Heat storage material for solar thermal power generation and preparation method of heat storage material

A technology for solar thermal power generation and heat storage material, which is applied in the field of using brown corundum as coarse aggregate and white corundum clinker as fine aggregate, to achieve the advantages of improving stability and service life, improving thermal shock resistance and improving comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

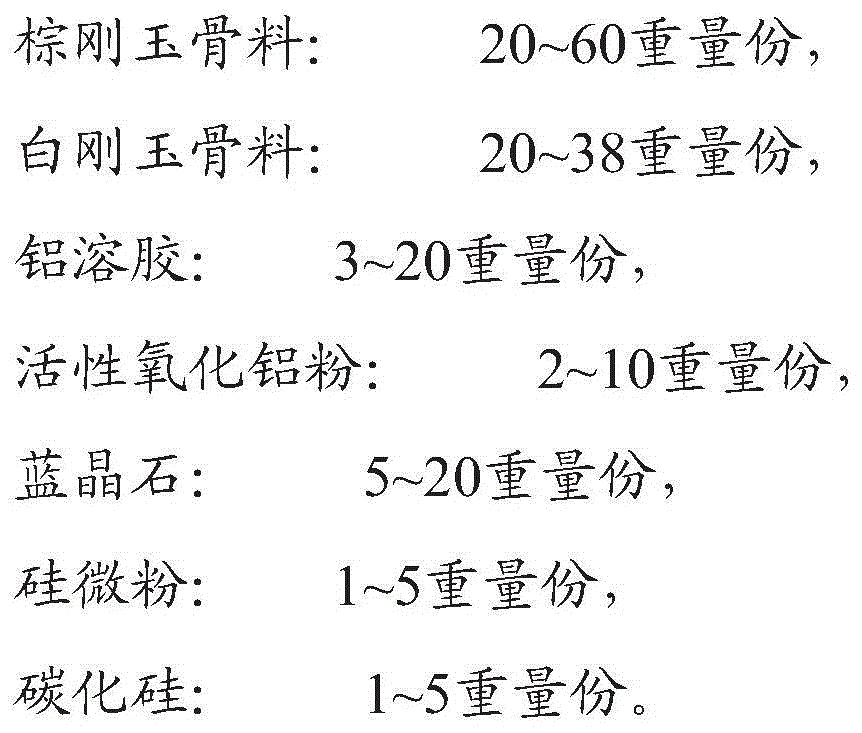

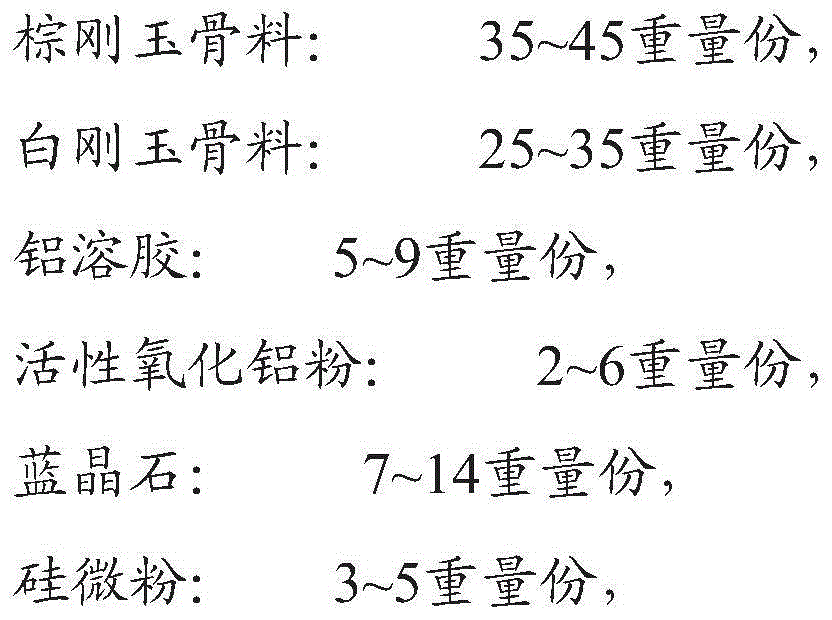

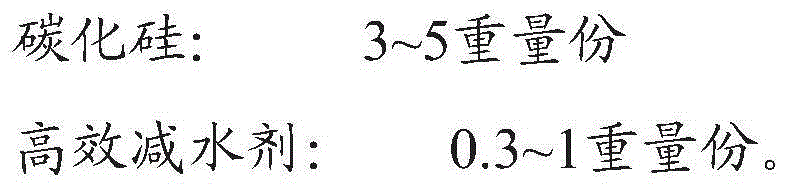

Method used

Image

Examples

Embodiment 1

[0051] Formula: brown corundum aggregate: particle size 10-30mm, 36 parts by weight

[0052] White corundum aggregate: particle size 1-10mm, 34 parts by weight

[0053] Aluminum sol: 9 parts by weight

[0054] Activated alumina powder: particle size 500 mesh, 4 parts by weight

[0055] Silica powder: particle size 500 mesh, 5 parts by weight

[0056] Kyanite: particle size 500 mesh, 7 parts by weight

[0057] Silicon carbide: particle size 800 mesh, 5 parts by weight

[0058] Add 0.3 parts by weight of high-efficiency composite water reducer.

[0059] Preparation:

[0060] Take brown corundum aggregate, white corundum aggregate, aluminum sol, activated alumina powder, silicon micropowder, kyanite and silicon carbide, add high-efficiency composite water reducer, dry mix evenly, add 5 parts by weight of water, After mixing evenly, place it in a steel mold, demould after 24 hours, cure in water at a temperature of 20-25°C for 72 hours, and bake at a temperature of 100-120°C...

Embodiment 2

[0063] Formula: brown corundum aggregate: particle size 10-30mm, 38 parts by weight

[0064] White corundum aggregate: particle size 1-10mm, 32 parts by weight

[0065] Aluminum sol: 8 parts by weight

[0066] Activated alumina powder: particle size 500 mesh, 5 parts by weight

[0067] Silica powder: particle size 500 mesh, 4 parts by weight

[0068] Kyanite: particle size 500 mesh, 9 parts by weight

[0069] Silicon carbide: particle size 800 mesh, 4 parts by weight

[0070] Add 0.3 parts by weight of high-efficiency composite water reducer.

[0071] Preparation:

[0072] Take brown corundum aggregate, white corundum aggregate, aluminum sol, activated alumina powder, silicon micropowder, kyanite and silicon carbide, add high-efficiency composite water reducer, dry mix evenly, add 6.2 parts by weight of water, After mixing evenly, place it in a steel mold, demould after 24 hours, cure in water at a temperature of 20-25°C for 72 hours, and bake at a temperature of 100-120...

Embodiment 3

[0075] Formula: brown corundum aggregate: particle size 10-30mm, 40 parts by weight

[0076] White corundum aggregate: particle size 1-10mm, 30 parts by weight

[0077] Aluminum sol: 7 parts by weight

[0078] Activated alumina powder: particle size 500 mesh, 6 parts by weight

[0079] Silica powder: particle size 500 mesh, 5 parts by weight

[0080] Kyanite: particle size 500 mesh, 9 parts by weight

[0081] Silicon carbide: particle size 800 mesh, 3 parts by weight

[0082] Add 0.3 parts by weight of high-efficiency composite water reducer.

[0083] Preparation:

[0084] Take brown corundum aggregate, white corundum aggregate, aluminum sol, activated alumina powder, silicon micropowder, kyanite and silicon carbide, add high-efficiency composite water reducer, dry mix evenly, add 5.3 parts by weight of water, After mixing evenly, place it in a steel mold, demould after 24 hours, cure in water at a temperature of 20-25°C for 72 hours, and bake at a temperature of 100-120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com