Reworked material working lining of continuous casting tundish and preparation method for reworked material working lining

A continuous casting tundish and working lining technology, applied in casting equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high service life, high cost of working lining refractory materials, heavy erosion of the working lining impact area of continuous casting tundish, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

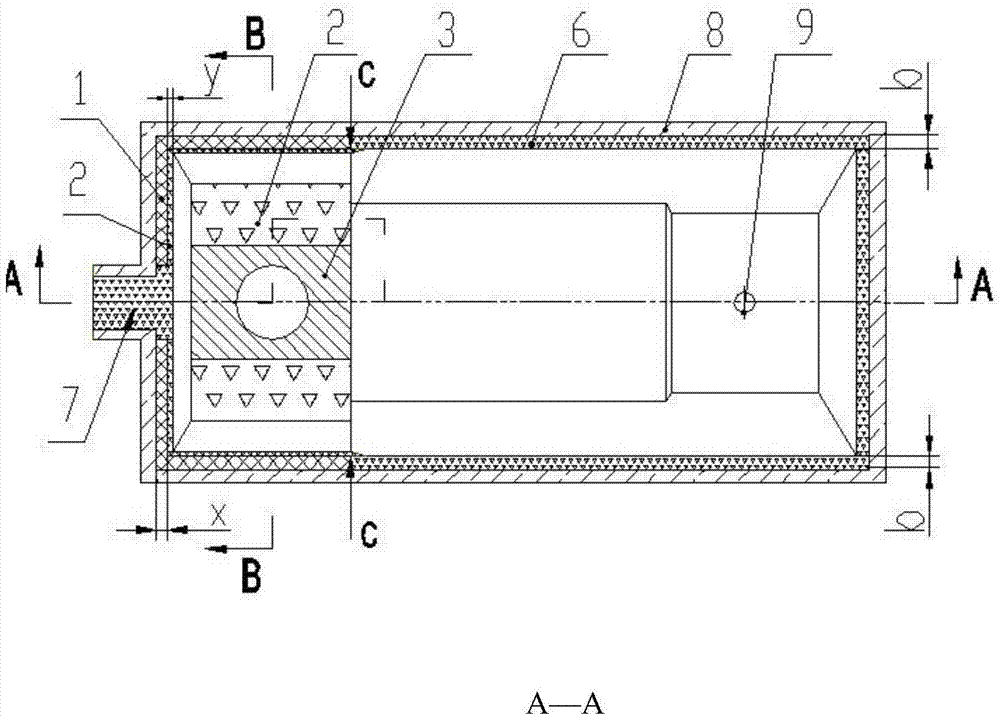

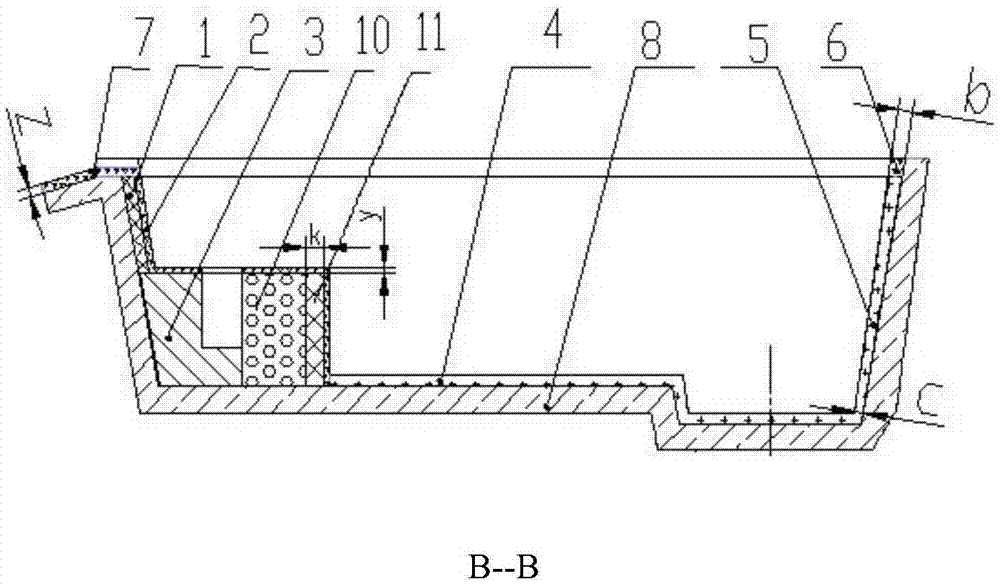

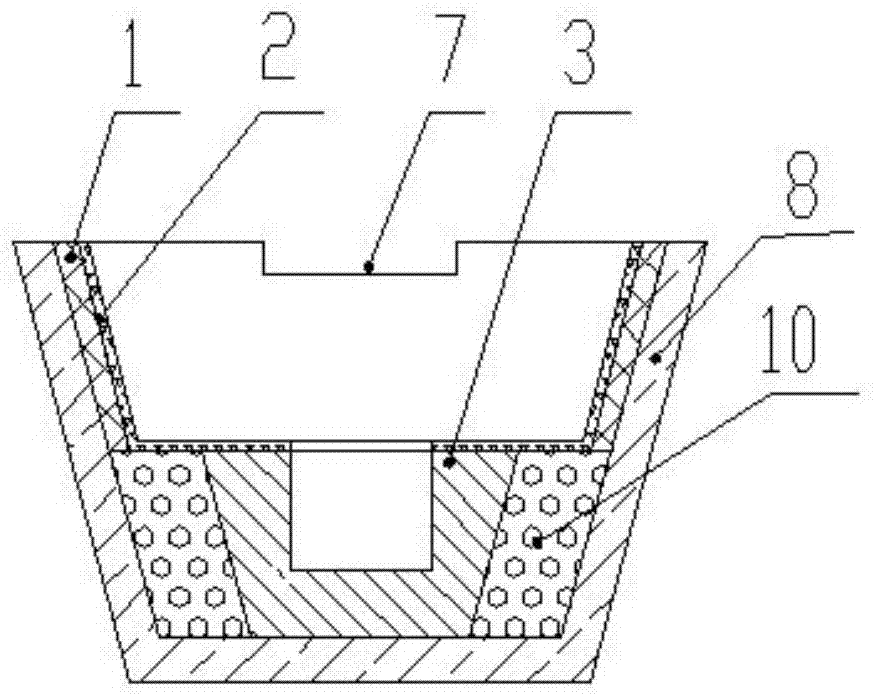

[0008] A continuous casting tundish working lining made of recycled materials, which is divided into an impact zone working lining (1) and a non-impact zone working lining according to different parts, both of which are internally attached to the permanent lining (8); the impact zone working lining (1) is located in the tundish One side of the interface (C-C) between the impact zone and the non-impact zone, and connected to the working lining (7) of the overflow port; the working lining of the non-impact zone is located on the other side of the interface (C-C) between the impact zone and the non-impact zone of the tundish, The working lining in the impact area is sequentially from top to bottom: the working lining of the bag edge (6), the working lining of the wall wall (5), and the working lining of the bottom of the bag (4). It is characterized in that the elevation of the lower edge of the working lining (6) is On the working lining (7) of the tundish overflow port and conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com