Sludge incineration treatment system

A treatment system and sludge incineration technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high energy utilization, pollute the environment, low pollution discharge, etc., and achieve the effect of improving the drying medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

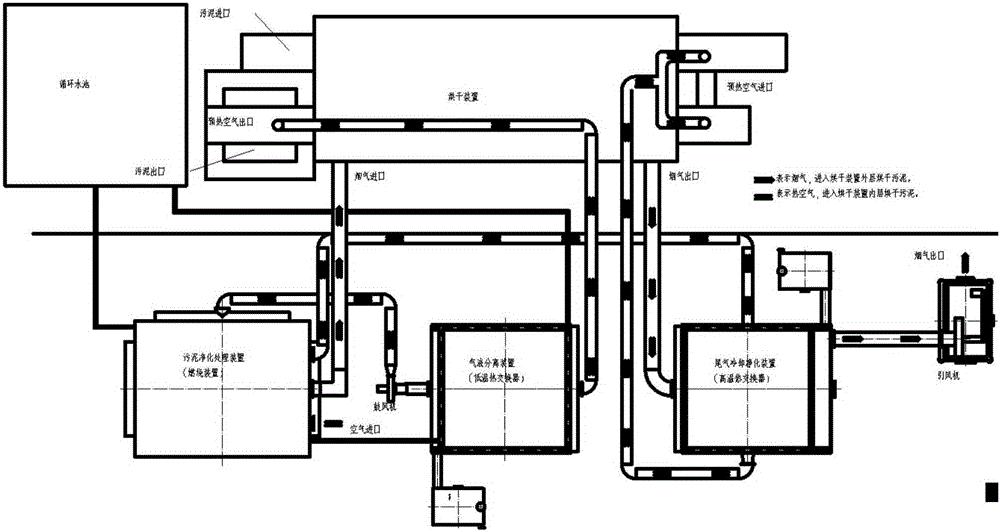

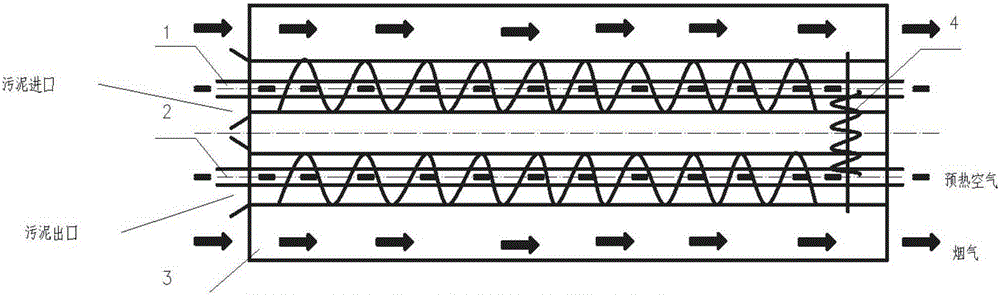

[0019] A sludge incineration treatment system, which includes a sludge purification treatment device, a gas-liquid separation device, a tail gas purification device, a drying device, a blower and an induced draft fan, characterized in that: the drying device and the tail gas purification device are divided into two Layer, the flue gas produced by the sludge purification treatment device enters the outer layer of the drying device to indirectly dry the sludge, and the flue gas entering the outer layer of the drying device enters the outer layer of the exhaust gas purification device from the outlet of the outer layer of the drying device; The hot air generated by the sludge purification treatment device enters the inner layer of the exhaust gas purification device for preheating, and the preheated air enters the inner layer of the drying device through the inner layer outlet of the exhaust gas purification device to directly dry the sludge, and the preheated air It enters the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com