Patents

Literature

239results about How to "Reduce grinding energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicate cement grinding aid and preparation method thereof

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

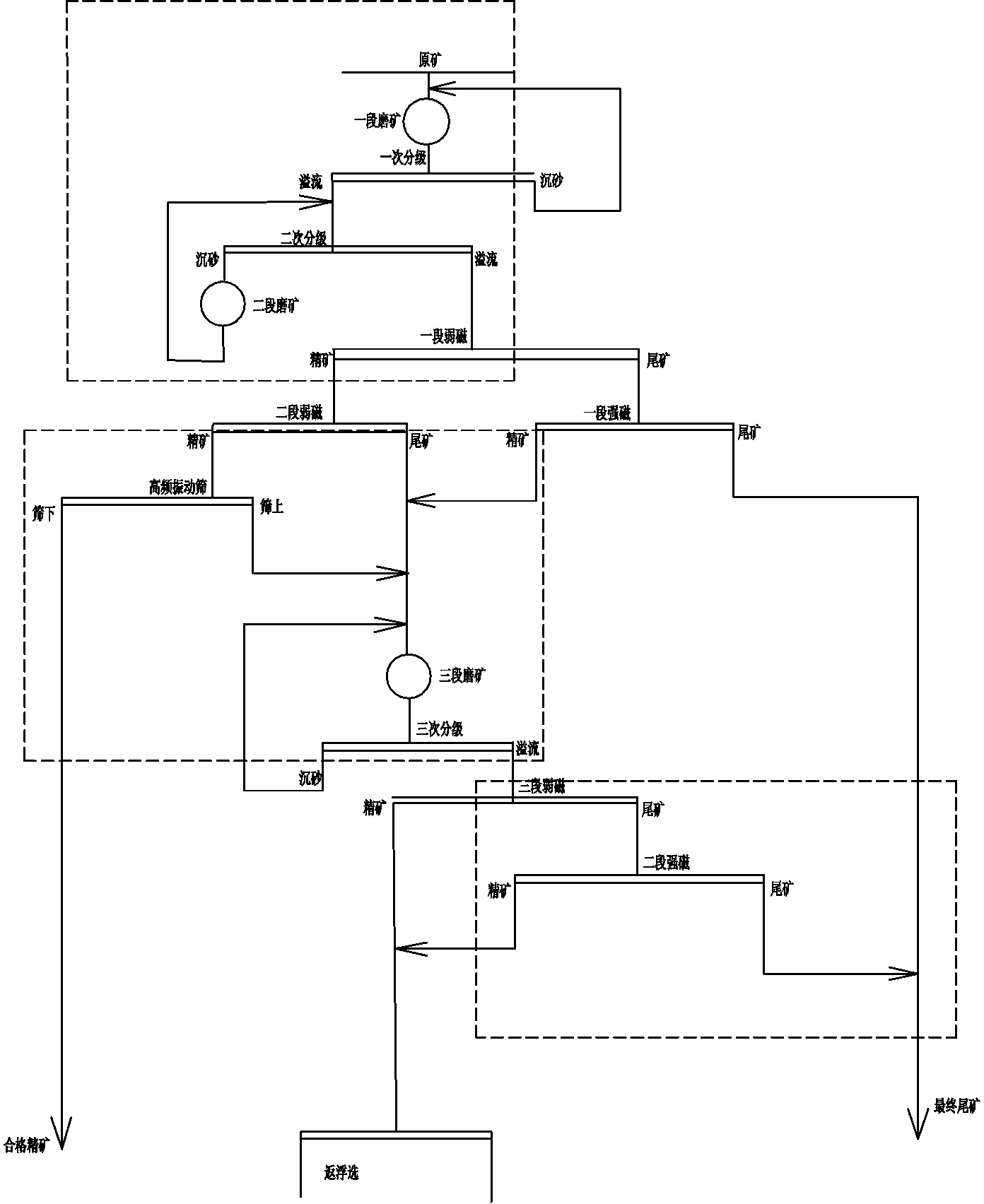

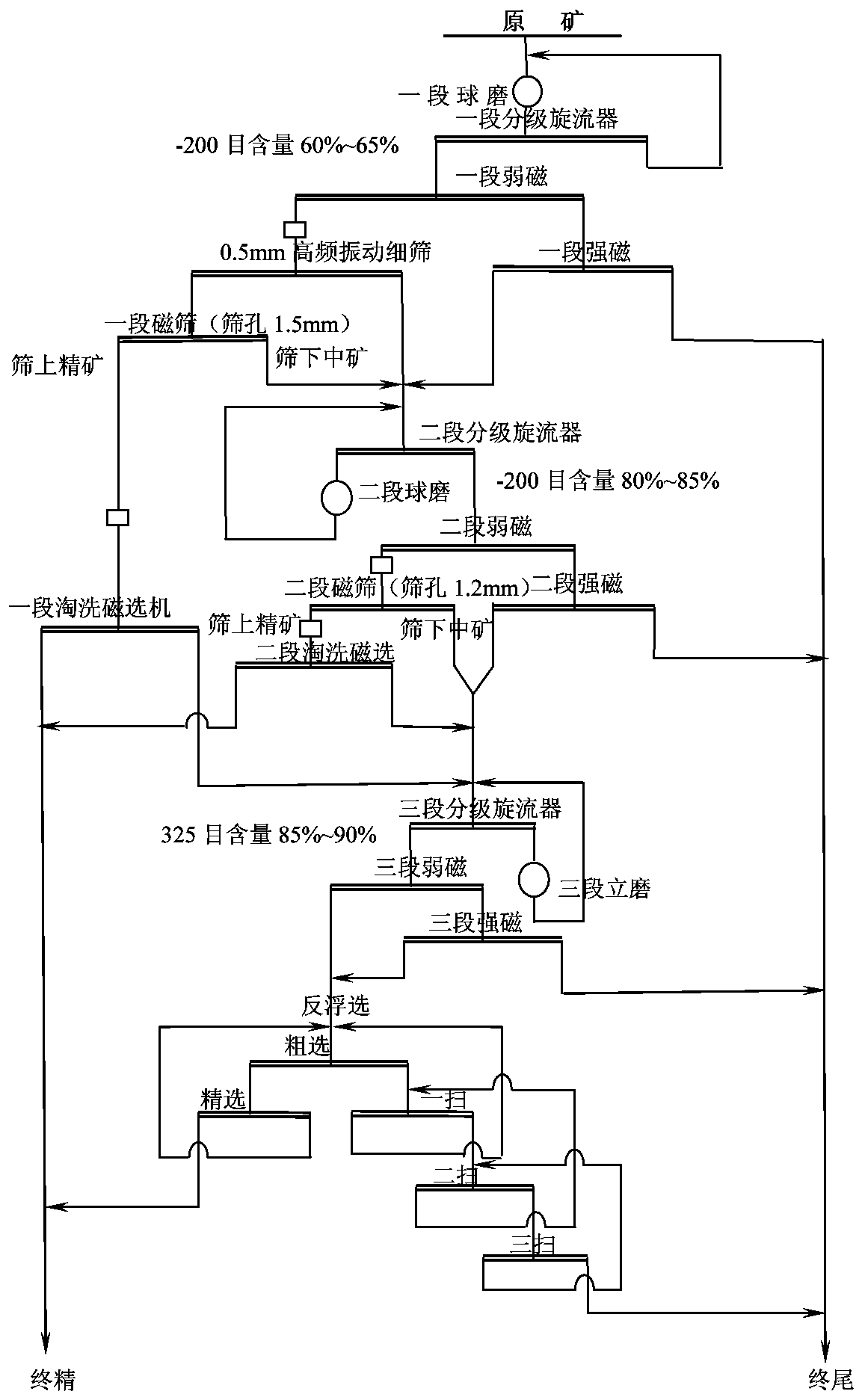

Mineral processing process for processing mixed ore of magnetic iron ore and hematite-limonite ore

The invention relates to a mineral processing process for processing mixed ore of magnetic iron ore and hematite-limonite ore. The mineral processing process comprises steps as follows: raw ore containing the mixed ore of the magnetic iron ore and the hematite-limonite ore is smashed and then subjected to two-stage continuous ore grinding; overflowing ore of a secondary classifying cyclone is subjected to two-stage low-intensity magnetic separation and one-stage fine screening and separation in combination of a single magnetic separation, fine screening and regrinding process for processing magnetic ore; under the condition of rougher ground ore particles, a part of undersize qualified magnetite concentrate products are firstly obtained, the other part of oversize products are combined with one-stage high-intensity magnetic separator concentrate and two-stage low-intensity magnetic separator tailings to serve as middlings, and the middlings are subjected to three-stage ore grinding classification operation for regrinding and separation; and overflowing ore of a tertiary classifying cyclone is subjected to three-stage low-intensity magnetic separation and high-intensity magnetic separation, fine-grain qualified tailings are thrown again, three-stage low-intensity magnetic concentrate and two-stage high-intensity magnetic concentrate are combined to obtain mixed magnetic concentrate, the mixed magnetic concentrate is subjected to a reverse flotation process for separation, and a qualified flotation concentrate product is obtained. According to the mineral processing process, the mixed ore of the magnetic iron ore and the hematite-limonite ore with different dissemination particle sizes is reasonably processed, the qualified iron ore concentrate product is obtained, and the mineral processing process is economical, energy-saving and environment-friendly.

Owner:ANSTEEL GRP MINING CO LTD

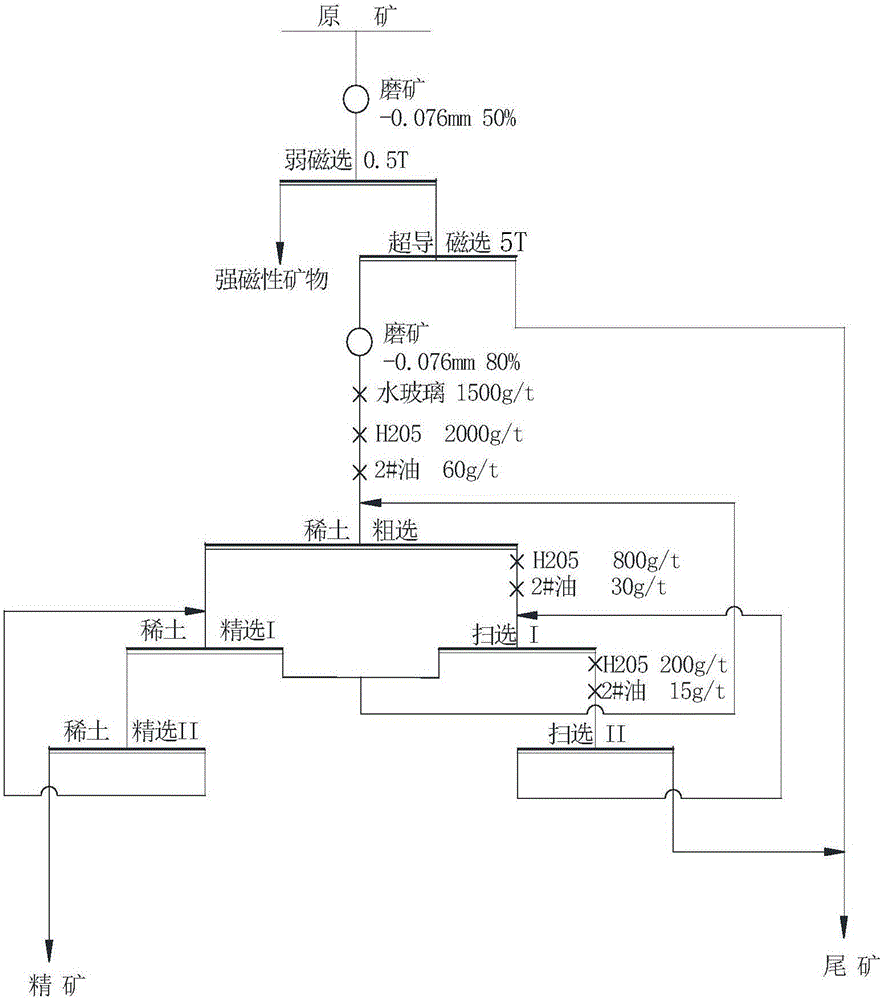

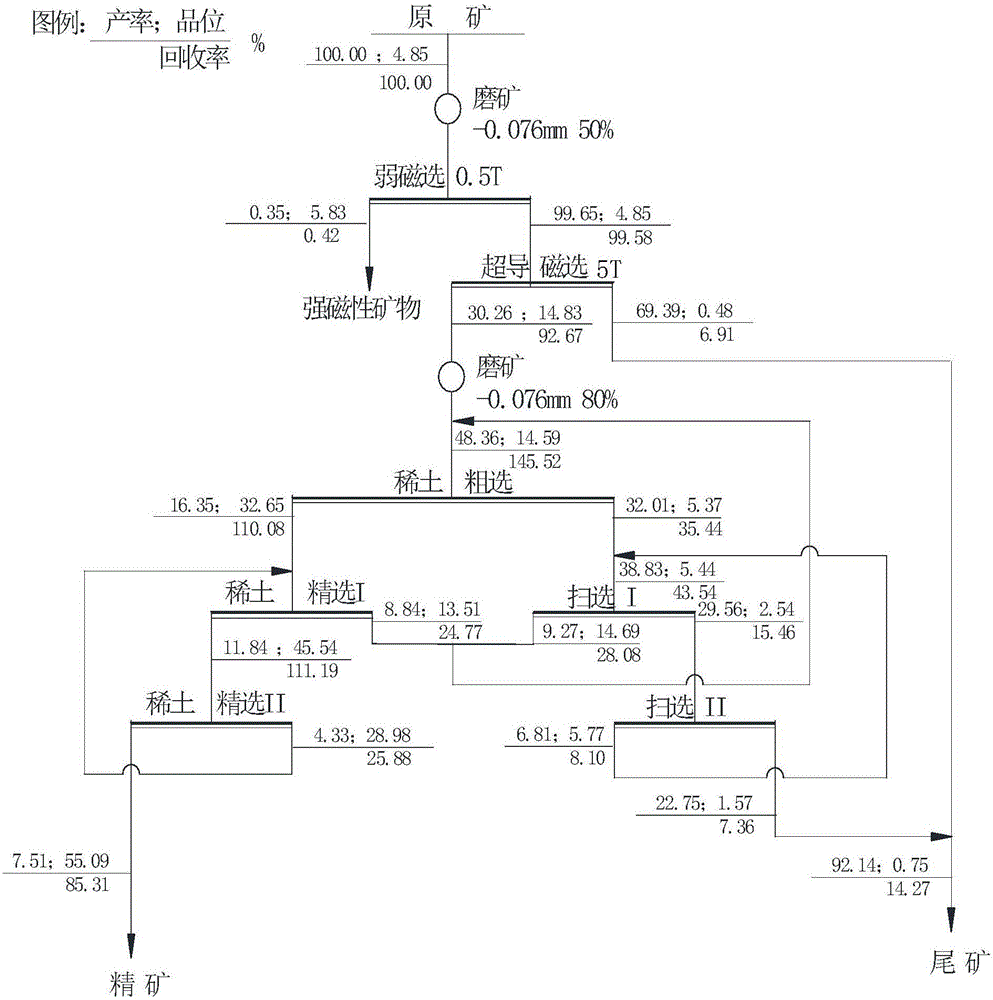

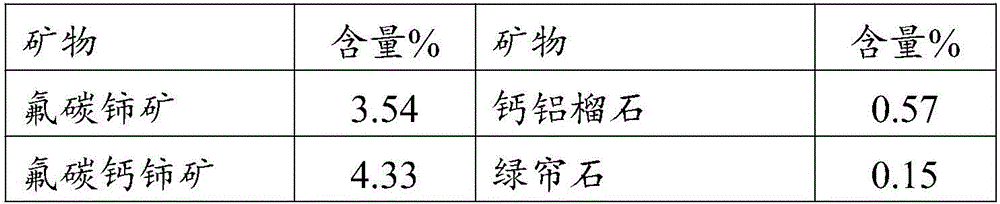

Beneficiation method of rare earth ore

ActiveCN106799300AReduce the amount requiredQuality assuranceWet separationRare earthUltimate tensile strength

The invention discloses a beneficiation method of rare earth ore. The beneficiation method comprises the steps that crude ore is subjected to crushing and ore grinding till the crude ore with the fineness being -0.076 mm accounting for 50% or above, low intensity magnetic separation is carried out to remove strongly magnetic minerals, then superconducting magnetic separation rougher flotation is carried out to obtain rare earth rough concentrates, the rare earth rough concentrates are ground till the rare earth rough concentrates with the fineness being -0.076 mm accounting for 80% or above, conventional flotation work is carried out, and final rare earth ore concentrates are obtained; conventional flotation work includes the processes of one-section rougher flotation, two-section concentration and two-section scavenging; according to low intensity magnetic separation, the magnetic field intensity ranges from 0.1 T to 0.5 T, and the magnetic field force is (3-15)*10<5>kA<2> / m<2>; and according to superconducting magnetic separation, the magnetic field intensity is larger than 0.5 T, and the magnetic field force is larger than 3*10<7>kA<2> / m<2>. According to the method, the high-grade rare earth rough concentrates can be obtained through superconducting magnetic separation, a large quantity of tailings can be thrown out, the grading efficiency is high, the two-section ball grinding ore feeding quantity is greatly reduced, grinding and selecting energy consumption is reduced, the rare earth grade of the obtained rare earth ore concentrates is improved, and the recovery rate is high.

Owner:江苏旌凯中科超导高技术有限公司

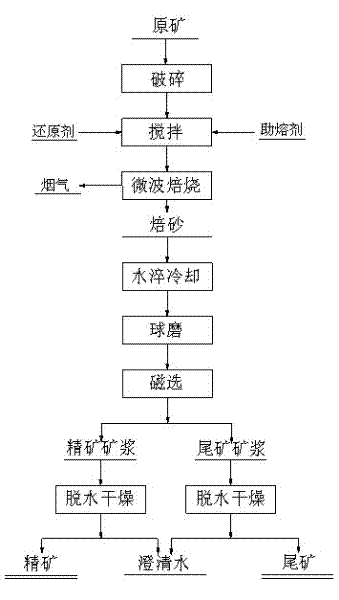

Method for sorting high-phosphorus iron ore by combining microwave reduction roasting and low intensity magnetic separation

InactiveCN102212677AReduce grinding energy consumptionShorten milling timeMagnetic separationMixed materialsQuenching

The invention relates to a method for refining iron and removing phosphorus from complex refractory high-phosphorus iron ore, in particular to a method for sorting high-phosphorus iron ore by combining microwave reduction roasting and low intensity magnetic separation, and belongs to the technical field of mineral processing, particularly iron ore beneficiation. The method comprises the following steps: crushing refractory high-phosphorus iron ore used as raw material into granules with granularity of less than 2mm; mixing the crushed raw ore with a fluxing agent and a reducing agent in a certain proportion; transferring the obtained mixed material into a microwave reaction furnace for reduction roasting; and carrying out water-quenching, cooling, ball-milling and wet-magnetic-separating on the obtained roasted ore to finally obtain iron ore concentrate. In the method, the ore is reduced by utilizing a microwave roasting technology, wherein microwave reduction roasting time is short, and the temperature of the ore is raised quickly; and meanwhile the fluxing agent is added so as to promote gangue softening and improve refractory ore structure together with microwave roasting reaction. By utilizing the method for sorting the high-phosphorus iron ore, the iron ore concentrate with grade of more than 58.39% can be obtained, and phosphorus removal rate reaches over 70.44%, thus a new technique is provided for sorting the high-phosphorus iron ore.

Owner:KUNMING UNIV OF SCI & TECH

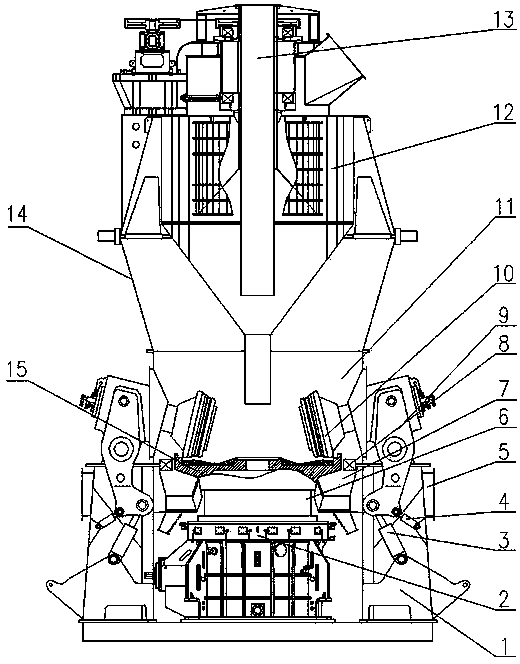

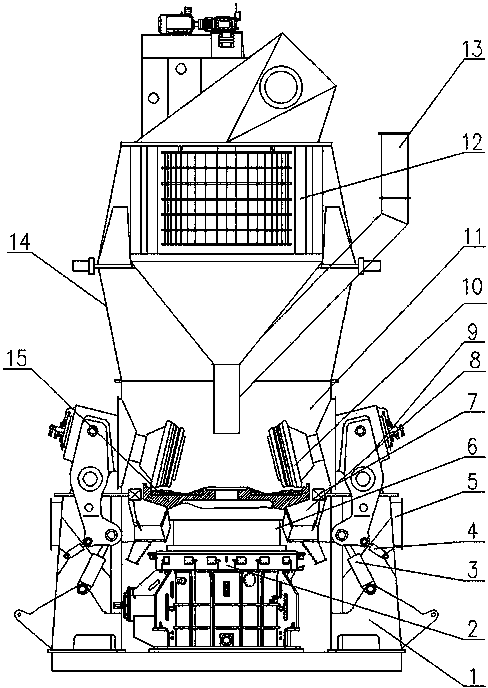

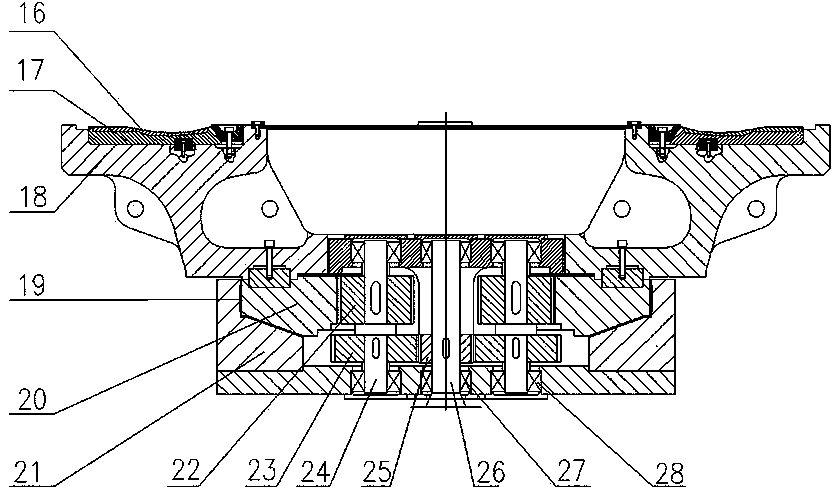

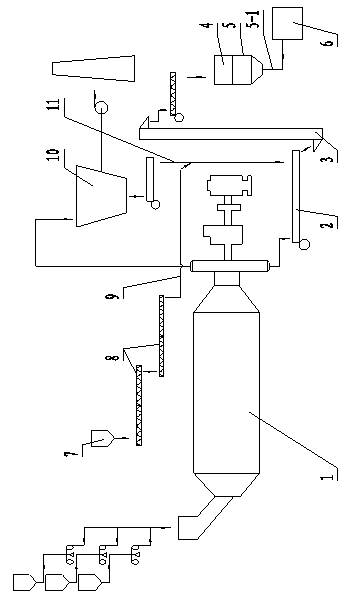

Self-adaptive vibration accumulation and energy supply high-efficiency vertical roller mill

ActiveCN103639018AAvoid collision riskReduce vibration intensityGrain treatmentsEngineeringRocker arm

The invention relates to a self-adaptive vibration accumulation and energy supply high-efficiency vertical roller mill which comprises a hydraulic transmission system, an intelligent control system, a stand (1), a transmission device (2) and a speed reducing mechanism (6), wherein the transmission device (2) and the speed reducing mechanism (6) are arranged on the stand (1); an output end of the speed reducing mechanism (6) is provided with a grinding table device (15); an air ring (8) is arranged at the excircle of the grinding table device (15) and at an upper opening of an air inlet duct (7) communicated with an air inlet pipe (5); a plurality of grinding roller devices (10) are arranged above the grinding table device (15) by a mill door arranged on a lower shell (11); a rocker arm (9) is arranged at the outer ends of the grinding roller devices (10); one ends of a pressurizing oil cylinder (3) and a magnetic fluid damping adjustment device (4) are respectively connected with the rocker arm (9), and the other ends of the pressurizing oil cylinder (3) and the magnetic liquid damping adjustment device (4) are respectively connected with the stand (1); the upper end of a middle shell (14) is provided with a powder concentrator (12). The self-adaptive vibration accumulation and energy supply high-efficiency vertical roller mill has the advantages that the extrusion energy and the impact energy are efficiently utilized, the vibration intensity of a grinding host machine can be reduced, the grinding efficiency is improved, the grinding energy consumption is reduced, the stability of equipment is improved, the service life of the equipment is prolonged, and the running cost is lowered.

Owner:临沂市博信机械有限公司

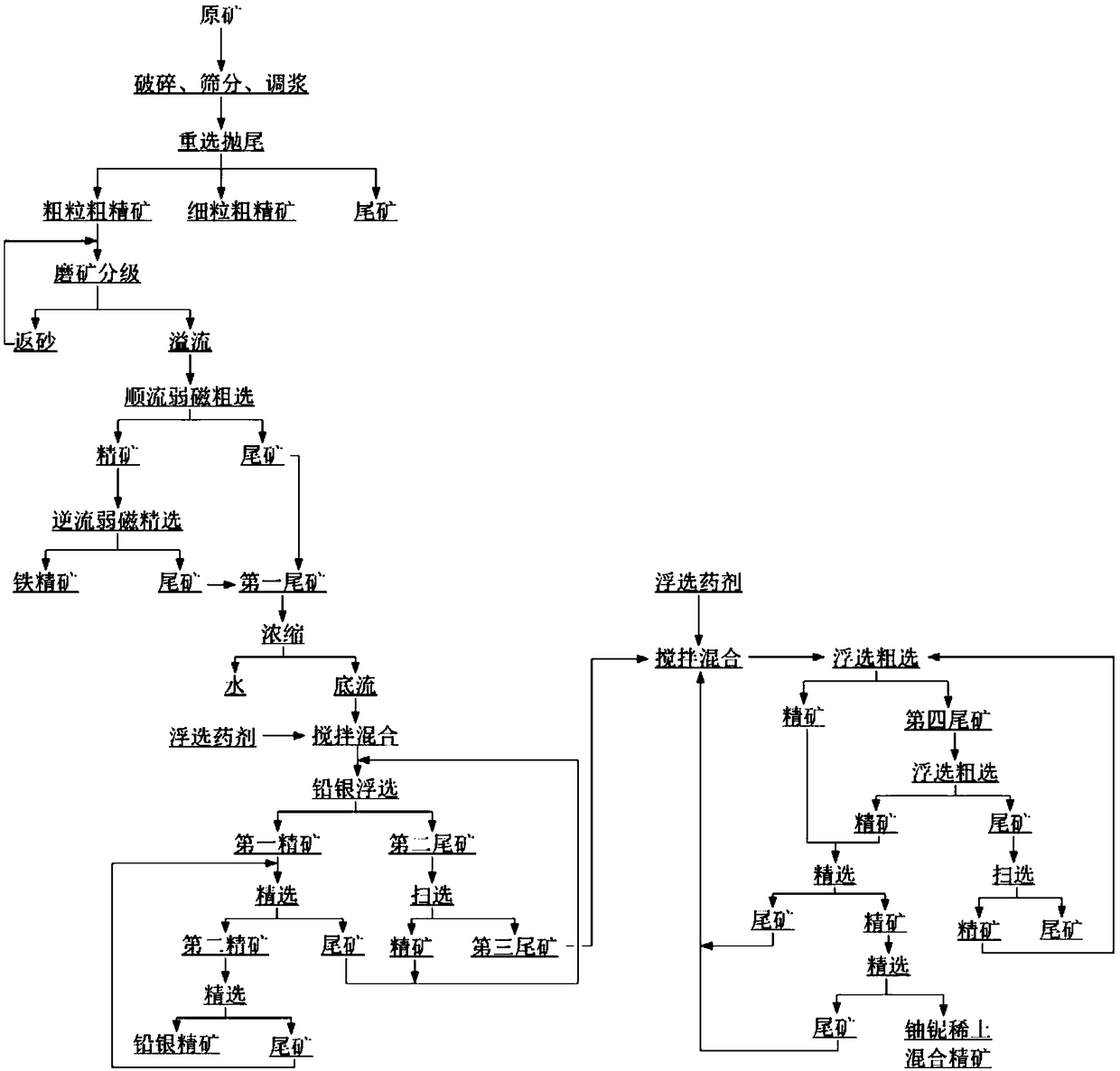

Comprehensive recovery and beneficiation method for low-grade uranium-containing polymetallic ore

The invention provides a comprehensive recovery and beneficiation method for low-grade uranium-containing polymetallic ore. The comprehensive recovery and beneficiation method comprises the followingsteps that (1) overflow products obtained by grinding the uranium-containing polymetallic ore are subjected to direct flow magnetic separation roughing operation and reverse flow magnetic separation concentration operation in sequence, and iron concentrate and first tailings are obtained; (2) the tailings are subjected to condensation and flotation to obtain first concentrate and second tailings,the first concentrate is subjected to concentration to obtain lead silver concentrate, and the second tailings are subjected to scavenging to obtain third tailings; and (3) the third tailings are subjected to flotation roughing and condensation, and then uranium, niobium and rare earth mixed concentrate is obtained. The beneficiation index is good, the purpose of fully recovering all useful components in coarse-grain coarse concentrate subjected to tailing discarding through gravity concentration under the coarse grinding condition is achieved, an efficient beneficiation separation and enrichment technology is provided for large-scale development and utilization of the low-grade complex polymetallic hard rock uranium ore in China, and the subsequent cost of extracting uranium, niobium andrare earth in the uranium ore through hydrometallurgy is greatly lowered.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

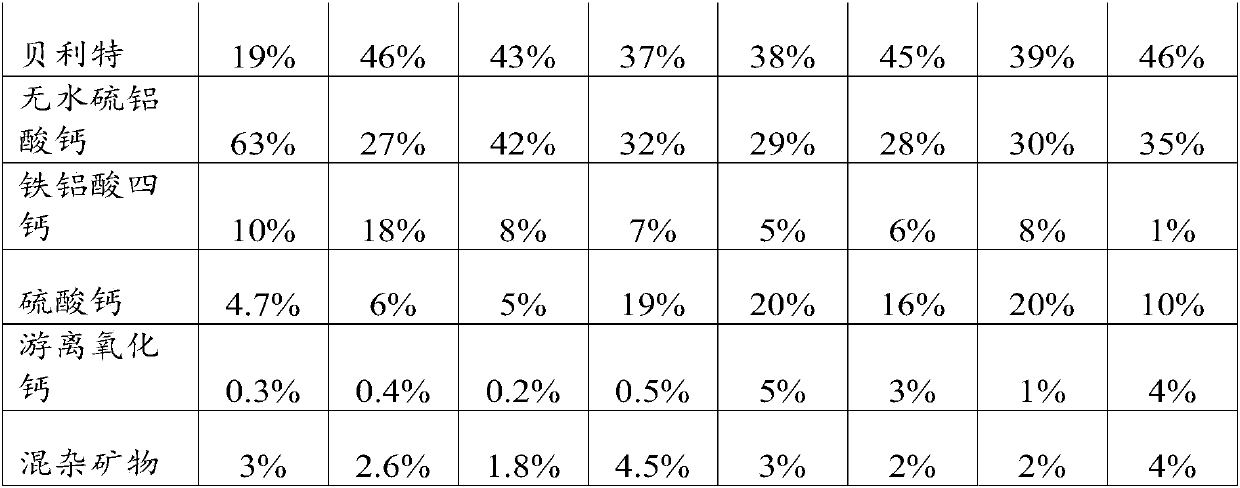

High-bending-strength supersulfate cement and preparation method thereof

ActiveCN107827379AHigh activityAccelerate the rate of hydration hardeningSolid waste managementCement productionGypsumSlag

The invention provides high-bending-strength supersulfate cement and a preparation method thereof and relates to the field of building materials. The high-bending-strength supersulfate cement comprises granulated blast-furnace slag, gypsum and high-belite sulfate aluminum cement clinker. By utilizing the high-bending-strength supersulfate cement, the problem that existing supersulfate cement is low in hydration and hardening speed and early strength and prone to sand shedding caused by the fact that excitants cannot fully excite granulation blast-furnace slag activity in the prior art is solved, and bending strength of the cement is improved greatly; the high-bending-strength supersulfate cement has the advantages of high early-later strength and is ultrahigh in bending strength especially.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

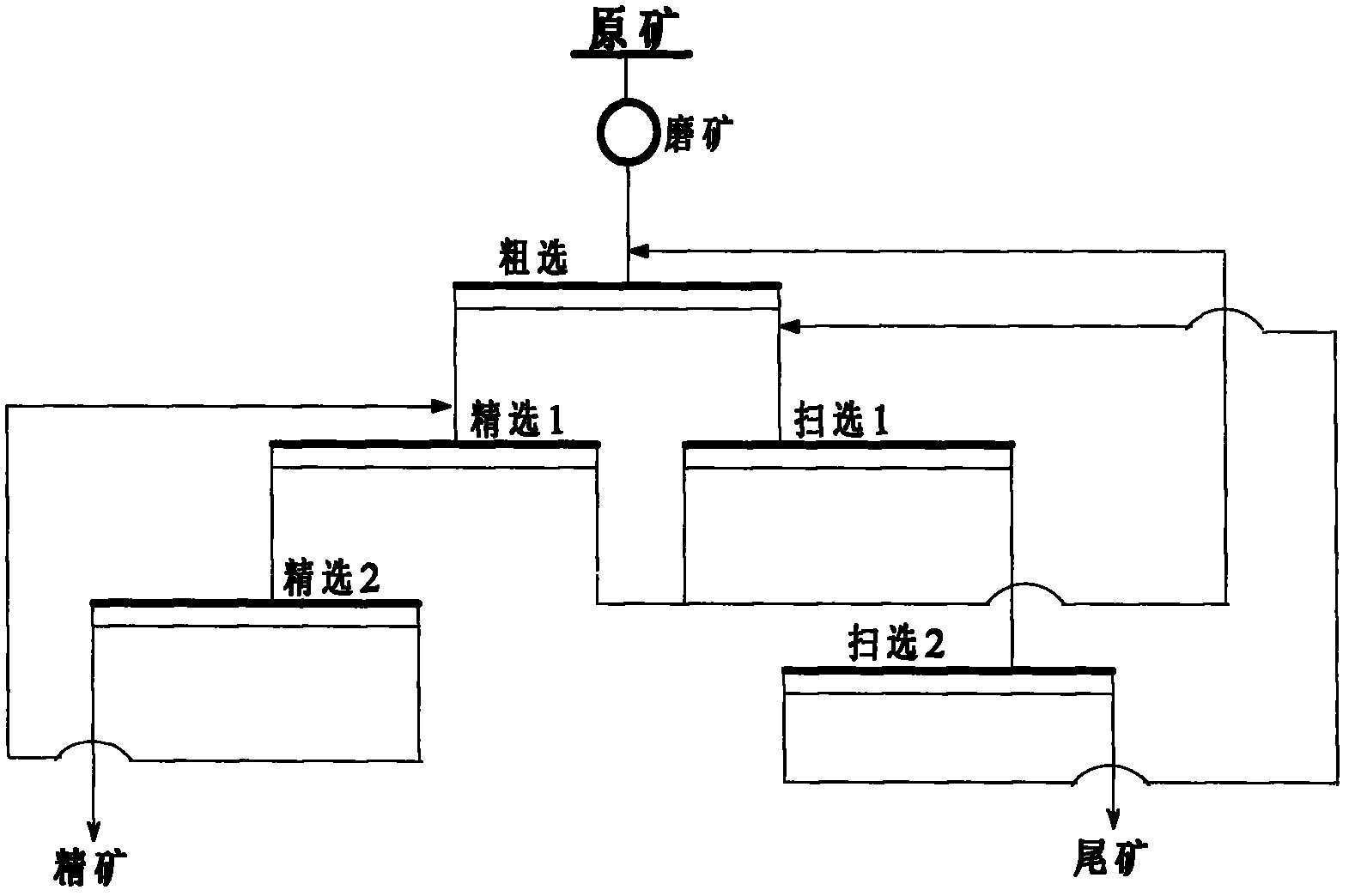

A method of improving flotation recovery rate

The invention relates to a flotation method, in particular to a flotation method for improving the flotation recovery rate of a target mineral in a complex ore. The method comprises the following steps: grinding a target mineral in a raw ore until the target mineral is basically dissociated; producing a concentrate 1 and a tailing 1 through roughing one or twice, cleaning twice or three times, as well as scavenging three to ten times; combining a bottom product of the concentrate 1 and all scavenged foam products to form a middling; concentrating and grinding; returning the grinded ore pulp to a flotation process through an independent sequence to obtain a concentrate 2 and a tailing 2; and combining the concentrate 1 and the concentrate 2 to obtain a final concentrate. According to the flotation method in the invention, the grinding energy consumption can be effectively reduced, partial target mineral with low floating speed is recovered, and the flotation recovery rate of the target mineral is improved by 5 to 20 percent.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

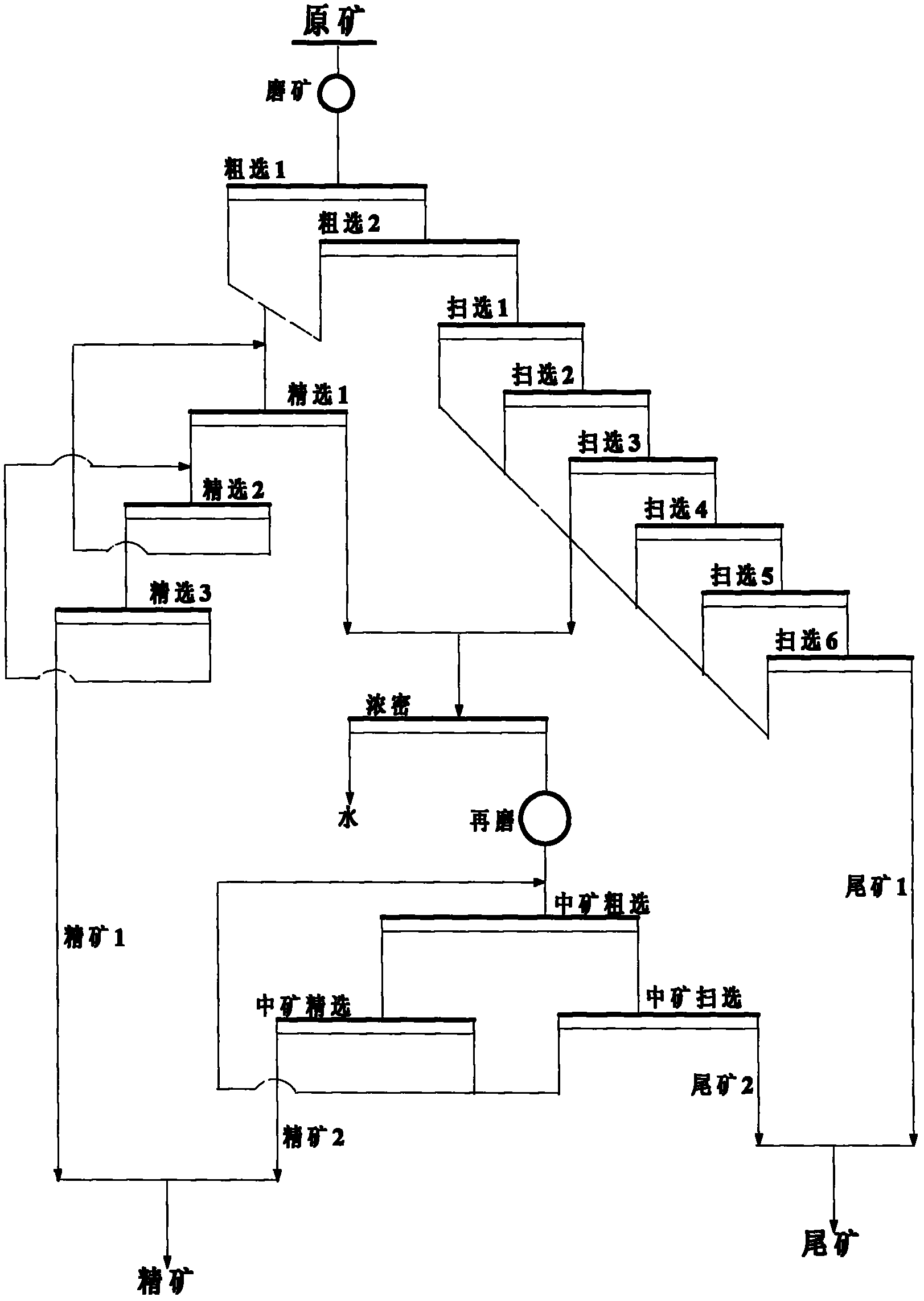

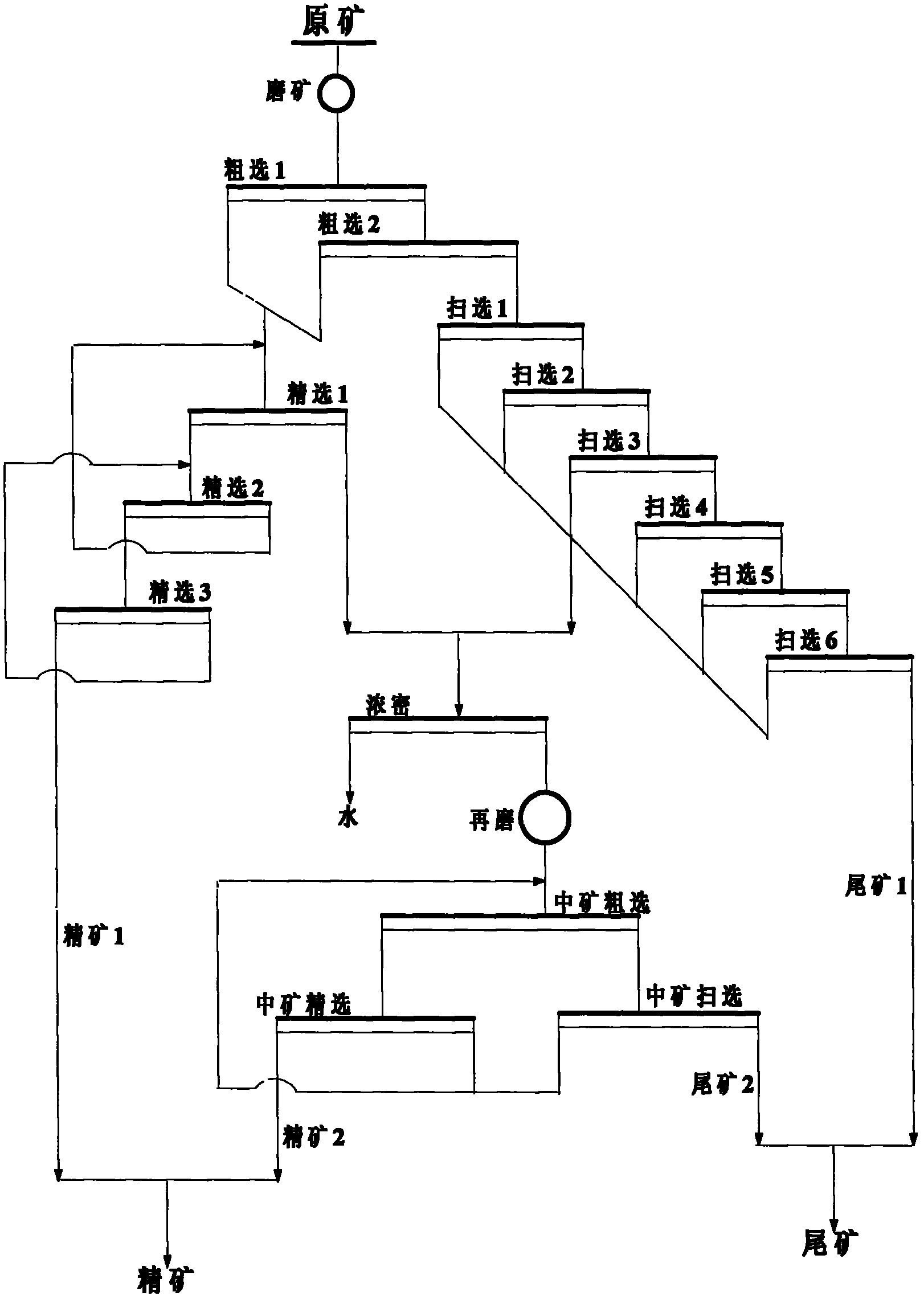

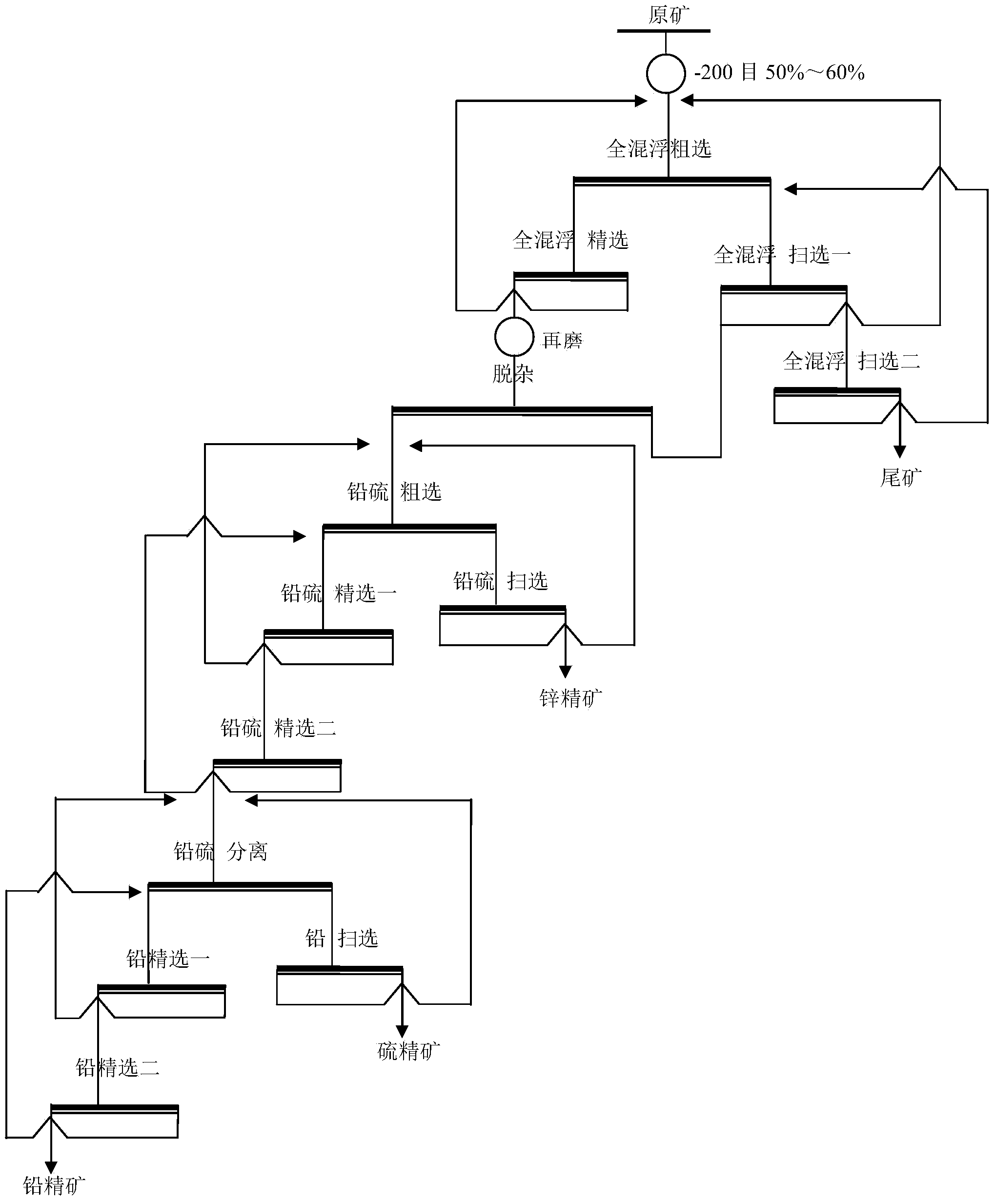

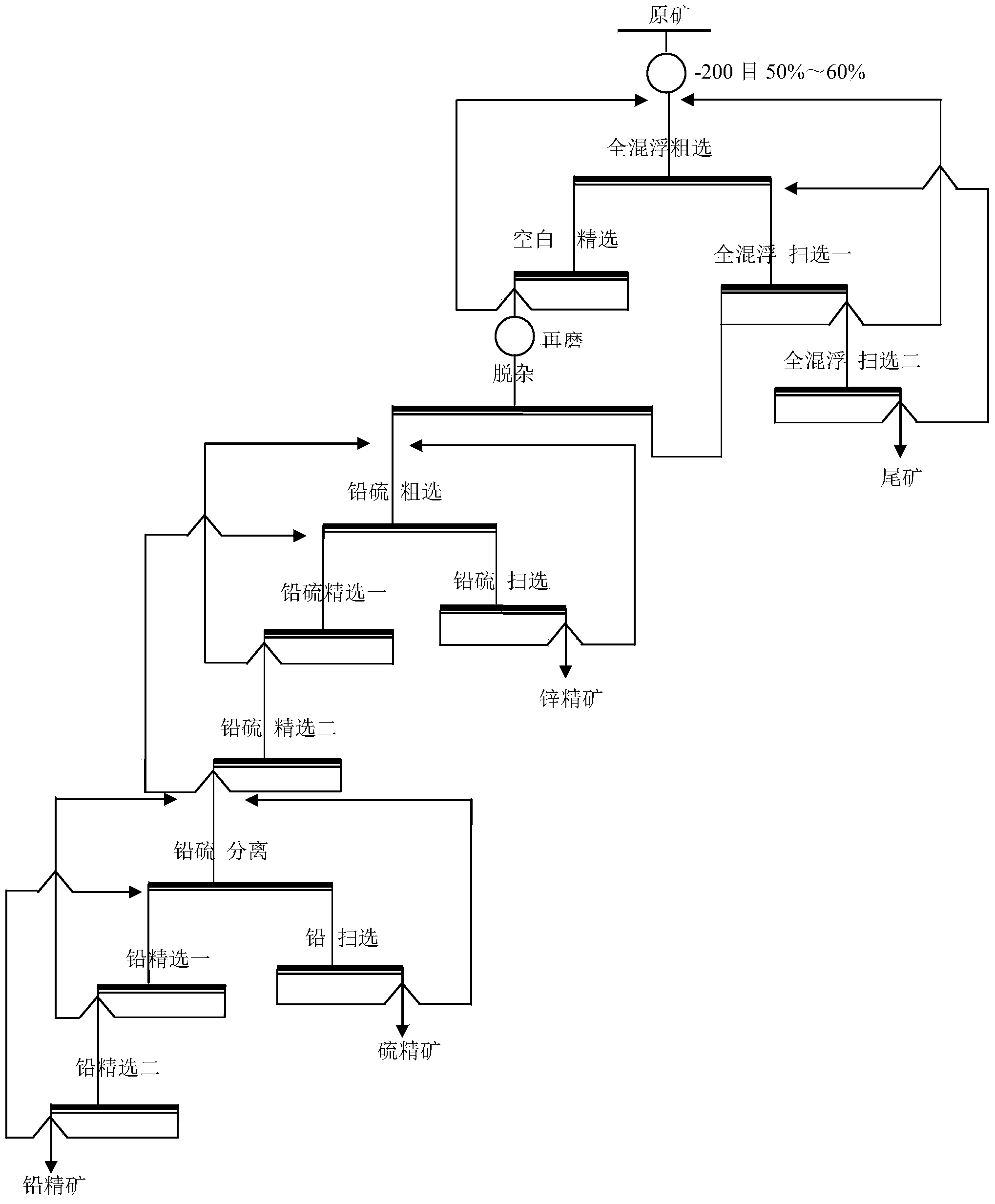

Method for obtaining valuable ores from multi-metal sulfide ores containing lead and zinc through flotation separation

ActiveCN104001626AReduce grinding energy consumptionImprove beneficiation efficiencyFlotationZincMaceral

The invention discloses a method for obtaining valuable ores from multi-metal sulfide ores containing lead and zinc through flotation separation. The method comprises the steps of firstly performing ore grinding on raw ores; then adding a combined flotation agent to perform complete-mixing rough flotation treatment on the raw ores subjected to the ore grinding; continuing to perform fine flotation on rough concentrates subjected to the rough flotation, and continuing to add the combined flotation agent to perform scavenging on tailings subjected to the rough flotation; re-grinding lead-zinc-sulfur mixed rough concentrates subjected to the fine flotation; adding the combined flotation agent into the grinded lead-zinc-sulfur mixed rough concentrates to perform impurity removal treatment, and performing scavenging on the tailings subjected to the impurity removal. On the basis of the method, lead-sulfur rough flotation, lead-sulfur fine flotation and lead-sulfur separation can be additionally performed to obtain lead concentrates, the tailings subjected to the flotation separation is subjected to lead scavenging, and finally sulfur concentrates are obtained. The method has the advantages of being simple and convenient to operate, reasonable in technological process, small in agent dosage, low in energy consumption, long in service life, good in separation effect and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

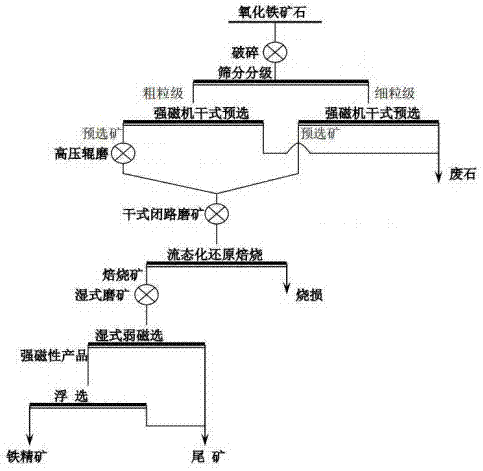

Combined mineral separation technology for ferric oxide mineral

InactiveCN107185686AThrow out earlyReduce transportationMagnetic separationGrain treatmentsIronstoneOxide minerals

The invention discloses an iron oxide ore joint beneficiation process, which comprises the following steps: (1) dry selection and discarding of iron oxide ore to obtain pre-selected coarse-grained ore, pre-selected fine-grained ore and waste rock; (2) high-pressure Roller mill crushing: the pre-selected coarse-grained ore obtained in step (1) is fed into a high-pressure roller mill for crushing; (3) dry grinding: the crushed product in step (2) and the pre-selected fine-grained ore in step (1) Combined for dry closed-circuit grinding; (4) Fluidized reduction roasting: a. Put the ground product obtained in step (3) into the fluidized reduction roaster; b. Preheating; c. Heating; d. Magnetization roasting; e . Cool to below 200°C to obtain roasted ore with a magnetite content greater than 90%; (5) beneficiation of roasted ore to obtain iron concentrate products with a grade of 57%-65%. The present invention can effectively solve the current iron oxide ore beneficiation There are technical problems such as low resource utilization rate, poor concentrate quality and high energy consumption in the process.

Owner:JIUQUAN IRON & STEEL GRP

Cement production method

ActiveCN103214198ASimple manufacturing methodImprove the mixing effectClinker productionExhaust valveSlag

The invention discloses a cement production method, relating to the technical field of cement production. The cement production method disclosed by the invention comprises the following steps of: pre-grinding slag to form superfine slag powder for later use; proportioning cement clinker, gypsum and limestone and grinding in a ball mill; feeding grinded fine powder into an air conveying inclined groove at the tail part of the mill, and mixing the fine powder with the superfine slag powder; conveying the mixed material by using a pneumatic hoister, and feeding formed mixed powder into a small storage cabin; and opening a feeding valve and an exhaust valve of a cabin pump, so that the mixed powder in the small storage cabin enters the pump body, when the weight of the mixed powder in the pump body is up to a pre-set value, closing the feeding valve and the exhaust valve, opening a fluidizing valve and a conveying valve after delaying for 8s, and feeding the mixed powder into a finished product storeroom after sufficiently and uniformly mixing through a conveying pipeline. Compared with the prior art, the cement production method disclosed by the invention has the advantages that the method is simple and easy; the production efficiency is high; the mixing effect is better; activity of mixed materials is sufficiently excited; the mixed materials are high in admixture amount; the production cost is low; and produced cement is high in intensity, steady in quality and high in yield.

Owner:GUANGXI YUFENG CEMENT +1

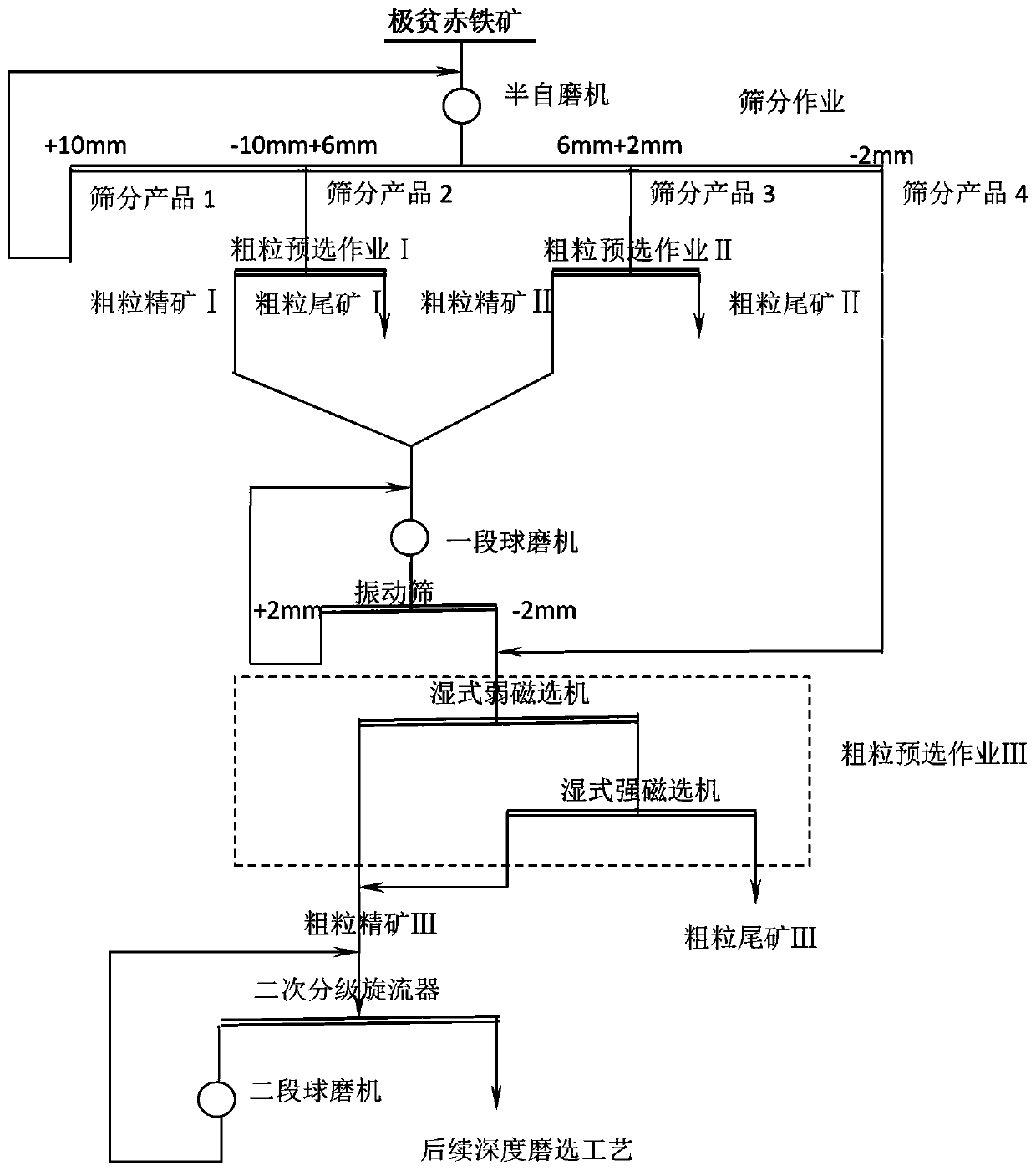

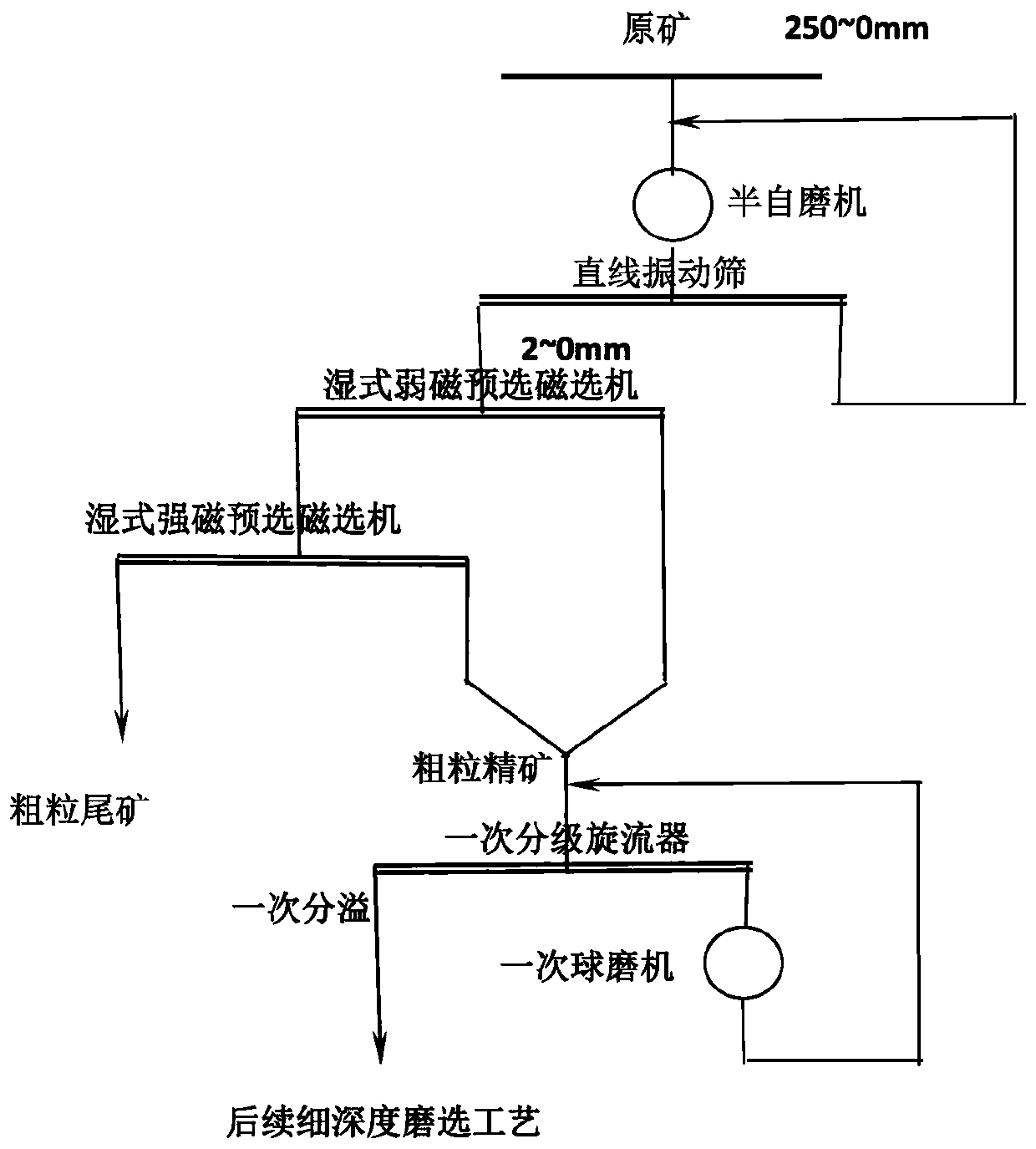

Size-fractionated pre-selection tailing discarding process of extremely-poor hematite

ActiveCN110898957AReduce cycle loadProcessing capacity when releasing the tableSievingScreeningEngineeringTailings

The invention relates to a size-fractionated pre-selection tailing discarding process of extremely-poor hematite. The process comprises a step of carrying out semi-autogenous grinding to obtain semi-autogenous grinding discharge ore with a particle size of 14-0mm. The process is characterized by screening; carrying out coarse grain pre-selection I; carrying out coarse grain pre-selection II; carrying out first-section closed-circuit grinding; carrying out coarse grain pre-selection operation III; and carrying out second-section closed-circuit grinding. A three-layer linear vibrating screen isadopted for screening. In four products, the product with a size fraction of-14 mm to 10 mm is returned to semi-autogenous grinding. The coarse grain pre-selection I and the coarse grain pre-selectionII are used for pre-selecting a -10mm-6mm size fraction and a -6mm-2mm size fraction. Coarse-grain tailings are thrown out, coarse-grain concentrates are combined and fed into first-section closed-circuit ore grinding, a first-section closed-circuit ore grinding product and the screened -2 mm size fraction are fed into coarse-grain pre-selection operation III for pre-selection tailing discarding,coarse-grain pre-selection operation III concentrates are fed into second-section closed-circuit ore grinding, and second-section closed-circuit ore grinding overflow is fed into subsequent sorting operation. The process has advantages that discharge ore is divided into narrow grades for respective pre-selection; qualified coarse grain tailings are thrown out; and a problem of stubborn stone accumulation is solved, and a processing capacity of a semi-autogenous mill is improved.

Owner:ANSTEEL GRP MINING CO LTD

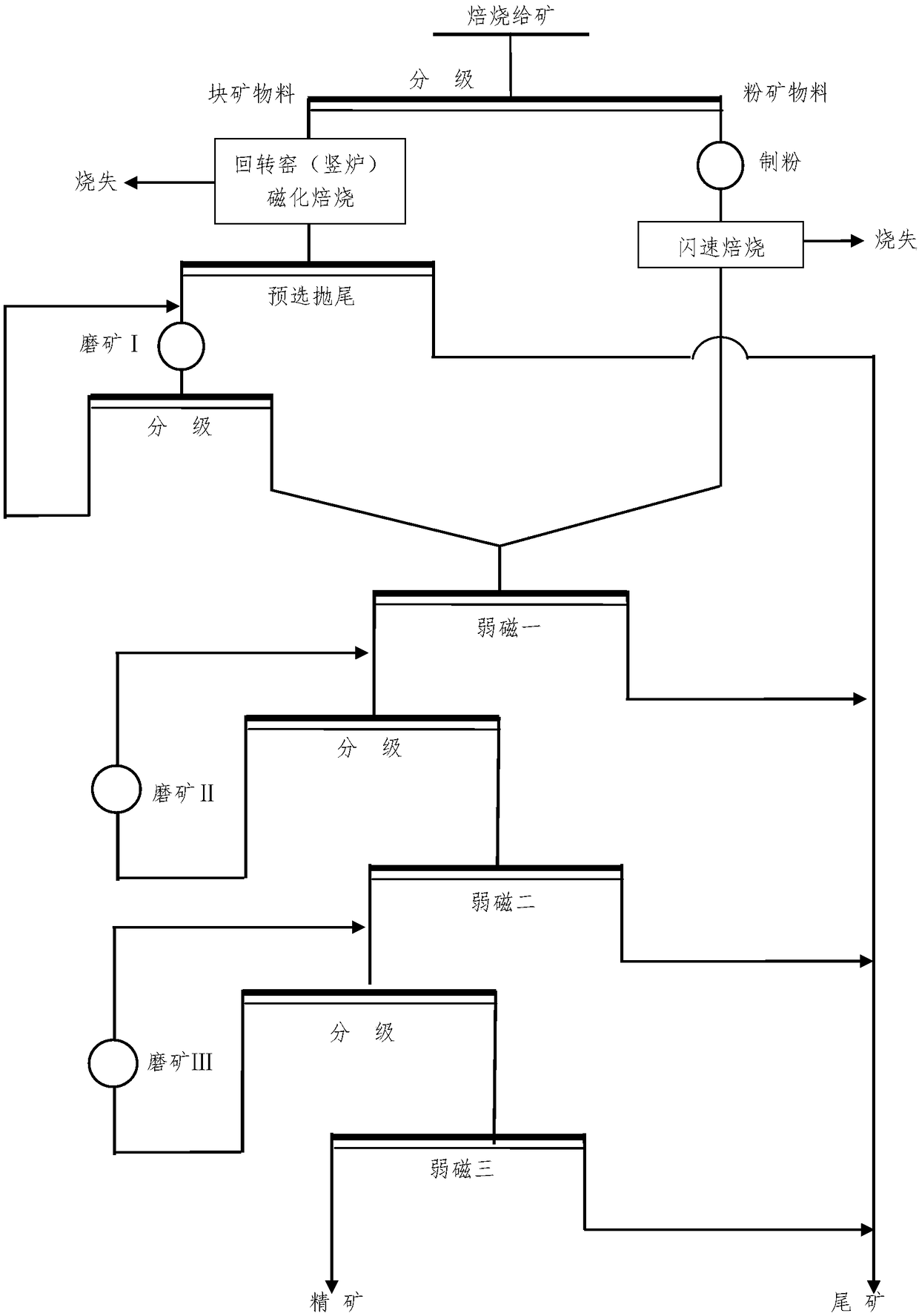

Method for treating refractory red iron ore based on staged combined magnetizing roasting

The invention provides a method for treating refractory red iron ore based on staged combined magnetizing roasting. The method comprises the following steps of (1) crushed refractory red iron ore rawore is screened and classified, and the crushed refractory red iron ore raw ore is divided into a powder ore material and a lump ore material; (2) dry powder preparation is carried out on the powder ore material, a fine grain powder ore material is obtained, flash magnetizing roasting of the fine grain powder ore material is carried out, and a powder ore roasting ore is obtained; and magnetizing roasting is carried out on the lump ore material by adopting a vertical furnace or a rotary kiln, and a lump ore roasting ore is obtained; (3) the lump ore roasting ore is carried out pre-selection tailing, so that lump ore tailing rough concentrate ore is obtained, and tailing ore is directly thrown away; and (4), the lump ore tailing rough concentrate ore is carried out a primary grinding and classifying operation, and a primary classifying overflow product is obtained; and the primary classifying overflow product and the lump ore roasting ore are combined to enter a sorting process, a finaliron ore concentrate product is obtained, and the tailing is directly thrown away. The method for treating refractory red iron ore based on staged combined magnetizing roasting has the advantages of being simple in process, stable in control, energy-saving and environment-friendly, high in adaptability, and good in beneficiation product quality.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

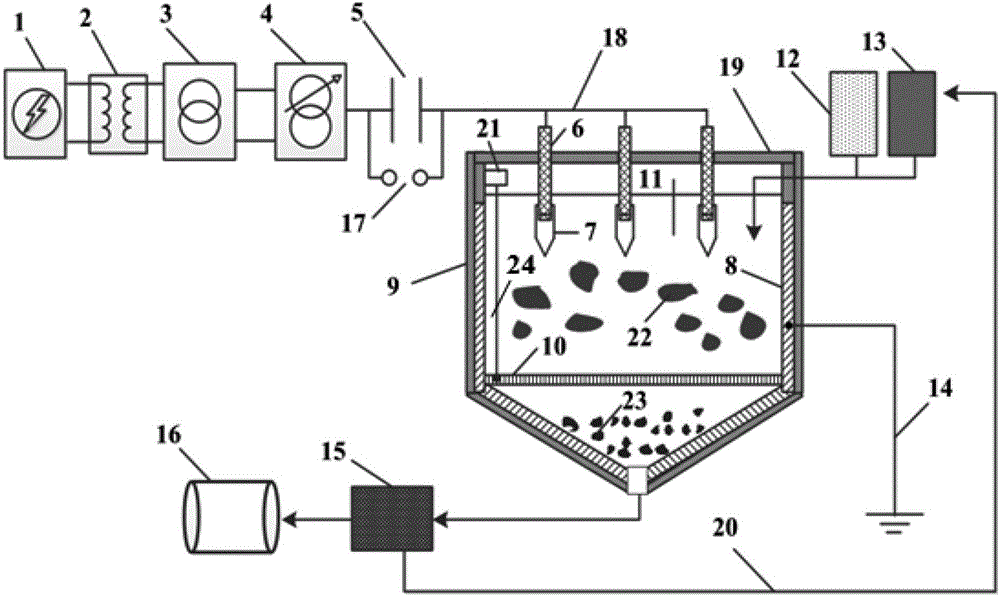

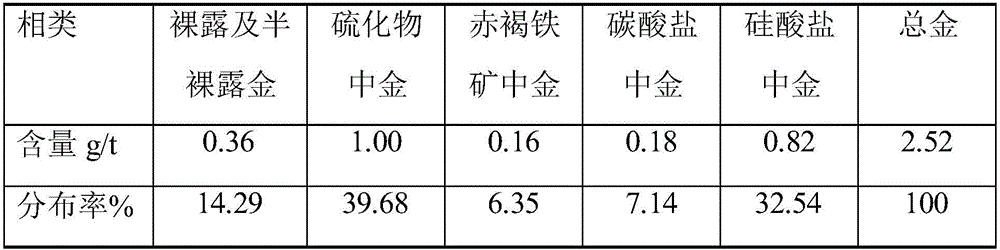

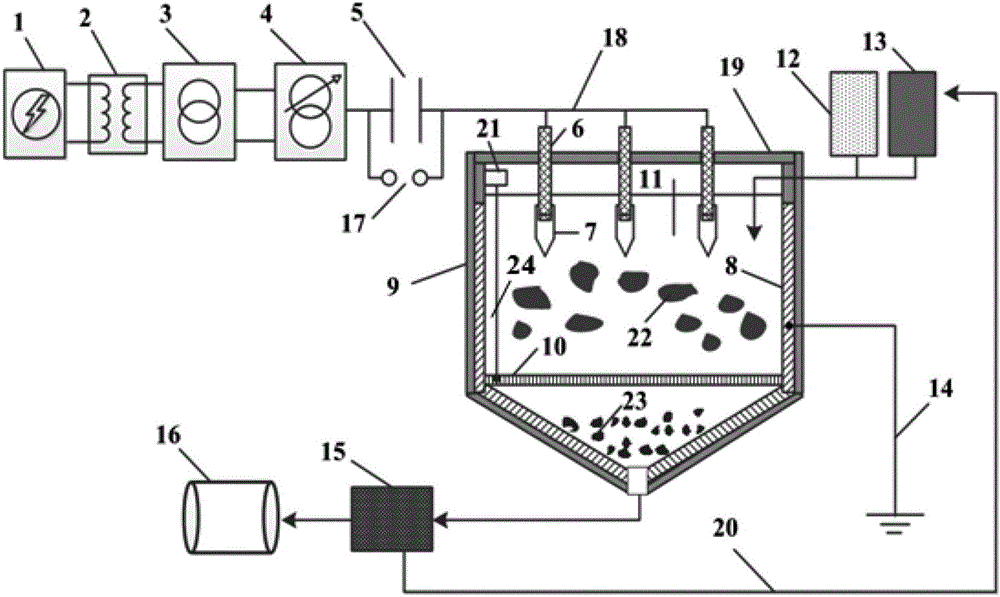

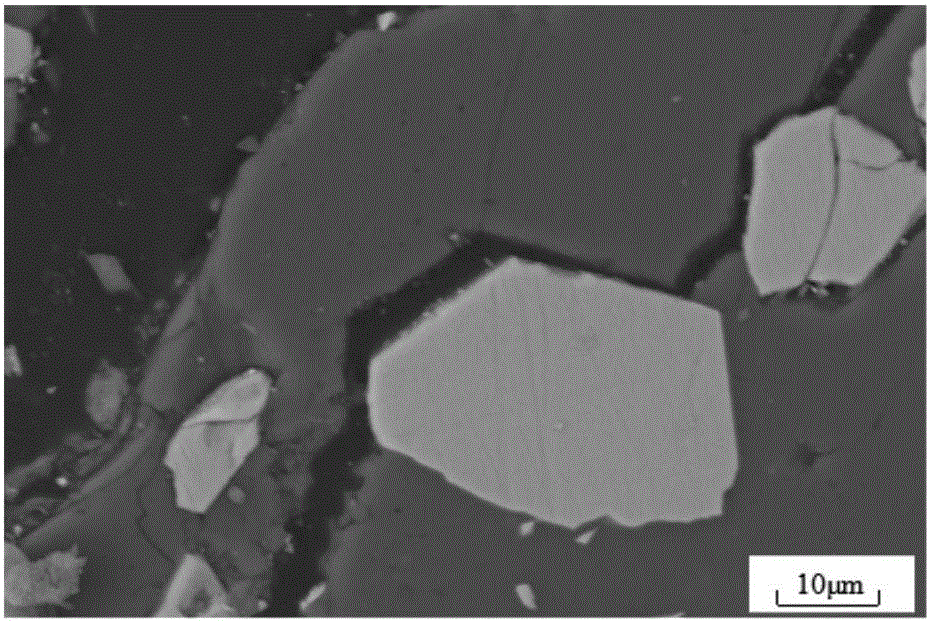

High-voltage electric pulse pretreatment method for intensifying leaching of difficult-to-treat gold ore

ActiveCN106824454AIncrease the content of useful mineralsIncrease monomer dissociationGrain treatmentsPretreatment methodMineral particles

The invention discloses a high-voltage electric pulse pretreatment method for intensifying the leaching of difficult-to-treat gold ore, and belongs to the technical field of the processing of minerals of gold ore. According to the method, the high-voltage electric pulse crushing pretreatment is realized by utilizing the differences of the dielectric properties of different minerals in ore; a high-voltage electric pulse discharge crushing device is used for carrying out selective crushing on gold-containing ore; gold and a gangue mineral in a gold-containing material are prompted to generate a micro crack and a running crack at an interface; a crystal of a gold-containing mineral is completely dissociated into monomer mineral particles; in this way, the exposed surface area of the gold is increased; therefore, the contact probability of cyanide and a gold grain is increased, so that the sufficient improvement of the leaching rate of the gold is facilitated.

Owner:NORTHEASTERN UNIV

Separation process for magnetic red mixed ore based on iron material disseminated particle size treatment

ActiveCN109351467AReduce grinding energy consumptionReduce overgrindingSolid separationOre concentrateSeparation process

The invention relates to a separation process for magnetic red mixed ore based on iron material disseminated particle size treatment. The process comprises the operation of feeding the mixed ore withthe grade of 27%-29% and with magnetite as a main raw material into first-section closed circuit ore grinding operation to obtain a primary grading overflow product, and is characterized by further comprising first-section weak magnetic and strong magnetic operation, fine screening operation, first-section magnetic separation and first-section washing magnetic separation operation, second-sectionclosed circuits ore grinding operation, second-section weak magnetic strong magnetic operation, second-section magnetic separation and washing magnetic separation operation, third-section closed circuit ore grinding, third-section weak magnetic strong magnetic operation and reverse flotation operation. The final concentrate with the grade of 66%-66.5% is obtained through the operation. Compared with the prior art, the separation process has the advantages that 1) an efficient separation process which is characterized in that the concentrate can be obtained once dissociation is achieved and segmented ore grinding, segmented concentrate taking and segmented tailings discharging are achieved is provided for the magnetic red mixed ore with the non-uniform iron material disseminated particle sizes, so that overgrinding is reduced, and energy conservation and consumption reduction are achieved; 2) magnetic separation equipment is adopted for upgrading, and three sections of ore grinding is carried out by adopting vertical mills; and 3) the process is simple in structure, free of middling circulation, easy to implement on site and easy to produce and manage.

Owner:ANSTEEL GRP MINING CO LTD

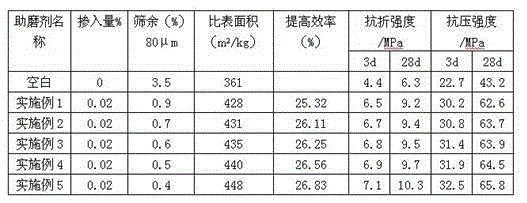

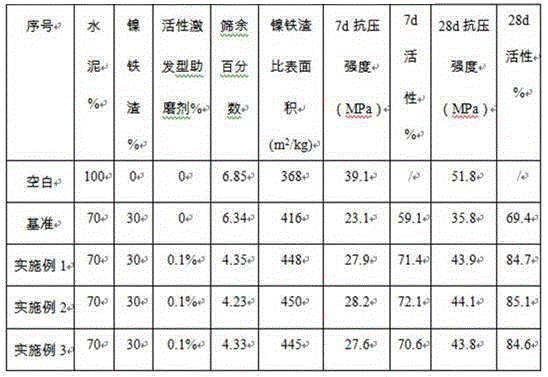

Active excitatory grinding aid for ferronickel slag and preparation method for active excitatory grinding aid

ActiveCN105084793ASolve the problem of poor wearabilityResolve low activitySolid waste managementPolyolMetallurgy

The invention discloses an active excitatory grinding aid for ferronickel slag and a preparation method for the active excitatory grinding aid. The grinding aid is composed of polymeric glycol, cocoanut fatty acid diethanolamide, sodium pyrophosphate, ethyl acetate, an excitant and water, wherein the excitant is composed of calcined alunite, water glass and sodium abietate. The additive amount of the grinding aid in the ferronickel slag is 0.02-0.10% by mass of the ferronickel slag. The active excitatory grinding aid disclosed by the invention is sufficient in raw materials, simple to process and prepare, low in doping amount, stable in performance and high in cost performance. As the ferronickel slag which is ground is added, the problem that the ferronickel slag is poor in grindability can be solved. Under the condition that the grinding time is equal, the specific surface area of the ferronickel slag micropowder can be improved by 4.5-9%, the mill output is increased by over 15%, the energy consumption is remarkably reduced, and moreover, the active index of the ferronickel slag can be further improved by 10-35%.

Owner:UNIV OF JINAN +1

High-voltage electric pulse ore crushing device and method for ore pre-treatment

ActiveCN106824455ADoes not destroy crystal formImproved cleavage propertiesSievingScreeningTransformerCeramic capacitor

The invention discloses a high-voltage electric pulse ore crushing device and a method for ore pre-treatment and belongs to the technical field of ore crushing pre-treatment in mineral processing. The device mainly comprises a power supply, a single-phase voltage regulator, an alternating-current ignition transformer, a six-time-voltage rectification circuit, an ultrahigh-voltage ceramic capacitor, a gas switch, a high-voltage electrode, a conductive barrel body, a discharging and ore crushing bucket, a vibration screen mesh, insulating liquid, a solid-liquid separator, a product collector and the like; all the units are fixedly connected through a lead wire and other auxiliary devices to form a complete equipment system. The ores are treated and then are selectively dissociated and crushed according to different conductive properties of useful metal minerals and non-metal mineral components of gangues, and extension cracks and fissures are generated on mineral interfaces on the ores, so that physical properties of the minerals are improved and subsequent treatment energy consumption is reduced; meanwhile, useful minerals are prevented from excessive abrasion and separation indexes are improved.

Owner:NORTHEASTERN UNIV

Method for producing calcium fluoraluminate clinker through aluminum cell carbon waste

ActiveCN107352819AImprove adsorption capacityAdd depthClinker productionCalcium in biologyTunnel kiln

The invention discloses a method for producing calcium fluoraluminate clinker through aluminum cell carbon waste. The method comprises the following steps of 1, securing treatment, wherein crushing is performed, a detoxicating agent solution is sprayed in an atomization mode to obtain a granulated detoxicating material; 2, fuel treatment, wherein a catalytic oxidant is added, and homogenizing modification is performed to obtain fluorine-containing fuel; or the catalytic oxidant, lime and water are added to be stirred or rolled and mixed or pulverized through a wet process or filtered or filtered and washed to obtain dealkalized fluorine-carbon residue fluorine-containing fuel; 3, manufacturing a raw material, wherein waste alumina, calcium raw materials and waste gypsum are prepared, grinding and homogenizing are performed, and plastifying molding is performed; 4, manufacturing the clinker, wherein the material is fed into a tunnel kiln or a vertical kiln to be calcinated and quenched to obtain the clinker. The clinker obtained through the method can be supplied to dual high early strength cement production, and has the good economical efficiency and good performance; the method can utilize a large quantity of aluminum silicon and calcium containing waste; the method is safe, simple, large in handling capacity, low in energy consumption, low in cost, free of secondary pollution and suitable for industrial production.

Owner:长沙紫宸科技开发有限公司

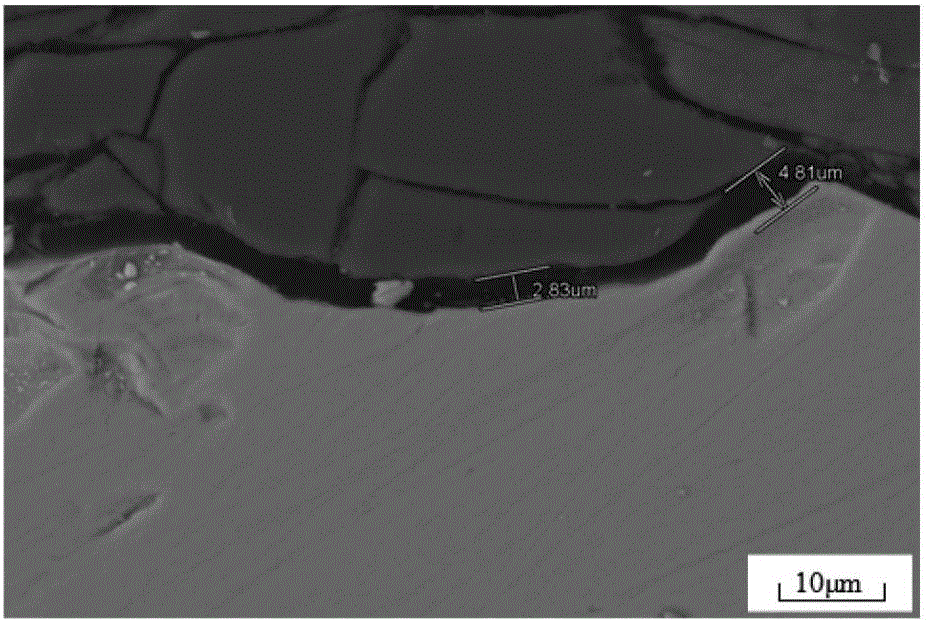

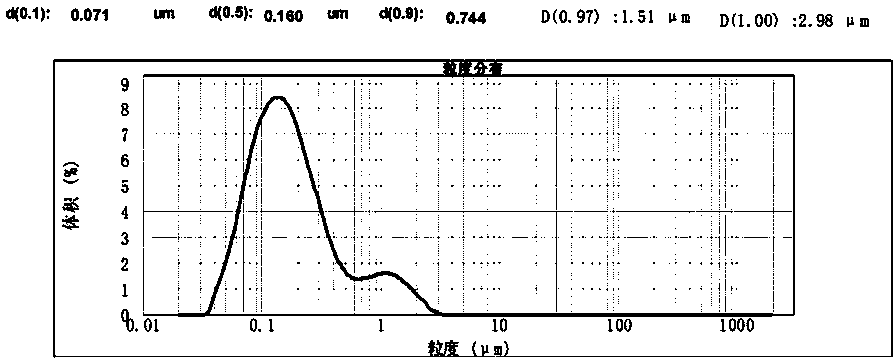

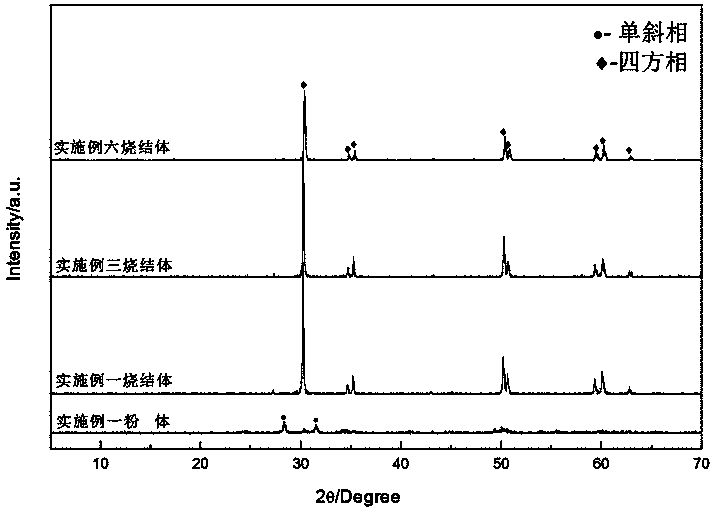

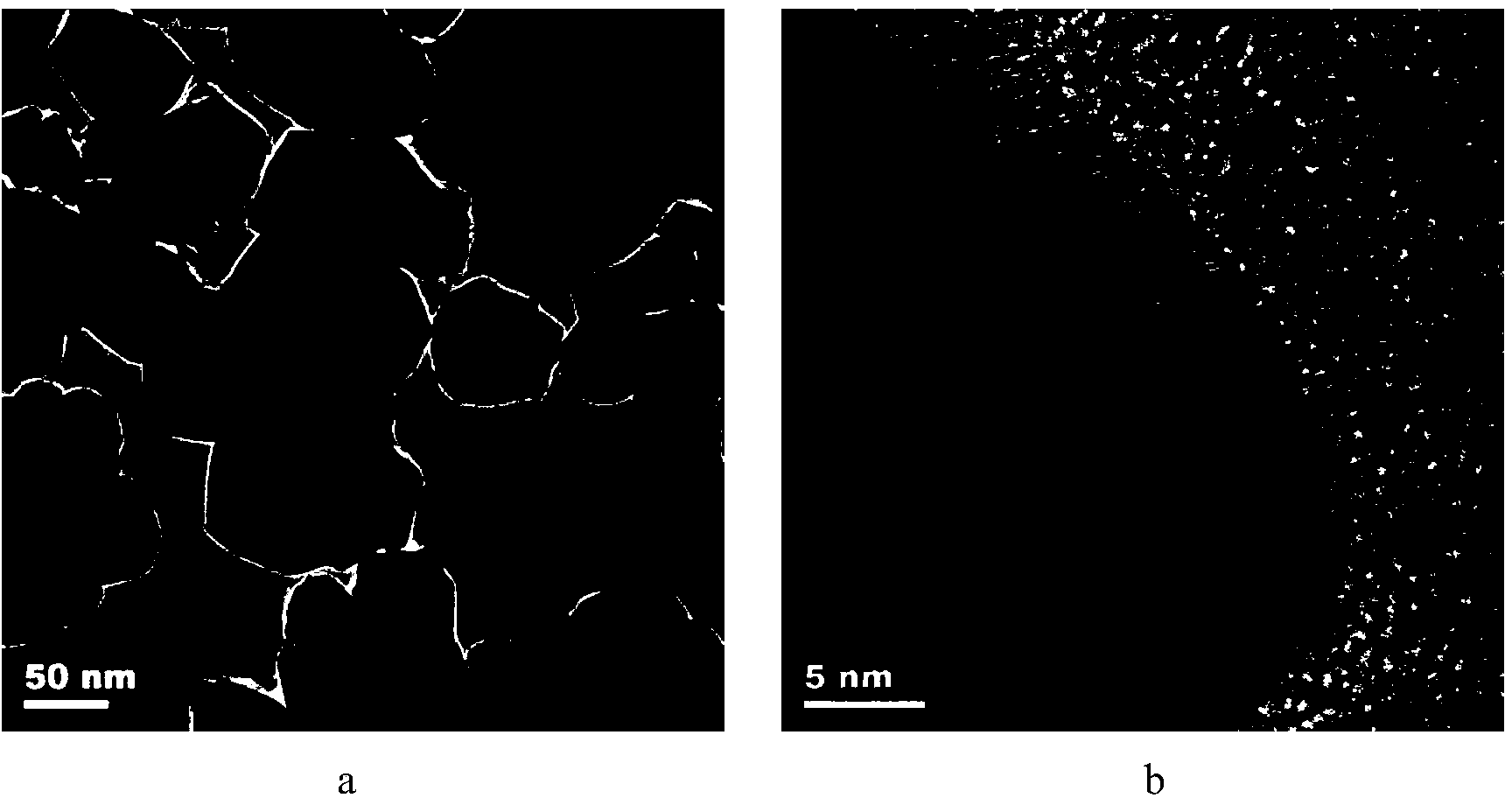

Powder material for preparing high-strength high-toughness yttrium stabilized tetragonal polycrystal zirconia ceramics and preparation method of powder material

The invention discloses a powder material for preparing high-strength high-toughness yttrium stabilized tetragonal polycrystal zirconia ceramics. The powder material is prepared from zirconia and yttrium oxide, wherein the content of the yttrium oxide is 1.4-2.6mol% of the total amount of Zr<4+>; and the average grain size of raw crystal of the powder material is 50-110nm. Moreover, the invention further discloses a preparation method of the powder material. According to the zirconia powder material, the doping amount of yttrium is reduced, the tetragonal polycrystal ceramics prepared by using the powder are capable of realizing full tetragonal phase stable existence of zirconia at room temperature to guarantee the characteristic of high strength, activating the tetragonal phase in TZP (tetragonal zirconia polycrystalline), improving the transformation toughening performance and further optimizing the fracture toughness of TZP ceramics. The preparation method is safe and reliable, has the advantages of wide raw material source, low energy consumption and remarkable effect on energy conservation and emission reduction, is convenient for popularization and application, is suitable for industrial large-scale production, and can be used for effectively promoting application and development of zirconia materials.

Owner:江西赛瓷材料有限公司 +1

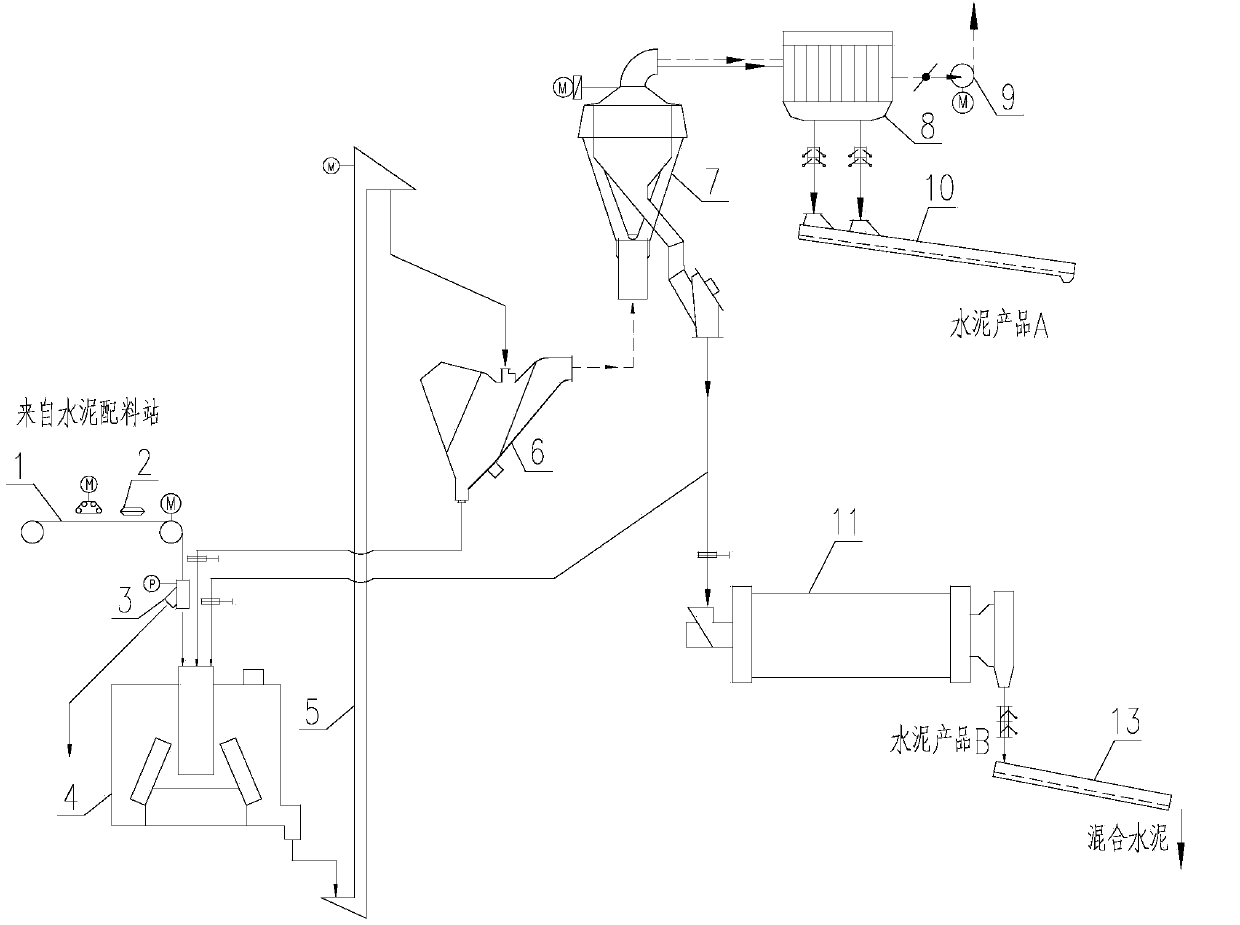

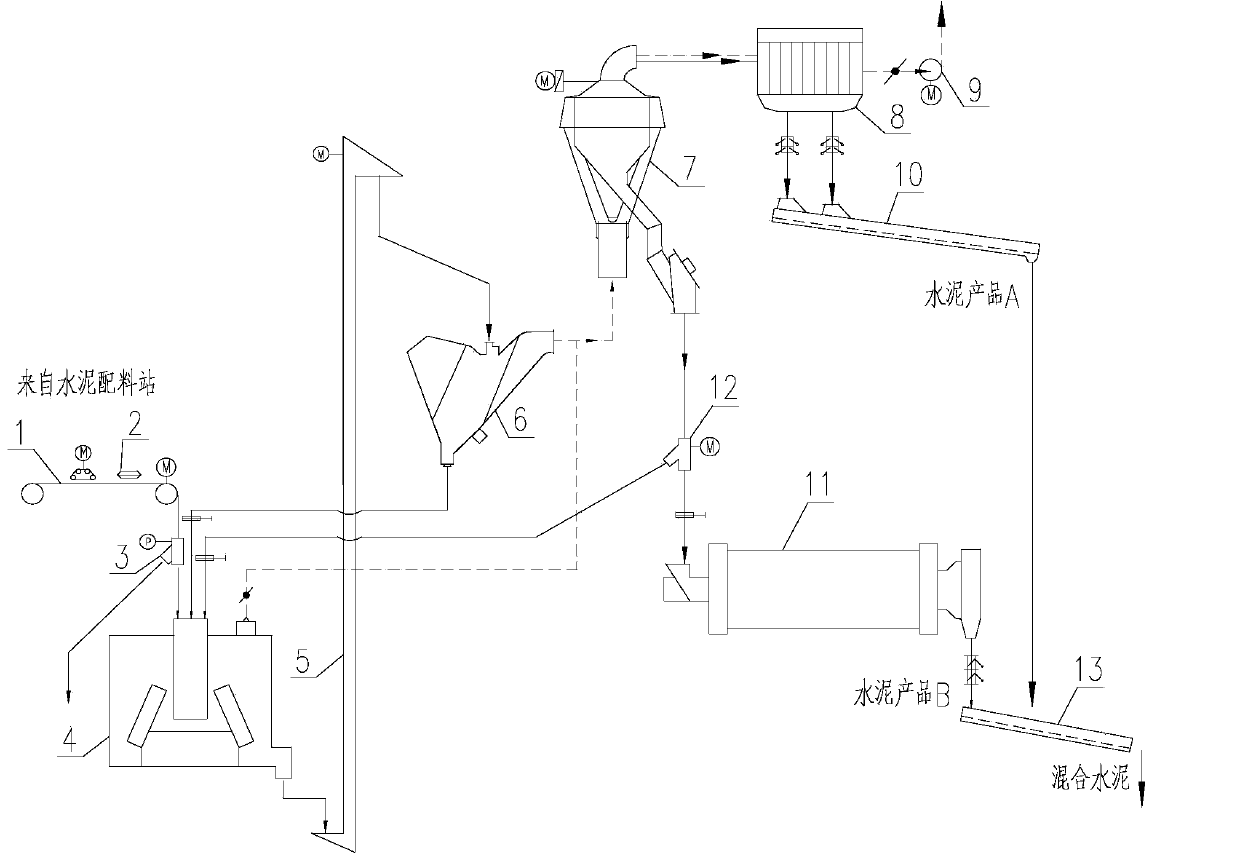

Cement outer-circulating semi-finish grinding system of vertical mill

ActiveCN104211312AEfficient grinding functionImprove grinding efficiencyCement productionAir blowerBucket elevator

The invention relates to a cement outer-circulating semi-finish grinding system of a vertical mill. The cement outer-circulating semi-finish grinding system comprises a belt conveyor, a magnetic separator, a metal detector, a three-way valve, the vertical mill, a bucket elevator, a powder concentrator, a dust collector, an air blower, a tube grinder and a chute, wherein the vertical mill is an outer-circulating vertical mill, and no powder concentrator is arranged in the outer-circulating vertical mill; the powder concentrator is formed by connecting a coarse powder V-shaped powder concentrator and a fine powder concentrator in series, and fine powder obtained from the coarse powder V-shaped powder concentrator enters the fine powder concentrator for concentration again; the fine powder obtained from the fine powder concentrator is served as a cement product A and collected through the dust collector and the air blower, and separated coarse powder is divided into two ways, wherein one way enters the tube grinder, and one way returns to the vertical mill for circulating grinding; and the powder which enters the tube grinder is ground into a cement product B by the tube grinder. The cement outer-circulating semi-finish grinding system disclosed by the invention achieves relatively high grinding efficiency by sufficiently exerting the high-efficiency crushing and grinding functions of the vertical mill and the high-efficiency grinding function of the tube grinder on the fine powder, thereby reducing the grinding energy consumption.

Owner:NANJING KISEN INT ENG

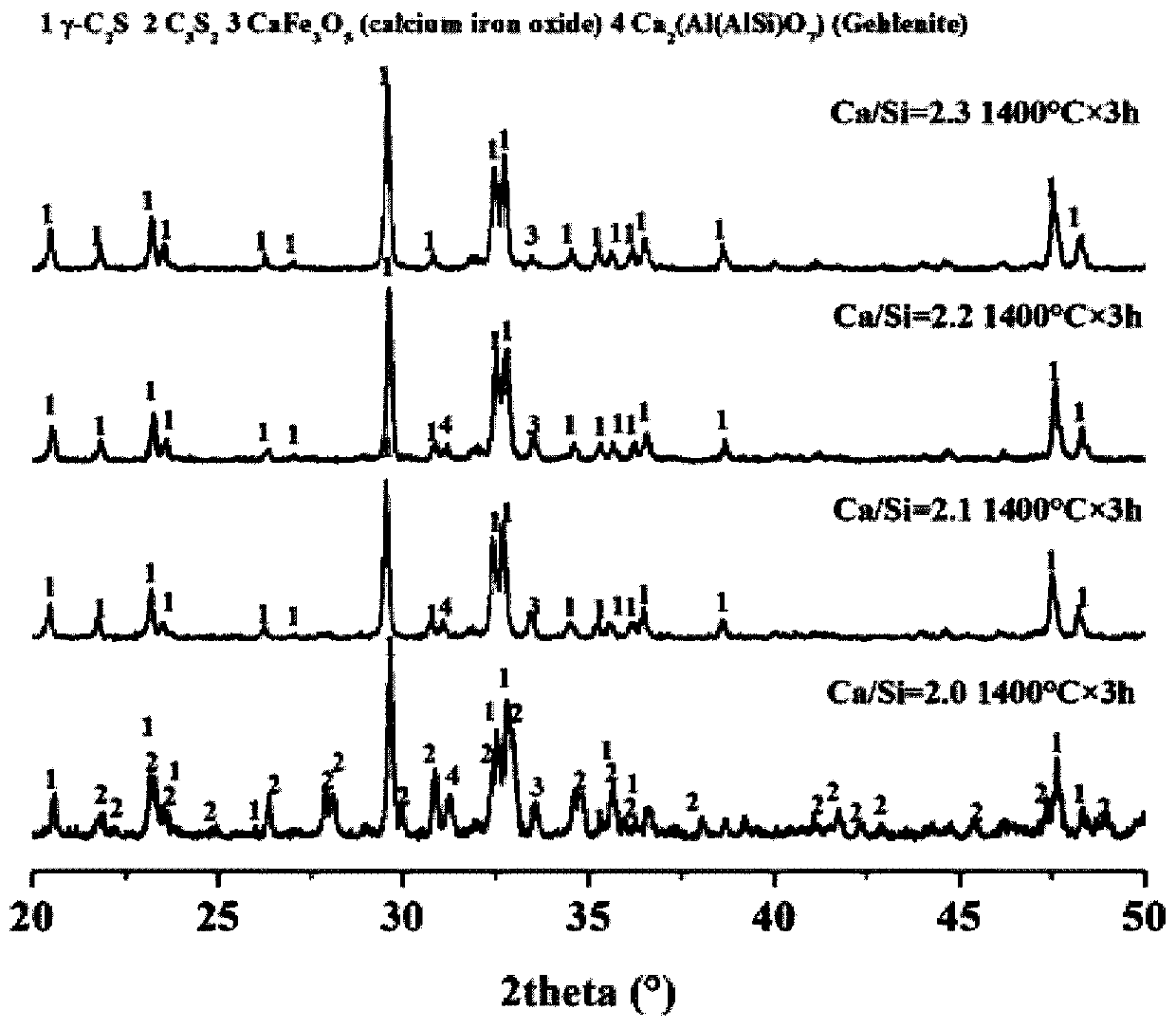

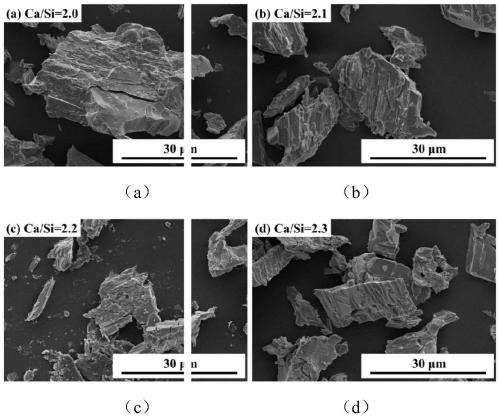

Preparation method of gamma-C2S-based cementing material

PendingCN111393050AHas self-pulverizing propertiesReduce grinding energy consumptionCement productionSlagCarbonization

The invention provides a preparation method of a gamma-C2S-based cementing material. The method comprises the following steps: 1, mixing a calcium raw material and a siliceous raw material according to a calcium-silicon molar ratio of 2.0: 2.3, and carrying out ball-milling mixing to obtain a sintering raw material, wherein the calcium raw material is one of limestone, marl and steel slag, and thesiliceous raw material is one or more of sandstone and silica; and 2) mixing the sintering raw material with absolute ethyl alcohol with the mass fraction of 10%, pressing into a green body, drying,sintering, and naturally cooling to obtain the gamma-C2S-based cementing material. The gamma-C2S-based cementing material is prepared from industrial raw materials, the prepared gamma-C2S-based cementing material has a self-pulverization characteristic, the grinding energy consumption of clinker can be reduced, and a carbonized product of the gamma-C2S-based cementing material has the characteristics of quick hardening and high strength of a gamma-C2S carbonized product at the same time. In addition, the gamma-C2S-based cementing material is prepared by sintering the industrial raw materials,so that the production cost of the gamma-C2S is greatly reduced, and the method has very important practical significance for industrial production and application of the carbonized hardened cementingmaterial.

Owner:山东汉博昱洲新材料有限公司

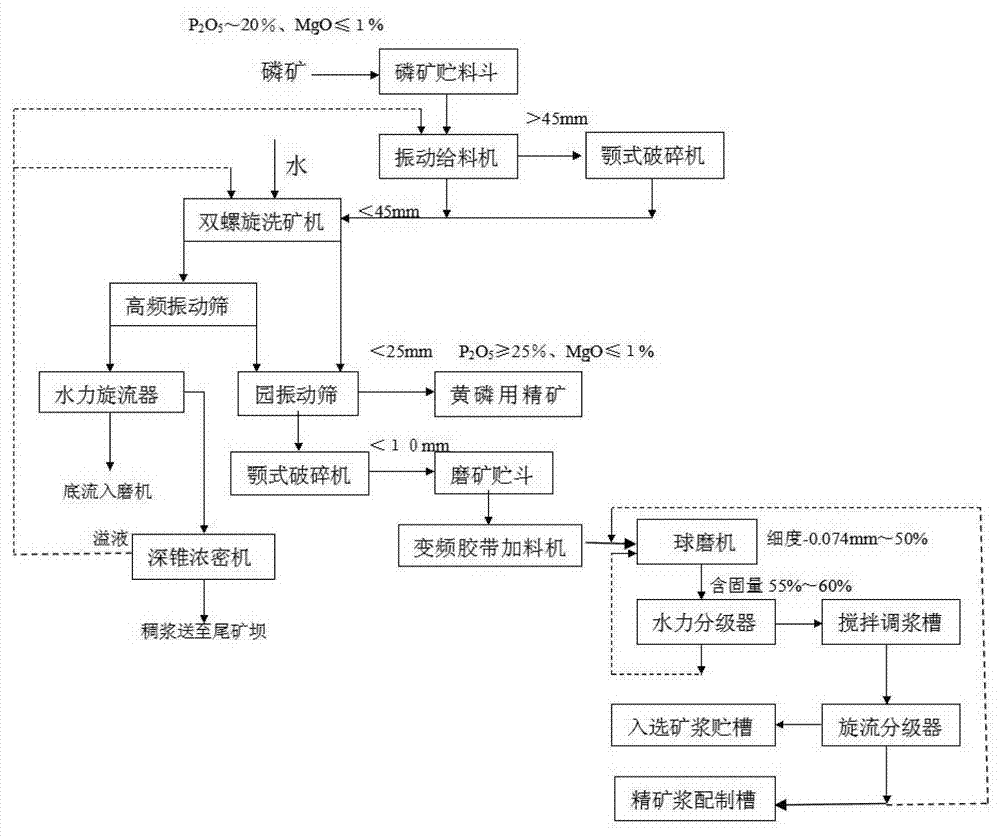

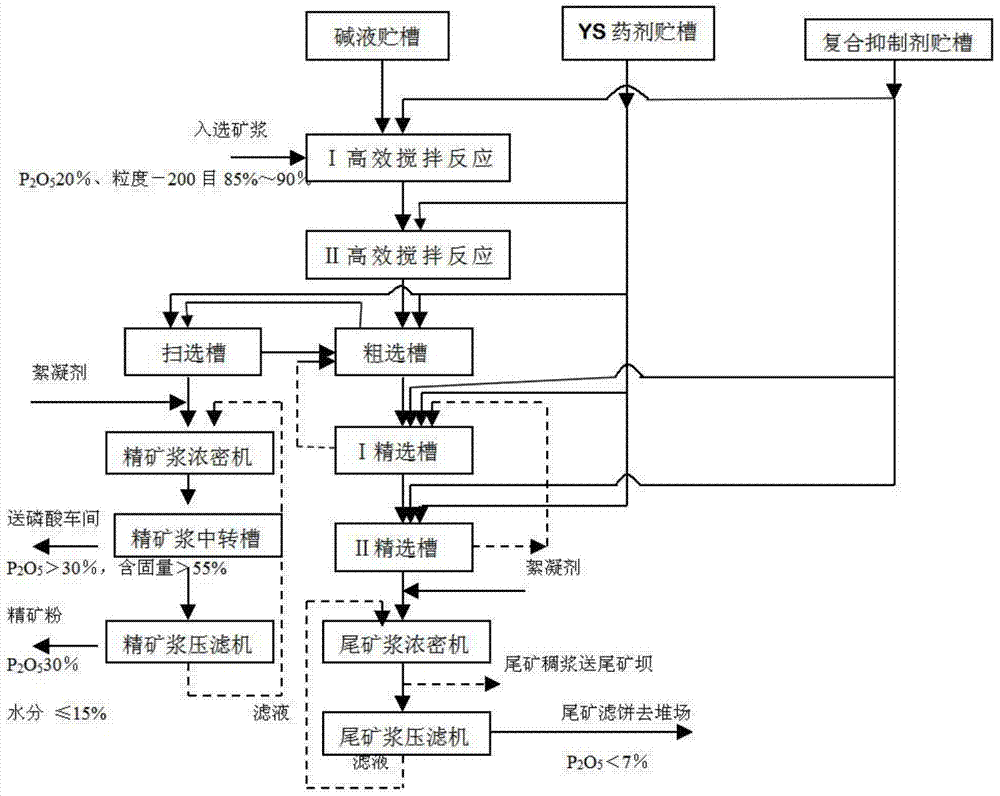

Direct and reverse flotation technique for high-magnesium low-grade phosphorus ore coarse grains

The invention relates to a direct and reverse flotation technique for high-magnesium low-grade phosphorus ore coarse grains. The technique comprises the following steps: crushing and grinding high-magnesium low-grade phosphorus ores; transferring into a flotation machine stirring tank and adding water for mixing slurry; keeping the temperature of the ore slurry at 10-30 DEG C, and then respectively adding regulator sodium silicate and inorganic base into the ore slurry; adding a direct flotation collecting agent for mixing the slurry; adding water for performing direct flotation system operation; transferring a direct flotation foam product into a reverse flotation stirring tank, respectively adding the regulator sodium silicate and reverse flotation mixing collecting agent into the reverse flotation stirring tank, and mixing the slurry without adding fresh water; adding fresh water and performing the reverse flotation system operation; discharging and stacking the foam products which are reverse flotation tailings, wherein the products in the tank are low-magnesium phosphorus ore concentrates; concentrating, filtering and drying, thereby acquiring the end products of concentrates. According to the technique, the last magnesium content of the concentrates is reduced and the quality of the concentrates is increased; the process is simple; the energy consumption for ore grinding is low; the dosage of agents is less; the separation effect is good; the discharging rate of magnesium is high; the water quality of concentrate and tailing is improved.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Retarding-type cement grinding aid

InactiveCN106082761AImprove early and late strengthSpeed up the flowPolyaspartic acidCement grinding

The invention relates to the technical field of cement additives, particularly a retarding-type cement grinding aid. The retarding-type cement grinding aid is prepared from the following raw materials in parts by weight: 18-28 parts of triethanolamine, 12-24 parts of diethanolisopropanolamine, 2-8 parts of sodium tartrate, 5-17 parts of coco fatty acid diethanol amide, 8-16 parts of sodium gluconate, 6-14 parts of polyaspartic acid and 50-70 parts of water. The retarding-type cement grinding aid has favorable retarding effect, can enhance the early strength and later strength of cement, and is beneficial to enhancing the impermeability and freeze-thaw resistance of hardened concrete.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

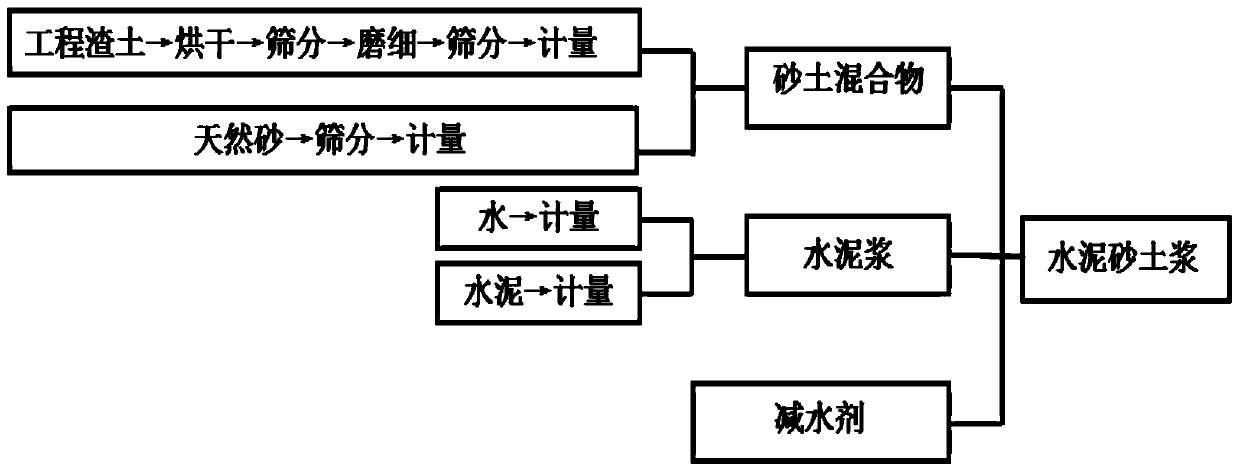

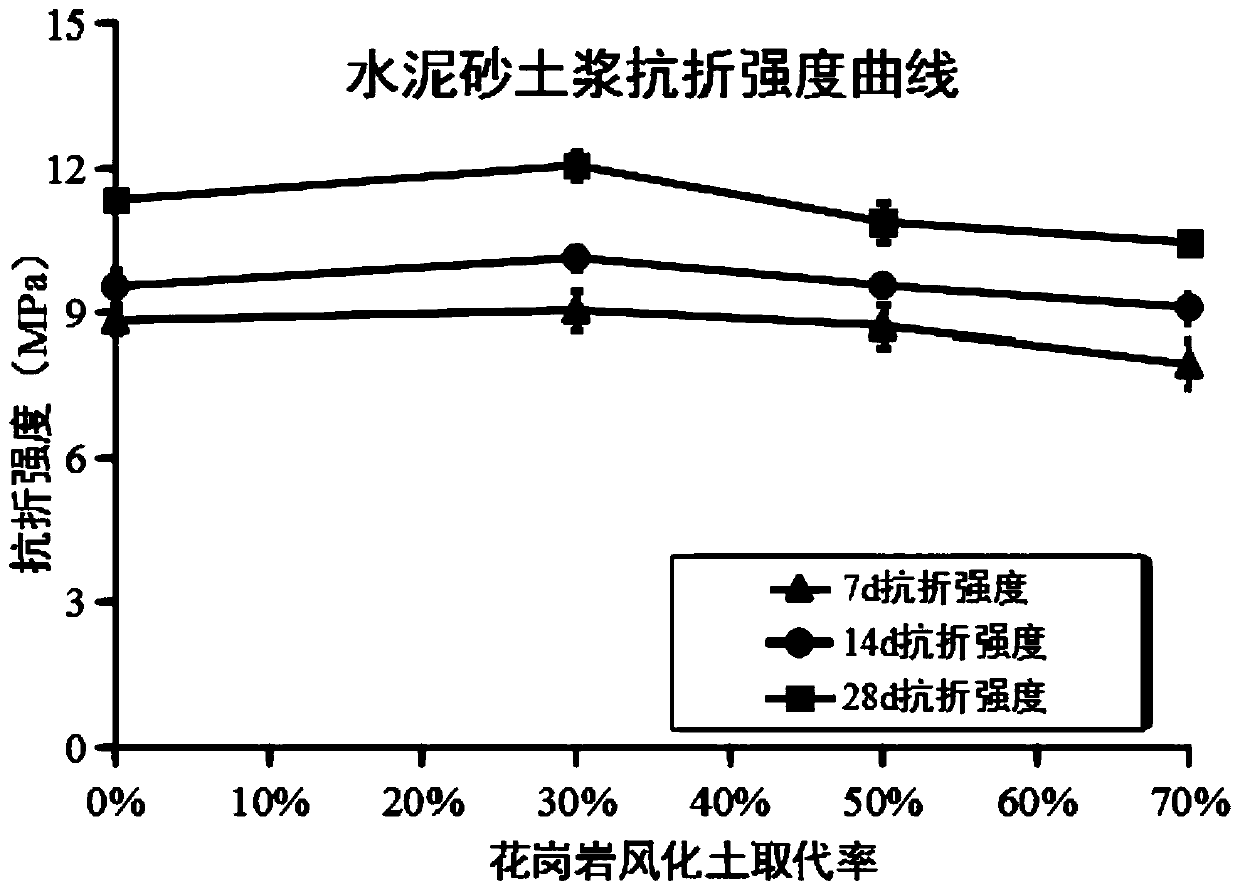

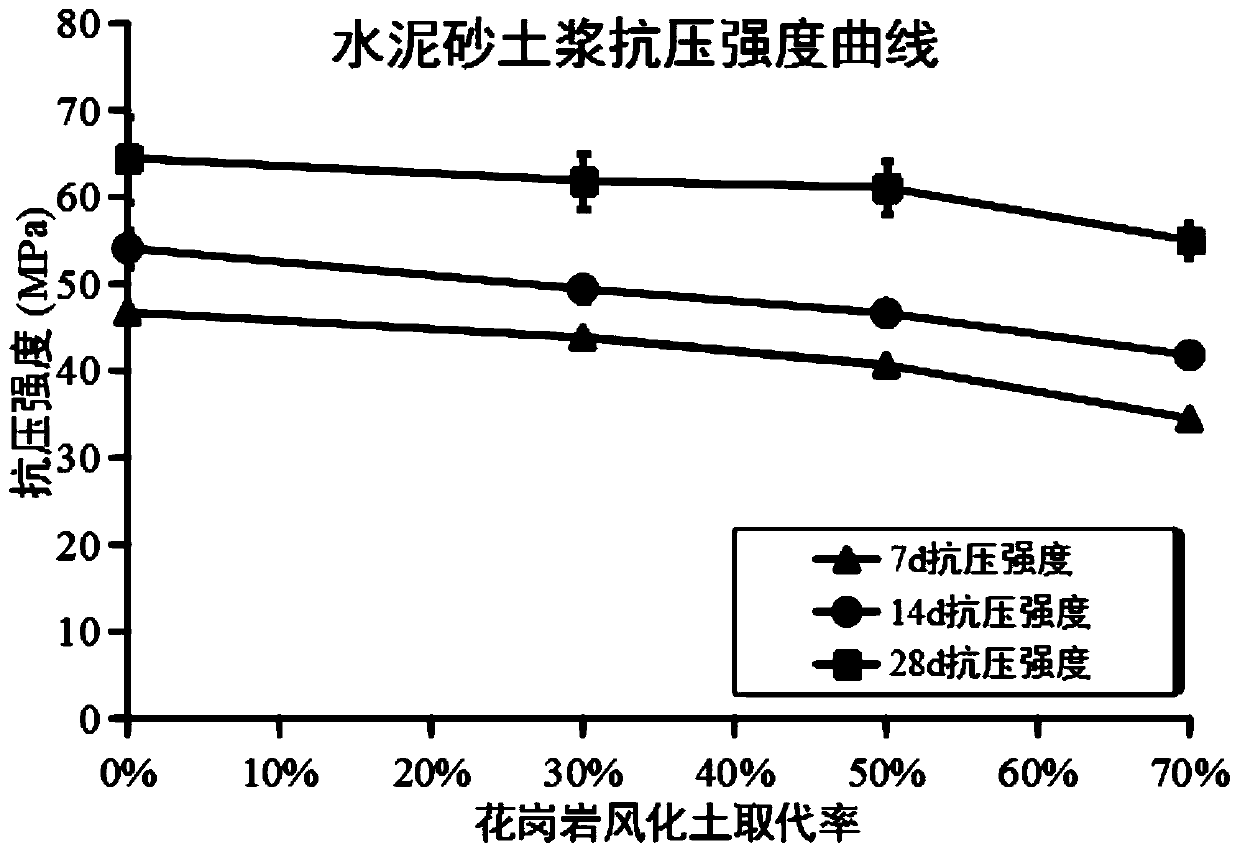

Cement and sandy soil mortar prepared from engineering muck instead of natural sands, and preparation method and application thereof

The invention discloses a cement and sandy soil mortar prepared from engineering muck instead of natural sands, and a preparation method and an application thereof. The preparation method comprises the following steps: drying and grinding waste engineering muck taken from the construction site, sieving and mixing the dried and ground waste engineering muck to form reclaimed engineering muck, and adding the reclaimed engineering muck and natural sands into a mortar stirrer according to a certain ratio in order to form a sand mixture; pouring water and cement into the mortar stirrer, adding a part of the sand mixture and a part of a water reducing agent, and performing uniform stirring; and adding the remaining sand mixture and the remaining water reducing agent, and performing uniform stirring to prepare the cement and sandy soil mortar prepared from engineering muck instead of natural sands. The preparation method provided by the invention has the advantages of realization of full utilization of a large amount of the engineering waste much through a reasonable proportioning ratio of materials, saving of river sand resources, protection of the ecological environment, reduction of the production cost and the under the engineering muck treatment cost on the premise of ensuring excellent working performances and mechanical performances of the sandy soil mortar, and excellent economic and social benefits.

Owner:SOUTH CHINA UNIV OF TECH

Washing and direct flotation method of low-grade refractory argillaceous phosphorite

ActiveCN104261361AReduce grinding energy consumptionTo achieve hierarchical useFlotationRaw phosphate material treatmentWet grindingLow graded

The invention relates to a washing and direct flotation method of low-grade refractory argillaceous phosphorite, which is characterized by comprising the following steps: a. phosphorite closed coarse crushing, fine crushing, screening, water washing and fine ore closed wet grinding grading; and b. phosphorite rough separation, twice concentrating, once scavenging direct flotation, thickening and pressure filtration direct flotation. The step a is performed to prepare the phosphorus concentrate for yellow phosphorus production, of which the mass percent of P2O5 is greater than or equal to 25% and the particle size is less than or equal to 25mm, and prepare the phosphorite slurry for phosphoric acid production, extraction and slurry preparation without flotation, of which the content of particles with the particle size of 100 meshes is greater than 85% and the mass percent of P2O5 is 28.5%. By adopting the more-crushing / less grinding-closed screening-washing technique, the method can lower the grinding energy consumption by 10kw.h / t, and has the advantages of obvious separating effect between the phosphorite and gangue mineral and favorable separation indexes. Compared with the traditional technique, the phosphorus concentrate recovery rate is enhanced by 10% or so, and the tailing remaining phosphorus is lowered by 2-3%.

Owner:YUNNAN HONGFU CHEM FERTILIZER

Modified cement grinding aid

InactiveCN104844058AConducive to energy saving and emission reductionIncrease productionHydration reactionSucrose

The invention relates to a modified cement grinding aid, belonging to the technical field of cement assistants. The modified cement grinding aid is prepared from the following substances in parts by weight: 20-30 parts of polymerized polyalcohol, 10-30 parts of lignin-based alkylol amine, 2-10 parts of sodium soap, 5-10 parts of polytetrafluoroethylene powder, 1-5 parts of solid aluminum dihydrogen phosphate, 1-4 parts of gelatin and 2-6 parts of sucrose. The particle size of the solid aluminum dihydrogen phosphate is 50-80nm. The modified cement grinding aid is beneficial to highly fine milling and superfine grinding, is beneficial to enhancing the yield of the grinder, and enhances the yield of the ball grinder by 25%. The modified cement grinding aid is beneficial to lowering the grinding energy consumption, enhancing the clinker utilization ratio and saving the cost. The clinker powder in the cement can basically complete the hydration reaction within 20 days, thereby completely displaying the strength action. The modified cement grinding aid is beneficial to improving the production of special cement, and is beneficial to energy saving and emission reduction in cement industry.

Owner:湖州华仑助剂科技有限公司

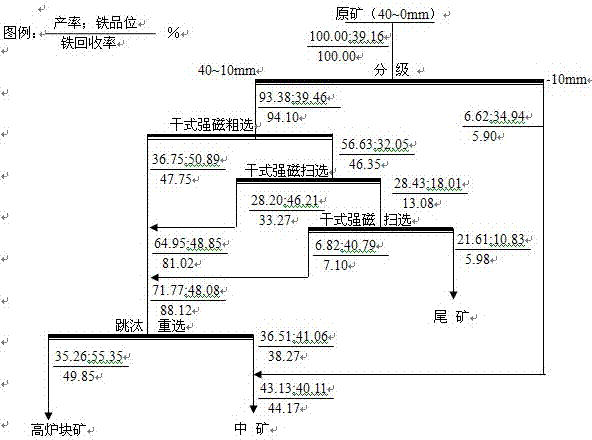

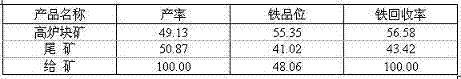

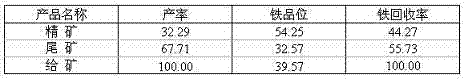

Beneficiation method for producing blast furnace lump ore by hematite at medium-high grade

InactiveCN102773156AHigh recovery rateThe amount of ball grinding is reducedMagnetic separationWet separationEnergy consumptionFerric

The invention discloses a beneficiation method for producing blast furnace lump ore by hematite at a medium-high grade. The method comprises the following steps of: crushing the hematite with the iron grade being greater than or equal to 39%, and grading the hematite into materials with two size fractions of 40mm-10mm and -10mm; carrying out dry-type strong magnetic roughing, primary dry-type strong magnetic scavenging and secondary dry-type strong magnetic scavenging on the materials with the size fraction of 4mm-10mm to respectively obtain dry-type strong magnetic roughing ore concentrate, primary dry-type strong magnetic scavenging ore concentrate, secondary dry-type strong magnetic scavenging ore concentrate and lump ore tails, and combining and feeding the dry-type strong magnetic scavenging ore concentrate, the primary dry-type strong magnetic scavenging ore concentrate and the secondary dry-type strong magnetic scavenging ore concentrate to a jigging reselection operation to obtain the blast furnace lump ore; and combining tails in the jigging reselection with the materials with the grade of -10mm into middlings, and feeding the middlings to subsequent grinding and selecting operations for grading. By adopting the method, part qualified blast furnace lump ore can be obtained in advance, the lump tails can be ejected, the goal ore grinding amount (namely the amount of the middlings) can be greatly reduced, and thus the energy consumption for grinding and selection can be greatly reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Liquid cement grinding aid

The invention relates to the technical field of cement additives, in particular to a liquid cement grinding aid. The liquid cement grinding aid is prepared from, by weight, 20-30 parts of triisopropanolamine, 10-20 parts of sulfated coconut oil fatty acid monoethanolamide sodium, 8-16 parts of borax, 2-6 parts of ethyl acetate, 1-6 parts of Arabic gum, 0.6-2.2 parts of zinc stearate and 35-55 parts of water. The liquid cement grinding aid is efficient, stable in performance and capable of lowering grinding energy consumption and improving the cement strength and the durability of concrete.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for producing belite-gypsum material by using sludge and waste gypsum through dry-process rotary kiln

The invention discloses a method for producing a belite-gypsum material by using sludge and waste gypsum through a dry-process rotary kiln. The method comprises the following steps of (1) melting a sludge ridge grain seed crystal with high water content into modified sludge residues; (2) proportioning raw materials of the modified sludge residues, the waste gypsum and a correcting material according to a certain ratio, and grinding the raw materials by using a vertical mill to form raw material powder; (3) delivering the raw material powder obtained in the step (2) into a dry-process rotary kiln system, and calcining the raw material powder to form clinker; and (4) grinding the obtained clinker to obtain powder with the fineness of 0.08mm and the screen residue content of less than 20%. The method disclosed by the invention is simple, low in investment and cost, free of other secondary pollution and capable of absorbing the sludge and the waste gypsum on a large scale and in a recycling way, greatly reducing the energy consumption and relieving the environment pollution.

Owner:长沙紫宸科技开发有限公司

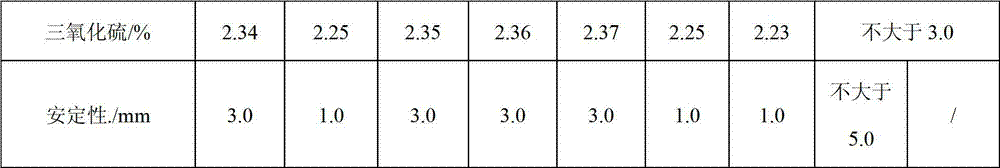

Modified coal ash used in cement and concrete and preparation method of modified coal ash

InactiveCN102951862AImprove activity indexReduce grinding energy consumptionSolid waste managementPolymer scienceCoal

The invention discloses modified coal ash used in cement and concrete and a preparation method of the modified coal ash. The modified coal ash comprises the following raw materials: 95-99wt% of F-class coal ash or C-class coal ash and 1-5wt% of sintering dry-process desulfurized fly ash. The modified coal ash has the characteristics of fineness being not more than 25.0 percent, water demand ratio being not more than 105 percent, ignition loss being not more than 8.0 percent, water content being not more than 1.0 percent, sulfur trioxide content being not more than 3.0 percent, free calcium oxide content being not more than 4.0 percent, qualified stability and strength activity index being not less than 78 percent. Compared with the common coal ash, the modified coal ash disclosed by the invention has the advantages that the 28-day activity index is greatly increased, the fineness requirement can be properly reduced, and the grinding energy consumption can be effectively reduced.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com