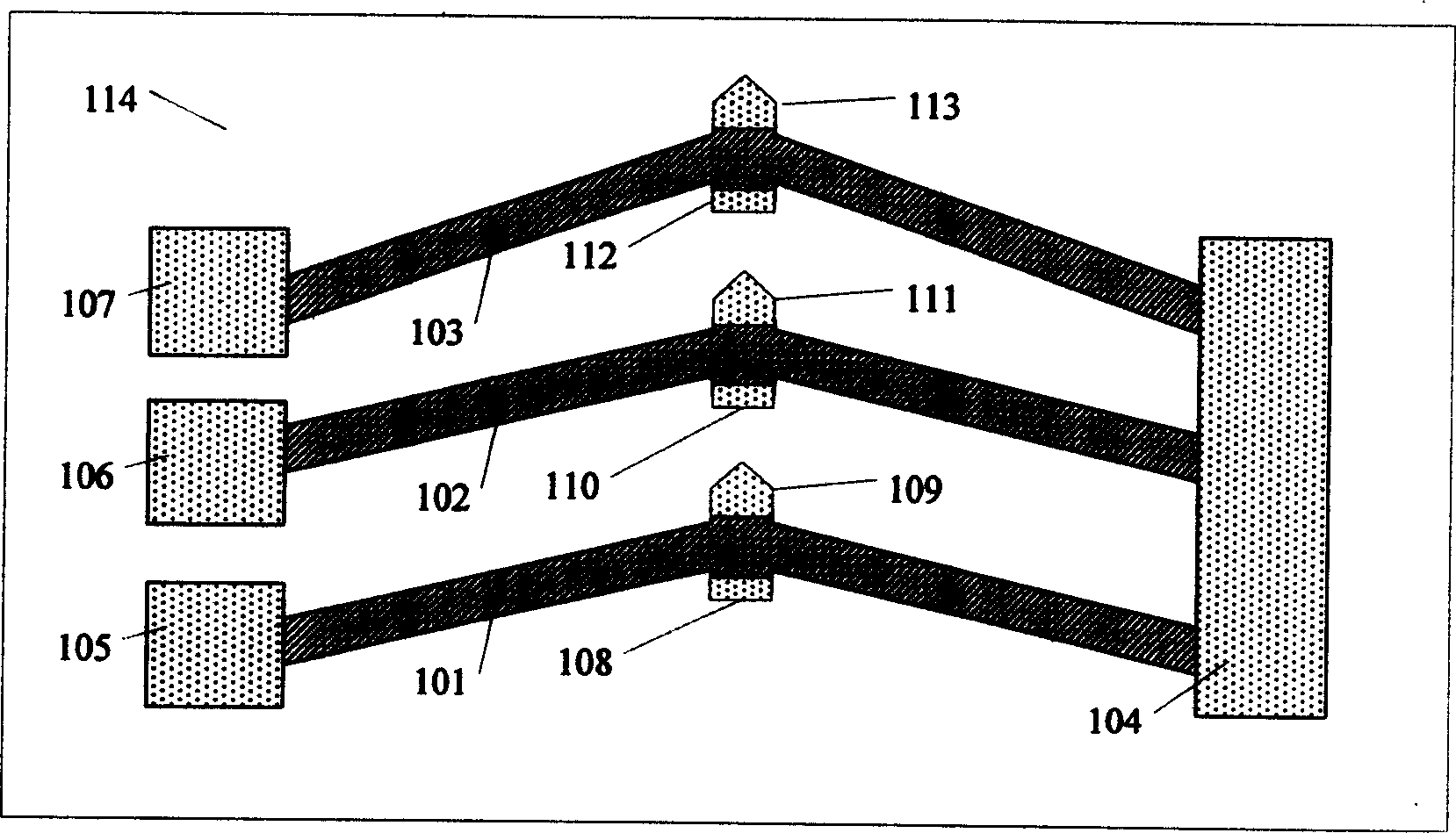

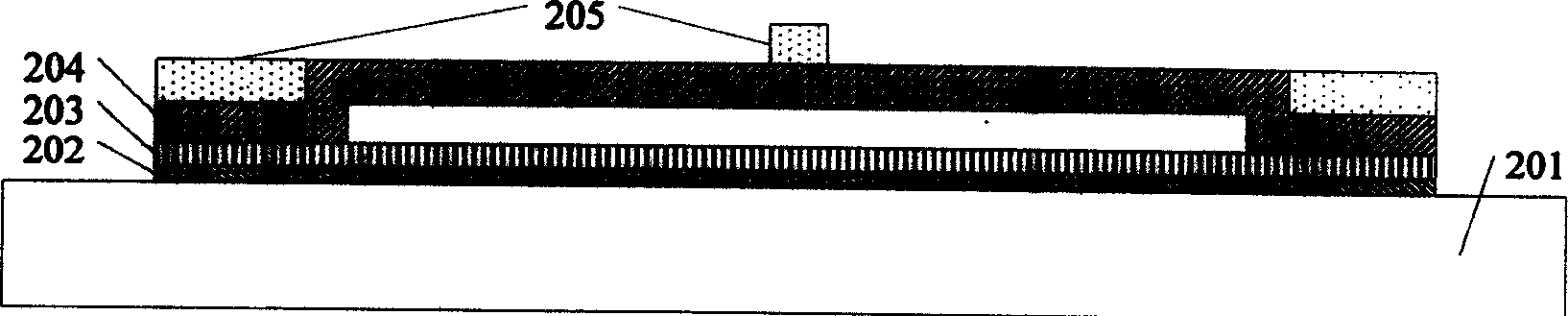

[0012] The present invention is an on-line detection structure for the residual strain of polysilicon thin films based on the surface processing technology. The soldering blocks are the first pressure-bonding block 105, the second pressure-bonding block 106, the third pressure-bonding block 107, and the fourth pressure-bonding block 104; the three polysilicon bending beams are arranged in parallel, in the middle of the three polysilicon bending beams Contacts are respectively provided on both sides of the point, and the distance between the contacts is equal; The second pressure welding block 106 and the fourth pressure welding block 104 are respectively connected, and the two ends of the third curved beam 103 are respectively connected with the third pressure welding block 107 and the fourth pressure welding block 104 . In order to make the adjacent curved beam structures have better electrical contact, the middle of each curved beam is plated with a metal film, that is, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com