Long-acting no-leakage plunger sealing structure for plunger type measuring pump

A technology of sealing structure and metering pump, which is applied to the components of pumping devices for elastic fluids, variable displacement pump components, pumps, etc., can solve problems such as restricting the use range of plunger type metering pumps, and achieve excellent sealing effect. , The effect of simple process structure, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

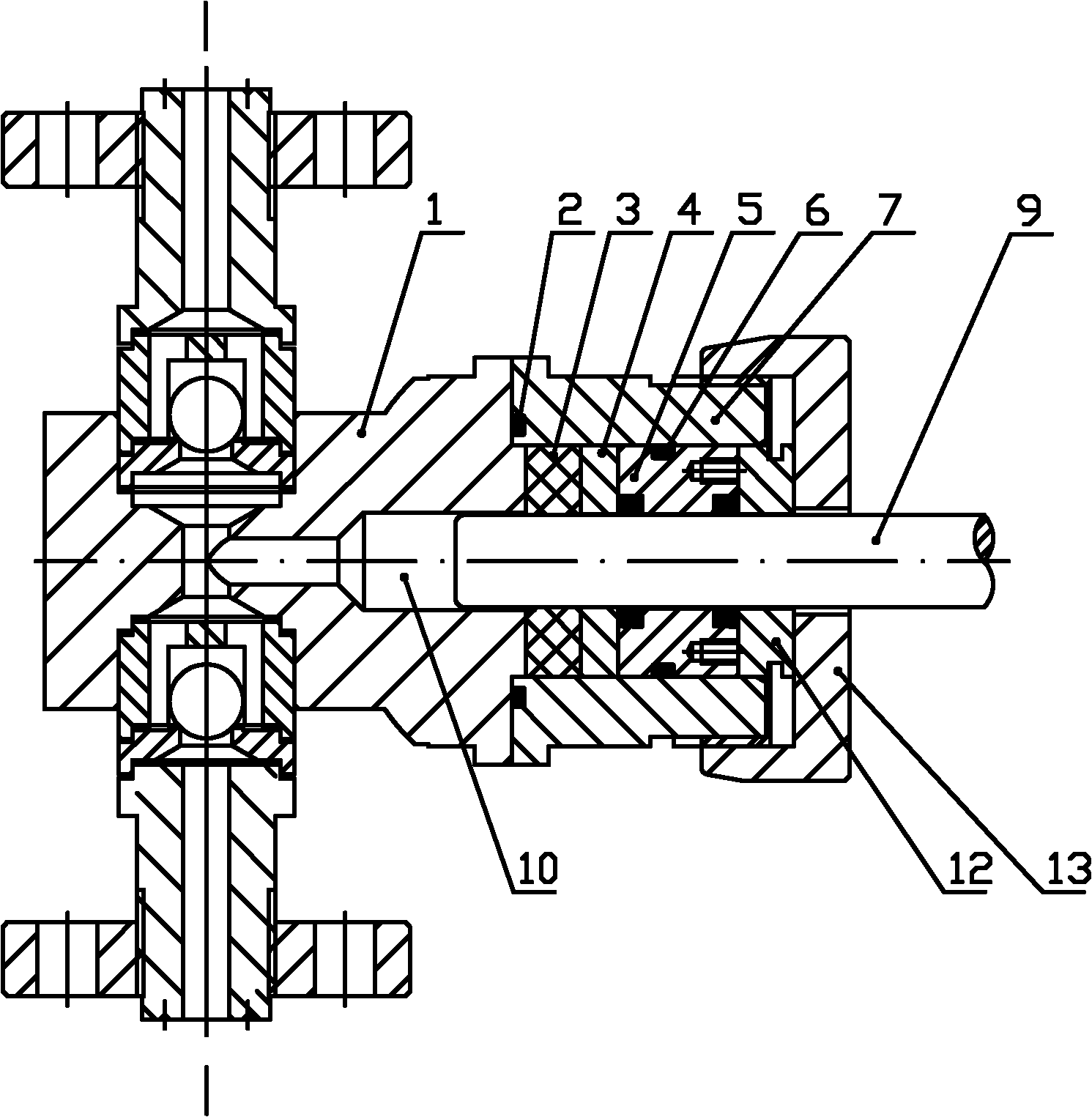

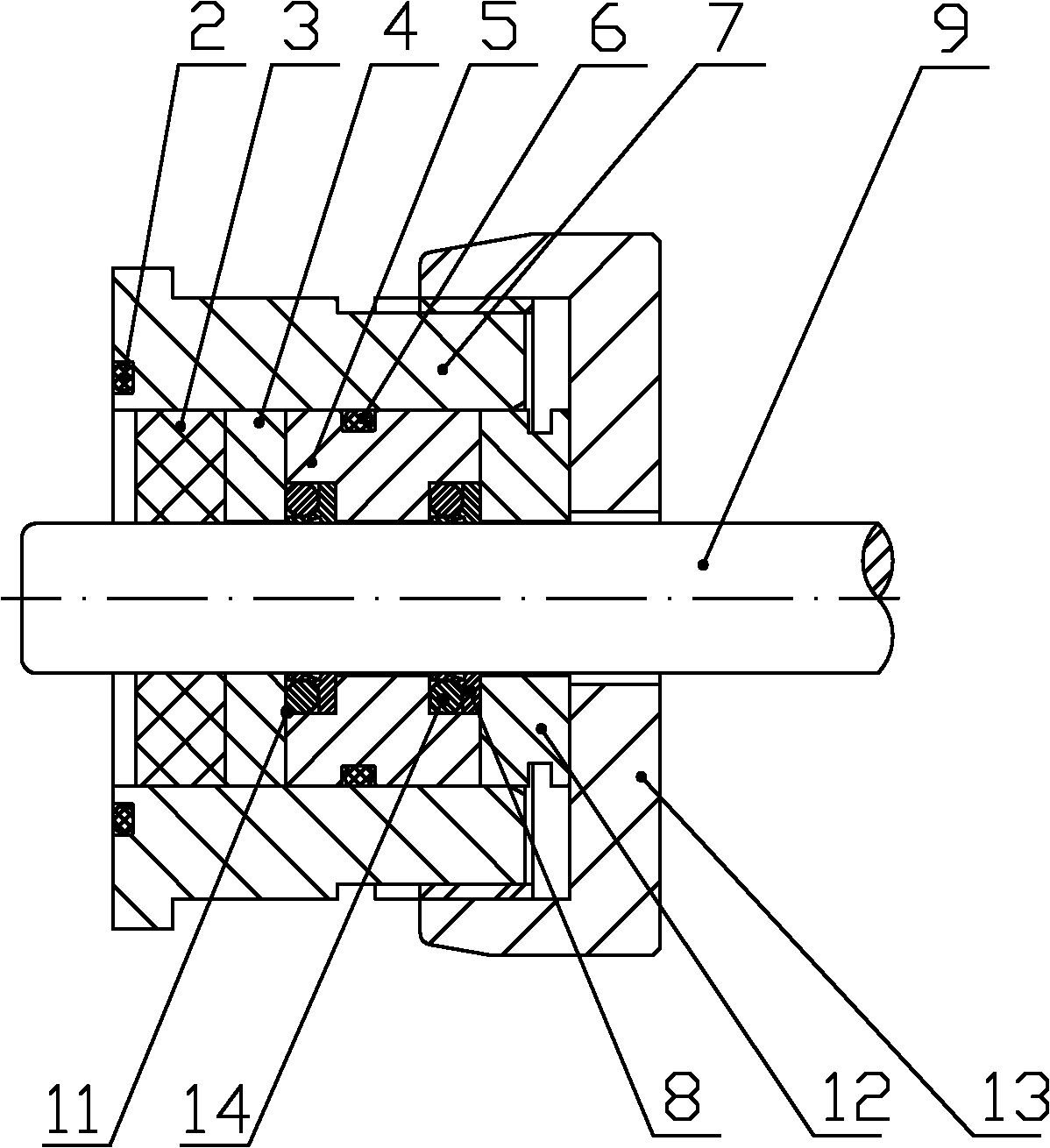

[0020] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0021] In this embodiment, the plunger seal structure includes a stuffing box 7, a gland 12, and a compression nut 13 screwed to the stuffing box 7; the end surface of the stuffing box 7 connected to the plunger pump head 1 is provided with a built-in O-shaped Ring groove for seal ring 2.

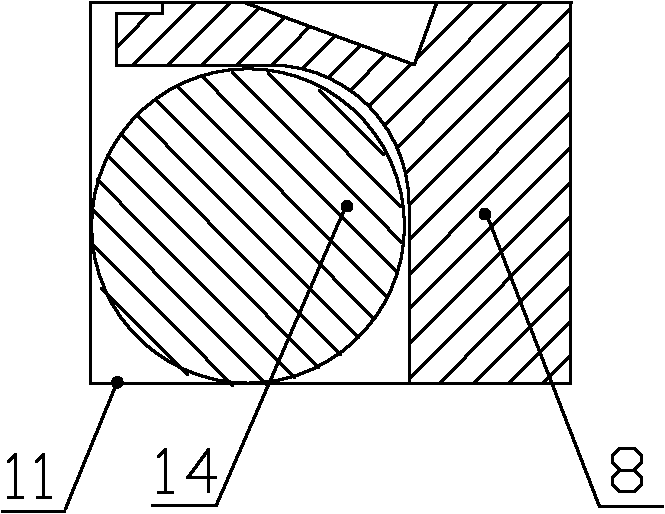

[0022] The inside of the stuffing box 7 is a cylindrical through hole, which is equipped with a guide ring 3, a spacer ring 4 and a combined sealing sleeve 5 sequentially. The plunger 9 of the plunger type metering pump passes through the compression nut 13 and the gland in sequence. 12. Combined sealing sleeve 5, spacer ring 4 and guide ring 3; the combined sealing sleeve 5 is in the shape of a ring column, and its outer cylindrical surface is provided with an annular groove with a built-in O-shaped sealing ring 6; the inner surface of the combined se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com