High-strength elastic concrete for heavy-haul railway sleepers

An elastic concrete and railway track technology, which is applied in the field of concrete structures, can solve the problems of ballast extrusion and wear, sleeper damage, frequent line maintenance and repair operations, etc., to reduce water consumption, improve early strength, and improve self-compacting The effect on the penetration properties of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

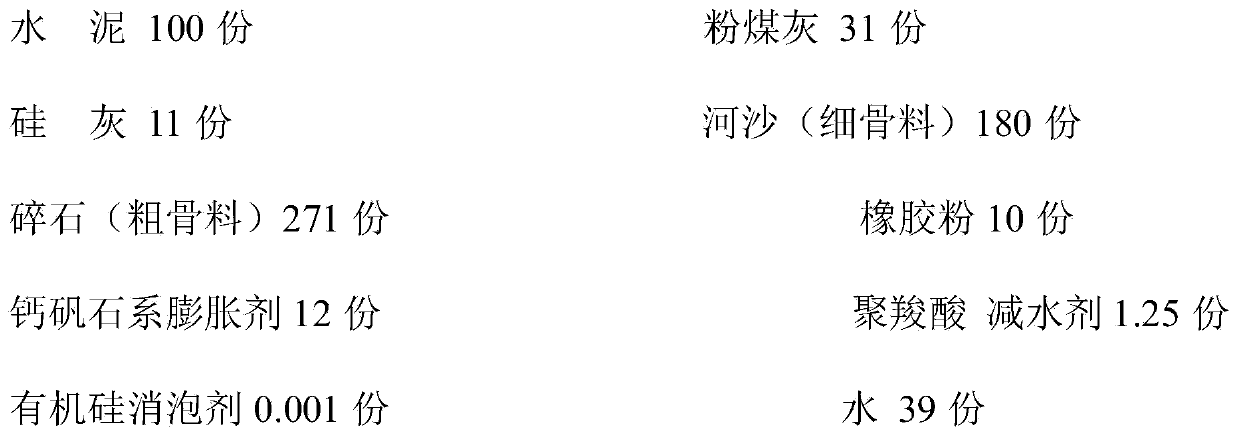

[0021] The high-strength elastic concrete of the heavy-duty railway sleeper in this embodiment is composed of cement, rubber powder, fly ash, silica fume, fine aggregate, coarse aggregate, expansion agent, water reducing agent, defoamer, water and the like. The parts by weight of each component are:

[0022]

[0023] The performance index of fresh concrete is: slump 85mm, apparent density 2410kg / m 3 , no segregation, no bleeding; performance indicators of hardened concrete: concrete steamed at 45°C for 3 days compressive strength 95.8MPa, 28d compressive strength 97.8MPa, 28d flexural strength should be 10.2MPa, ACI 544 impact resistance 5100 times (ACI-544 method), 56d concrete electric flux 150C, 56d concrete frost resistance times (quick freezing method) ≥ F500.

Embodiment 2

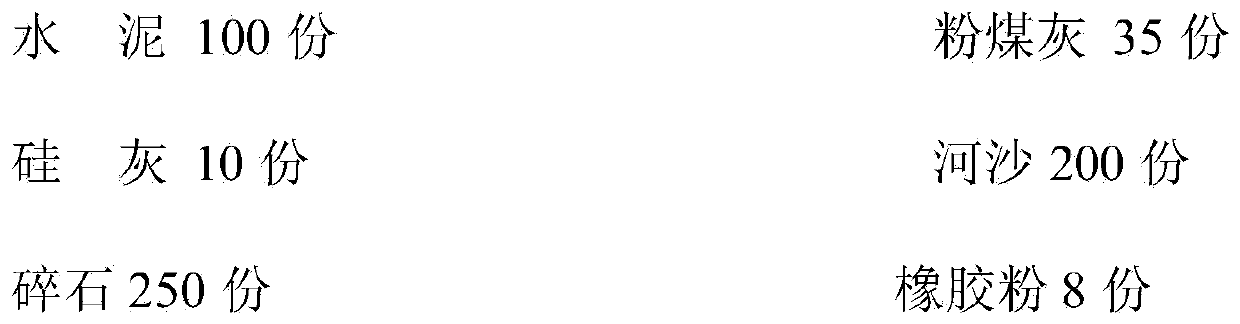

[0025] The high-strength elastic concrete of the heavy-duty railway sleeper in this embodiment is composed of cement, rubber powder, fly ash, silica fume, fine aggregate, coarse aggregate, expansion agent, water reducer, defoamer, water and the like. The parts by weight of each component are:

[0026]

[0027]

[0028] The performance index of fresh concrete is: slump 90mm, apparent density 2420kg / m 3 , no segregation, no bleeding; performance indicators of hardened concrete: concrete steamed at 45°C for 3d compressive strength 95.8MPa, 28d compressive strength 98.2MPa, 28d flexural strength should be 10.4MPa, ACI 544 impact resistance 5500 times (ACI-544 method), 56d concrete electric flux 180C, 56d concrete frost resistance times (quick freezing method) ≥ F500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com