Method for degrading perfluorinated compounds

A compound and substance technology, applied in the field of degrading perfluorinated substituted compounds, can solve the problems of non-substitution, harsh reaction conditions, and high equipment, and achieve the effects of reduced toxicity and simple process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

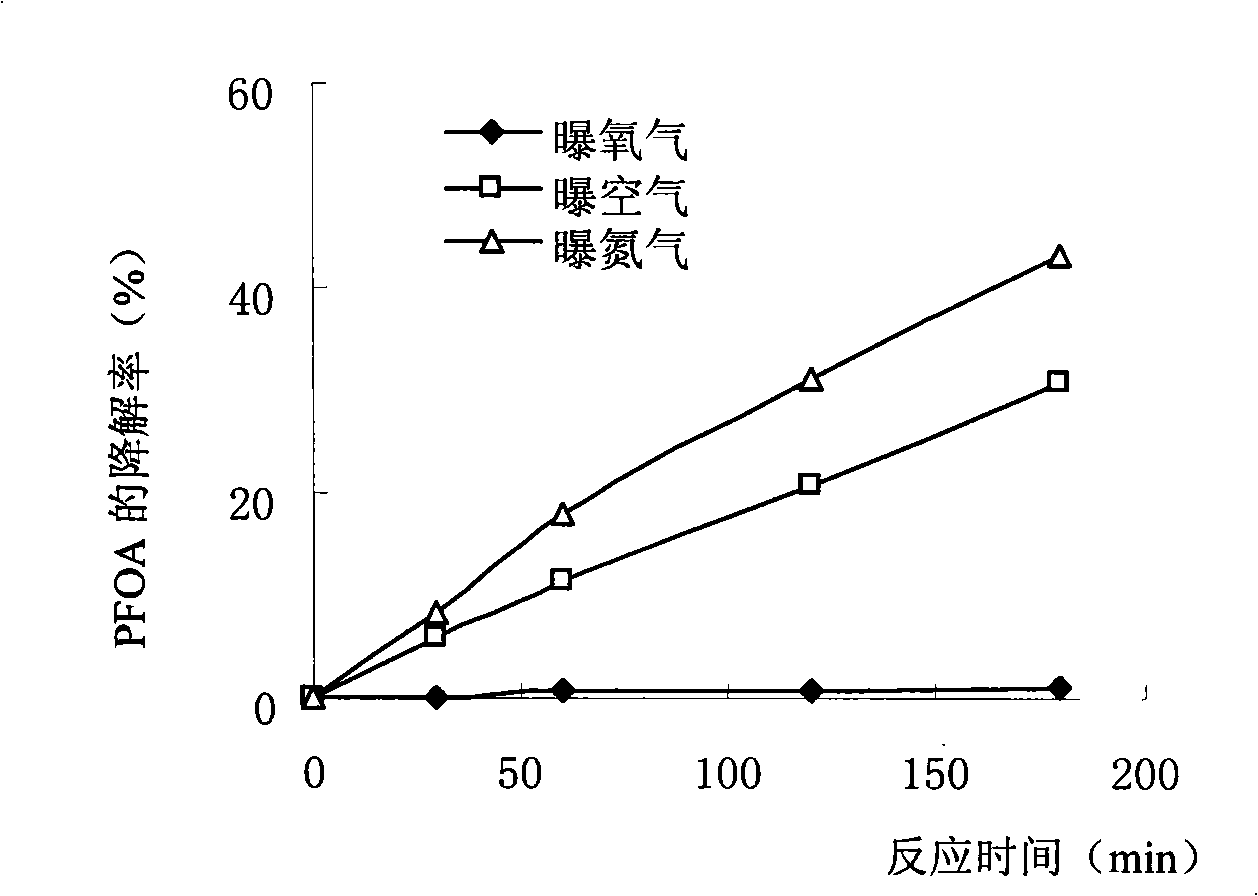

[0028] The photocatalytic degradation of embodiment 1, perfluorooctanoic acid (PFOA)

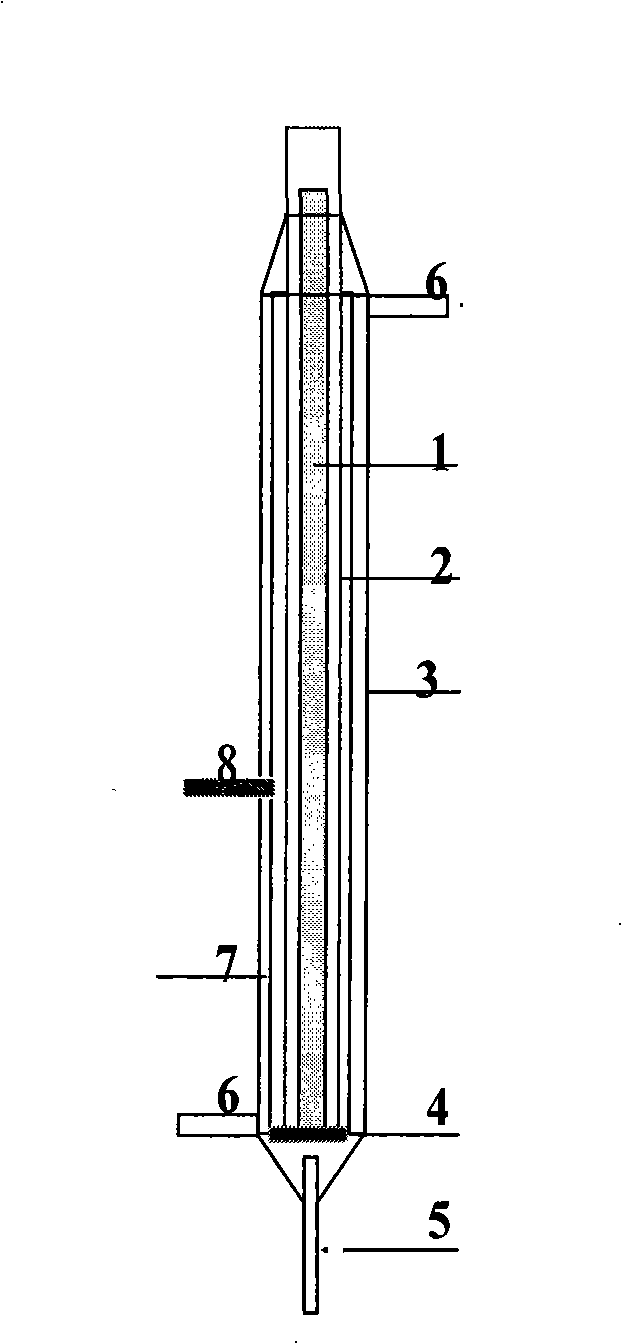

[0029] A reaction device for photocatalytic degradation of perfluorinated compounds such as figure 1 shown. The device includes the following components: a light source 1, which is used to emit ultraviolet light with a wavelength less than 400nm; a quartz sleeve 2, which can pass through ultraviolet rays, and is used to isolate ultraviolet rays from the reaction solution; a reaction vessel 3, which is a place for degradation of perfluorinated compounds; The aeration plate 4 is used to pass inert gases such as nitrogen and argon or reducing gases such as ammonia into the reaction vessel 3 to drive away the oxygen in the reaction vessel 3 and also to stir the reaction solution; the gas is added Port 5 is used to add inert gas or reducing gas to the reaction system; condensed water inlet and outlet 6; cooling water circulation device 7 is used for cooling water circulation to reduce the heat g...

Embodiment 2

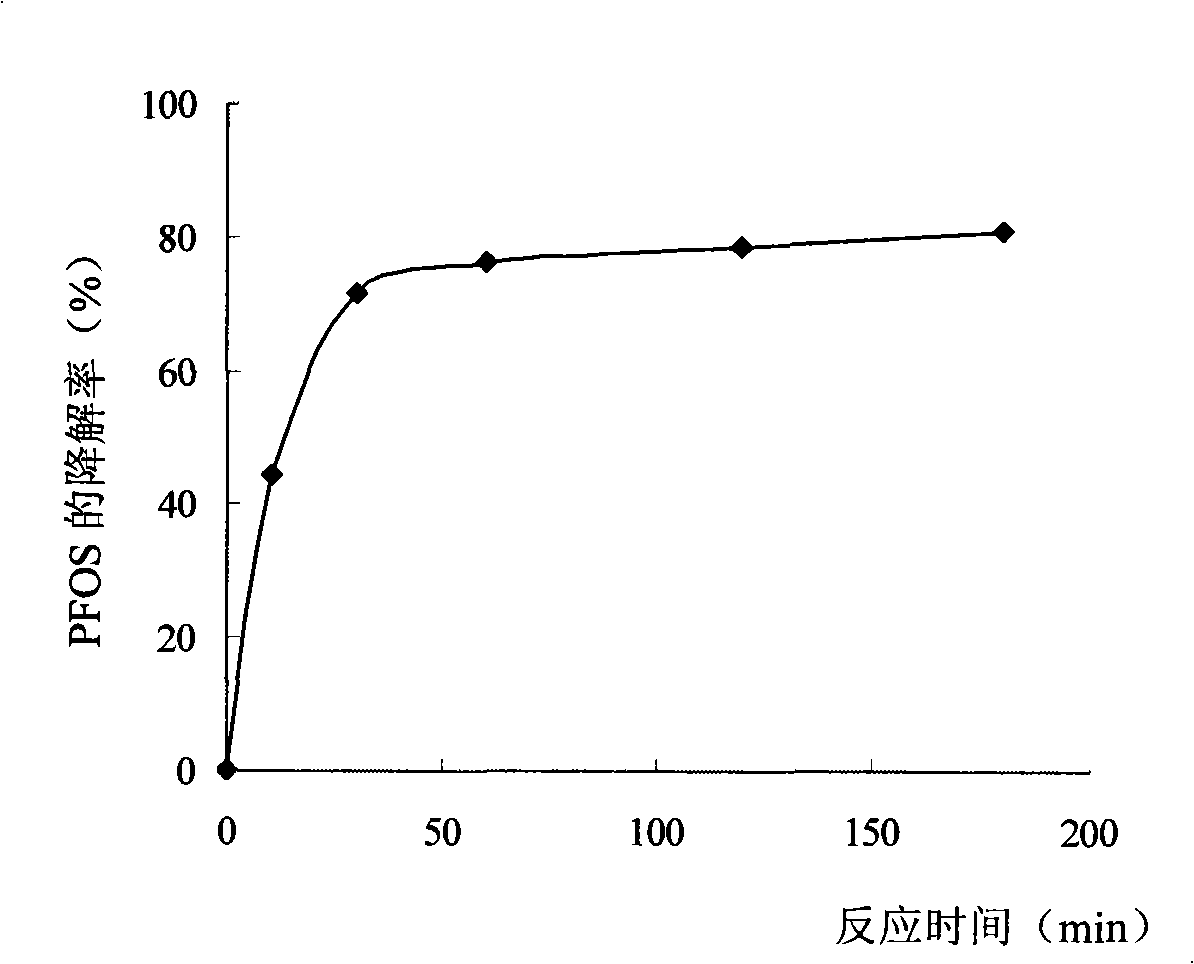

[0033] The photocatalytic degradation of embodiment 2, perfluorooctane sulfonate (PFOS)

[0034] To 100mL 7.25×10 -5 Add β-Ga to mol / L PFOS aqueous solution 2 o 3 Powder and reducing substance Na 2 S 2 o 3 , stirred for 3h, a clear homogeneous solution was obtained, and the β-Ga in the homogeneous solution 2 o 3 The final concentration was 2.67×10 -3 mol / L, Na 2 S 2 o 3 The concentration is 5×10 -5 mol / L.

[0035] like figure 1 As shown, open the aeration plate 4 at the bottom of the reaction device, pass nitrogen gas into the reaction vessel 3 from the gas inlet 5, then add the clear homogeneous solution obtained above into the reactor 3, and aerate for about half an hour , and then turn on the cooling water circulation device 7 and the light source 1 to start the reaction. Take the reaction solution from the sampling port 8 at regular intervals, detect the concentration of PFOS and its short-chain perfluorocarboxylic acid compounds, and use the electrospray neg...

Embodiment 3

[0037] Embodiment 3, the photocatalytic degradation of PFOA under the condition that reducing substance exists

[0038] To 100mL 7.25×10 -5 Add β-Ga to mol / L PFOA aqueous solution 2 o 3 powder, and then add reducing substances KI, Na 2 S 2 o 3 and methanol, stirred for 3h to obtain a clear homogeneous solution, in which β-Ga 2 o 3 The final concentration was 2.67×10 -3 mol / L, KI, Na 2 S 2 o 3 and methanol at a final concentration of 5 × 10 -5 mol / L.

[0039] like figure 1 As shown, open the aeration plate 4 at the bottom of the reaction device, pass nitrogen gas into the reaction vessel 3 from the gas inlet 5, then add the clear homogeneous solution obtained above into the reactor 3, and aerate for about half an hour , and then turn on the cooling water circulation device 7 and the light source 1 to start the reaction. Take the reaction solution from the sampling port 8 at regular intervals, detect the concentration of PFOA and its short-chain perfluorocarboxylic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com