Cement outer-circulating semi-finish grinding system of vertical mill

A technology of external circulation and vertical mill, which is applied in cement production, etc., can solve the problems of low grinding efficiency, powder affecting the stable operation of vertical mill, broken tube mill and low efficiency of coarse grinding, etc., so as to reduce the energy consumption of grinding , Avoid over-grinding and improve the efficiency of powder selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

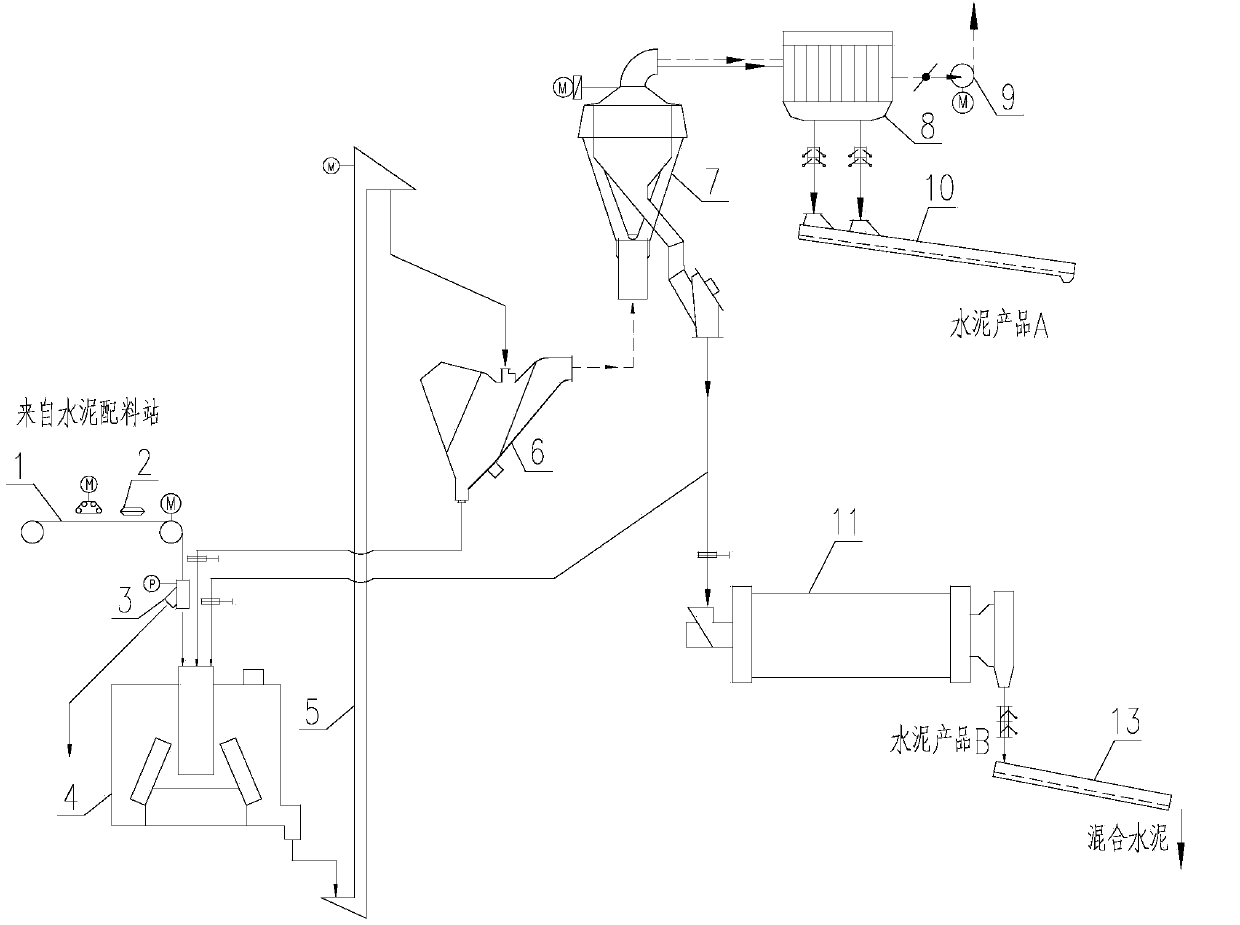

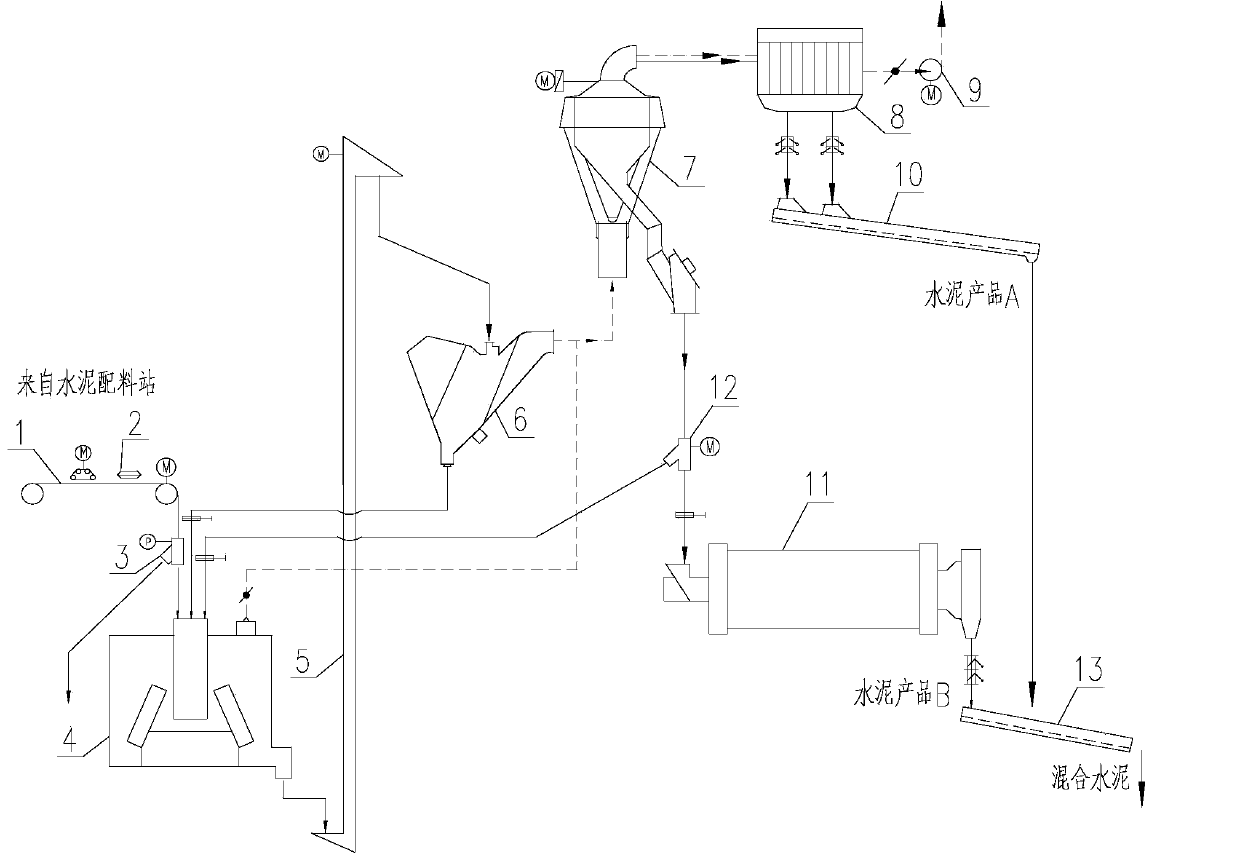

[0021] Such as figure 1 , 2 As shown, the present invention provides a cement external circulation vertical mill semi-final grinding system, including a belt conveyor 1, a metal detector 2, a three-way valve 3, a vertical mill 4, a bucket elevator 5, a dust collector 8, and a fan 9, chute I 10, tube mill 11, chute II 13, powder selection device, the powder selection device is placed outside the vertical mill 4, and the powder selection device is composed of V-type powder separator 6 and fine powder separator 7 connected in series , the fine powder of the V-type separator 6 enters the fine powder separator 7, and the coarse powder returns to the vertical mill 4; the fine powder of the fine separator 7 is selected as cement product A, and the coarse powder of the fine separator 7 is divided into two routes One way returns to the vertical mill 4, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com