Galling, grinding and derusting device for mobile robot

A mobile robot and hair-pulling technology, applied in the field of mobile robots, can solve the problems of high labor intensity, dangerous manual work, low efficiency, etc., and achieve the effects of not easily damaging the surface, good adaptability, and convenient source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

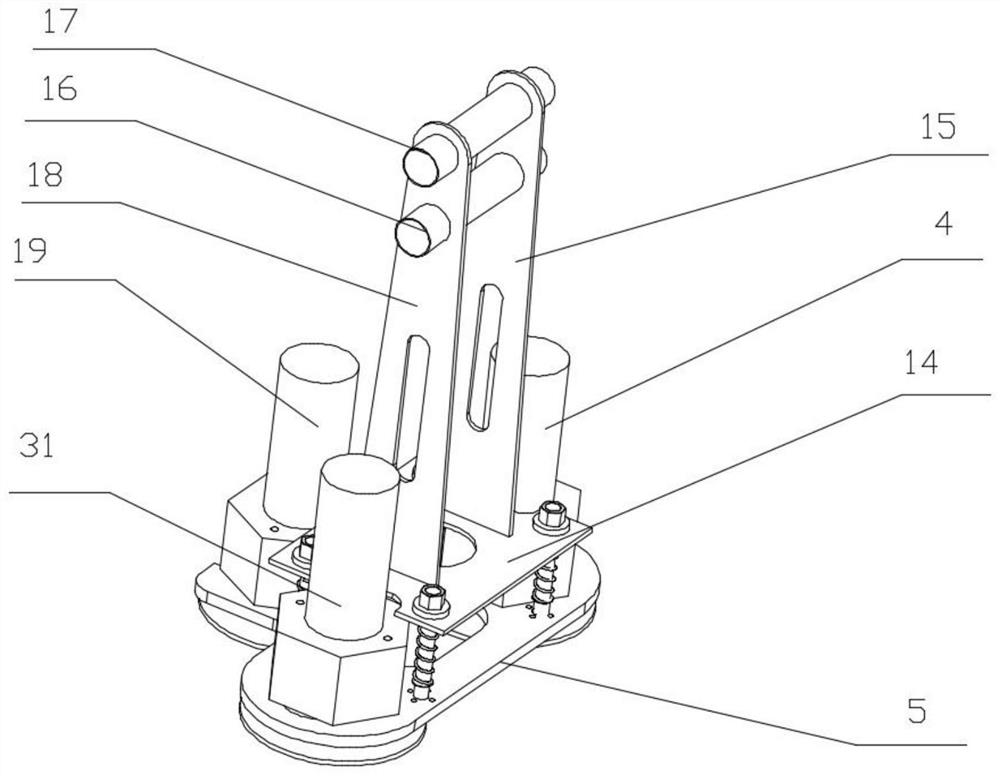

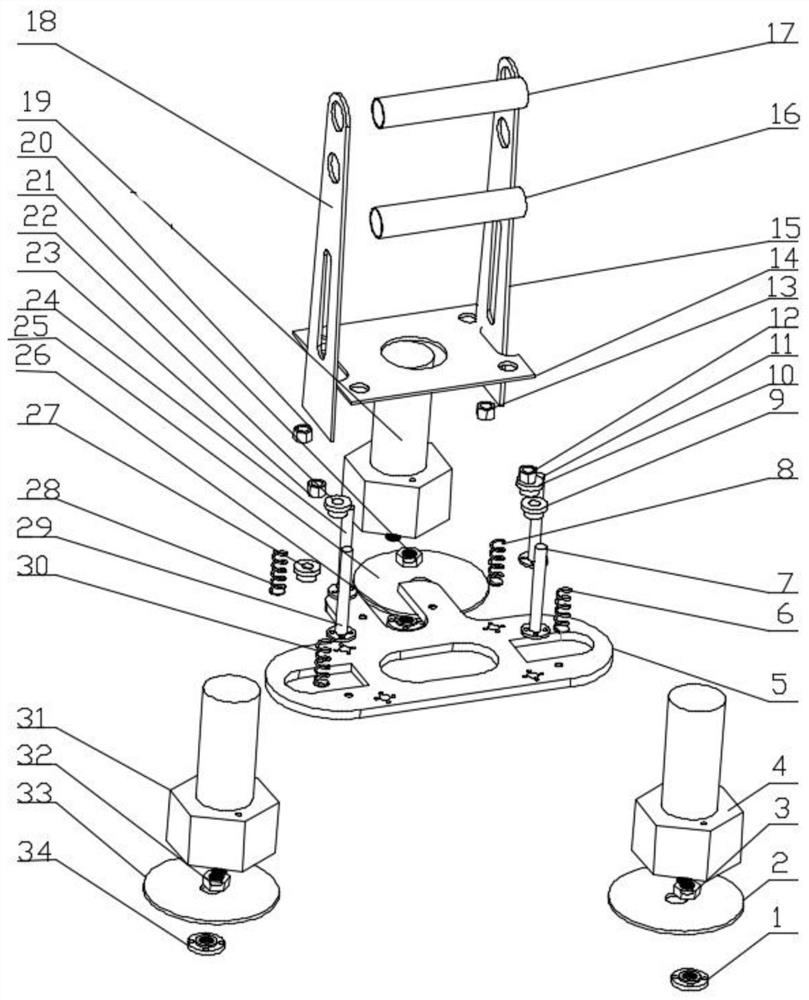

[0028] A brushing, grinding and derusting device for mobile robots, such as figure 1 and figure 2 As shown, including the adjustment mechanism and the grinding and derusting mechanism, among which:

[0029] Described adjusting mechanism comprises connection bottom plate 5, welding bottom plate 14, first guide rod 7, second guide rod 11, third guide rod 24, fourth guide rod 29, first spring 6, second spring 8, third spring 28. The fourth spring 30, the first fixed nut 12, the second fixed nut 13, the third fixed nut 20, the fourth fixed nut 23, the first copper sleeve 9, the second copper sleeve 10, the third copper sleeve 22, the first Four copper sleeves 27, the first welded steel pipe 16, the second welded steel pipe 17, the first welded steel plate 15, and the second welded steel plate 18. The specific installation relationship of this a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com