Plane grinding device for mobile robot

A mobile robot and plane technology, applied in the field of mobile robots, can solve the problems of high labor intensity, low efficiency, and dangerous manual work, and achieve the effect of efficient grinding function, convenient source, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

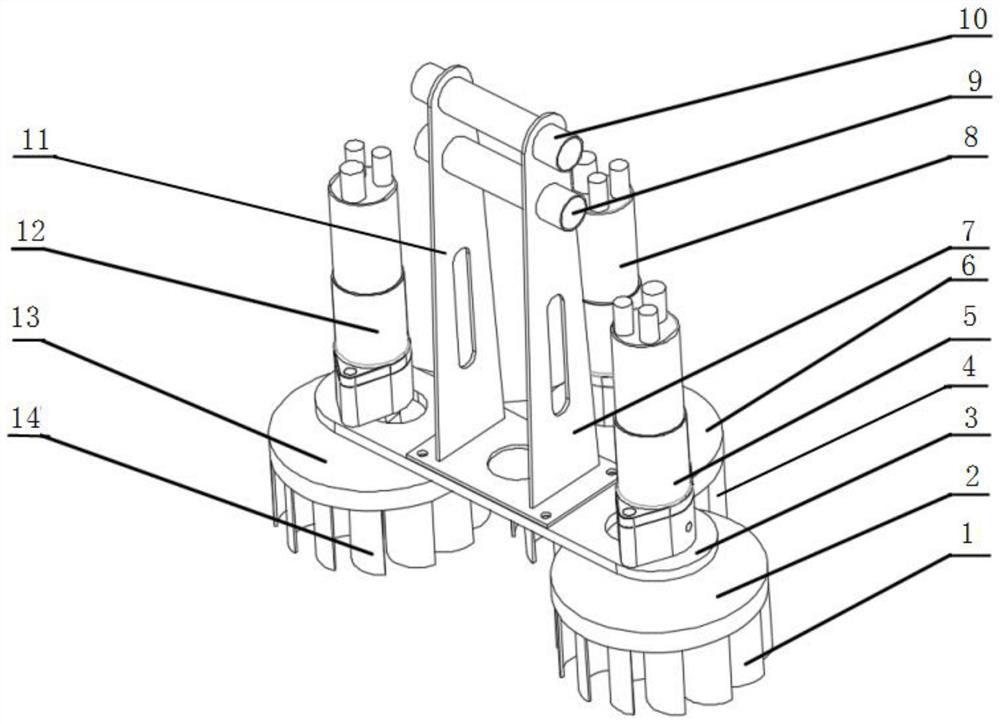

[0024] A flat grinding device for a mobile robot, such as figure 1 As shown, it includes connecting bottom plate 3, two welded steel plates, two welded steel pipes, three air motors, three louver discs and three sandpaper groups, and its specific connection relationship is: the first welded steel plate 7, the second The welded steel plate 11 is symmetrically and vertically fixed on the connection base plate 3, and the first welded steel pipe 9 and the second welded steel pipe 10 pass through the through holes on the upper ends of the first welded steel plate 7 and the second welded steel plate 11 horizontally respectively and are connected to the first A welded steel pipe 9 and a second welded steel pipe 10 are welded into one body. The first welded steel pipe 9 and the second welded steel pipe 10 are used to be installed together with the mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com