Modified coal ash used in cement and concrete and preparation method of modified coal ash

A technology for fly ash and concrete, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve unseen problems, reduce grinding energy consumption, reduce fineness requirements, and improve activity index Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Class C fly ash 99wt%, 28d activity index 77%;

[0021] Sintering dry desulfurization ash 1wt%.

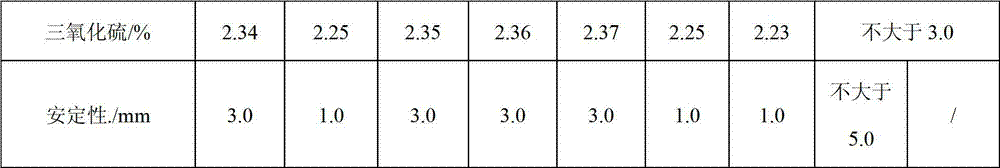

[0022] The above two materials are mixed uniformly by mechanical stirring to make modified fly ash. Check the activity index with reference to GB / T1596-2005 "Fly Ash Used in Cement and Concrete". The test results are shown in Table 1.

Embodiment 2

[0024] Class C fly ash 97wt%, 28d activity index 77%;

[0025] Sintering dry desulfurization ash 3wt%.

[0026] The above two materials are mixed uniformly by mechanical stirring to make modified fly ash. Check the activity index with reference to GB / T1596-2005 "Fly Ash Used in Cement and Concrete". The test results are shown in Table 1.

Embodiment 3

[0028] Class C fly ash 95wt%, 28d activity index 77%;

[0029] Sintering dry desulfurization ash 5wt%.

[0030] The above two materials are mixed uniformly by mechanical stirring to make modified fly ash. Check the activity index with reference to GB / T1596-2005 "Fly Ash Used in Cement and Concrete". The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| loss on ignition | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com