Patents

Literature

91results about How to "Reduce mixing water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

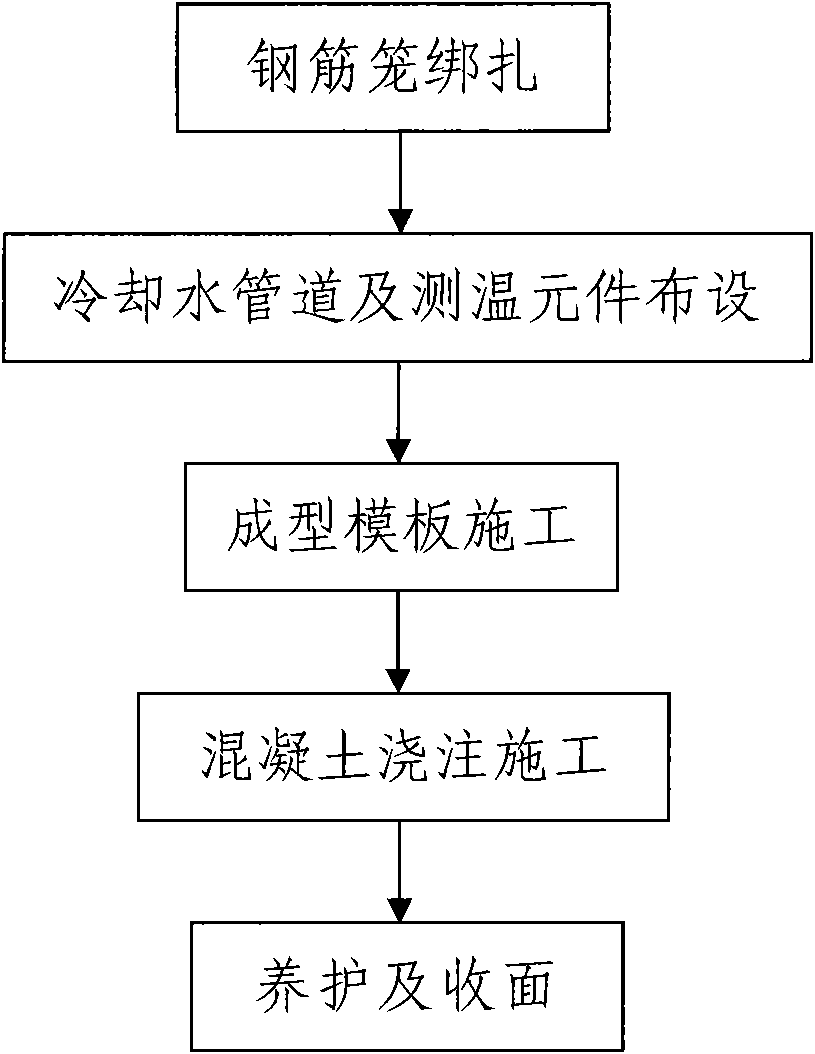

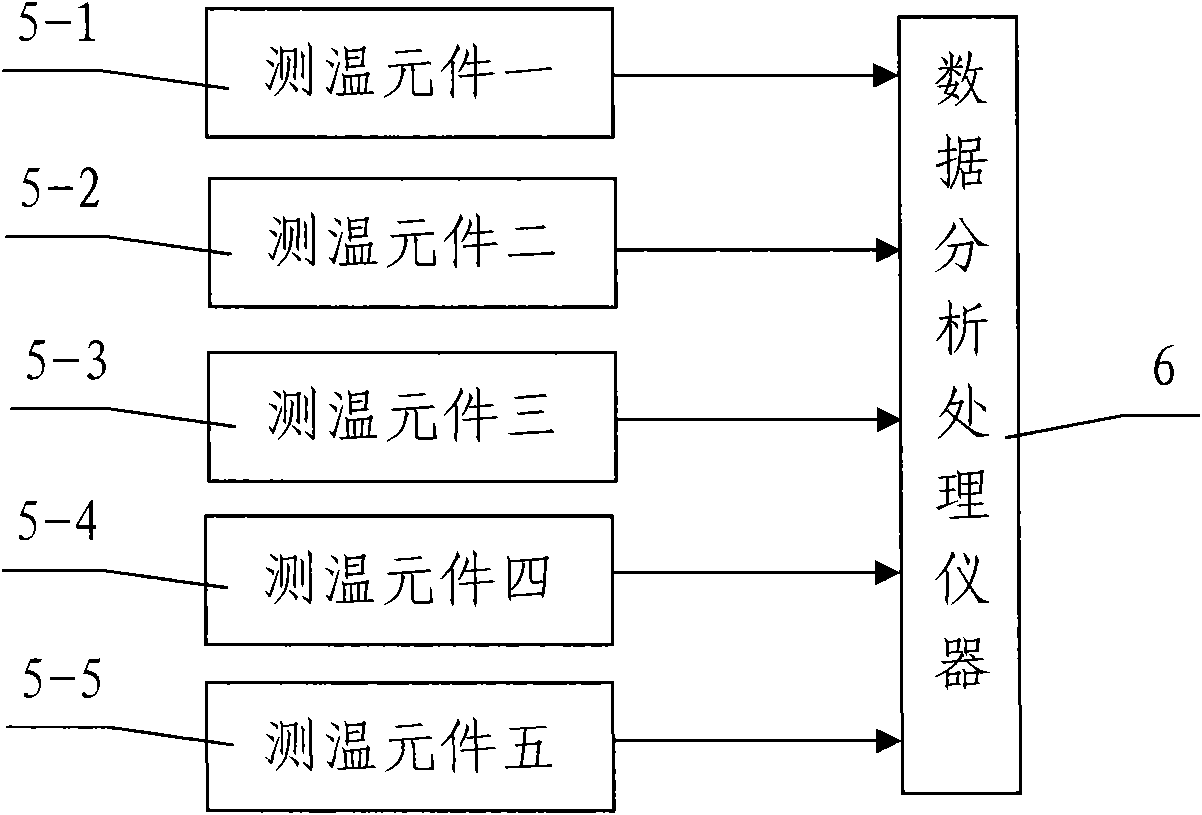

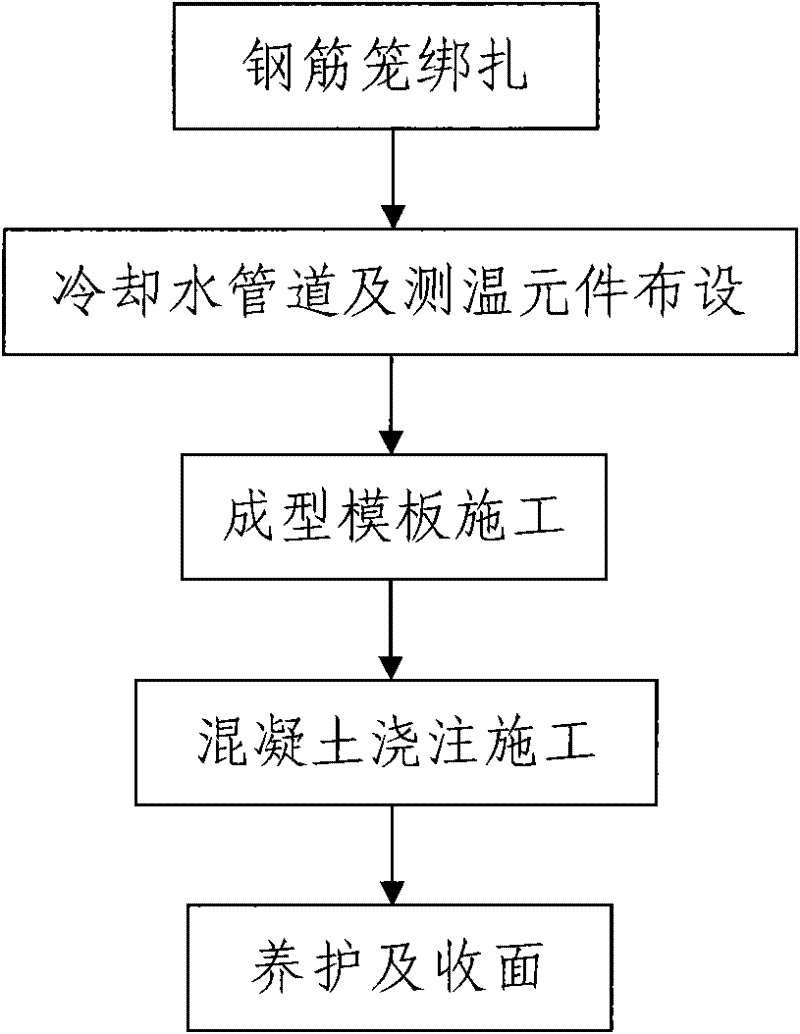

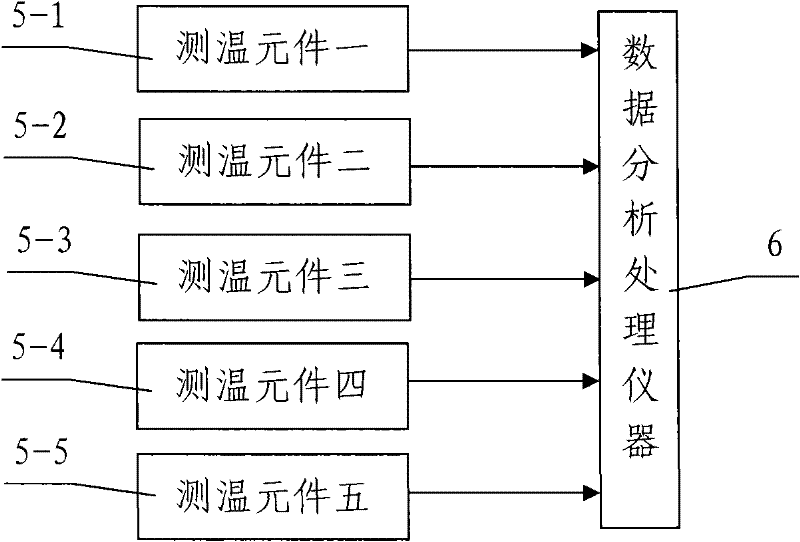

Construction method of large-volume concrete bearing platform with one-time pouring in winter

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and the surface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

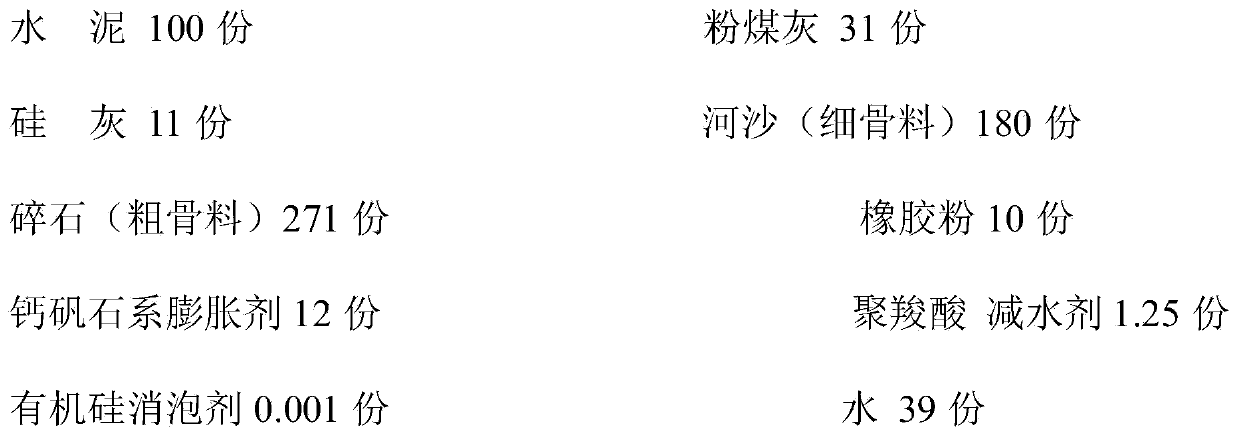

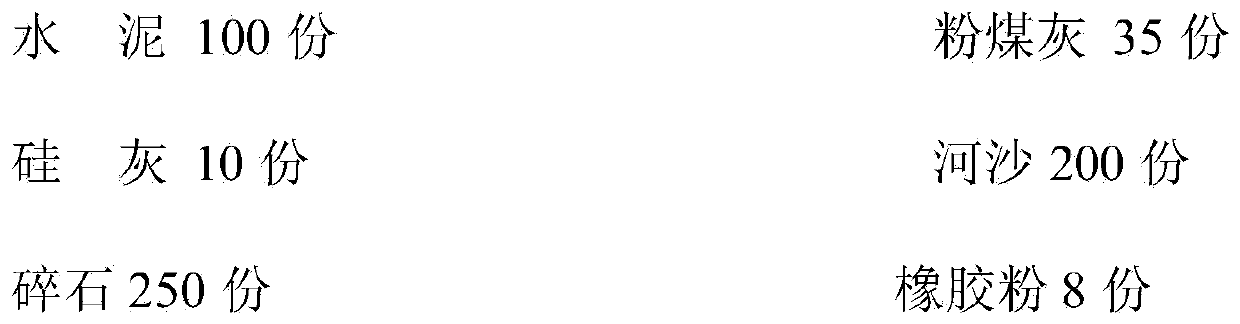

High-strength elastic concrete for heavy-haul railway sleepers

InactiveCN104193258AReduce water consumptionReduce drying shrinkageSolid waste managementPre stressUltimate tensile strength

The invention discloses a high-strength elastic concrete for heavy-haul railway sleepers, which is prepared by mixing and stirring cement, rubber powder and accessories with water. The high-strength elastic concrete for heavy-haul railway sleepers comprises the following components in parts by weight: 100 parts of cement, 3-8 parts of rubber powder, 20-50 parts of pulverized coal ash, 5-20 parts of silica fume, 200-300 parts of fine aggregates, 250-300 parts of coarse aggregates, 5-15 parts of an expanding agent, 1.0-2.0 parts of a water reducing agent, 0.001 part of a defoaming agent, and 40-60 parts of water. The concrete has the advantages of high strength, high anticracking, high impact resistance, high durability and the like, the 3d strength is more than or equal to 95MPa after the concrete is subjected to steam curing at 45DEG C, and the impact resistance times is more than or equal to 3000 (ACI-544 method). The high-strength elastic concrete can be used for heavy-haul railway sleepers and other concrete structures which are subjected to certain serious impact.

Owner:SOUTHWEST JIAOTONG UNIV

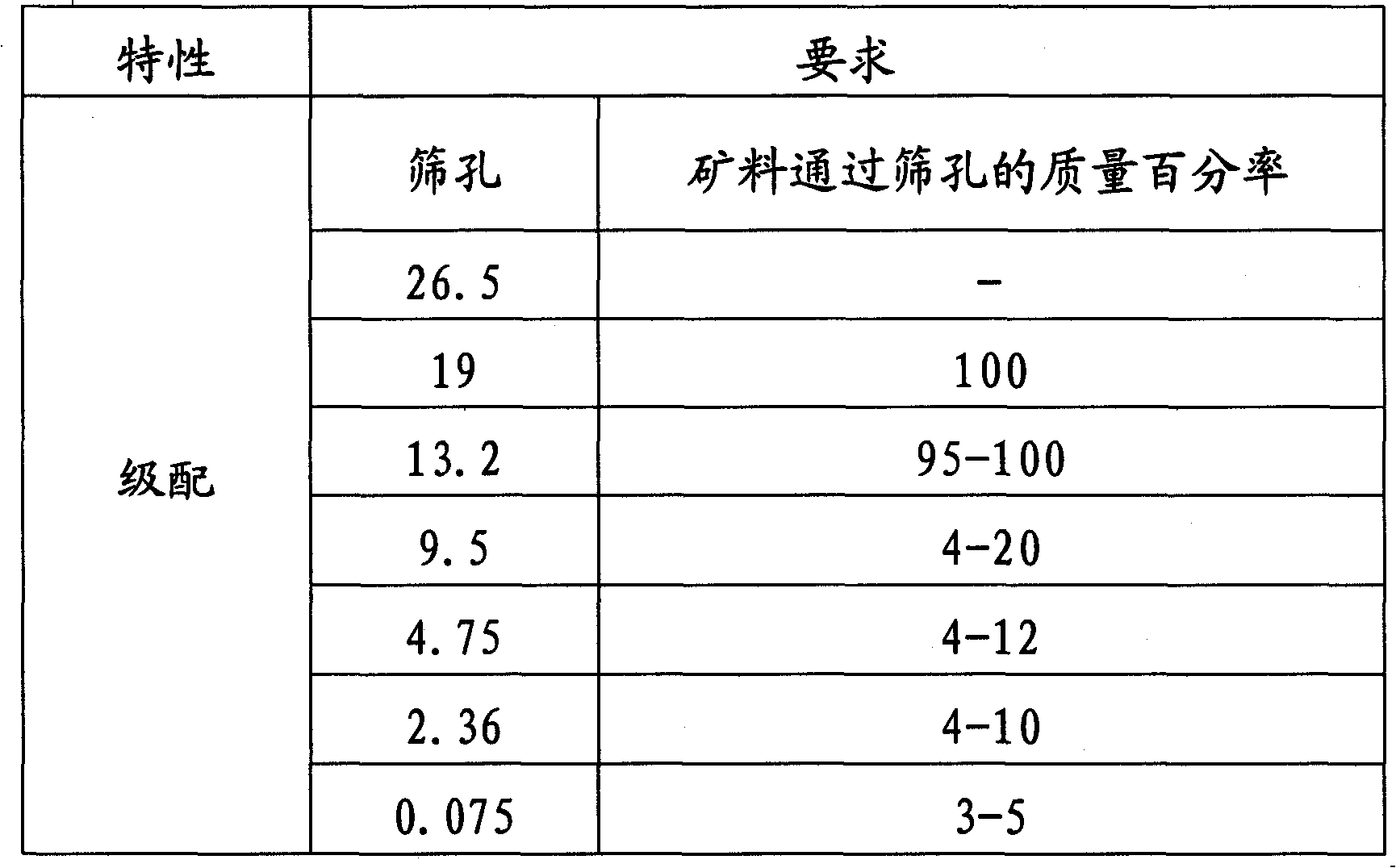

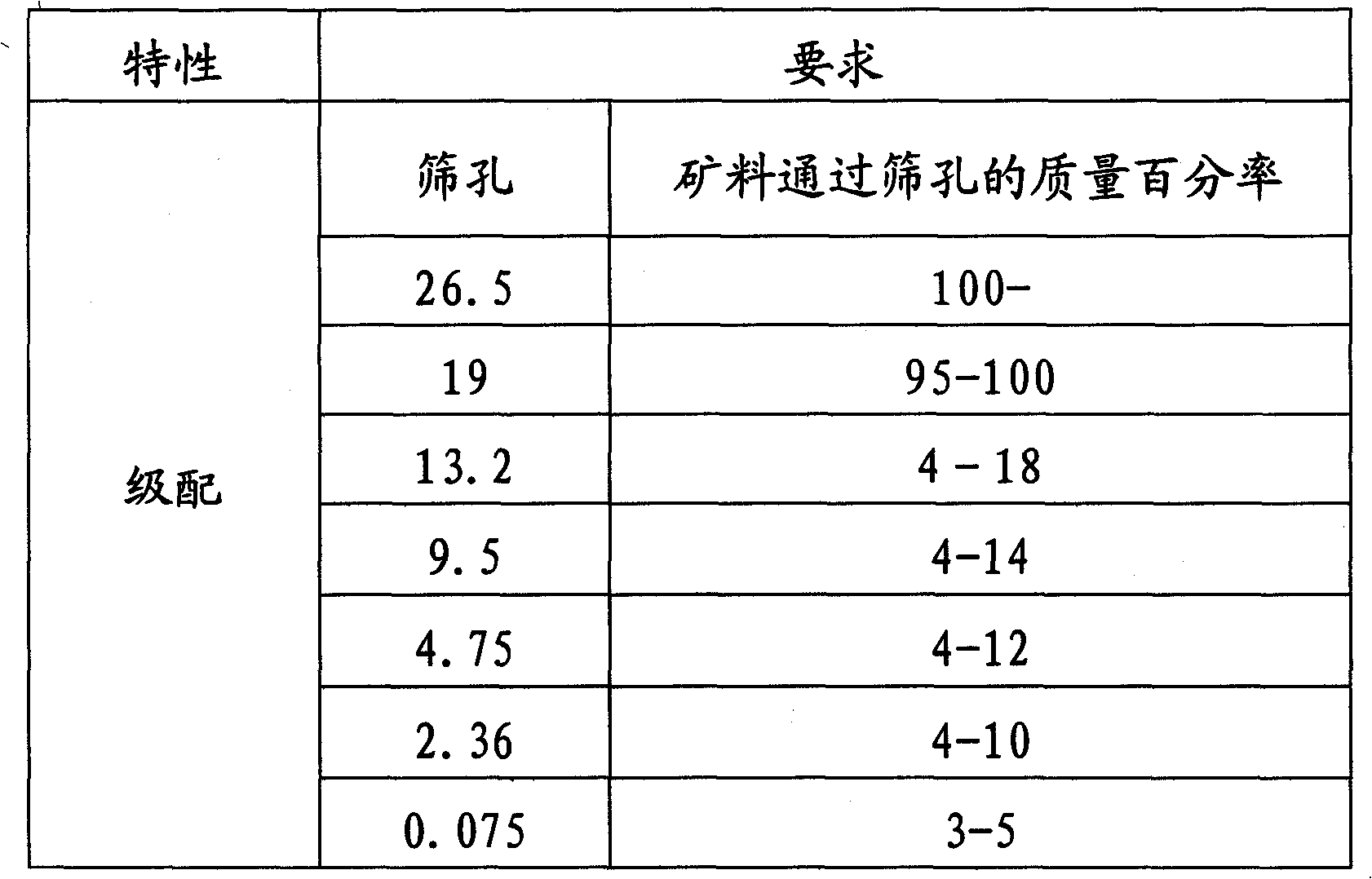

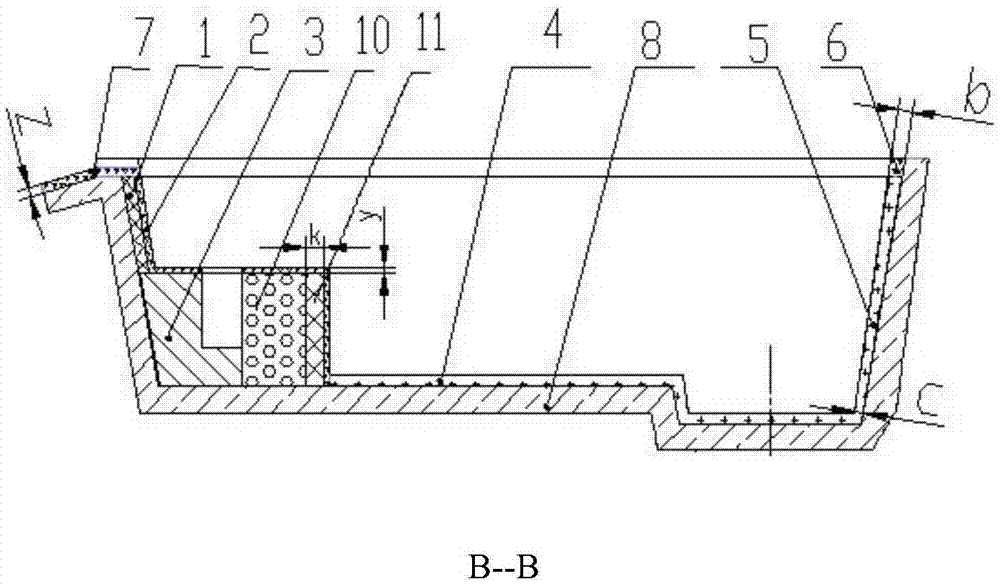

Self-inflow type semi-flexible composite pavement and construction method thereof

The invention relates to a semi-flexible composite pavement of which mixed cement slurry can automatically flow in holes of an asphalt mixture in a construction process. The composite pavement comprises an open-graded macro-porous asphalt mixture structure layer and pavement mortar which is filled in the holes of the macro-porous asphalt mixture, wherein the pavement mortar comprises 30 to 50 percent cement, 20 to 40 percent of sand, 2 to 4 percent of organic binder, 10 to 20 percent of active filler, 3 to 10 percent of shrinkage reducer, 0.2 to 0.5 percent of water reducer, 0.1 to 1 percent of early strength agent and water in an amount of 20 to 28 percent based on the total weight of all the components of the pavement mortar. The composite pavement of the invention has the advantages of high compression strength, short maintenance time, smoothness, compactness, seamlessness, skid resistance, wear resistance, crack resistance, durability and convenient construction. The invention also provides a construction method of the semi-flexible composite pavement. The method comprises the steps of base pavement treatment, open-graded asphalt mixture paving, on-spot pavement mortar stirring and grouting, maintenance and the like. In the construction method of the invention, the mortar is automatically filled in the holes of the asphalt mixture according to the gravity per self and high workability and fluidity, so influences which are caused by adopting vibration paving on asphalt frameworks are avoided.

Owner:广东龙湖科技股份有限公司

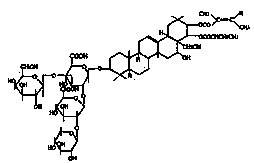

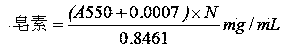

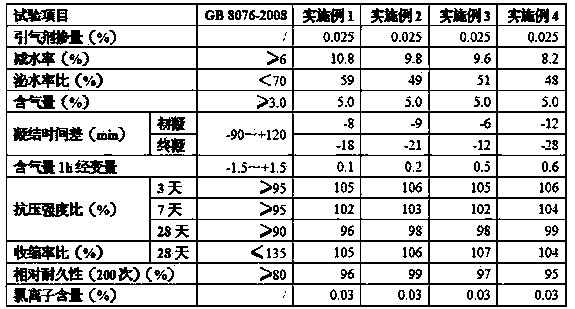

Sasanqua saponin concrete air entraining agent and preparation method thereof

The invention provides a sasanqua saponin concrete air entraining agent and a preparation method thereof. The air entraining agent is characterized by containing sasanqua saponin therein. The preparation method is characterized by extracting sasanqua as a raw material at normal temperature by hydrophilic solvent water solution, and filtering; removing large-molecule impurities from the filtrate by membrane separation under pressure, removing small-molecule impurities by membrane separation, concentrating to be concentrate with Baume degree of not lower than 10Be (60 DEG C), and spray-drying to form solid formulation; or adding a modifying agent to prepare the air entraining agent in liquid formulation. The idea is novel, the raw materials are abundant, the production efficiency is high, the energy consumption in the production is low, the production cost is low, the preparation method is simple in process, green and environment-friendly and is convenient to implement; when the air entraining agent is used in concrete engineering, the dosage of the air entraining agent is low, the air production rate is high, the aperture of the entrained air bubbles is small and the distance among the entrained air bubbles is small, and the air holes of the concrete are more even, more compact and non-communicated, therefore, the sasanqua saponin concrete air entraining agent is valuable for popularizing.

Owner:FUZHOU UNIV

High performance polycarboxylic acid type concrete water reducing agent and preparation method thereof

The invention relates to a high performance polycarboxylic acid type concrete water reducing agent, which is widely applied to the field of engineering construction such as buildings, water conservancy, road traffic and the like. The water reducing agent is prepared from the following raw materials: methacrylate polyglycol monoester, acrylamide, maleic anhydride, mercaptoethanol, an initiating agent, a defoaming agent, sodium bicarbonate and the like. A preparation method for the water reducing agent comprises the following process steps of: carrying out esterification reaction to obtain the methacrylate polyglycol monoester; and carrying out graft copolymerization reaction on the methacrylate polyglycol monoester to obtain the polycarboxylic acid type water reducing agent. The preparation method has the advantages of simple process, easy control of reaction materials, no environmental pollution and low cost, and a product has the advantages of high water reducing rate, high later strength of concrete, low air-entraining performance and the like. The water reducing agent can effectively restrain loss of concrete slump, solves the problem of poor later strength of the concrete, and has obvious economic benefit and social benefit.

Owner:丹凤县永鑫电子材料有限责任公司

Prepn of heat accumulating for solar energy medium temperature steam electricity generation

InactiveCN1888005AIncrease heating capacityReduce dosageFrom solar energyEnergy industrySolar powerNanoscopic scale

The present invention is the preparation process of heat accumulating material for solar energy medium temperature steam electric power generation. The heat accumulating material is prepared with basalt and steel slag or copper slag as aggregate, fine silica powder, mineral slag powder, aluminate cement and nanometer level attapulgite, and through mixing while adding water, molding, demolding, curing in water for 72 hr and stoving at 100-120 deg.c for 24 hr. The heat accumulating material has high heat storing efficiency and heat releasing efficiency, and the preparation process can reduce industrial slag pollution.

Owner:HUBEI KAIJIA ELECTRICAL TECH GROUP

Reworked material working lining of continuous casting tundish and preparation method for reworked material working lining

ActiveCN105436492ASolve the problem of bulging cracks and even material collapseEasy to useMelt-holding vesselsBrickRefractory

The invention relates to a reworked material working lining of a continuous casting tundish and a preparation method for the reworked material working lining. The reworked material working lining is divided into an impact zone working lining and a non-impact zone working lining, which are internally attached to a permanent lining; the non-impact zone working lining sequentially comprises a ladle edge working lining, a ladle wall working lining and a ladle bottom working lining from top to bottom; the impact zone working lining is built by adopting waste magnesia-carbon bricks and regenerated coating material mud through a wet process; the ladle wall working lining and the ladle bottom working lining are built by adopting a regenerated dry material; an overflow port working lining and the lade edge working lining are built by adopting the regenerated coating material; a space between the two sides of a turbulent flow controller and the ladle wall permanent lining is filled by waste; and a regenerated coating material layer coats the outer surfaces of the waste magnesia-carbon bricks, the outer surface of the waste and the upper surface of the turbulent flow controller. By applying the reworked material working lining, the service life of a shaped blank continuous casting tundish reaches 33-38 hours, and refractory material cost of the regenerated material working lining is reduced by more than 60% year on year.

Owner:SHANDONG IRON & STEEL CO LTD

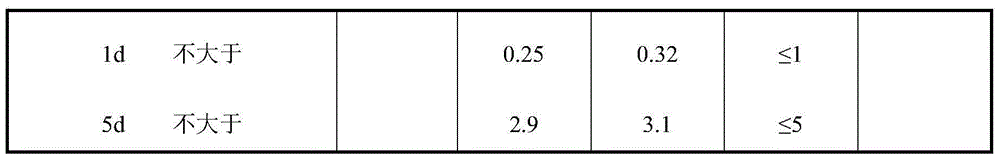

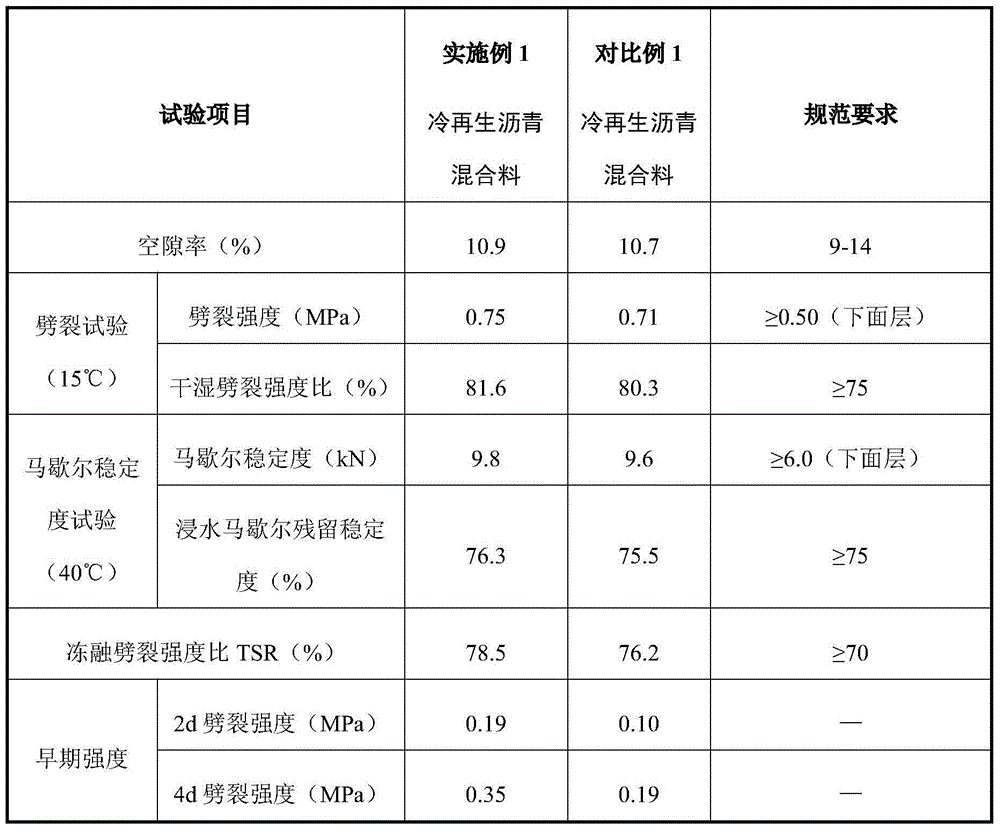

Early-strength emulsion for cold regeneration of waste asphalt pavement and preparation method and application thereof

ActiveCN104559254AReduce mixing water consumptionImprove early strengthSolid waste managementBuilding insulationsEmulsionPetroleum

The invention discloses an early-strength emulsion for the cold regeneration of a waste asphalt pavement and a preparation method and application thereof. The raw material component of the early-strength emulsion for the cold regeneration of the waste asphalt pavement is prepared from the following components in percentage by weight: 50%-65% of road petroleum asphalt, 1.0%-4.5% of an asphalt emulsifying agent, 0%-10% of a modifying agent, 0%-0.4% of an exciting agent, 0.01%-0.4% of a dispersing agent, 0.05%-2.0% of a stabilizer, 0%-0.5% of an auxiliary agent and the balance of water, wherein the auxiliary agent is used for regulating the pH value, and the modifying agent is cationic styrene-butadiene latex. The early-strength emulsion for the cold regeneration can be used for reducing the blended water usage amount of a cold regeneration mixture and accelerating the hydration of cement contained in the cold regeneration mixture, thereby enhancing the early strength of the cold regeneration mixture, shortening the curing time and enlarging the application range of the emulsified asphalt cold regeneration mixture.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Anti-cracking reinforced ecological cement

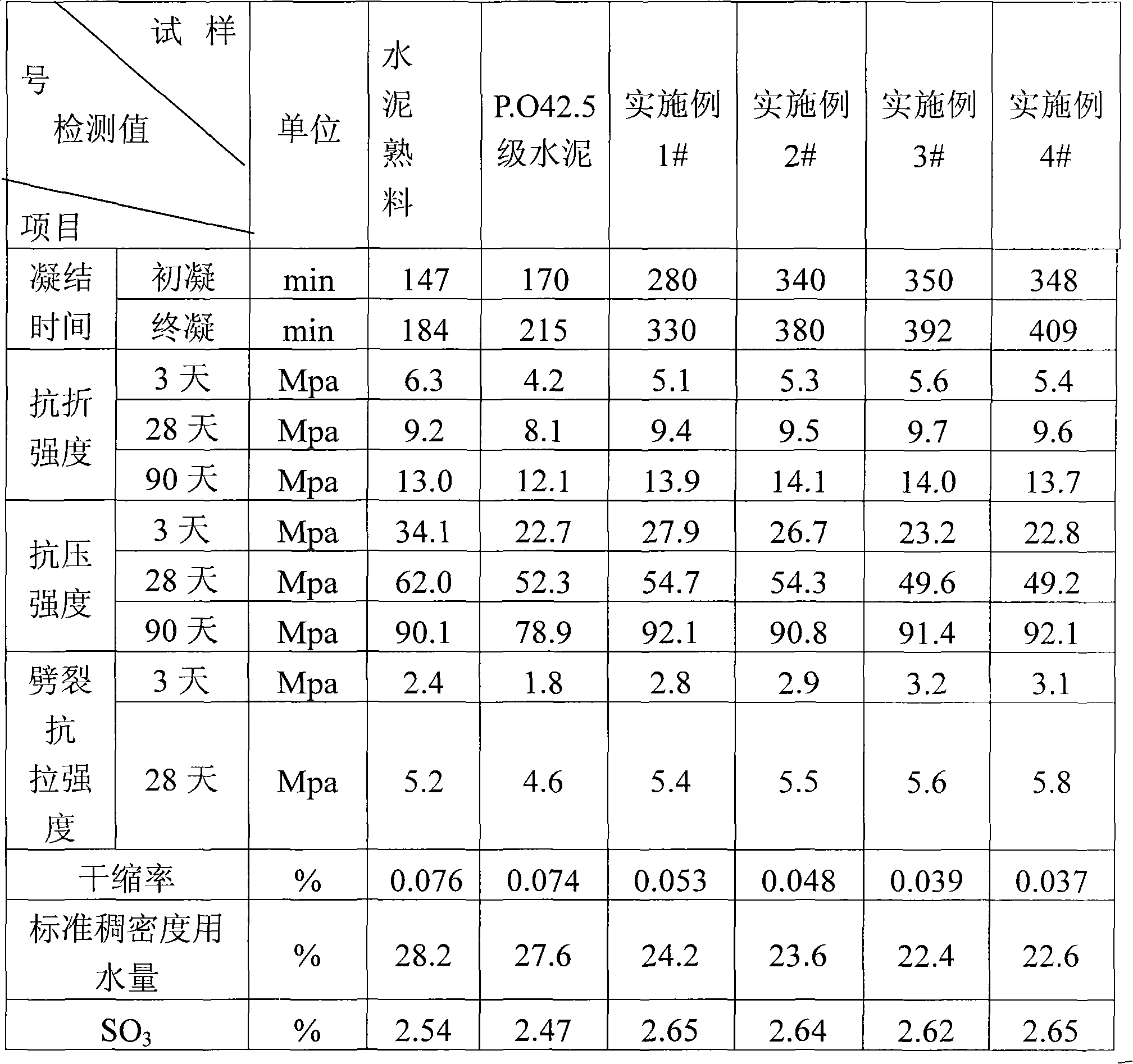

InactiveCN101134645AProlong initial setting timeReduce early thermal cracksSolid waste managementGypsumFiber

The anticracking high strength ecological cement is produced with Portland clinker 35-80 wt%, fly ash 5-30 wt%, ferroalloy slag 1.0-30 wt%, boiler slag 5-40 wt%, gangue 10-40 wt%, grinding aid 0.1-2.0 wt%, gypsum 0.5-10 wt%, reinforcing fibrous inorganic mineral material 1-20 wt% and polymer fiber 0.01-10 wt%, and through grinding and mixing. Compared with available technology, the anticracking high strength ecological cement of the present invention has the advantages of low hydration heat, low shrinkage, low water demand, high early strength, etc.

Owner:JIANGXI GANFENG CEMENT

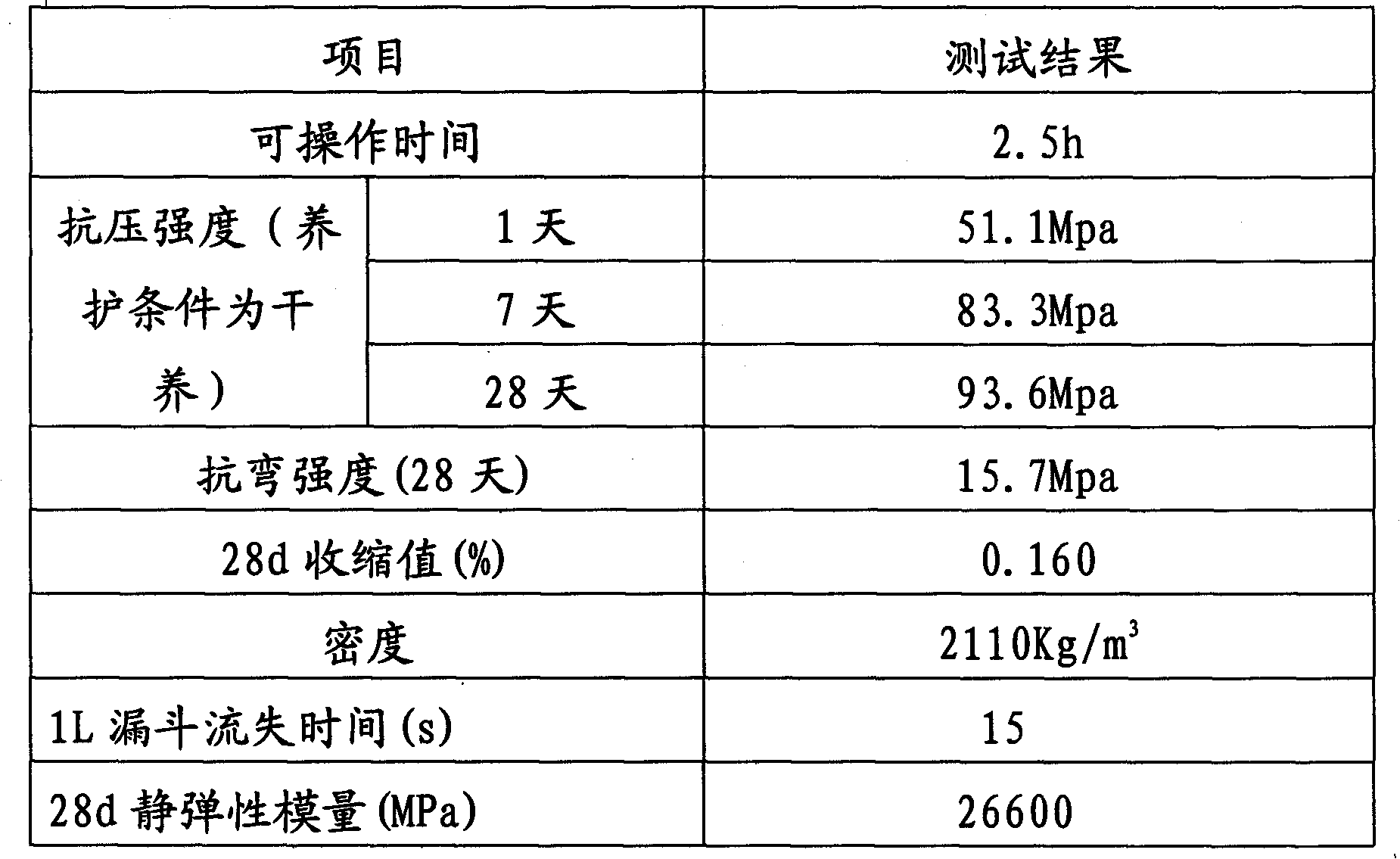

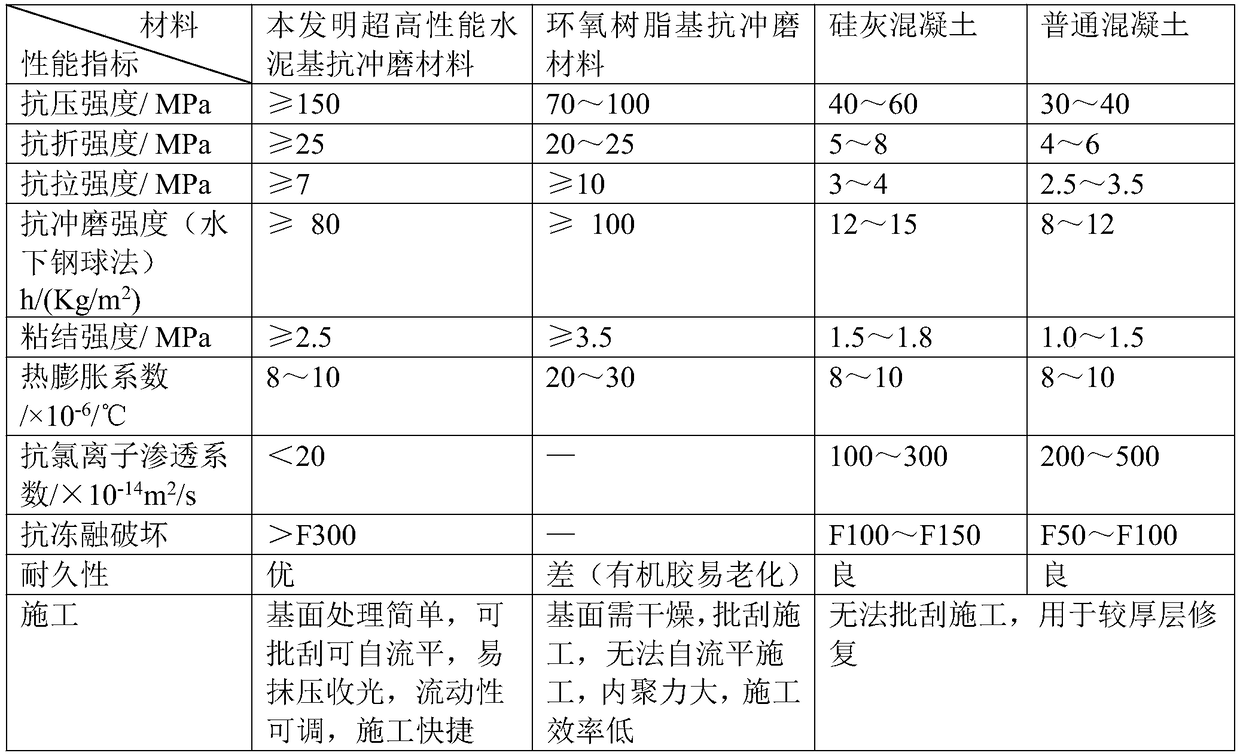

Ultrahigh performance cement-based erosion and abrasion resistant material

The invention discloses an ultrahigh performance cement-based erosion and abrasion resistant material which is prepared from the following components in parts by weight: 100 parts of portland cement,15-25 parts of micro silicon powder, 10-20 parts of mineral slag ultrafine powder, 10-20 parts of microsphere, 5-10 parts of a swelling agent, 160-200 parts of quartz sand, 15-25 parts of steel fiber,3-4.5 parts of a composite admixture and 30-40 parts of water, wherein the composite admixture is prepared from dispersible adhesive powder, a polycarboxylic water reducing agent, a defoamer and a viscosity modifier according to the weight part ratio of 30 : 20 : (1 to 2) : (0.5 to 2). The ultrahigh performance cement-based erosion and abrasion resistant material has the structure characteristicsof low porosity and high compactness, is excellent in mechanical strength, firm in adhesion to ordinary concrete, good in constructability and large and adjustable in fluidity within a range of 100mmto 270mm, has a coefficient of thermal expansion close to that of ordinary concrete can perform scraping construction in batch, and can also perform self-flowing and self-compaction, construction issimple, and the construction efficiency is about 2 times of the construction efficiency of an epoxy resin-based erosion and abrasion resistant material.

Owner:WUDA JUCHENG STRUCTURE CO LTD

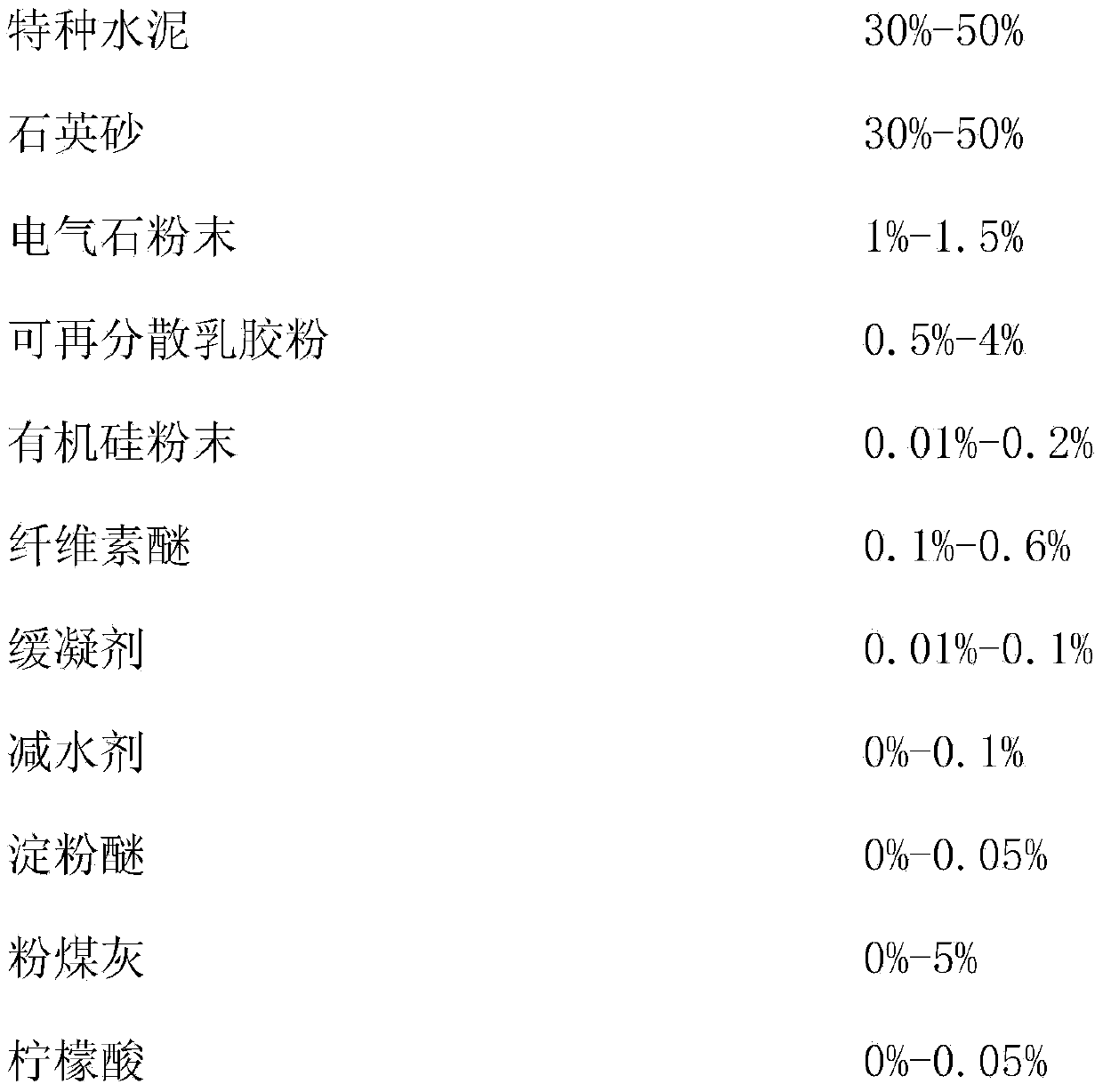

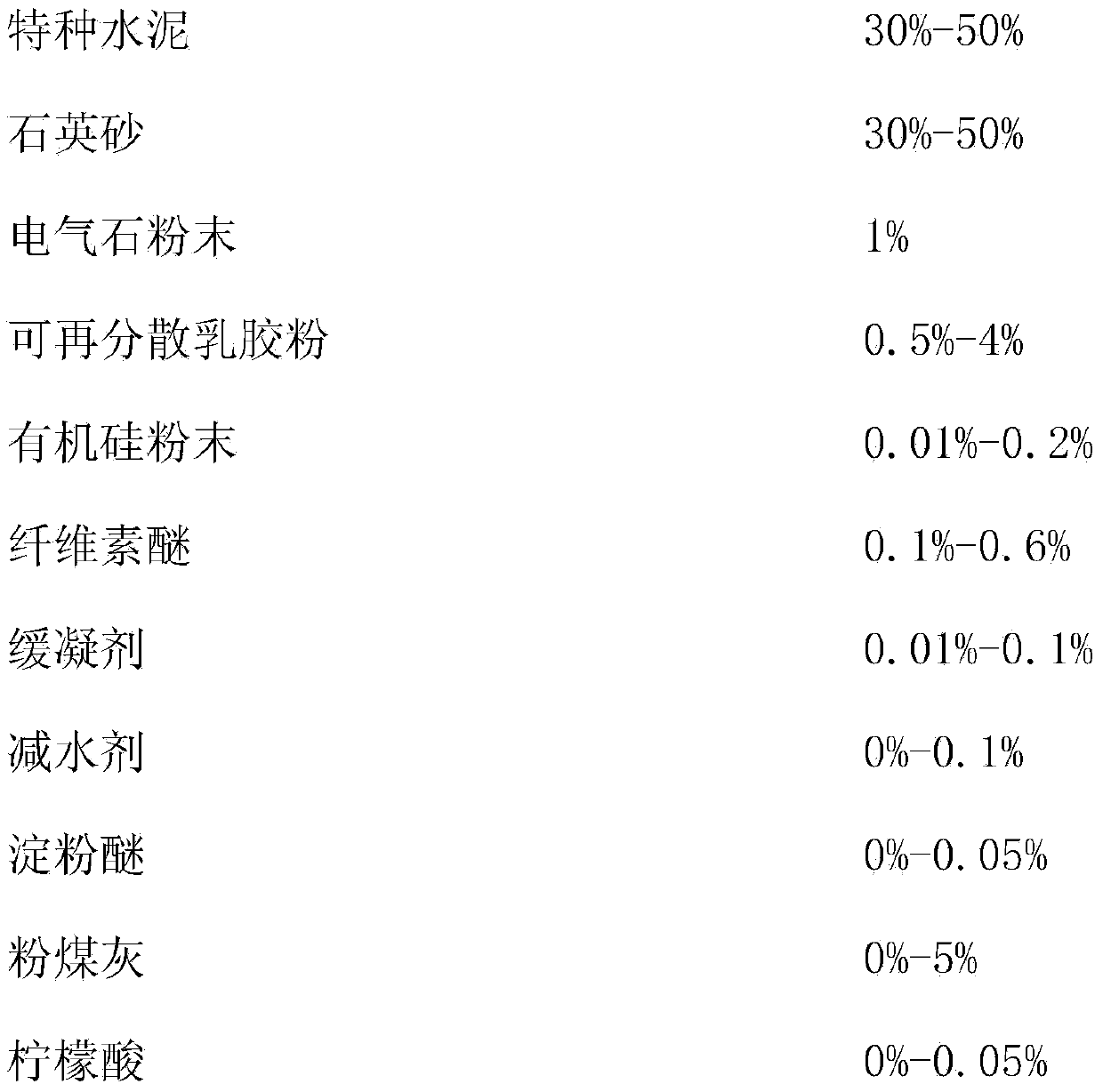

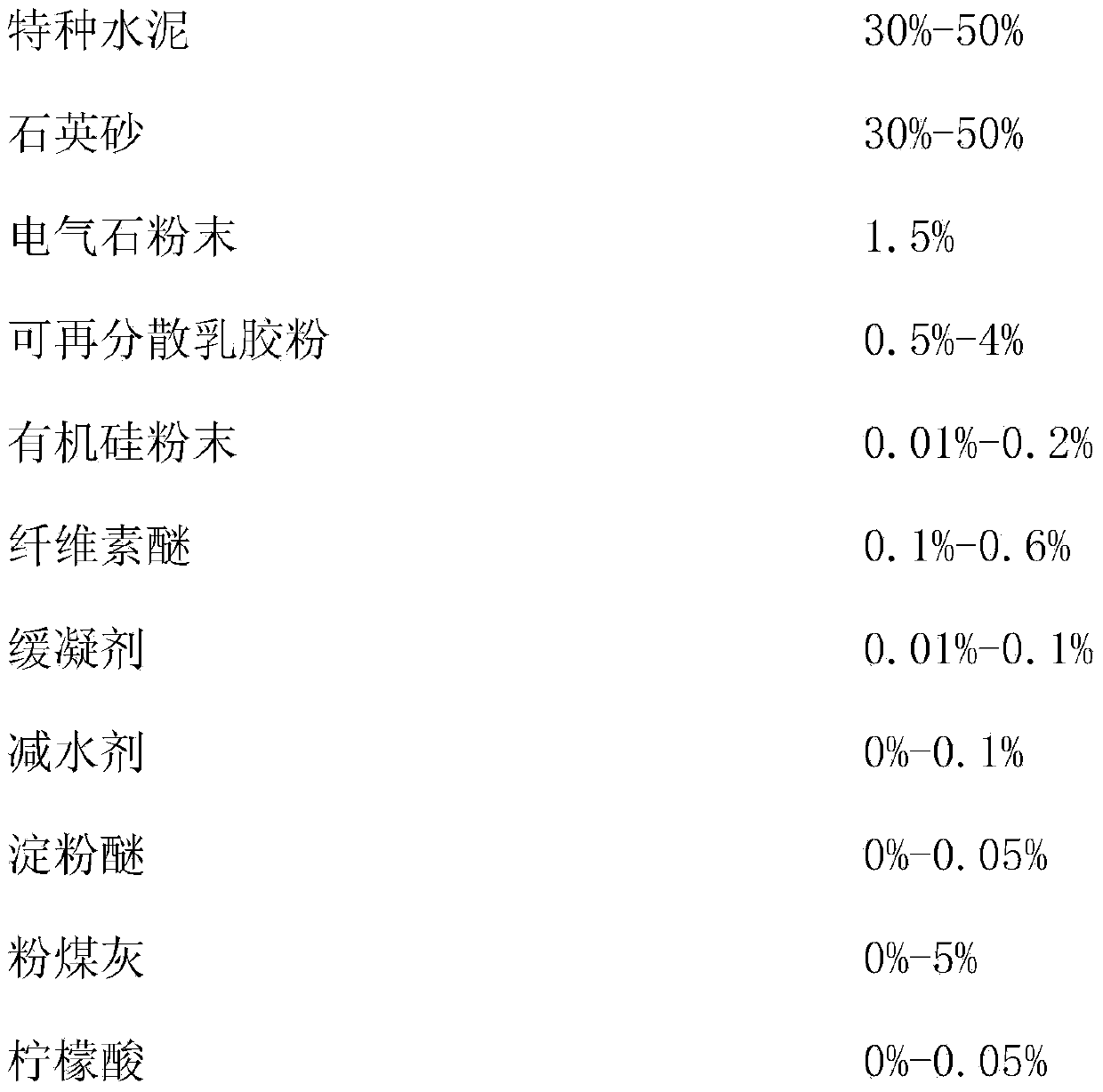

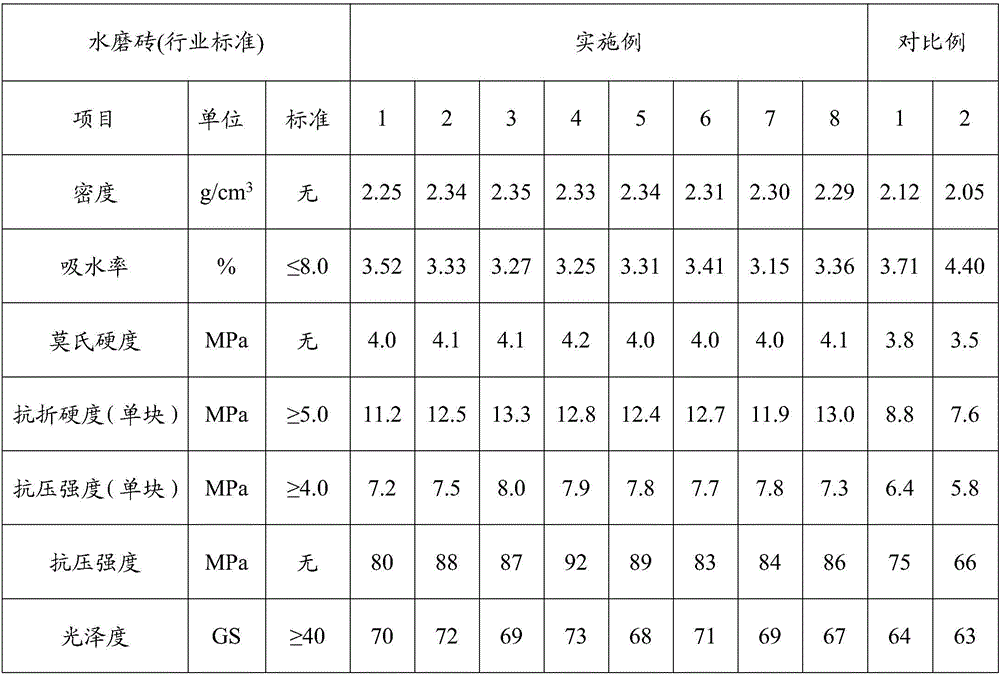

Improved low-alkaline ceramic tile adhesive

The invention discloses an improved low-alkaline ceramic tile adhesive which is prepared by adding tourmaline powder, redispersible emulsion powder, organosilicone powder, cellulose ether, a retarder, a water reducer, starch ether, coal ash, citric acid and the like by using special cement (low-alkaline sulphate aluminum cement) and quartz sands as raw materials. The adhesive disclosed by the invention is good in water-resisting, freeze thawing-resisting and aging-resisting performances, has excellent flexible performance, is high in adhesive strength and short in hardening time, and can be used for effectively avoiding saltpetering of a tapestry brick.

Owner:DEQING YANGTAI BUILDING MATERIAL

Artificial marble having decorative effect and manufacturing method thereof

The invention relates to the field of architectural decoration / finishing materials, and particularly relates to an artificial marble slab having a decorative effect and a manufacturing method thereof. The artificial marble slab having a decorative effect comprises sulfoaluminate cement, white quartz sand, water-based polycarboxylic acid water-reducing agent, water-based organosilicon defoaming agent, pigment and concrete antishrinking agent. The manufacturing method of the artificial marble slab having a decorative effect comprises the following steps: proportionally preparing mortar, defoaming, performing vibration compaction, netting to obtain a blank, then drying, demolding, and maintaining. According to the invention, the artificial marble slab having a decorative effect has favorable hardness, abrasion strength, shear strength, folding strength and weather resistance, low internal porosity and clear texture; the manufacturing method is short in maintenance time and low in mixing water consumption in the construction process, effectively compensates for dimensional instability caused by shrinkage of cement, and improves the demolding convenience; and the manufacturing method greatly improves the production efficiency and lowers the operating cost of production.

Owner:JIANGSU WONIUSHAN THERMAL INSULATION & WATERPROOF TEHNOLOGY

Phase change material wrapped thermal storage concrete and preparation method thereof

The invention provides phase change material wrapped thermal storage concrete and a preparation method thereof. The preparation method is characterized by taking dolomite as a coarse aggregate, bauxite powder as a fine aggregate and aluminate cement as a cementing material and adding silica micro powder, activated alumina micro powder, silicon carbide powder and adipic acid / silicon dioxide capsule granules to prepare the thermal storage material. The preparation method comprises the steps of adding 4-6% of water after drying and mixing the raw materials uniformly, then mixing water with the raw materials uniformly and putting the mixture into a steel mould, demoulding the product after putting the mixture in the steel mould at normal temperature for 24 hours, drying and curing the product at 20-25 DEG C for 72 hours, and then baking the product at 105-120 DEG C for 24 hours, thus obtaining the thermal storage material which can be used in the industrial field. The thermal storage material can be applied to dewatering and drying in the industries such as solar air conditioners, floor heating, chemical printing and dyeing and the like. The preparation method is reasonable in material selection and advanced in preparation process, thus the thermal storage material used in the industrial field can be produced at low cost. The material not only substantially improves the comprehensive properties including thermal storage, heat release efficiency and the like but also more importantly solves the technical difficulty of phase change material leakage.

Owner:SUZHOU PORCELAIN INSULATOR WORKS

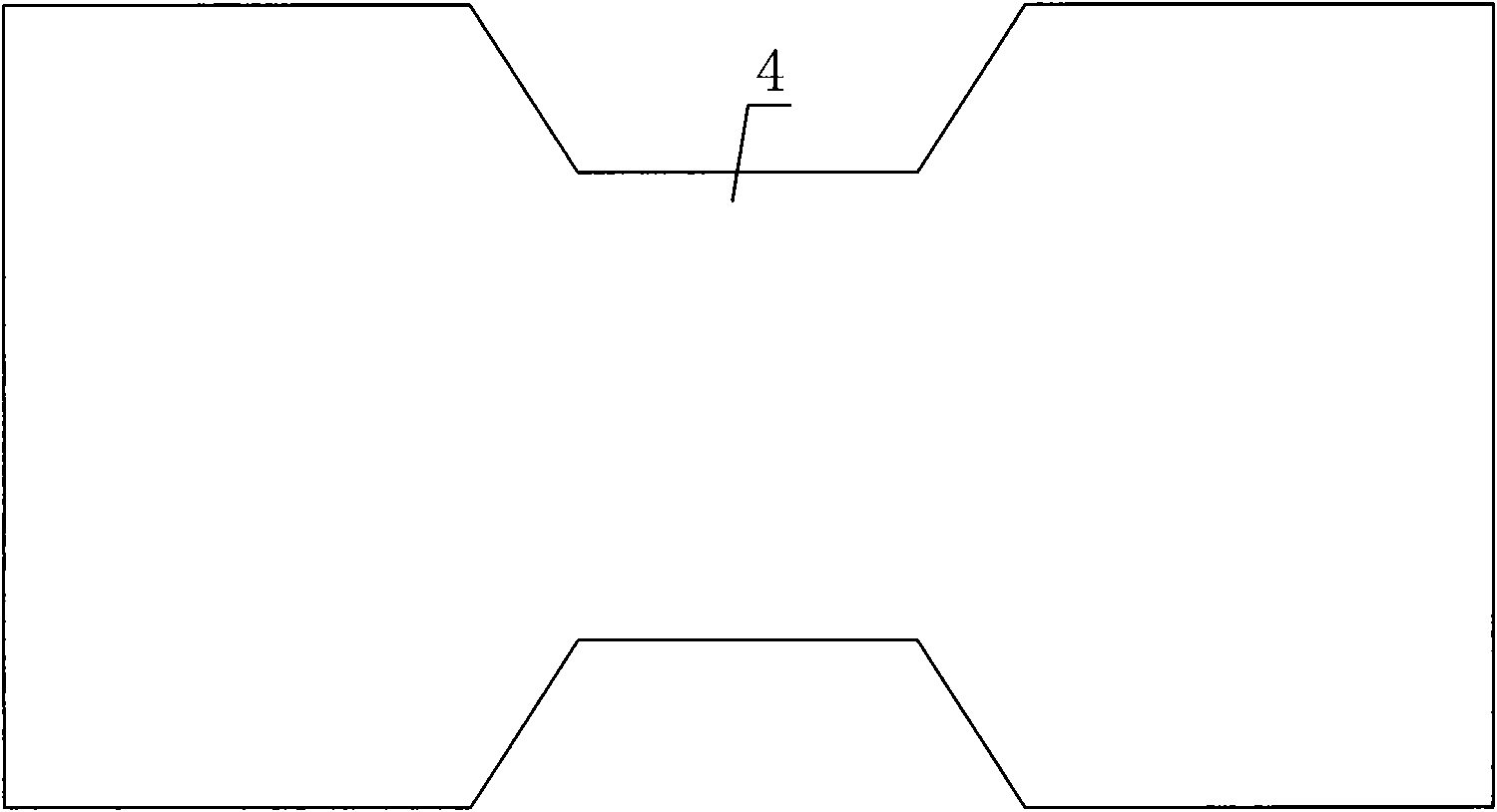

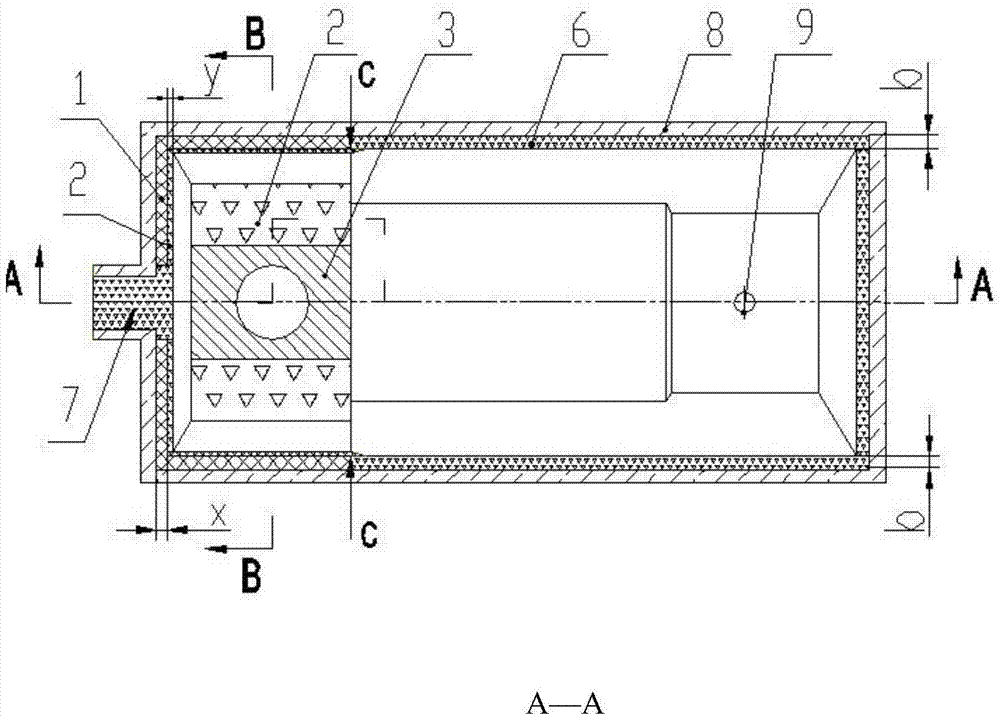

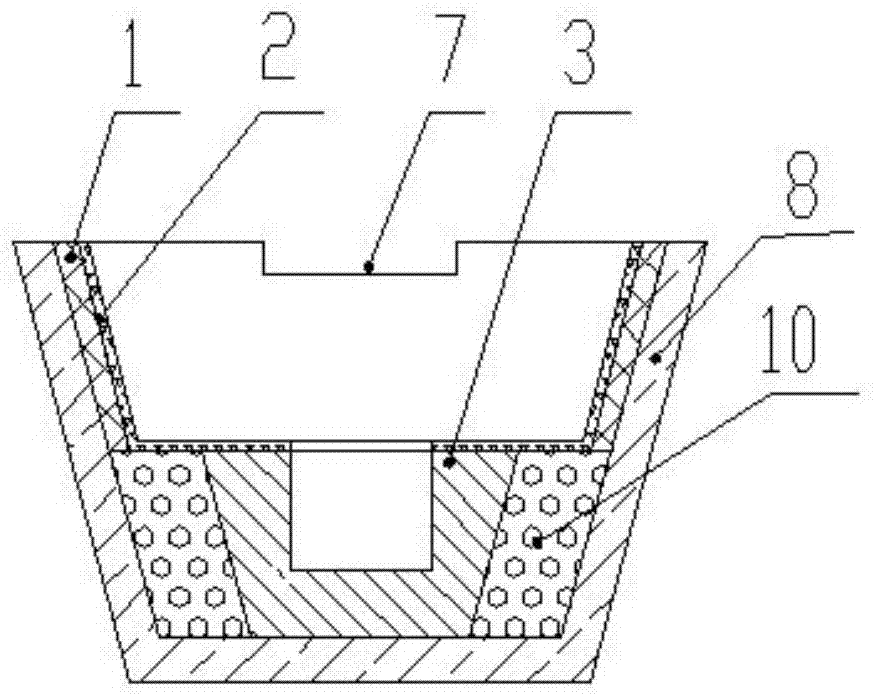

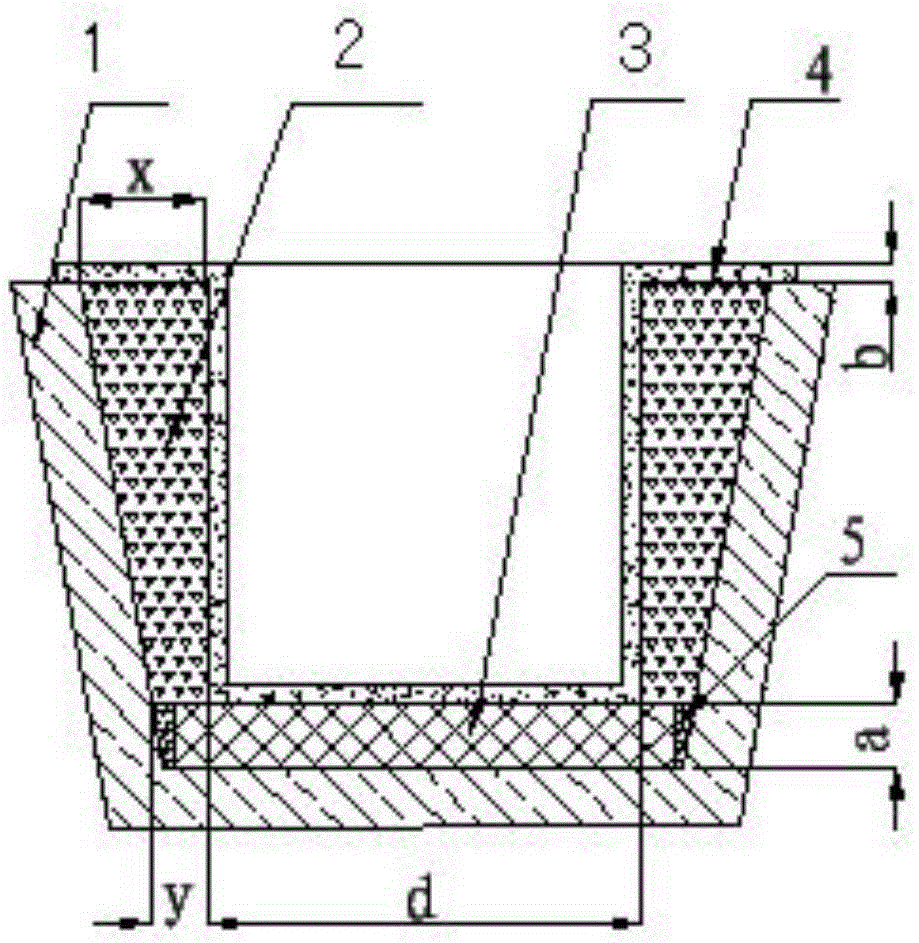

Low-cost long-service-life turbulence inhibitor for continuous casting tundish and preparation method for low-cost long-service-life turbulence inhibitor

ActiveCN105397075ASolve the problem of bulging cracks and even pulverizationEasy to useMelt-holding vesselsBrickMaterials science

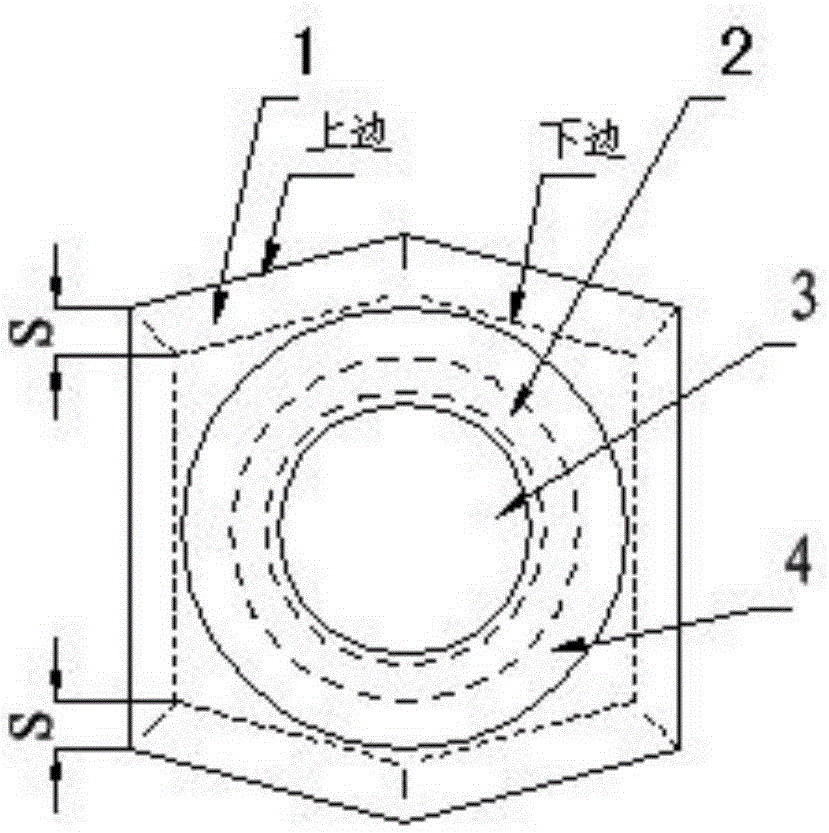

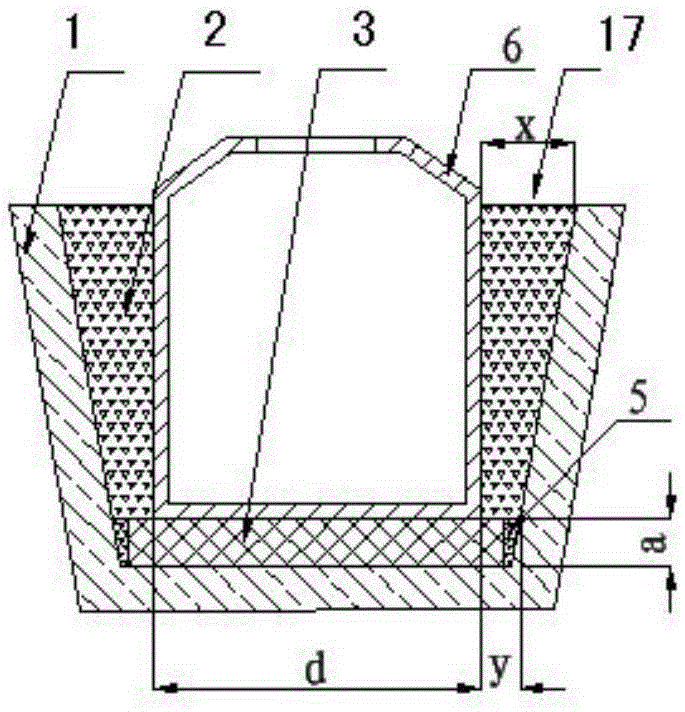

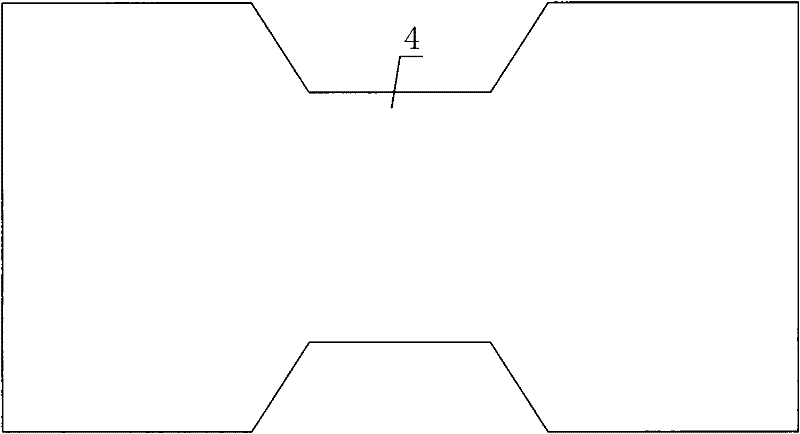

The invention discloses a preparation method for a low-cost long-service-life turbulence inhibitor for a continuous casting tundish. The turbulence inhibitor comprises a housing (1), an inner core (2), a bottom plate (3) and a coating layer (4). The low-cost long-service-life turbulence inhibitor is characterized in that the housing (1) of the turbulence inhibitor is molded by casting low-cost magnesium castable, the inner core (2) is molded by vibrating regenerated dry type materials; the bottom plate (3) is built by adopting waste magnesium-carbon bricks; the periphery (5) of the bottom plate is filled and compacted with regenerated dry materials in a leveling up mode; and the coating layer (4) coats the outer surface of the inner core (2) and the bottom plate (3) by adopting regenerated coating. The production cost for the turbulence inhibitor prepared through the preparation method is reduced by more than 45%, and the turbulence inhibitor used for the continuous casting tundish reaches 24-30 hours, so that low cost and long service life are realized.

Owner:SHANDONG IRON & STEEL CO LTD

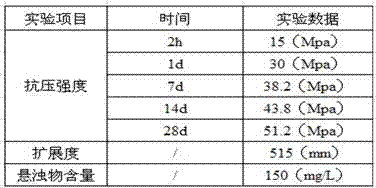

Underwater non-dispersive quick-setting and rapid-hardening cement-based composite material and preparation method and application thereof

The invention belongs to the field of composite materials and particularly relates to an underwater non-dispersive quick-setting and rapid-hardening cement-based composite material and a preparation method and application thereof. The underwater non-dispersive quick-setting and rapid-hardening cement-based composite material is prepared from the following raw materials in percentages by weight: 32-34% of portland cement, 8.8-9% of calcium aluminate, 5-7% of magnesium oxide, 0.5-2% of sulfur trioxide, 0.2-0.3% of a polycarboxylate concrete admixture, 0.3-0.7% of a flocculating agent, 0.05-0.2% of an accelerator, 0.05-0.2% of an air entraining agent, 0.05-0.3% of a corrosion inhibitor, 26-31% of a fine aggregate, 13-18% of a coarse aggregate and 8.4-8.5% of water. The material can be used for quickly repairing a concrete building in a water conservancy project, and the repair material is capable of quickly setting and ensuring the early strength.

Owner:俞家欢

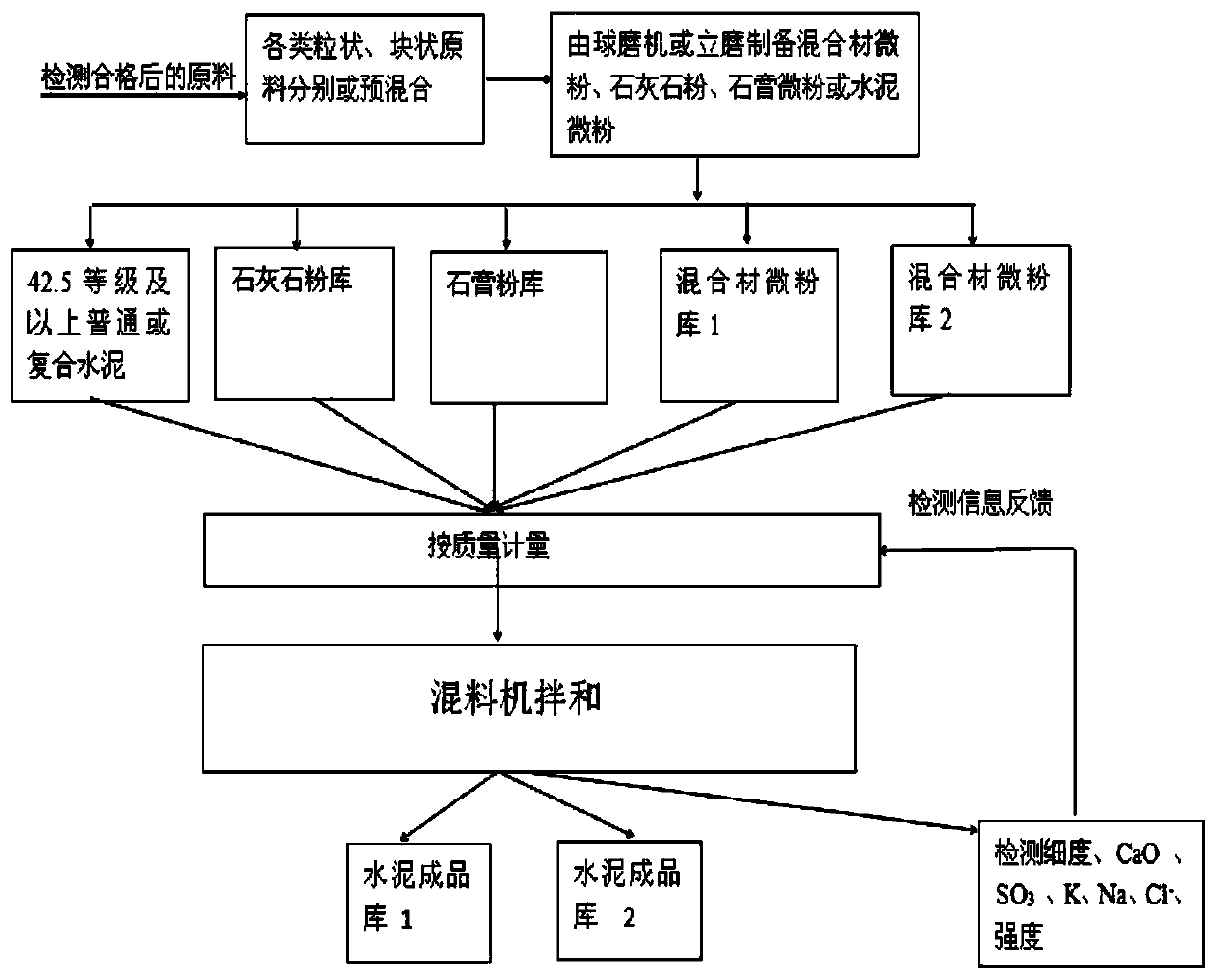

Special mixed cement for on-site preparation of concrete as well as preparation method and application

The invention relates to the field of cement and concrete. The invention discloses special mixed cement for on-site preparation of concrete as well as a preparation method and application. Except formixing and grinding cement clinker and other raw materials, the mixed cement is prepared from the following components in percentage by mass: 60%-80% of general Portland cement of the 42.5 grade or above, 3.0%-6.0% of gypsum, 5%-15% of limestone, 2%-29% of an admixture and 0.5%-3.0% of a functional additive. The general Portland cement with the grade of 42.5 or above meets the requirements of GB175, and parameters of the general Portland cement are controlled such that the mass ratio of the micro powder less than or equal to 3 [mu]m is less than or equal to 10%, the one-day compressive strength is less than or equal to 12 MPa, the 3-day compressive strength is more than or equal to 20 MPa, the 28-day compressive strength is more than or equal to 45 MPa, the water consumption of the standard consistency of the cement paste is less than or equal to 28%, the alkali content is less than 0.6% in terms of 0.658 K2O + Na2O, and the chloride ion content is less than 0.06%. The raw materials are wide in source, the mixed cement can be directly used for preparing or premixing concrete on site, no admixture or functional additive needs to be added again, crack resistance, workability and themechanical property of the concrete are improved, and construction operation is simplified.

Owner:程菲 +1

Portland cement foaming heat preservation board or block and manufacturing method thereof

InactiveCN102863251AStrong hydraulicStrong characteristicCeramicwareAluminium sulfatePolymer science

The invention relates to a Portland cement foaming heat preservation board or a block and a manufacturing method thereof. The Portland cement foaming heat preservation board or the block is capable of strengthening heat insulation and heat preservation performances. The Portland cement foaming heat preservation board or the block is prepared by raw materials of, by weight, 99 parts of Portland cement, 5 parts of saturated aluminum sulfate, 1 part of water reducing agents and 0.5-1 part of hydrogen peroxide, the Portland cement, the saturated aluminum sulfate and the water reducing agents are proportionally taken and then placed in a mixer, water is added into the mixer to be mixed with the raw materials and then stirred for 5-10 minutes to prepare a foaming cement slurry, the water is added according to the weight ratio of the water to the raw materials of 100: (60-80), the hydrogen peroxide is proportionally taken, water is added to the hydrogen peroxide, the hydrogen peroxide and the water are subjected to pre-foaming to manufacture foams by means of a foaming machine, the water is added according to the weight ratio of the hydrogen peroxide to the water of 0.01: 1, the foams and the foaming cement slurry are placed into a foam stirrer for even stirring, the mixture is injected to a mold for solidification molding, and the mold is removed to obtain the density Portland cement foaming heat preservation board or the block. Portland cement enables a solidified board to form a foaming structure under the action of the hydrogen peroxide so that weight of walls is reduced, and the heat insulation and heat preservation performances are strengthened.

Owner:重庆市三真建材有限公司

High-fluidity concrete additive and preparation method thereof

InactiveCN104591571AImprove liquidityReduce mixing water consumptionSolid waste managementActivity indexSURFACTANT BLEND

The invention relates to a high-fluidity concrete additive and a preparation method thereof. The high-fluidity concrete additive comprises a surfactant material and coal ash. The preparation method comprises the step of adequately mixing boiling coal ash with an atomized surfactant solution. According to the high-fluidity concrete additive, the fluidity and the gradual fluidity of concrete can be improved, the activity index of coal ash can be improved, and the adaptability of a water reducer can be improved; the high-fluidity concrete additive is low in cost and easy to prepare and is particularly applicable to pump concrete or self-compacting concrete with relatively high requirement for fluidity.

Owner:TONGJI UNIV

Steel slag aggregate and preparation method thereof

ActiveCN103864326AGelling activityEliminate or improve the interface transition zoneSolid waste managementPrillSlag

The invention discloses steel slag aggregate and a preparation method thereof. The preparation method comprises the following treatment steps: sieving the steel slag after iron selecting, getting and flushing particles with particle diameter between 0.5mm and 20mm with high pressure water, and naturally drying in air; uniformly mixing 15.0-45.0 (in parts by weight) parts of coal slag, 40.0-80.0 parts of lime and 2.0-8.0 parts of mirabilite, packaging the steel slag into balls, drying for 2 hours at 105 DEG C; roasting the dried ball particles at 1260 DEG C-1360 DEG C, and preserving the heat for 4 hours; and cooling to the room temperature under the natural condition to obtain the steel slag aggregate. The steel slag aggregate obtained by the method not only has cementitious activity on surface for eliminating or improving an interfacial transition zone of aggregate and a cement hardened body, but also has a compact surface-layer structure and low concrete stirring water consumption; moreover, industrial waste steel slag is changed into things of value, so that environmental and social burden is reduced; dosage of the natural aggregates is lowered, and non-renewable resources are saved; and materials are easy to obtain, and process is simple.

Owner:SHENZHEN GANGCHUANG BUILDING MATERIAL

Concrete additive and preparation method thereof

The invention provides a concrete additive and a preparation method thereof, relating to the technical field of concrete. The additive is prepared from the following raw materials: cement, kaolin, limestone, latex powder, mineral slag, polyacrylamide, butoxy polyalkaneneglycol ether, dodecathiol, glycerol, organic water-soluble polysaccharides, an initiator, a waterproofing agent, an antifreezing agent and an anticorrosive agent. The concrete additive can greatly reduce the quantity of water for mixing, improves the rheological properties of the concrete mixture, promotes the setting and demolding of the concrete, and accelerates the construction progress. The concrete additive improves the concrete strength and enhances the engineering quality.

Owner:萧县良宇混凝土有限责任公司

Hybrid fiber reinforced strain hardening cement-based composite material and preparation method thereof

InactiveCN110256013AImprove microstructureImprove and optimize the microstructureEnergy absorptionPortland cement

The invention discloses a hybrid fiber reinforced strain hardening cement-based composite material and a preparation method thereof, The raw material composition of the composite material is as follows: Portland cement, water reducer, fly ash, sand, PVA fiber, steel fiber, calcium carbonate whisker and water, the mass proportion of the above raw materials is as follows: Portland cement 300+-5 Kg / m3, water reducer 6+-1 Kg / m3, fly ash 1200+-50 Kg / m3, sand 540+-20 Kg / m3, PVA fiber 18+-4 Kg / m3, steel fiber 45+-25 Kg / m3, calcium carbonate whisker 110+-40 Kg / m3, water 510+-5 Kg / m3. The hybrid fiber reinforced strain hardening cement-based composite material of the present invention has excellent tensile deformation ability, extremely strong bending deformation ability, obvious multi-slot cracking characteristics under uniaxial tension and bending load, high level compressive energy absorption ability, high cost-performance ratio, low cost, easy availability of raw materials and simple preparation process.

Owner:JIANGNAN UNIV

Admixture for marine engineering concrete and preparation method of admixture

The invention relates to the field of buildings, in particular to an admixture for marine engineering concrete and a preparation method of the admixture. The admixture is prepared from raw materials in parts by weight: 100-150 parts of a water reducing agent, 0.5-1 part of tetramethylammonium iodide, 1-5 parts of sodium ethoxide, 3-5 parts of polyacrylamide, 30-50 parts of a surfactant, 15-20 parts of a rust inhibitor, 30-50 parts of an expansion agent, 3-5 parts of a retarder, 6-10 parts of a deforming agent and 0-80 parts of water. The invention aims to overcome the shortcomings of the priorart and provide the admixture for the marine engineering concrete and the preparation method of the admixture, the effects of water reduction, rust resistance, defoaming and retarding are achieved, and the effects are improved; the admixture is added into the concrete, so that the flowability of concrete slurry is improved, retentivity is good, the water reduction rate is high, the density of theconcrete is improved, good flocculability is achieved, and the friction resistance between liquid can be reduced; and the grinding efficiency is improved, and the admixture has the characteristics ofexcellent anti-permeability, fast hardening and early strength, high later strength and the like.

Owner:广西云燕特种水泥建材有限公司

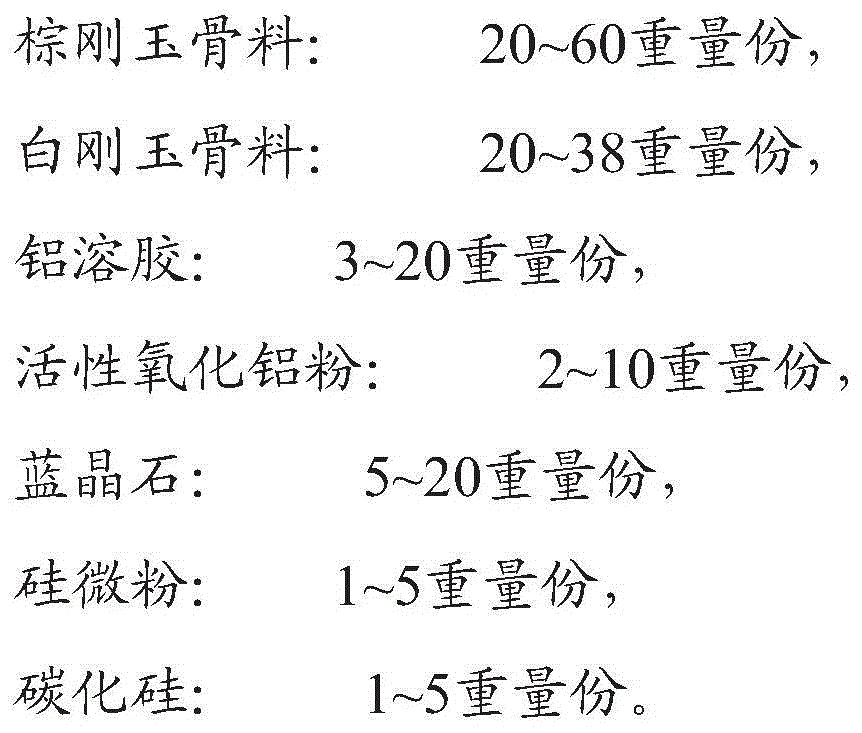

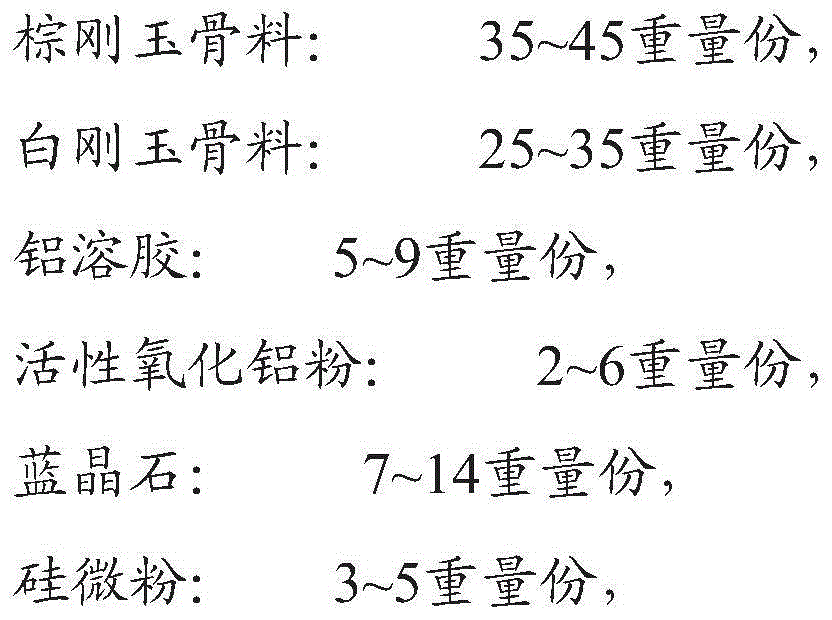

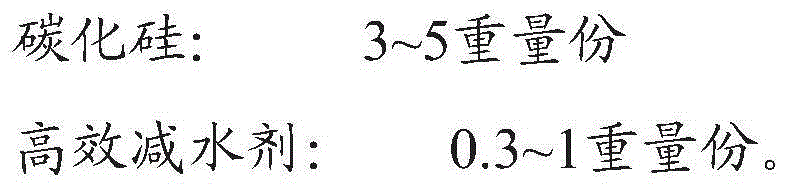

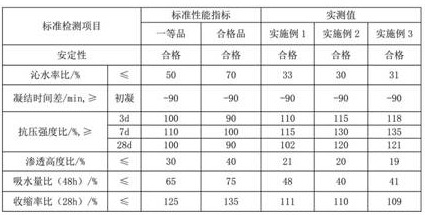

Heat storage material for solar thermal power generation and preparation method of heat storage material

The invention provides a heat storage material for a solar thermal power generation and a preparation method of the heat storage material. The composition of the heat storage material is subjected to optimization design, and the overall performance is greatly improved. A micro powder technology is adopted, an enhancement effect of nanoparticles is utilized, and high-efficiency water reducing agents and low-dosage alumina sol are taken as cementing agents, so that the amount of the alumina sol in the heat storage material is greatly reduced (namely the production energy consumption of raw materials is reduced), the amount of mixing water is reduced, the stability of the heat storage material at the operating temperature of 700-1000 DEG C is greatly improved, and the service life of the heat storage material is prolonged; brown aluminum oxide and white corundum are taken as aggregates, so that the high-temperature performance of the material can be greatly improved, and the thermal shock resistance of the heat storage material is improved; the pores in the concrete are filled with doped micro powder (silica powder and activated aluminum oxide powder), so that the density and strength of the concrete are improved; and moreover, because the carbon fibers have high heat-conducting property, high toughness and other performances, the heat storage rate and heat release rate of the heat storage material can be further improved.

Owner:中广核太阳能开发有限公司 +1

Concrete heat storage material for solar moderate-temperature steam electric power generation and preparation method thereof

InactiveCN104671728AImprove compactnessImprove crack resistanceSolid waste managementCarbon nanotubeSuperplasticizer

The invention provides a concrete heat storage material for solar moderate-temperature steam electric power generation and a preparation method thereof. The composition of the heat storage material is subjected to optimization design, thereby greatly enhancing the comprehensive properties of the heat storage material. By using dolomite with low price and excellent thermal properties as aggregate and adopting a micropowder technique, the enhancement effect of the nano material is utilized, and a high efficiency water reducing agent and low-doping-amount aluminate cement are used as binding agents, thereby greatly lowering the cement consumption (lowering the productive energy consumption of the raw materials) and the mixing water quantity of the heat storage material, and greatly enhancing the heat stability and service life of the heat storage material at working temperature (350-600 DEG C). Carbon nanotubes are doped and filled in the concrete pores to enhance the compactness and strength of the concrete. A novel high efficiency composite water reducing agent can be adopted to lower the mixing water quantity, thereby improving the workability of the concrete and enhancing the compactness and strength.

Owner:中广核太阳能开发有限公司 +1

GBL concrete waterproof compacting agent

The invention discloses a GBL concrete waterproof compacting agent. The compacting agent comprises, by weight, 10 to 17 parts of sodium silicate, 20 to 28 parts of aluminum potassium sulfate dodecahydrate, 1 to 4 parts of polyether, 0.05 to 0.5 part of a polyhydroxy compound, 1 to 6 parts of polyethylene glycol, 0.5 to 1.2 parts of n-butyl alcohol, 0.01 to 0.06 part of mineral fiber, 0.2 to 0.4 part of diethanol amine, 2 to 5 parts of lithium carbonate, 0.2 to 0.4 part of triethanolamine stearate, 0.05 to 0.1 part of a surfactant, 0.002 to 0.006 part of an NNO dispersing agent and 40 to 70 parts of water. The invention further discloses a preparation method of the compacting agent. The compacting agent can significantly improve the concrete anti-permeability, reduce the concrete shrinkage, prevent the concrete from cracking after hardening, and effectively prevent water molecule permeation, thereby improving the concrete strength and performance.

Owner:河南博浪实业有限公司

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

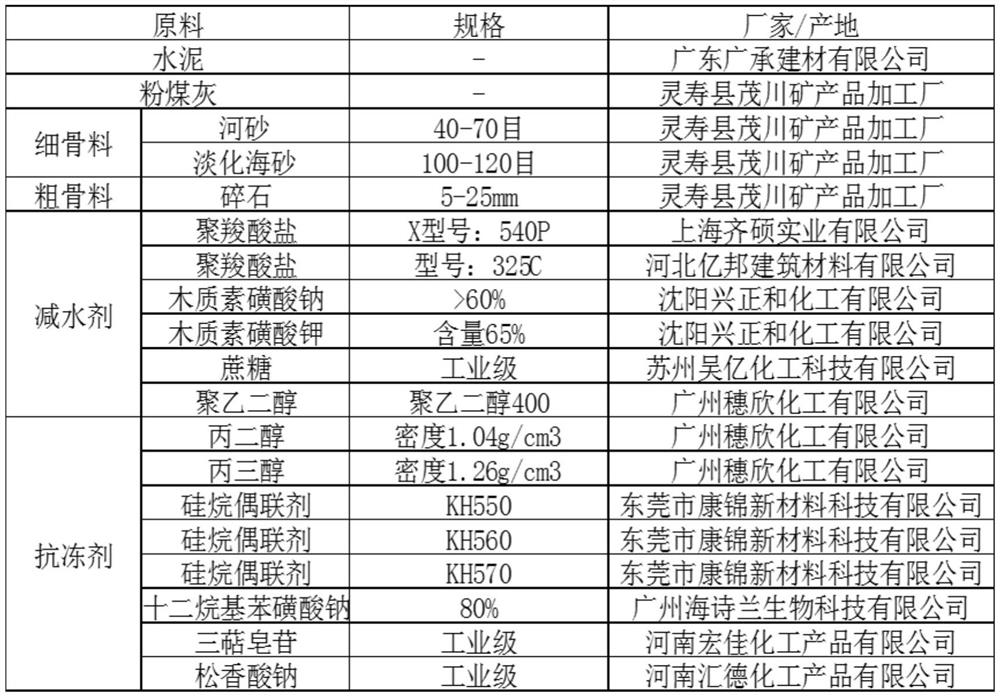

Anti-freezing concrete and preparation method thereof

The invention relates to the field of concrete, and particularly discloses an anti-freezing concrete and a preparation method thereof. The anti-freezing concrete comprises cement, fly ash, fine aggregate, coarse aggregate, a water reducing agent, an anti-freezing agent and water, wherein the anti-freezing agent is prepared from propylene glycol, glycerol, a silane coupling agent and alkyl benzenesulfonate according to a weight ratio of (2.0 to 2.5) to (1.0 to 1.5) to (0.1 to 0.2) to (0.3 to 0.4). The preparation method comprises the following steps: adding the water reducing agent and the anti-freezing agent into water for premixing to obtain an admixture solution; uniformly mixing the fine aggregate and the coarse aggregate to obtain an aggregate mixture; uniformly mixing cement and flyash to obtain a glue mixture; uniformly mixing the glue mixture and the aggregate mixture to obtain a pre-mixture; adding the admixture solution into the pre-mixture, and uniformly stirring to obtainthe anti-freezing concrete. The anti-freezing concrete can be used as building concrete in a low-temperature area and has the advantage of good anti-freezing performance.

Owner:佛山市南海区恒锵混凝土有限公司

Multifunctional specific waterproofing agent

InactiveCN1566251AReduce harmful poresImprove compactnessOther chemical processesCompressive strengthNanotechnology

The invention discloses a multifunctional highly performance waterproofing agent, which comprises plasticizing agent, air-entrainer, organic material, reduction material, the invention can be utilized to obtain water solution and powder preparation.

Owner:衡阳市银利实业有限公司

Construction method of large-volume concrete bearing platform with one-time pouring in winter

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and thesurface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP CORP LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com