High-fluidity concrete additive and preparation method thereof

A high-fluidity, concrete technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems that cannot be applied immediately, and achieve reduced concrete mixing water consumption, high economic benefits, and improved fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

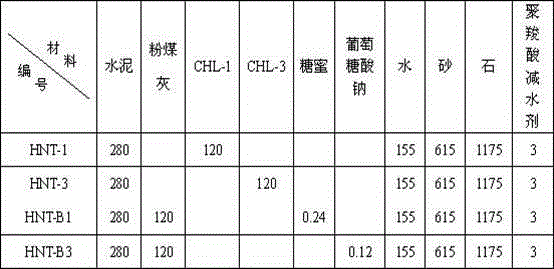

[0020] Table 1 High fluidity concrete admixture formula (mass ratio, unit: parts by mass)

[0021]

1 2 3 fly ash 1000 1000 1000 molasses 2 wood calcium 3 sodium gluconate 1

[0022] The preparation method is that the surfactant material is dissolved in water to prepare a surface modification material solution with a concentration of 20%; the fly ash is boiled by air fluidization, and then according to the mixing ratio in Table 1, ultrasonic The atomization device mixes the atomized surface modification material solution particles and the fly ash material evenly to obtain the patented product.

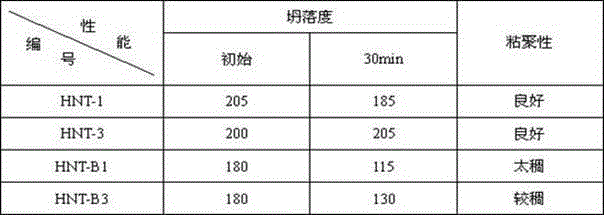

[0023] Prepare high-fluidity concrete admixtures (respectively denoted as CHL-1 and CHL-3) according to Scheme 1 and Scheme 3 in Table 1, and then prepare C40 concrete according to the material ratio in Table 2 (respectively denoted as HNT- 1 and HNT-3). In order to compare the traditional method, the same amount of or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com