Flotation separation method of fluorite and dolomite in acidic conditions

A separation method and dolomite technology, which is applied in the field of flotation separation of fluorite and dolomite, can solve the problems of using too much reagent, difficult flotation separation, high production cost, etc., and achieve the effect of less reagent consumption and simple process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Mineral raw materials:

[0022] In the mineral raw materials used, the content of fluorite is 53.27%, the content of quartz is 5.62%, the content of dolomite is 23.90%, and the content of calcium carbonate is 0.95%. The phase analysis shows that the ore mainly contains fluorite, dolomite, quartz and acid Calcium, and a small amount of barite minerals.

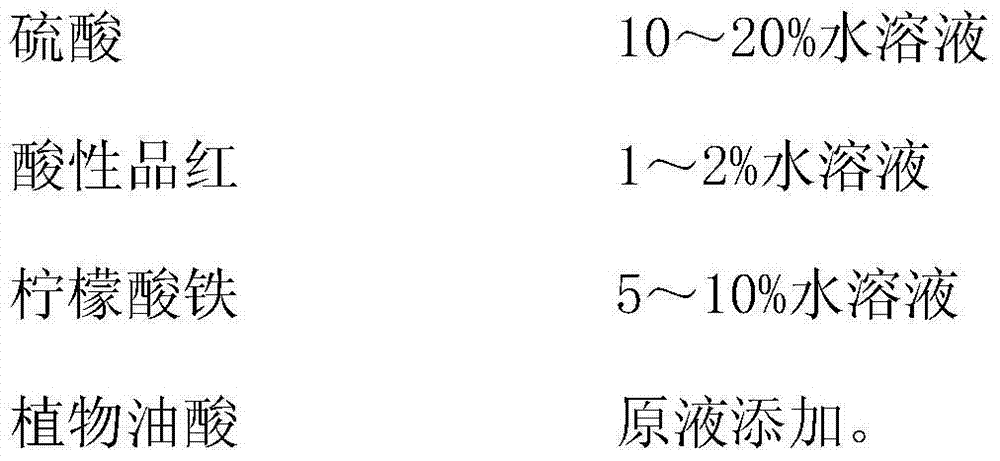

[0023] 2. Flotation agents and operating conditions:

[0024]

[0025] When in use, the medicament is first prepared into the following weight percent concentrations:

[0026]

[0027] During the flotation process, the ore is ground until the mineral monomers are dissociated, and sulfuric acid is added to adjust the pH value of the pulp to 5-5.5, then acid fuchsin and ferric citrate are added to suppress dolomite and other impurity minerals, and then plants are added to Fluorite minerals are collected to obtain fluorite concentrate products. Tests have shown that fluorspar minerals can be effectively recovere...

Embodiment 2

[0029] In the mineral raw materials used, the content of fluorite is 57.20%, the content of quartz is 4.91%, the content of dolomite is 25.19%, and the content of calcium carbonate is 1.25%. The phase analysis shows that the ore mainly contains fluorite, dolomite, quartz and acid Calcium, and a small amount of barite minerals.

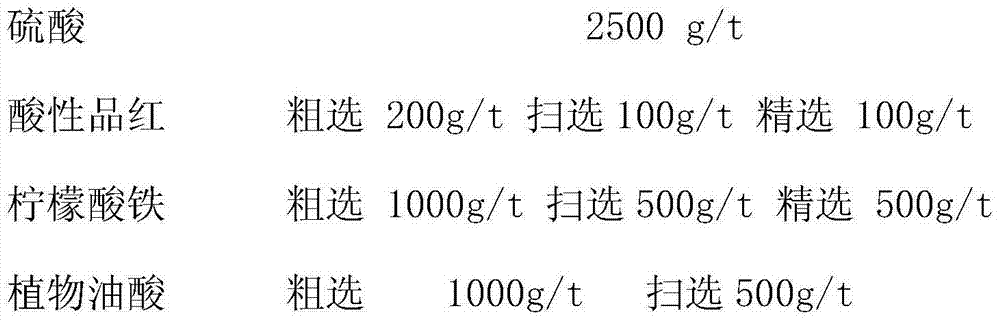

[0030] 2. Flotation agents and operating conditions:

[0031]

[0032] When in use, the medicament is first prepared into the following weight percent concentrations:

[0033]

[0034] During the flotation process, the ore is ground until the mineral monomers are dissociated, and sulfuric acid is added to adjust the pH value of the pulp to 5-5.5, then acid fuchsin and ferric citrate are added to suppress dolomite and other impurity minerals, and then plants are added to Fluorite minerals are collected to obtain fluorite concentrate products. Tests have shown that fluorspar minerals can be effectively recovered according to the above process par...

Embodiment 3

[0036] In the mineral raw materials used, the content of fluorite is 60.19%, the content of quartz is 3.67%, the content of dolomite is 26.20%, and the content of calcium carbonate is 1.30%. The phase analysis shows that the ore mainly contains fluorite, dolomite, quartz and acid Calcium, and a small amount of barite minerals.

[0037] 2. Flotation agents and operating conditions:

[0038]

[0039]

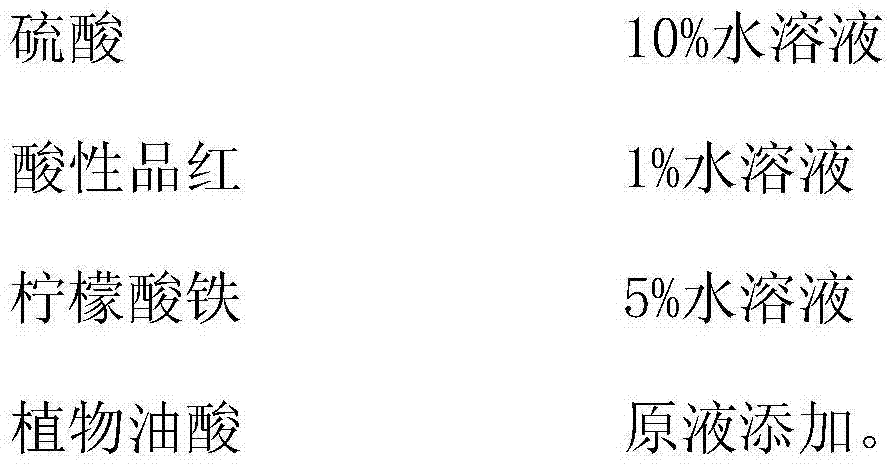

[0040] When in use, the medicament is first prepared into the following weight percent concentrations:

[0041]

[0042] During the flotation process, the ore is ground until the mineral monomers are dissociated, and sulfuric acid is added to adjust the pH value of the pulp to 5-5.5, then acid fuchsin and ferric citrate are added to suppress dolomite and other impurity minerals, and then plants are added to Fluorite minerals are collected to obtain fluorite concentrate products. Tests have shown that fluorspar minerals can be effectively recovered according to the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com