Sealing structure of automatic transmission clutch shell sealing tester

A technology of clutch housing and automatic transmission, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of seal molding, inconvenient use, complex structure, etc., and achieves low cost and saves Cost and simple process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

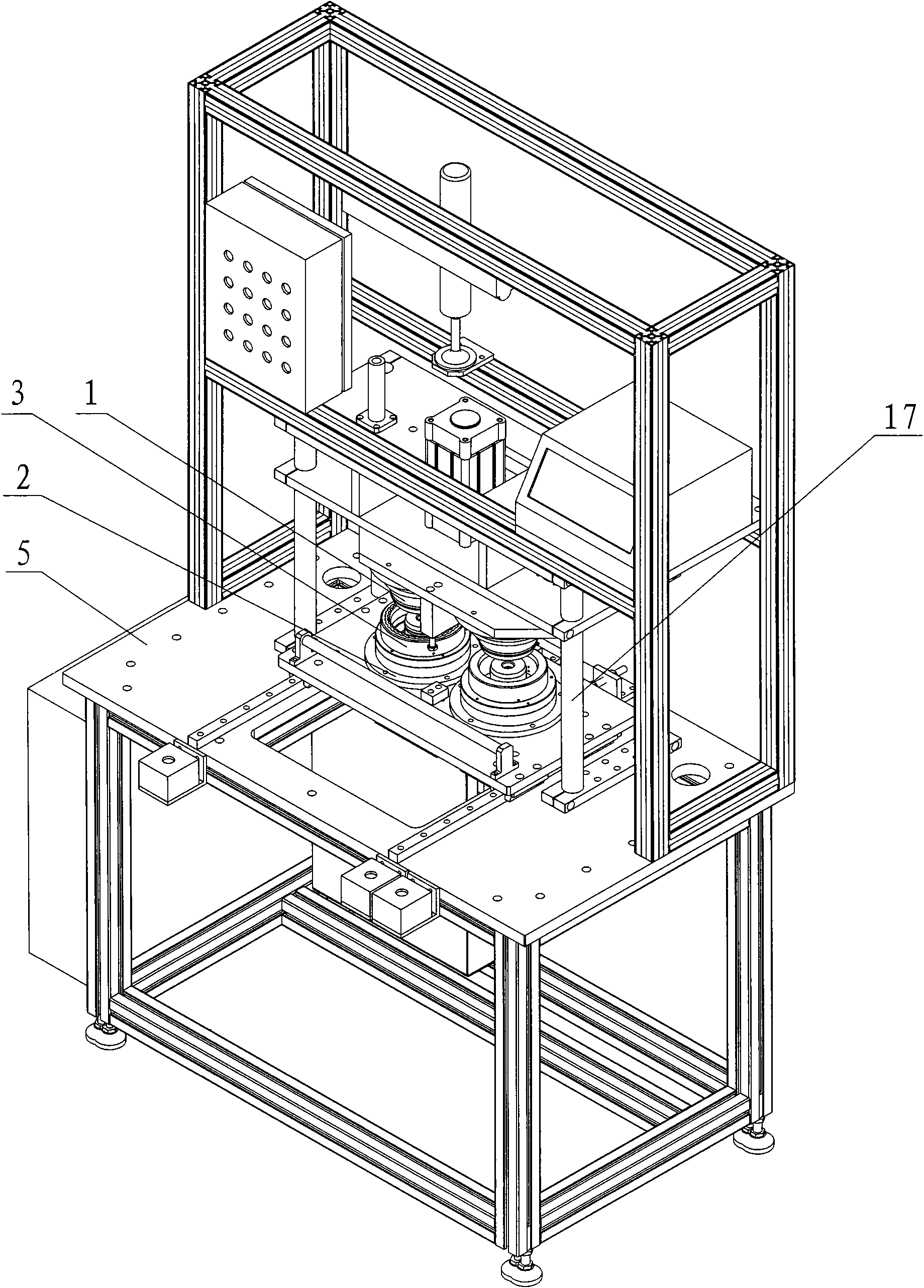

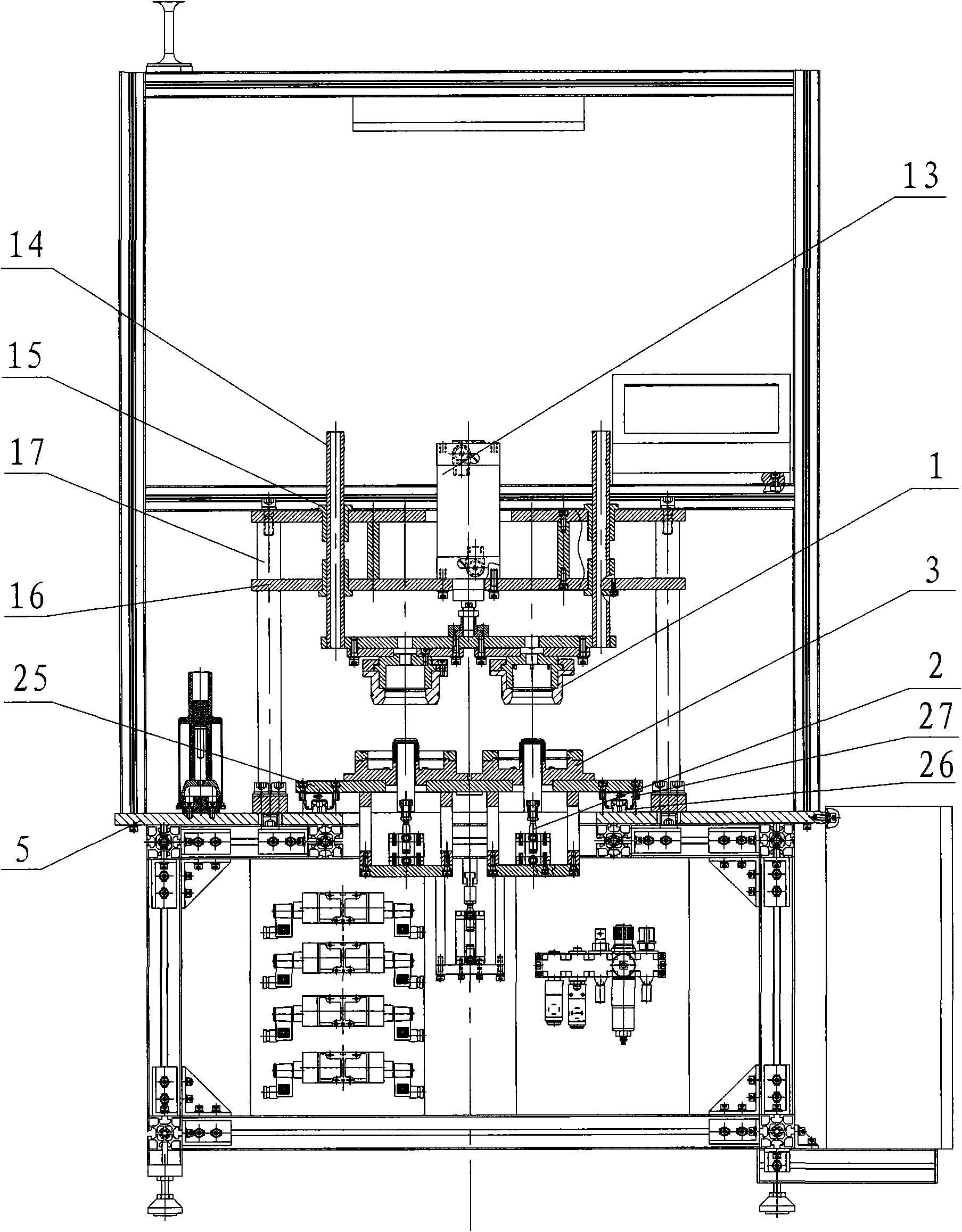

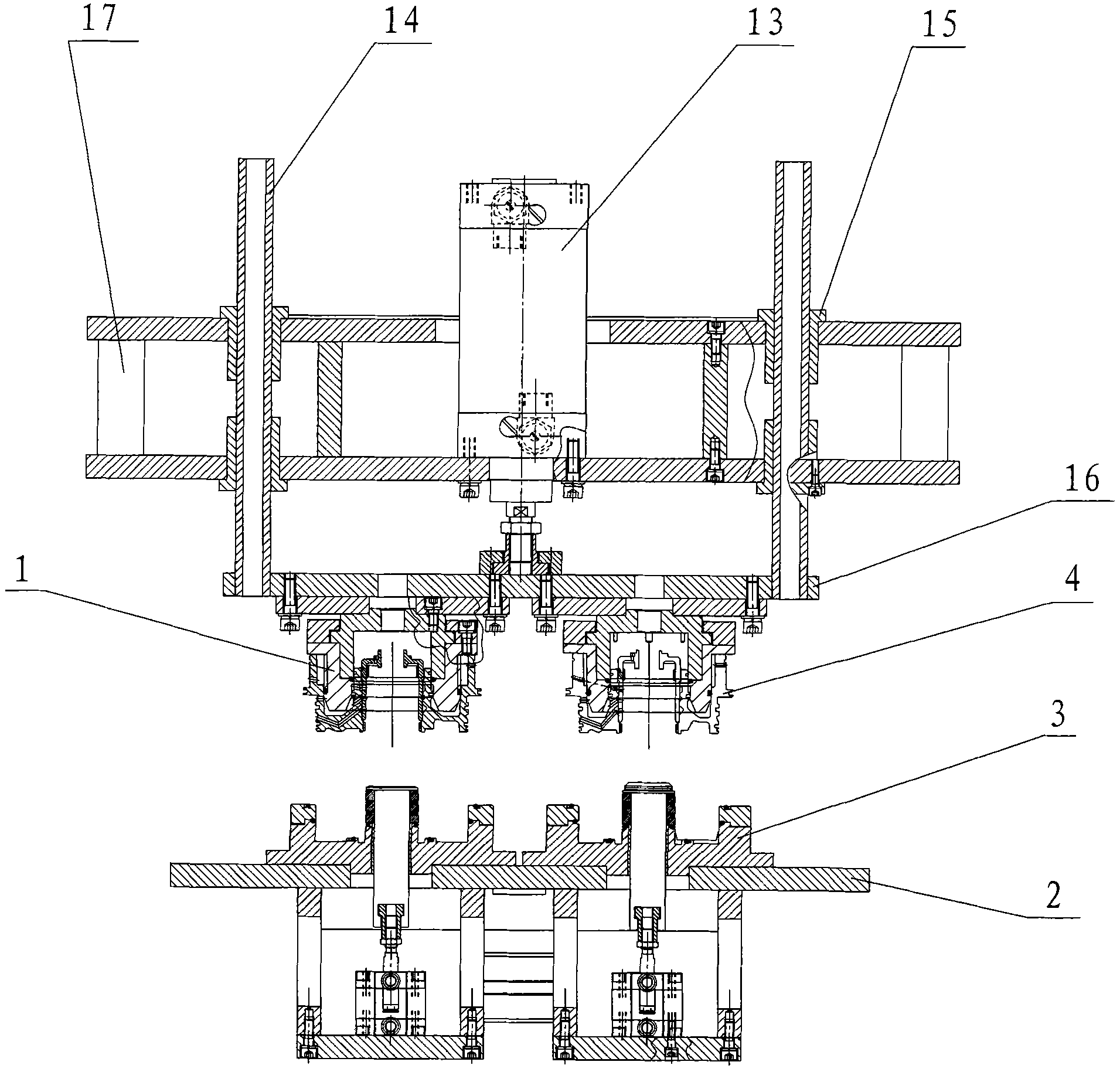

[0029] The present invention will be described in further detail below with reference to the drawings.

[0030] Such as Figure 1~3 As shown, the present invention includes an upper sealing jig 1, a lower sealing jig 2 and a sealing jig base 3. The lower sealing jig 2 is installed on the workbench 5 of the testing machine, and the sealing jig base 3 is set on the upper and lower sealing jigs 2. The sealing fixture 2 is linked. The lower sealing fixture 2 and the sealing fixture base 3 can move back and forth between the manual assembly station and the automatic inspection station, that is, install the tested workpiece at the manual assembly station, and then push the lower sealing fixture 2 and The sealing fixture base 3 is moved to the automatic inspection station; a support 17 is provided on the workbench 5, and the upper sealing fixture 1 is arranged on the support 17, above the sealing fixture base 3, and can move up and down.

[0031] Such as Figure 4 As shown, the lower seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com