Industrial powder explosive loading process and explosive loading machine set thereof

A charge and powder technology, applied in the field of explosives, can solve the problems of complex and bulky mechanical devices, large vibration and noise, etc., and achieve the effect of simple process structure, large charge quantity, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

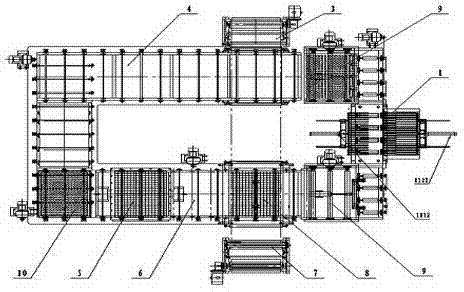

[0077] The invention provides an industrial powdery explosive charging process, which is realized through the following steps:

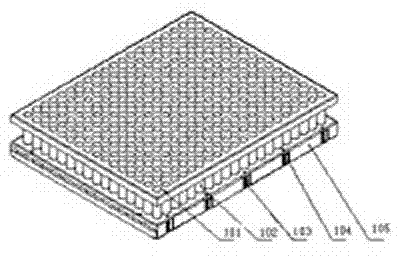

[0078] Step 1: Put the empty plastic tubes into the turnover mold in sequence;

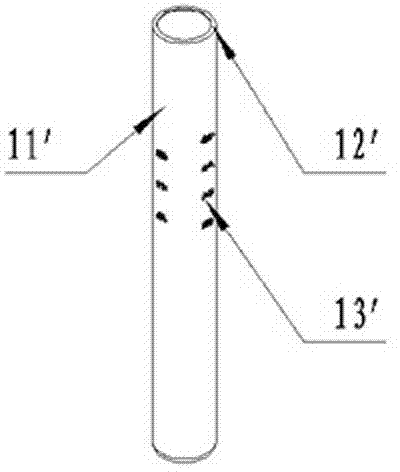

[0079] Step 2: Pull and transport the turnover mold to the charging process, and carry out the positioning charging of the turnover mold. The charging process adopts vibration filling to complete the charging of all empty plastic tubes in the turnover mold; cleaning process;

[0080] Step 3: The plastic tube in the turnover mold is pulled and transported to the sealing process, and the plastic tube is sealed and cut;

[0081] Step 4: After the turnover mold is turned 90 degrees, it is transported to the mold unloading and tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com