Patents

Literature

156 results about "Uniaxial tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

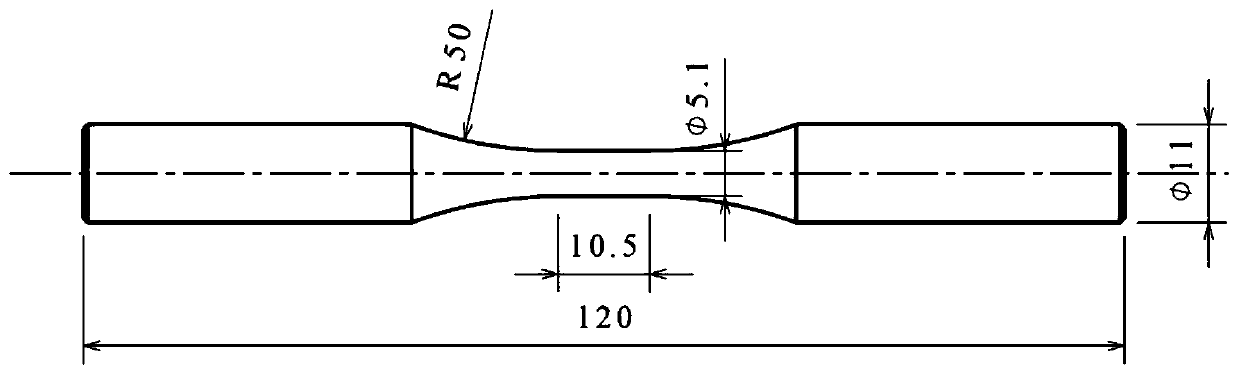

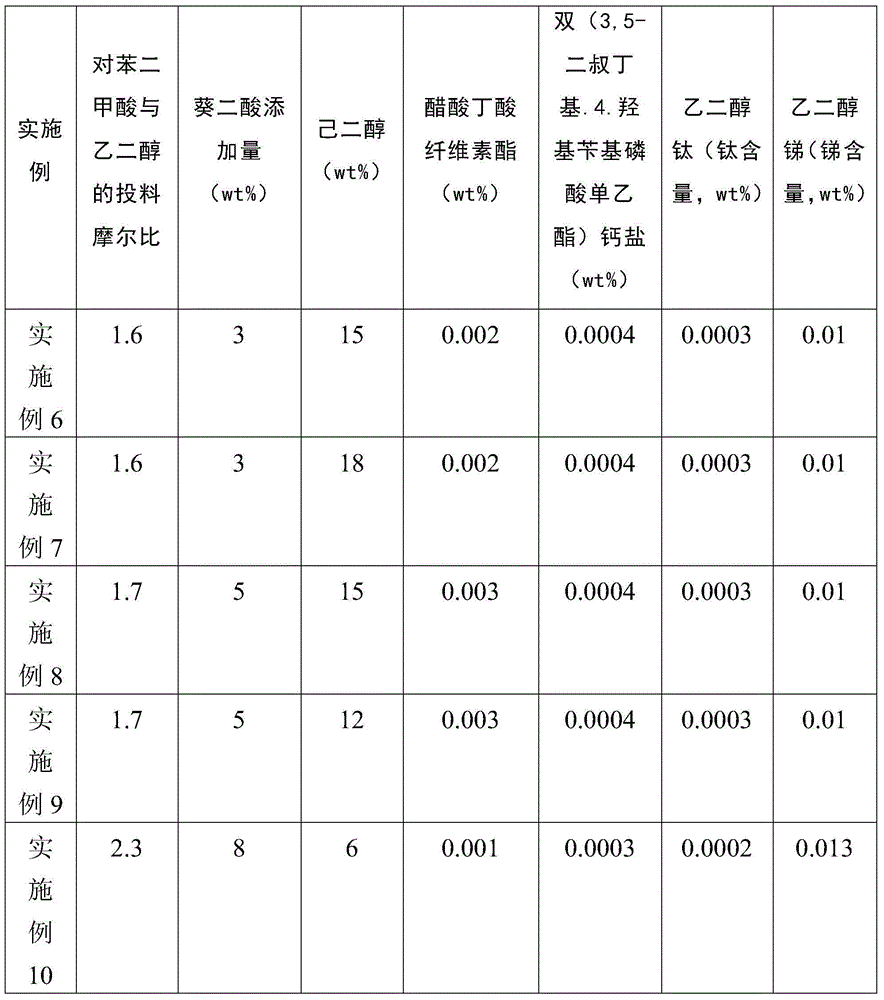

Uniaxial Tension (UT) Testing. The uniaxial tension test is one of the most commonly used tests to determine important material parameters such as Young’s modulus, yield strength, ultimate strength, elongation at break, Poisson’s ratio, and Lankford coefficients (r-values).

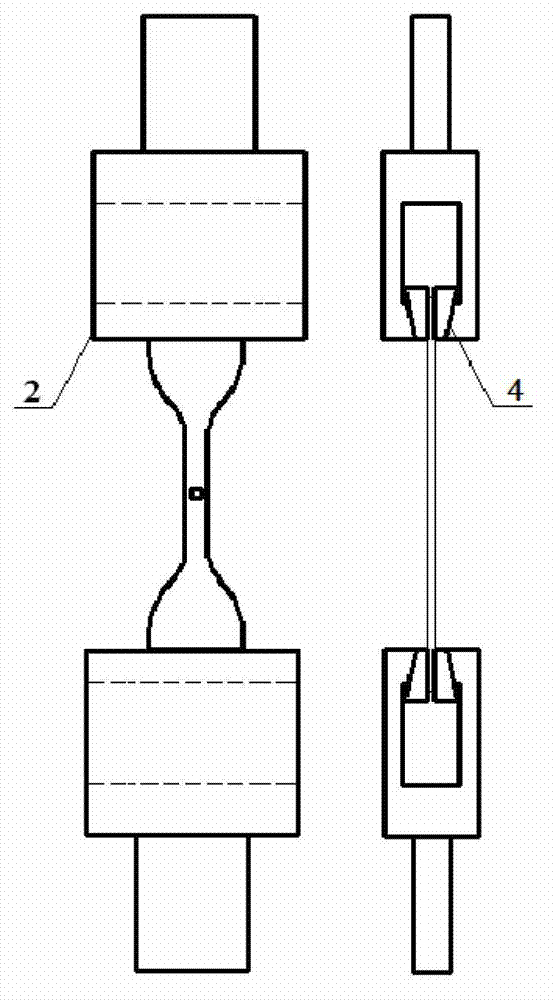

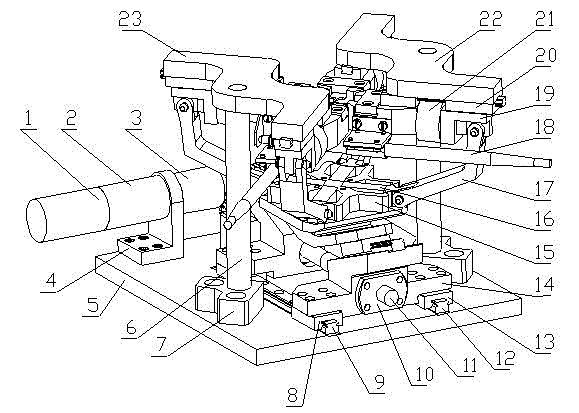

Clamp, device with clamp for testing mechanical property of hyper-elastic material and method

InactiveCN102768149AUniform deformationQuick disassemblyMaterial strength using tensile/compressive forcesData acquisitionHyper elastic

The invention relates to a device and a method for testing mechanical property of a hyper-elastic material. The device mainly comprises a reinforcing piece (4) at the end of a test piece and a test piece clamp, wherein the reinforcing piece (4) has a trapezoidal cross section; a clamping port of the clamp is an inclined surface; the reinforcing piece (4) is adhered to the end of the test piece and is arranged in the clamp, the inclined surface of the clamp tightly clamps the inclined surface of the reinforcing piece (4), and the clamp is self-locked in the tensioning process and is prevented from locally deforming. The device is applied to multiple stress-strain tests of the hyper-elastic material such as uniaxial tension, equally biaxial tension and planar tension (pure shear). Stress data is acquired by a data acquisition system of an electronic universal testing machine, and the strain data is acquired by a charge coupled device (CCD) image acquisition device. Due to the technical scheme, the clamping force is high when the tension is high in the process of tensioning the test piece, so that the test piece is uniformly stressed, more accurate testing data can be obtained, and the mechanical property parameters of the hyper-elastic material obtained accordingly are more reliable.

Owner:TSINGHUA UNIV

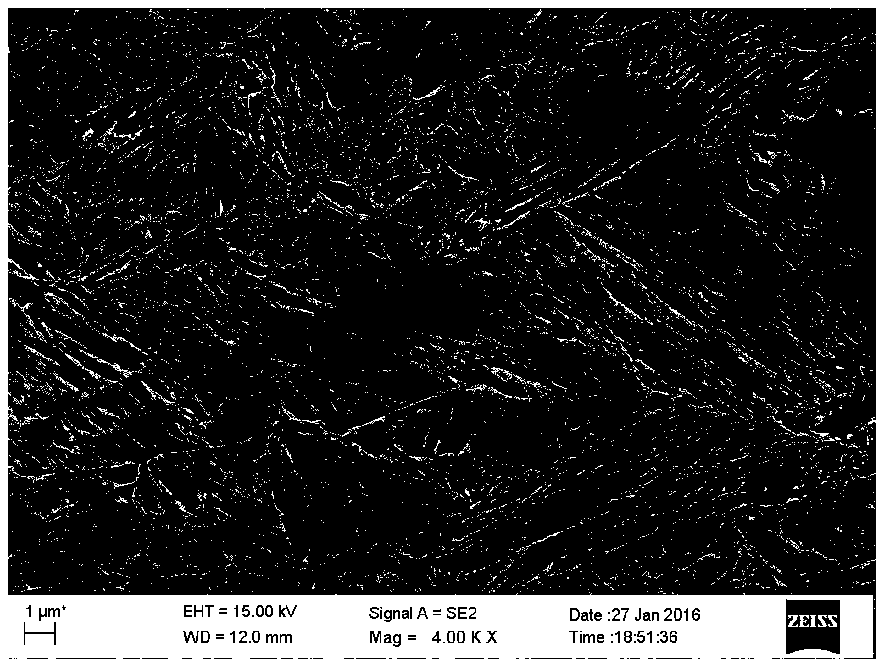

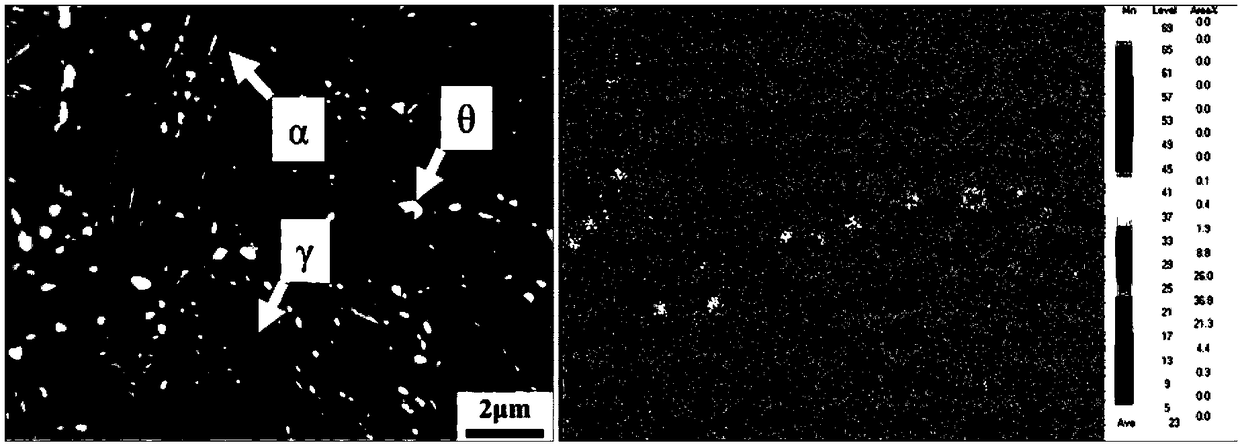

Preparation method of high-strength medium-manganese steel plate

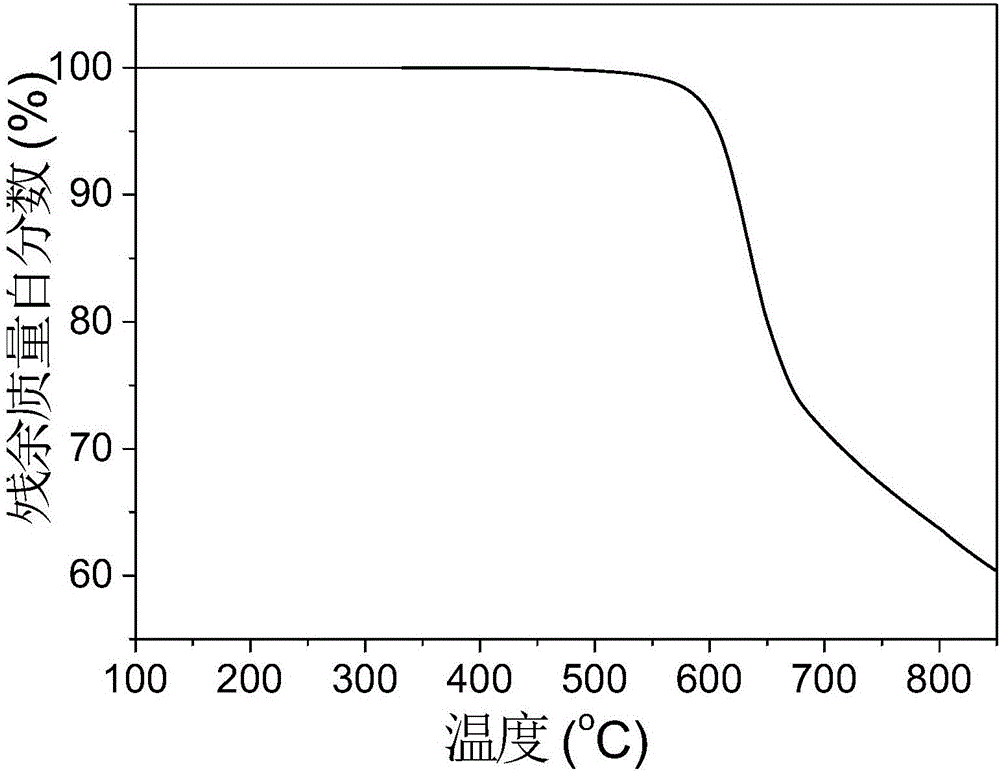

The invention discloses a preparation method of a high-strength medium-manganese steel plate, and belongs to the technical field of steel plates with high strength and toughness. The preparation method comprises the following steps that 1), smelting is carried out according the proportion of the components in the high-strength medium-manganese steel plate, and continuous casting or die casting iscarried out, then forging is carried out to obtain a blank; 2), heating and heat preservation are carried out on the blank, and the blank is air-cooled to the room temperature after subjected to multi-pass hot rolling so as to obtain a hot-rolled plate or a hot-rolled coiled plate; 3), the hot-rolled plate or the hot-rolled coiled plate is heated, undergoes heat preservation and then is cooled toobtain a primary annealing steel plate, and the primary annealing steel plate undergoes a step 4) or directly undergoes a step 5); 4), the primary annealing steel plate is cold-rolled to obtain a cold-rolled plate; and 5), the cold-rolled plate or the primary annealing steel plate is heated, undergoes heat preservation and is cooled to the room temperature to obtain the high-strength medium-manganese steel plate, wherein the yield strength of the high-strength medium-manganese steel plate is 450-1000 MPa, the tensile strength of the high-strength medium-manganese steel plate is 800-1500 MPa, the elongation percentage of the high-strength medium-manganese steel plate is 18%-60%, no Luders bands are generated during the uniaxial tension process, and the yield elongation rate of the high-strength medium-manganese steel plate is less than or equal to 1%. The preparation method has the advantage that high strength and elongation of the steel plate can be guaranteed, the steel plate can be yielded continuously in the deformation process, and the Luders bands and deformation can be prevented from being generated so as to facilitate cold stamping forming of the steel plates.

Owner:江苏育材堂车身技术有限公司

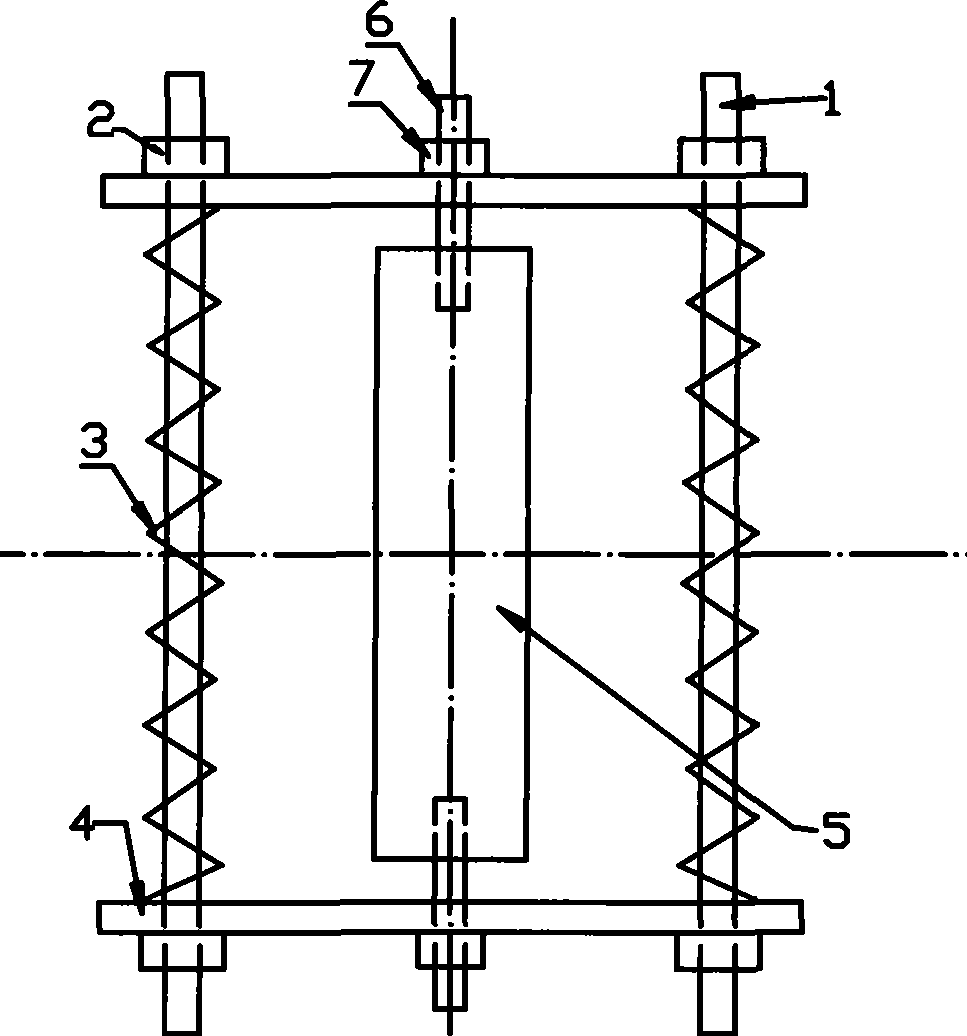

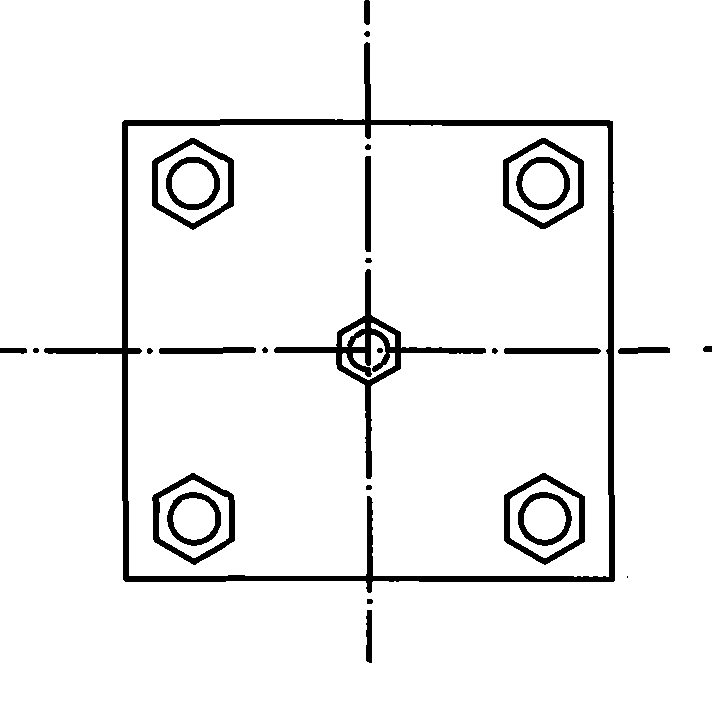

Uniaxial tension loading unit for testing concrete carbonizing performance under tensile stress and testing method

InactiveCN101387634AContinuous uniaxial tensionAchieve carbonization resistance durabilityMaterial testing goodsStrength propertiesSheet steelEngineering

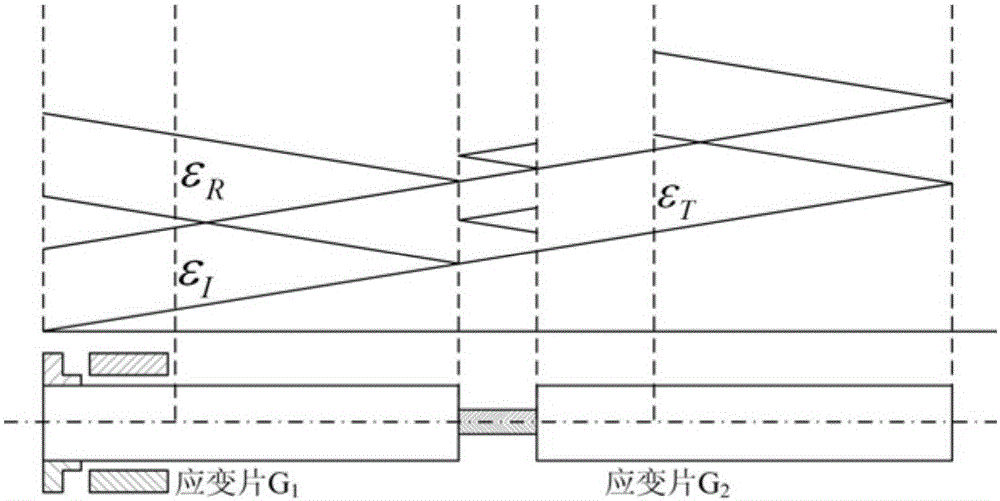

The invention discloses a single shaft tension loading device for testing the carbonation property of the concrete under tensile stress and a test method, wherein the hex nuts pre-embedded at the axis of two ends of the tested element connect the cylinder or rectangle tested element between two parallel steel plates, four same compressed springs are sheathed on four steel columns of the diameters smaller than the inner diameter of the springs, the two steel plates can parallel move between the four steel columns, the material parameters and the compressed quantity of the springs can be used to calculate the axial tensile load on the tested element, the tested element is axially patched with three stress sheets to find the actual tensile stress at different parts. The characteristic parameters of the springs can be changed to obtain the carbonation test parameters under different tensile stresses.

Owner:SOUTHEAST UNIV

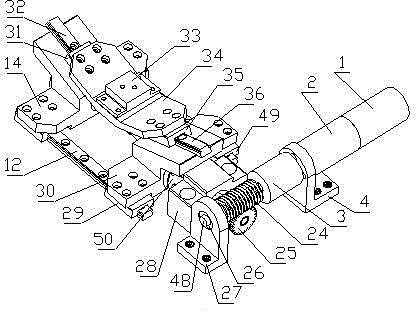

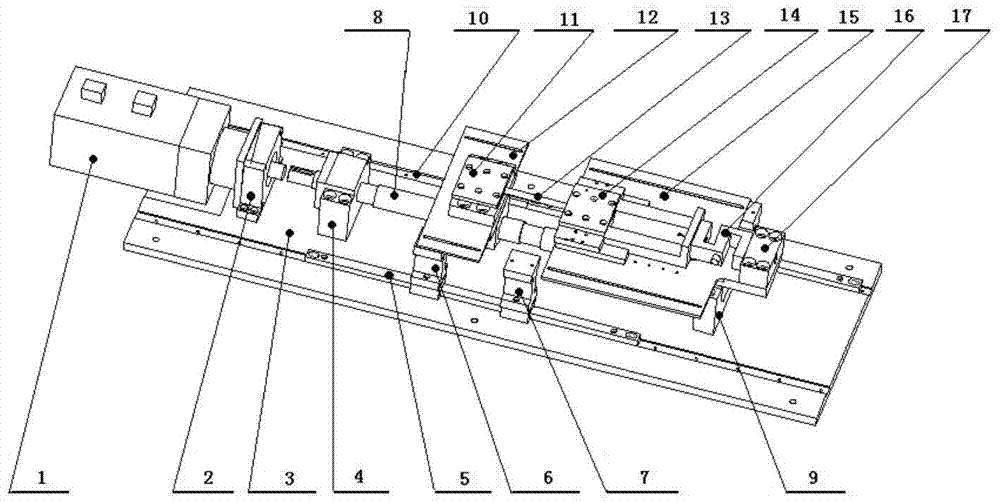

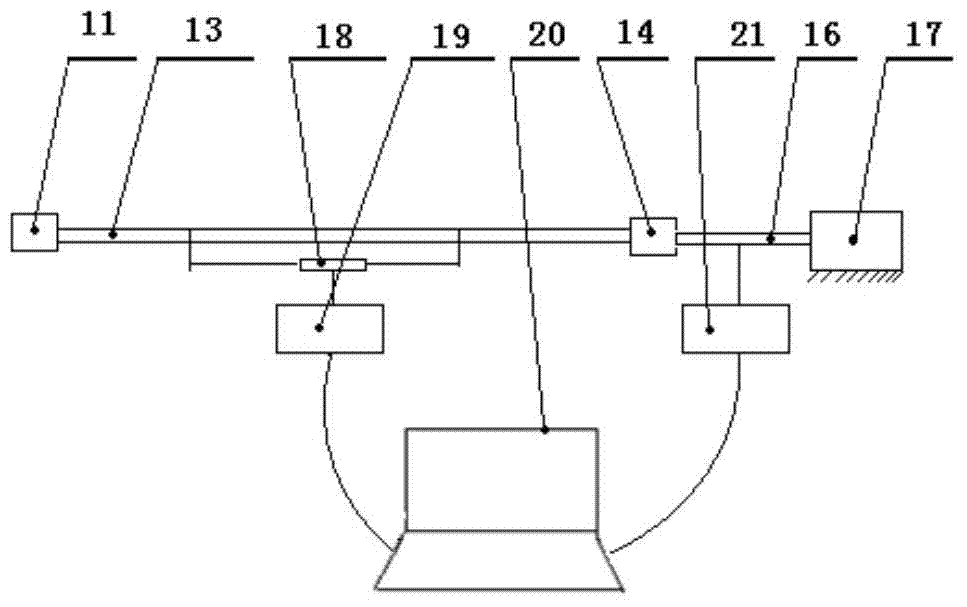

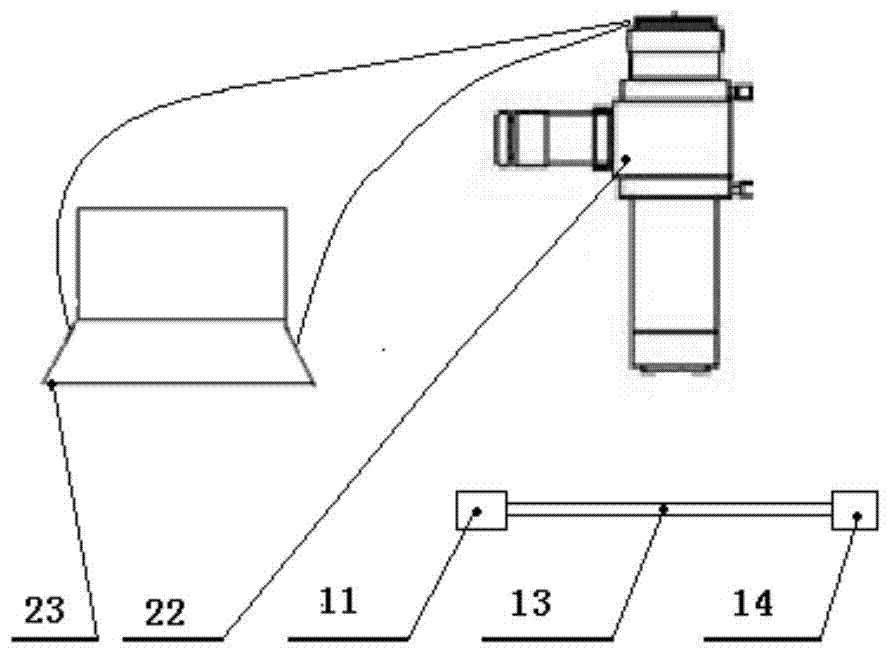

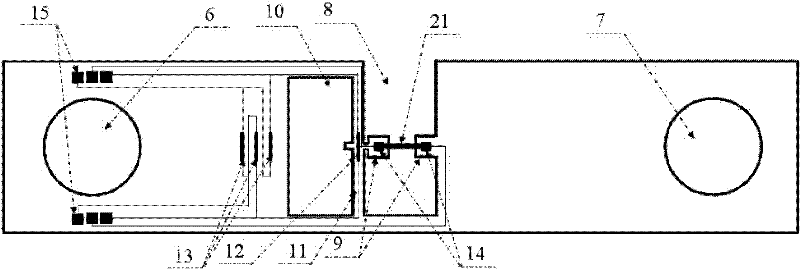

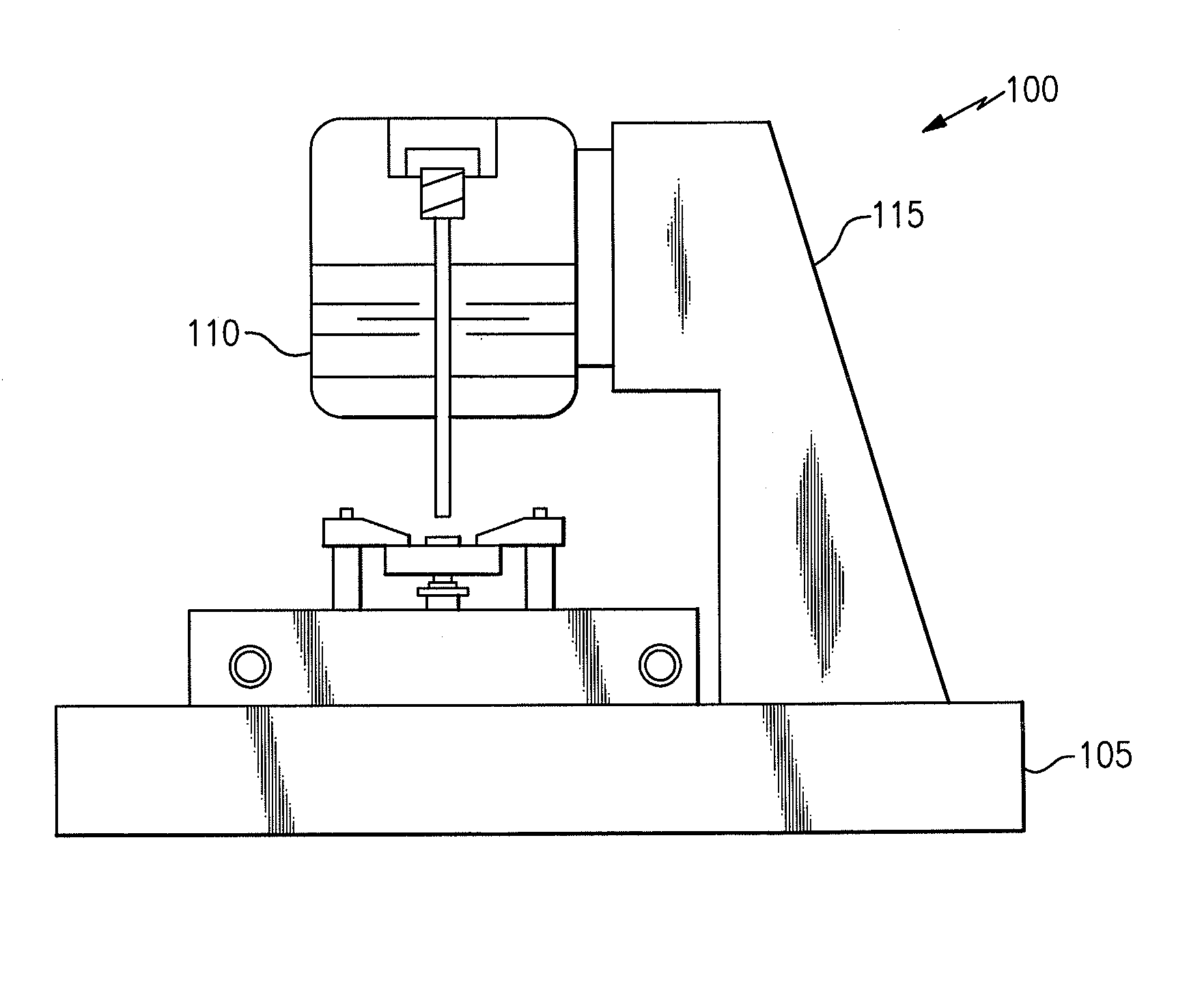

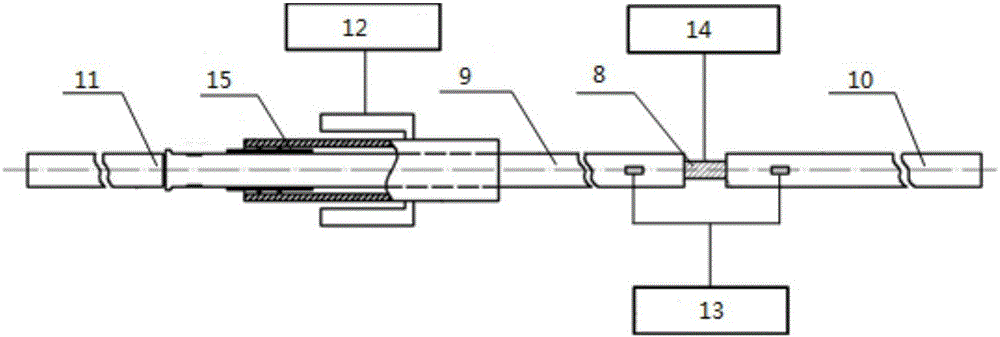

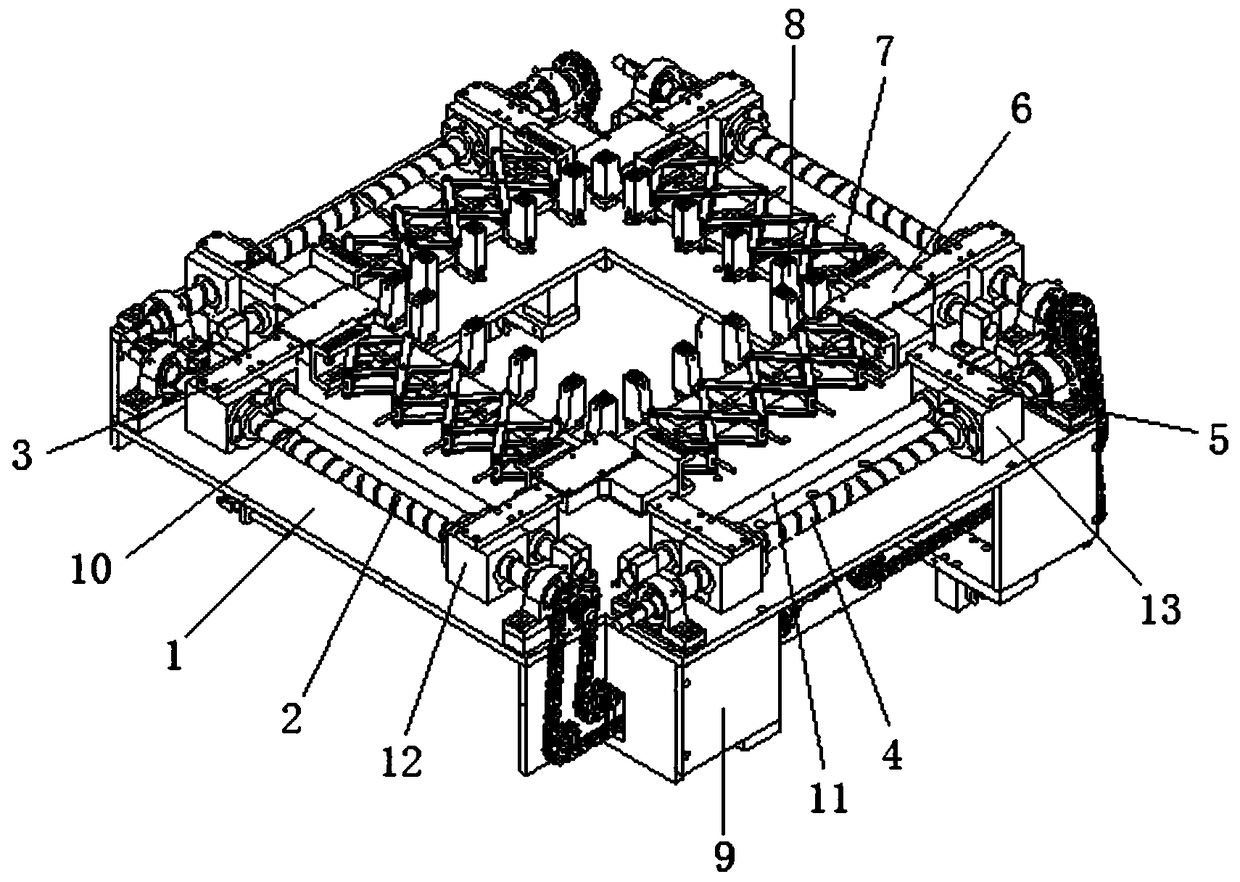

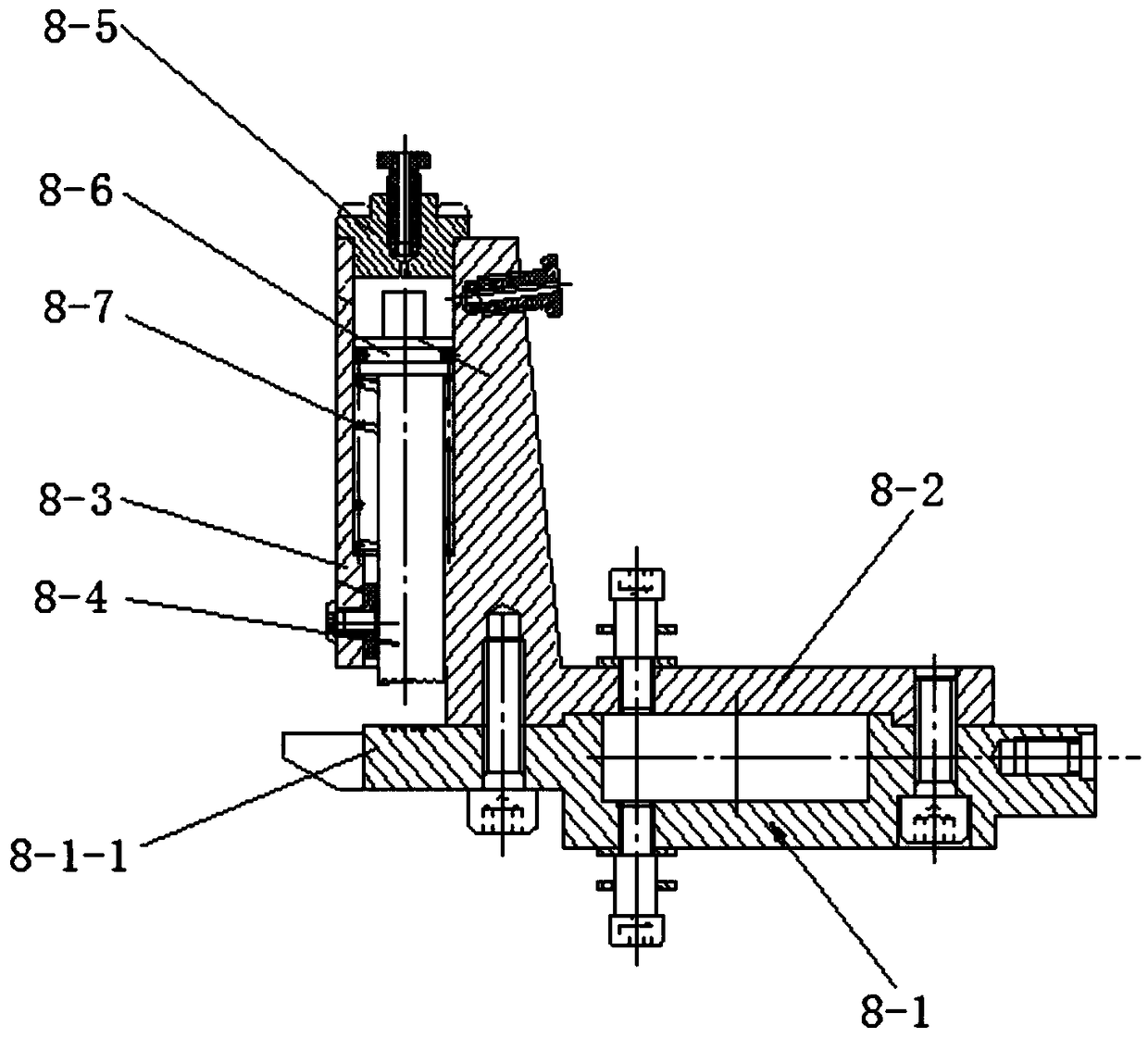

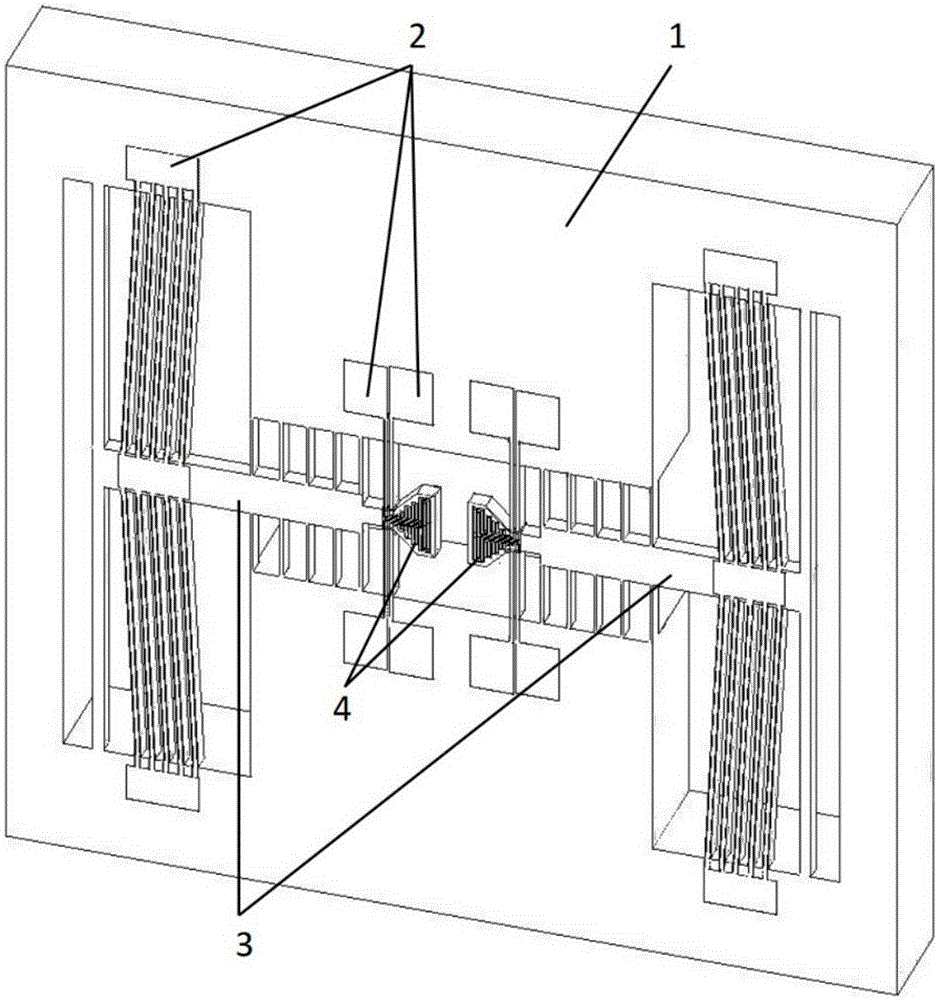

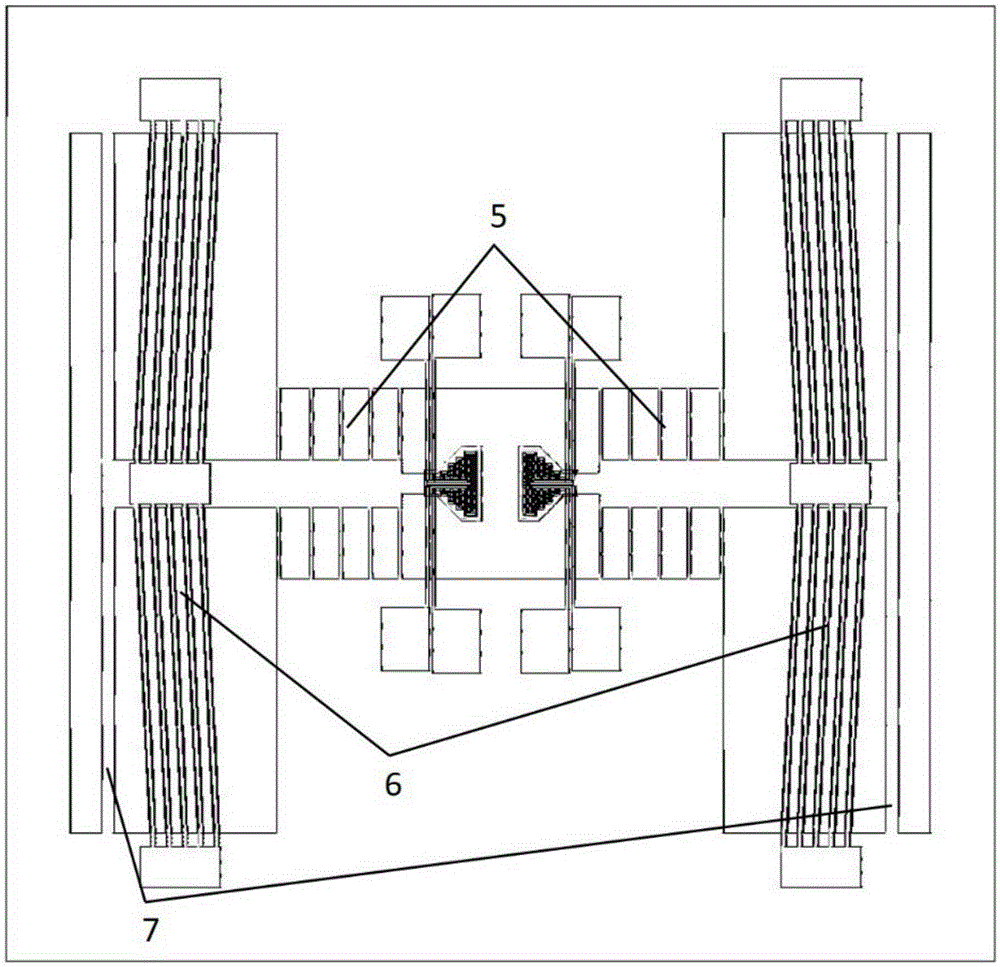

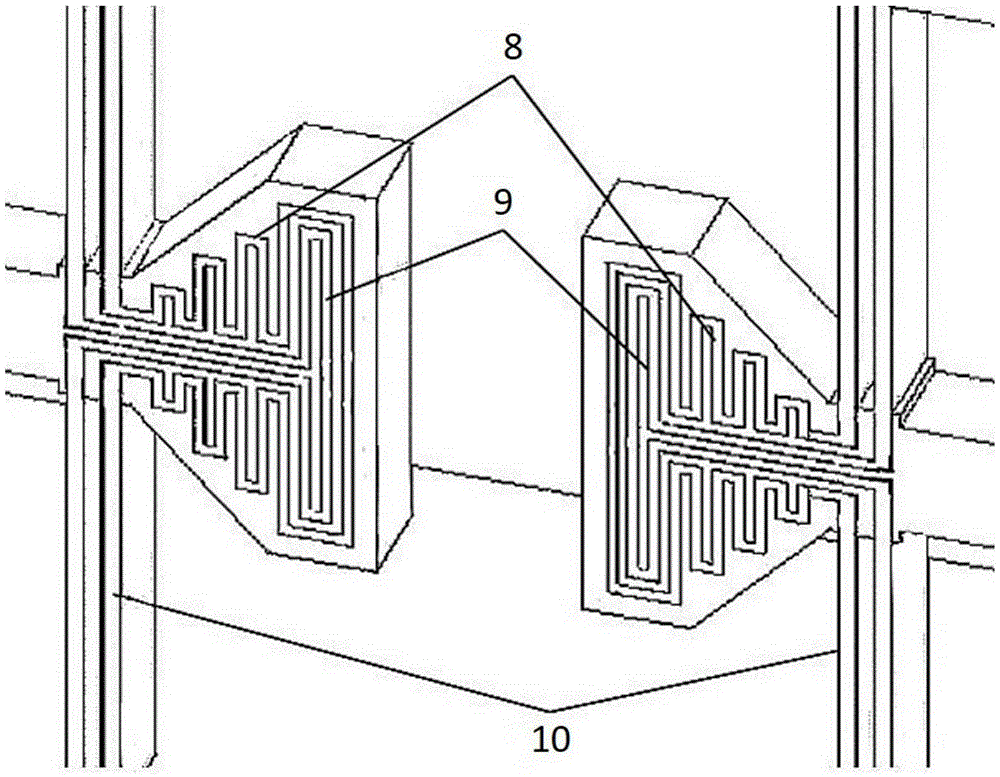

Material micro-mechanical property biaxial tension-fatigue test system and test method thereof

ActiveCN104913974ANovel structureCompact structureMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesFatigue loadingScientific instrument

The invention relates to a material micro-mechanical property biaxial tension-fatigue test system and a test method thereof, and belongs to the field of precise scientific instruments. The test method is characterized in that orthogonal tensile load is applied to a test piece to make two mutually vertical tensions exist in one plane, and fatigue load can also be applied to the test piece on the basis of the tensile load in order to research the micro-mechanical properties of a material under different load forms and load sizes. The system is composed of a precise loading-transmitting unit, a fatigue unit, a mechanics and deformation signal detection unit, and a test piece clamping unit. The test system has the advantages of novel and compact structure, respective realization of uniaxial tension test, biaxial tension test, uniaxial tension-fatigue test and biaxial tension-fatigue test, good compatibility with an optical microscope, and dynamic research of the relationship between the microstructure of the material and the deformation damage mechanism under tension-fatigue load conditions.

Owner:JILIN UNIV

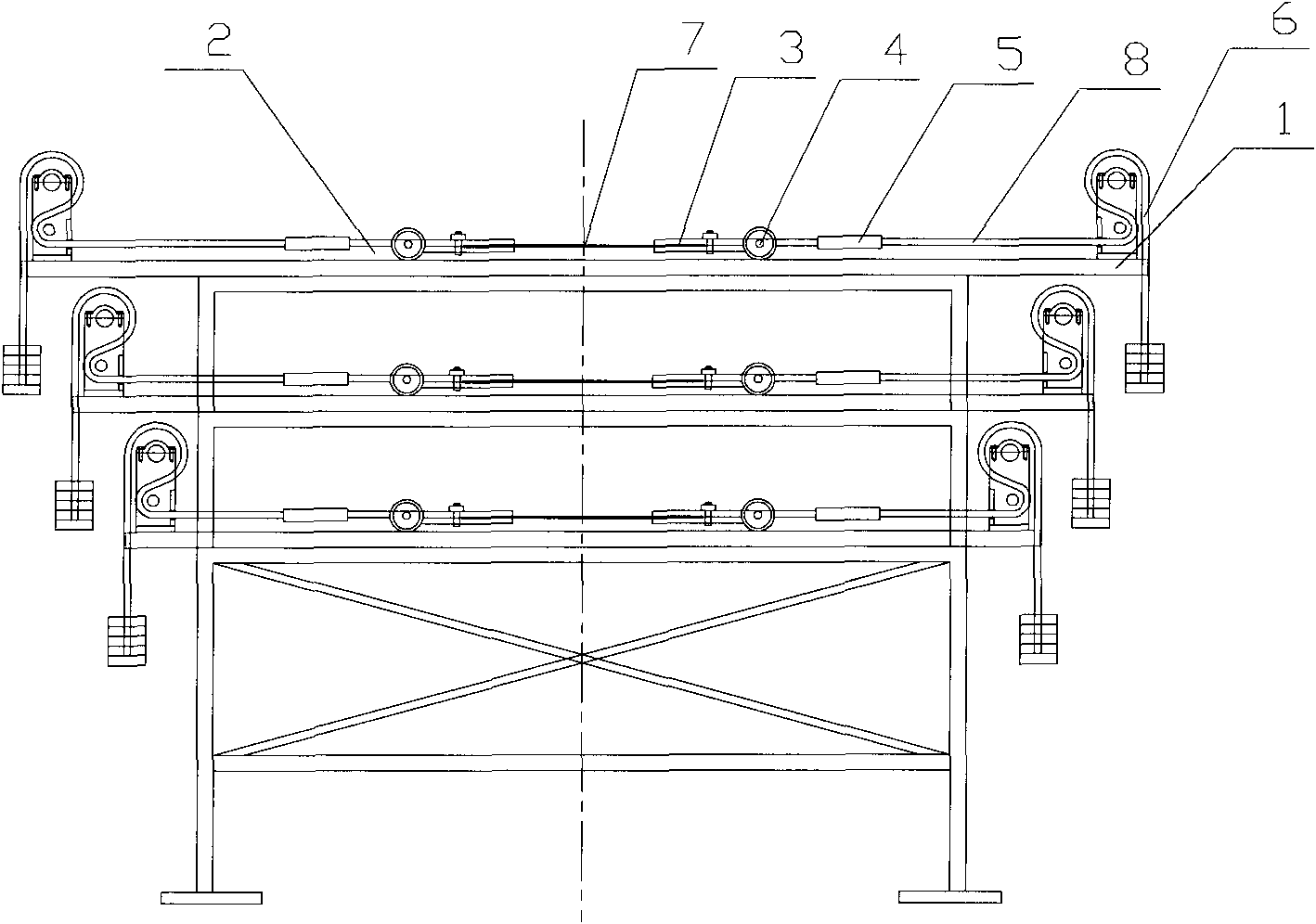

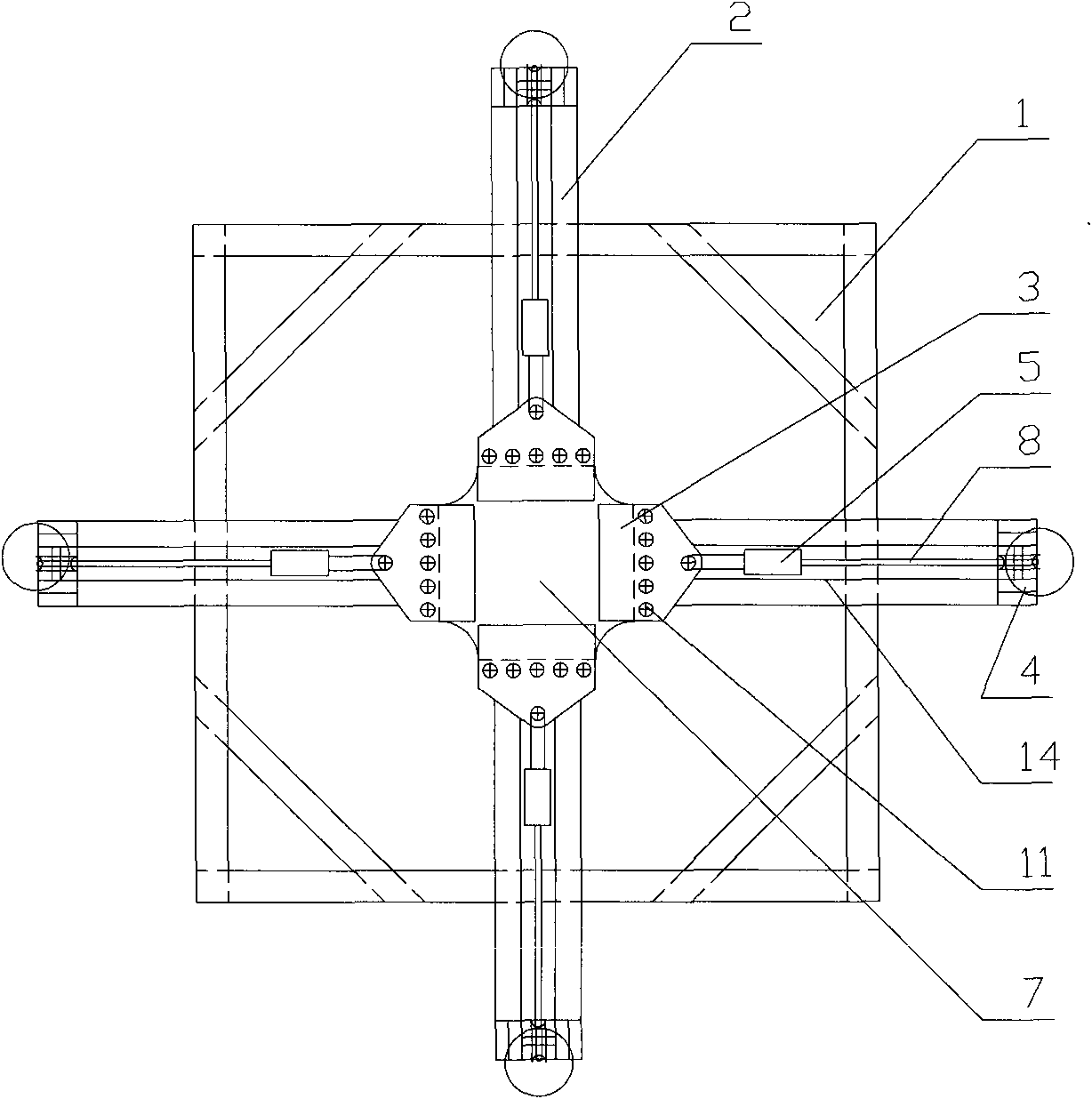

Geosynthetic biaxial tension creep tester

InactiveCN101776553ASolve the problem of long time-consuming and low efficiency of creep testImprove long-term stabilityMaterial strength using tensile/compressive forcesEngineeringGeosynthetics

The invention provides a geosynthetic biaxial tension creep tester. The tester comprises a main frame platform and a cross-shaped tensile testing device arranged on the main frame platform, wherein the cross-shaped tensile testing device comprises four groups of clamping devices, four groups of guiding devices, four groups of displacement sensors and four force-applying devices; the clamping devices are used to clamp the four edges of a test-piece placed in the middle of the cross-shaped tensile testing device and separately connected with the four force-applying devices arranged at the four ends of the cross-shaped tensile testing device through steel cables; the four groups of clamping devices can slide to the force-applying devices separately along the four groups of guiding devices; and the displacement sensors are separately arranged between the clamping devices and the force-applying devices. The geosynthetic biaxial tension creep tester of the invention can be used to perform creep test in any complex stress-strain loading path under the action of biaxial tensile loading, and compared with the easy uniaxial tension test, the creep test is more similar to the actual stress-strain state in engineers.

Owner:HOHAI UNIV

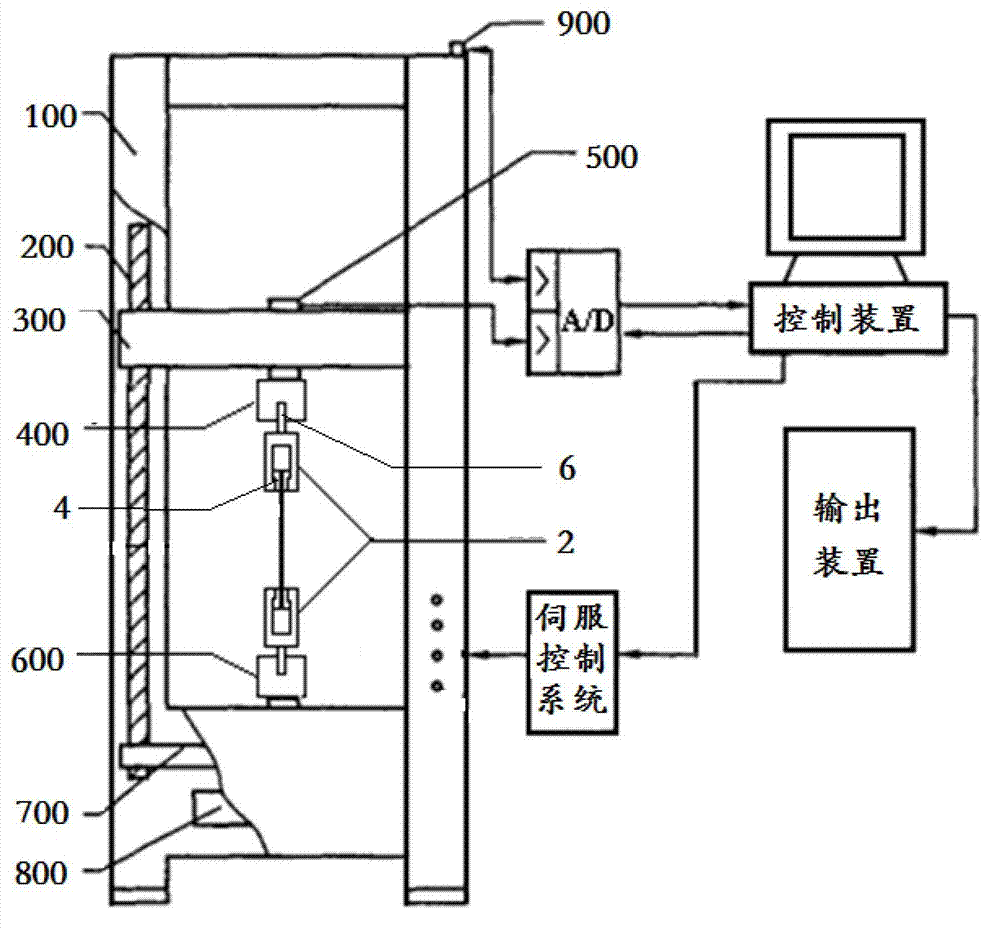

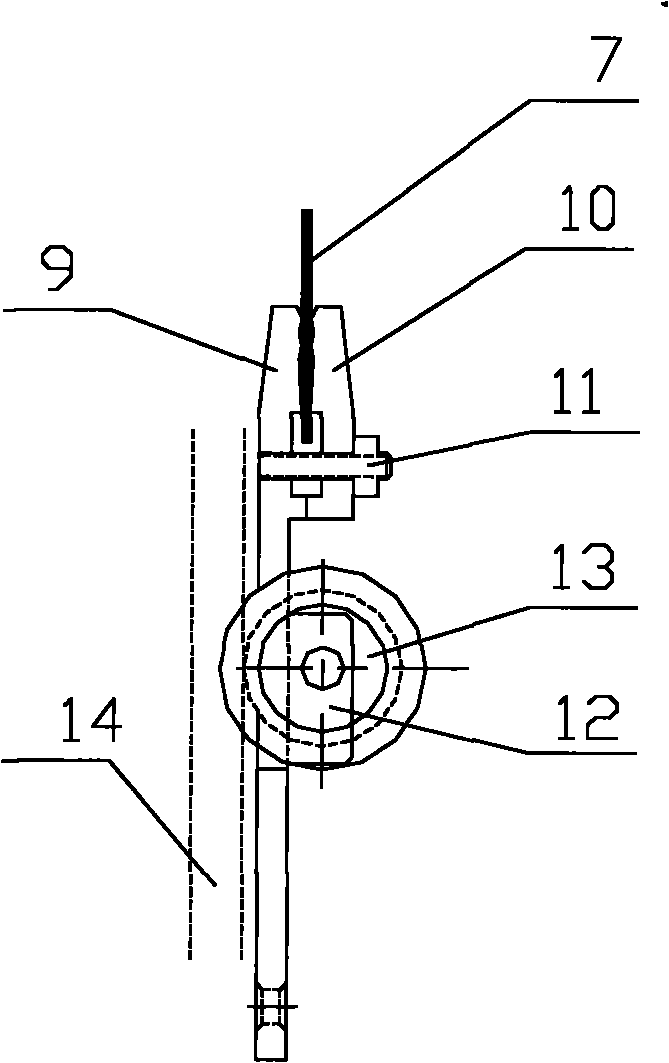

In-situ uniaxial tension observation device for mesoscale metal material

InactiveCN103575593AImprove deformationMaterial strength using tensile/compressive forcesUsing optical meansTest sampleMetallic materials

The invention relates to an in-situ uniaxial tension observation device for a mesoscale metal material. The in-situ uniaxial tension observation device comprises a mechanical part, a macro mechanical parameter test part and a micro deformation field test part, wherein a sample to be tested is clamped through a clamping module and is arranged on a supporting module; tension loads are simultaneously applied to two ends of the test sample in a transmission manner through a transmission module; microscopic equipment and an in-situ data acquisition system are used for acquiring micro structure change features of the test sample under conditions of different deformation degrees to construct a microscale deformation field feature under a condition of macro deformation; meanwhile, a force test module and a displacement test module are used for acquiring macro mechanical performance parameters under corresponding deformation conditions. Compared with the prior art, the in-situ uniaxial tension observation device has the advantages of accuracy and timeliness in in-situ data acquisition and the like.

Owner:SHANGHAI JIAO TONG UNIV

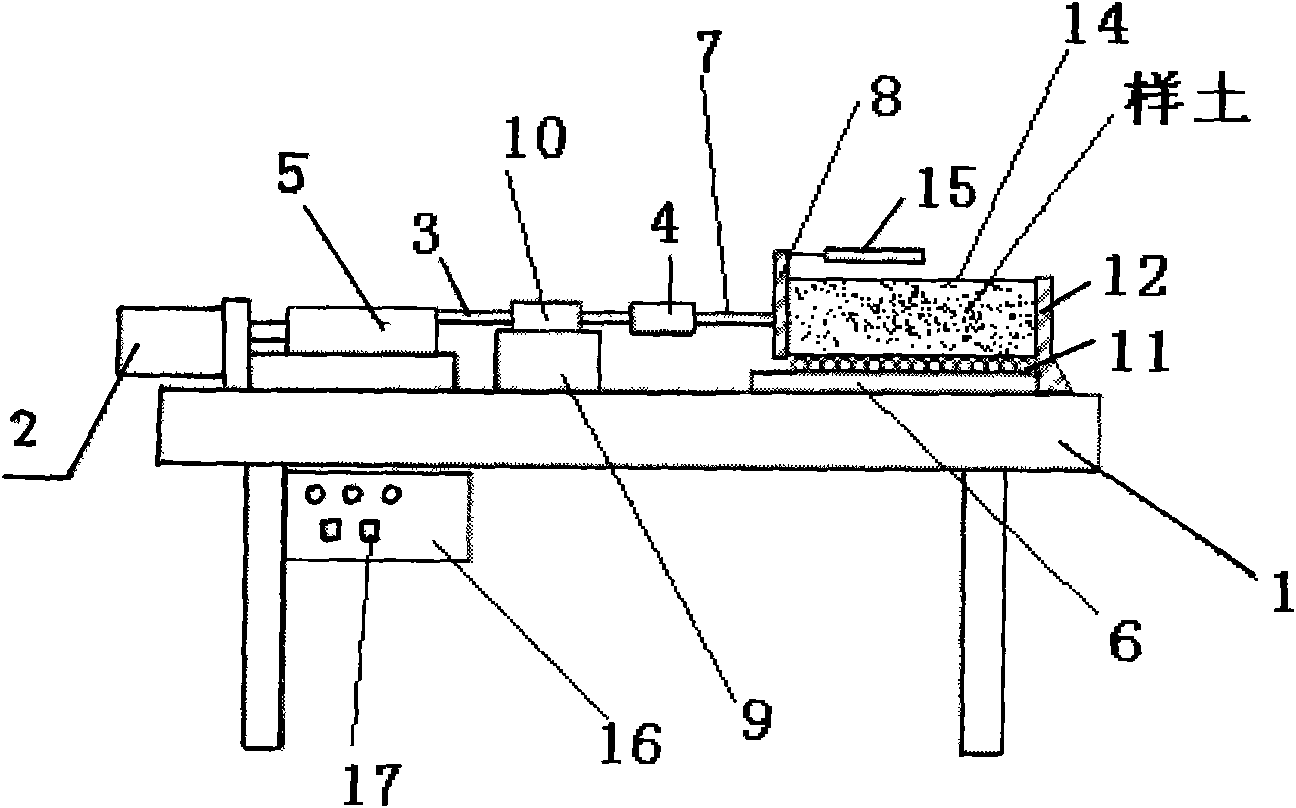

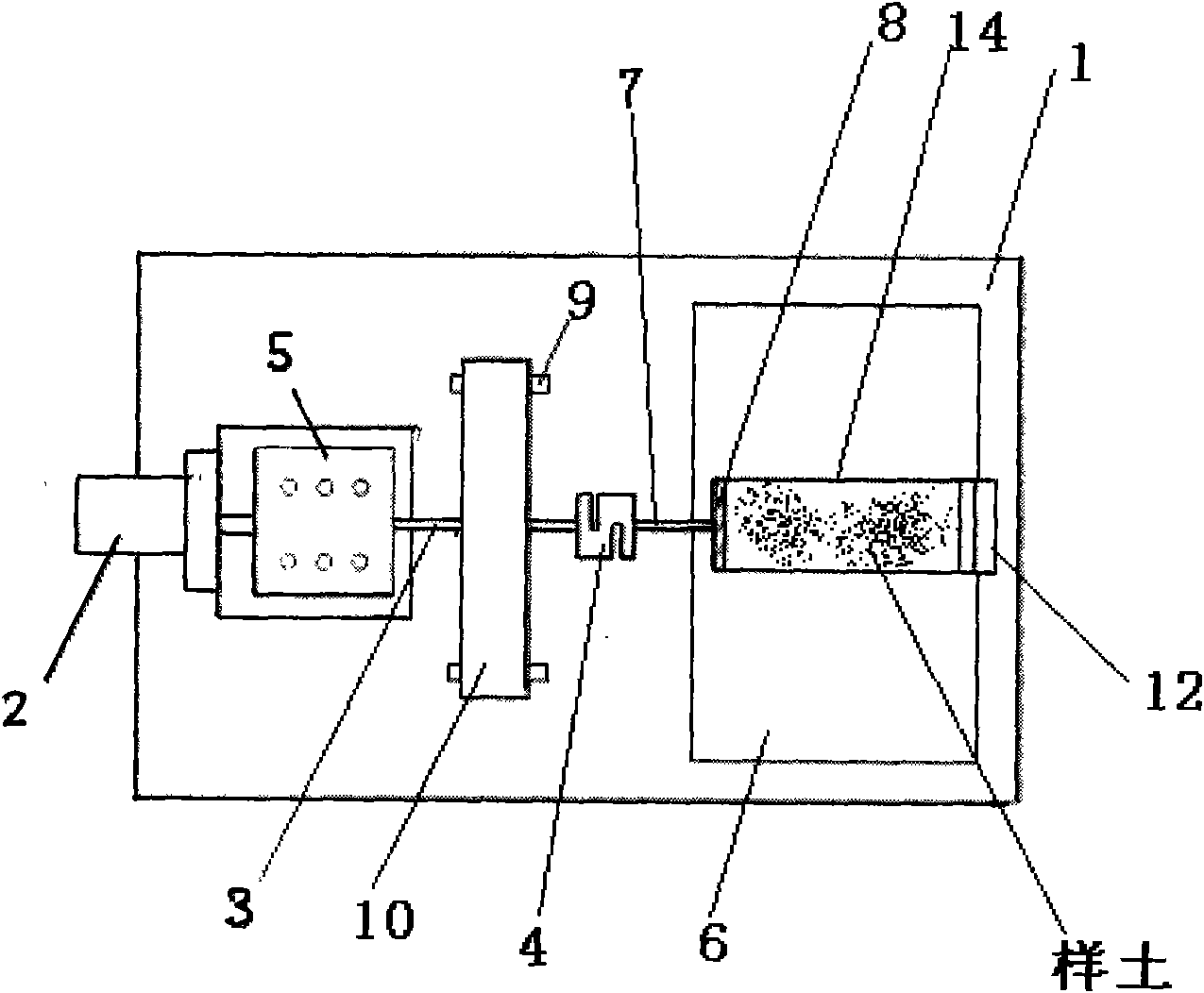

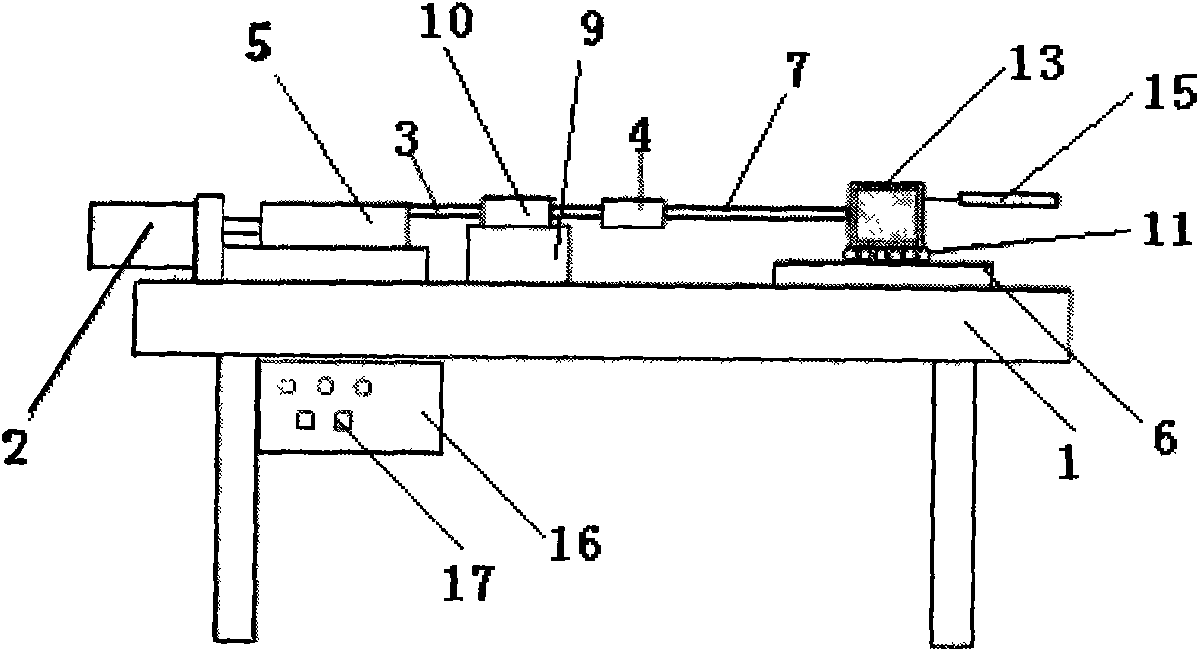

Uniaxial tension and soil beam bending tester

InactiveCN101655432AImprove utilization efficiencyEliminate the effects of self-weightMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesData acquisitionElectric machinery

A uniaxial tension and soil beam bending tester comprises a motor; one side of the motor is provided with an electric shifting platform; the motor is connected with a rigid transmission bar; the rigidtransmission bar is connected with a slide rail guide block; the slide rail guide block is connected with the rigid transmission bar; the rigid transmission bar is provided with a force sensor; the rigid transmission bar is connected with a loading unit arranged on a loading platform; a shift sensor is fixed on a primary platform; the shift sensor, the force sensor and a data collection card areconnected; soil body is fixed on the loading unit; velocity is set; the motor is used for driving the electric shifting platform; the slide rail guide block drives the soil body on the loading platform to perform the test; the data collection card collects and stores measurement values via the shift sensor and the force sensor; and the invention has the characteristics of low cost, stable loading,slow loading speed, settable and controllable velocity.

Owner:TSINGHUA UNIV

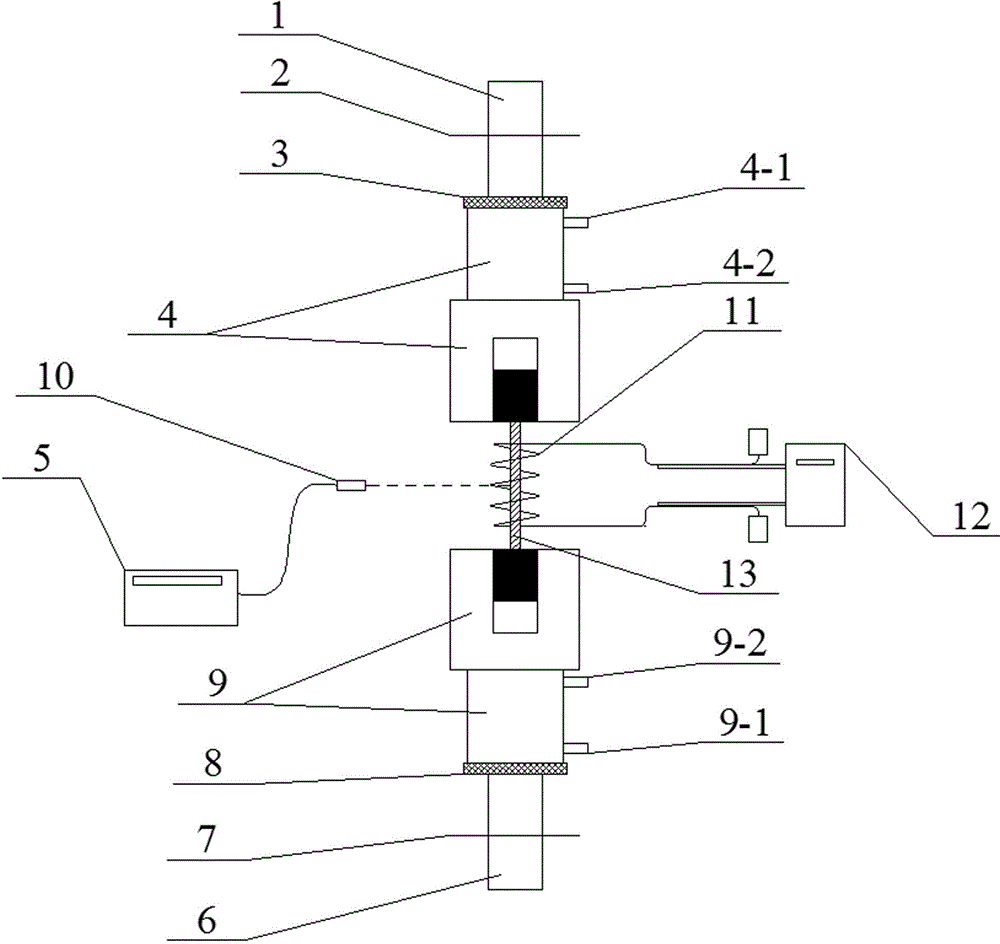

Device for testing uniaxial tension mechanical property of conducting material under high temperature environment

InactiveCN104865137AReduce volumeEasy to makeMaterial strength using tensile/compressive forcesElectrical conductorEngineering

The invention discloses a device for testing the uniaxial tension mechanical property of a conducting material under high temperature environment, and belongs to the technical field of material mechanical property testing. According to the device, an induction coil is wound by a copper pipe; an upper insulating tension bar is connected with the upper end surface of an upper clamp through an upper insulating spacer; a lower insulating tension bar is connected with the lower end surface of a lower clamp through a lower insulating spacer; when the upper end of a test piece to be tested is clamped at the lower end of the upper clamp, and the lower end of the test piece to be tested is clamped at the upper end of the lower clamp, the induction coil sleeves the outer side of the test piece to be tested at intervals, and the two ends of the induction coil are respectively connected with two high-frequency driving output ends of an induction heating system controller; the temperature testing end of a temperature testing probe remotely tests the temperature of the test piece to be tested; the temperature signal output end of the temperature testing probe is connected with the temperature signal input end of the induction heating system controller. The device adopts induction heating, is small in size of the induction coil, simple to manufacture, is connected with the heating system controller through a bolt, and is convenient to disassemble and relatively quick in temperature rise.

Owner:HARBIN INST OF TECH

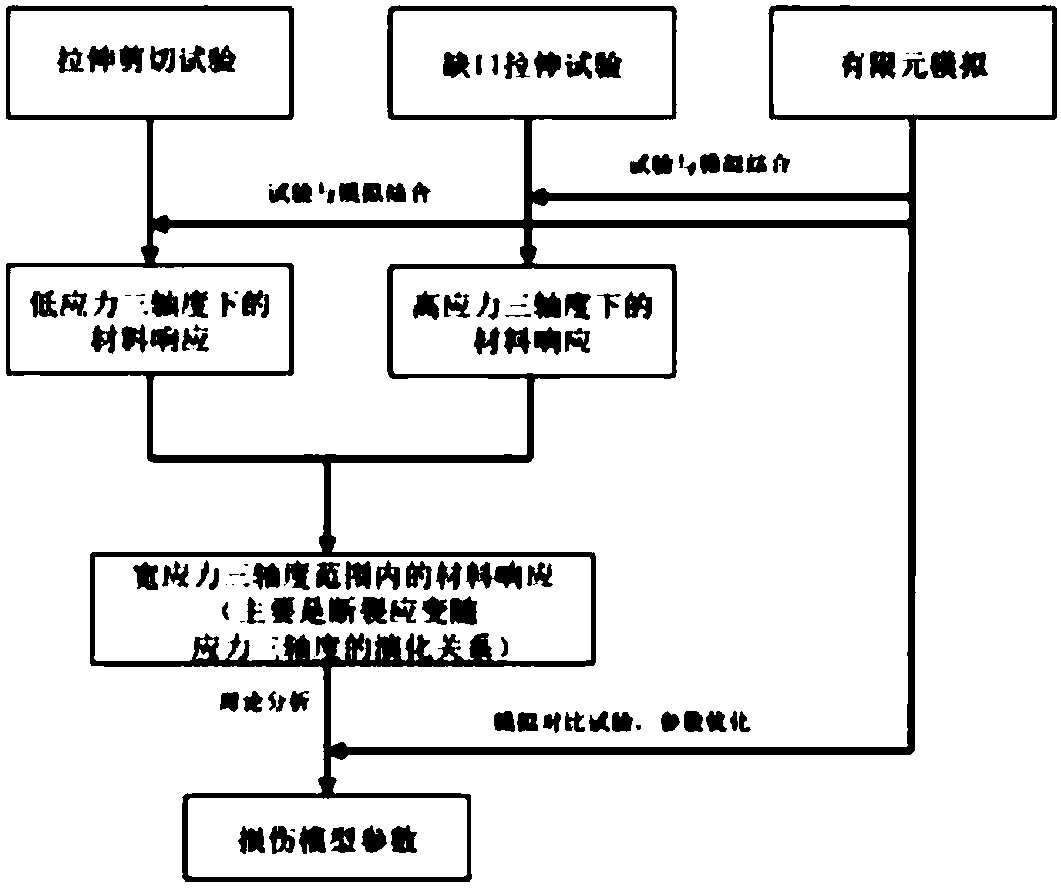

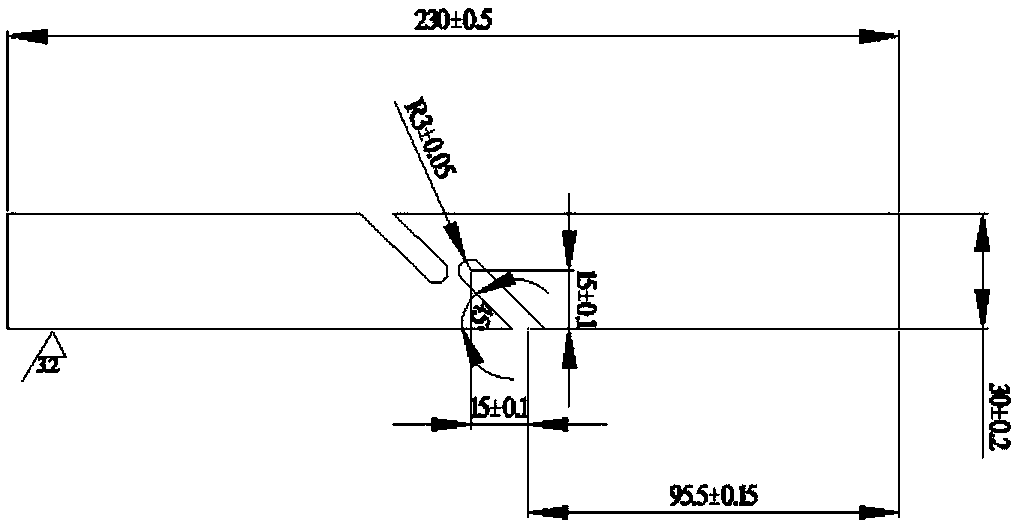

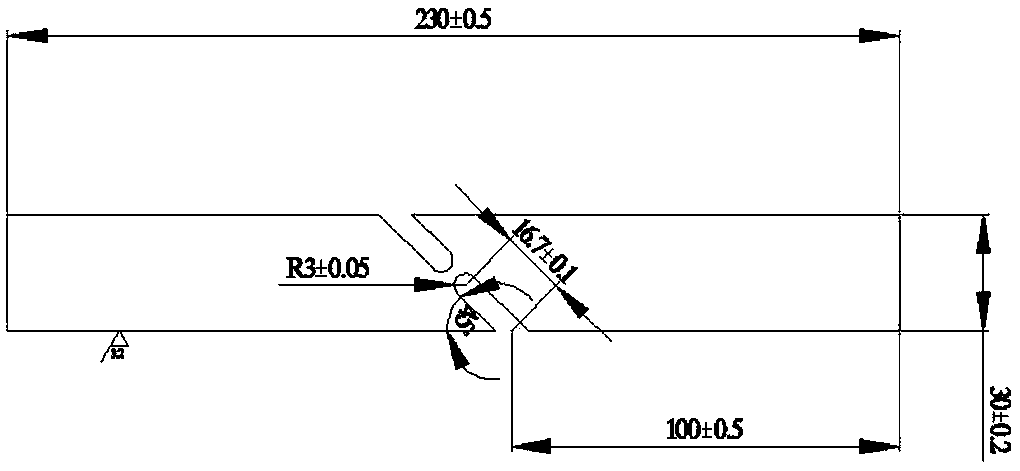

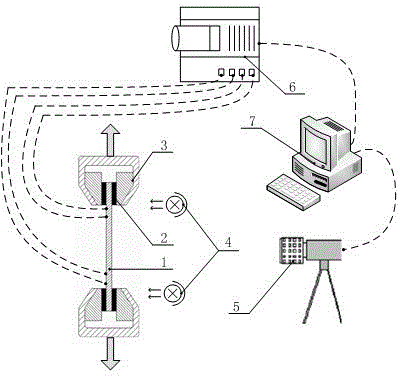

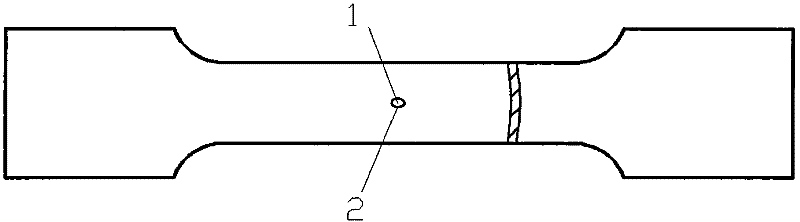

Damage model parameter calibration method based on tensile shear and notch tension tests

InactiveCN107655768AImprove calibration accuracyPrevent buildupDesign optimisation/simulationMaterial strength using steady shearing forcesShear stressStress–strain curve

The invention relates to the field of damage model parameter calibration and discloses a damage model parameter calibration method based on tensile shear and notch tension tests. The method includes:using a special-shaped tensile shear sample to convert uniaxial tensile load into pure shear load, and acquiring the shear stress-strain curve of a material under low stress triaxiality; using the notch tension test to convert uniaxial tension into triaxial tension, and acquiring the triaxial tension stress-strain curve of the material under high stress triaxiality; using full-size finite elementsimulation to acquire the precise stress-strain curve of the material in a wide stress triaxiality range and the evolutionary relationship of the fracture strain along with the stress triaxiality to provide a test foundation for damage model parameter calibration. By the method, workload can be reduced, and parameter calibration precision can be increased greatly.

Owner:CRRC QINGDAO SIFANG CO LTD

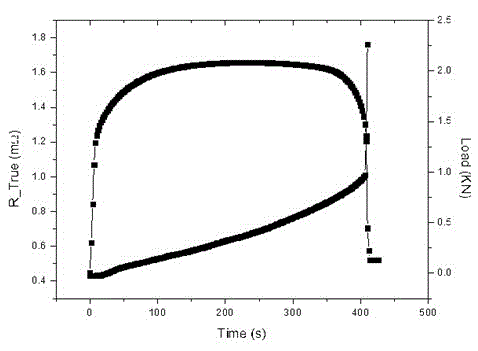

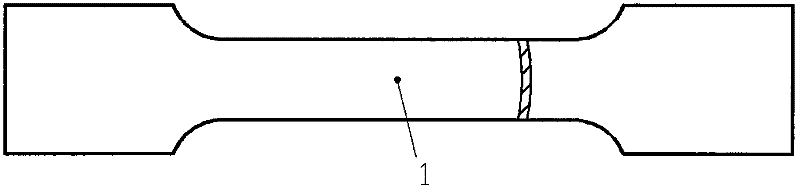

Device and method for measuring toughness damage evolution in process of metal uniaxial tension

ActiveCN103149086AEasy to buildOvercome the disadvantage of being unable to handle non-uniform strainStrength propertiesElectrical resistance and conductanceEvolution rule

The invention discloses a device and a method for measuring toughness damage evolution in process of metal uniaxial tension. The method includes a first step of utilizing a camera and a direct-current low-resistance tester to simultaneously record images and resistance of a sample in the stretching process, wherein the sample is sprayed with random free speckles, a second step of obtaining a strain field of the sample in the stretching process through a digital image correlation DIC) method, and a third step of combining strain increment and resistance increment of the sample in the stretching process to indirectly obtain a damage evolution rule in the stretching process.

Owner:SOUTH CHINA UNIV OF TECH

Uniaxial tension sample holder capable of testing in-situ stress and electrical property for transmission electron microscope

InactiveCN102353580AIn situ mechanicsRealize electrical comprehensive performance testStrength propertiesMicroscope slideConventional transmission electron microscope

A uniaxial tension sample holder capable of testing in-situ stress and electrical property for a transmission electron microscope belongs to the researching fields of transmission electron microscope fitting and nano-material in-situ measurement. A prior art can realize stress signal reading during material deformation, but has strict requirements on a sample and only suits for a none-dimensionalnano-material like a nano wire or a nanotube, or a sample prepared by focused ion beam cutting; besides the prior art can not realize electrical property measurement under a stress state. The sample holder comprises a self-design transmission electron microscope sample holder, a deformation microscope slide, a sample head and compressing tablets. The deformation microscope slide is fixed on the sample head through the compressing tablets; a circuit used for measuring cantilever beam minimal deformation and a circuit used for measuring sample electrical signals of the deformation microscope slide are connected to electrodes on two sides of the sample head and connected to external testing equipment through a lead in the sample holder, so as to realize real time monitoring on the stress and the electrical signals.

Owner:BEIJING UNIV OF TECH

Test sample and method for testing performance parameters of pipe under complex stress state

ActiveCN102410957AFit plane stress-strain propertiesLarge strain rangeMaterial strength using tensile/compressive forcesTest performanceAxial compression

The invention relates to a test sample and method for testing performance parameters of a pipe under the complex stress state. A common uniaxial tension arc-shaped test sample is processed into an arc-shaped test sample with an elliptical hole. The center line of a long shaft of the elliptical hole is in superposition with a center line in the length direction of the uniaxial tension arc-shaped test sample; and the center of the circle of the elliptical hole is in superposition with the center of the shape of the arc-shaped tension test sample with the elliptical hole. Two sections of pipe compressed test samples are cut out along the axial direction of the pipe to be tested. The verticality of the cross section of each pipe compressed test sample to the axial line of the pipe is 0.08-0.1, and the degree of roughness of the cross section of each pipe compressed test sample is 0.8-0.2. The tension testing is performed on the arc-shaped tension test sample with the elliptical hole, the axial compression testing is performed on the pipe compressed test samples, the lateral compression testing is performed on the pipe compressed test samples and reverse engineering is further performed on obtained force-displacement data, thereby testing the performance parameters of the pipe under the complex stress state.By adopting the whole set of test sample for testing the performance parameters of the pipe under the complex stress state and the testing method, the testing precision and the efficiency of the performance parameters of the pipe are improved.

Owner:JIANGSU NEW HENGJI SPECIAL EQUIP

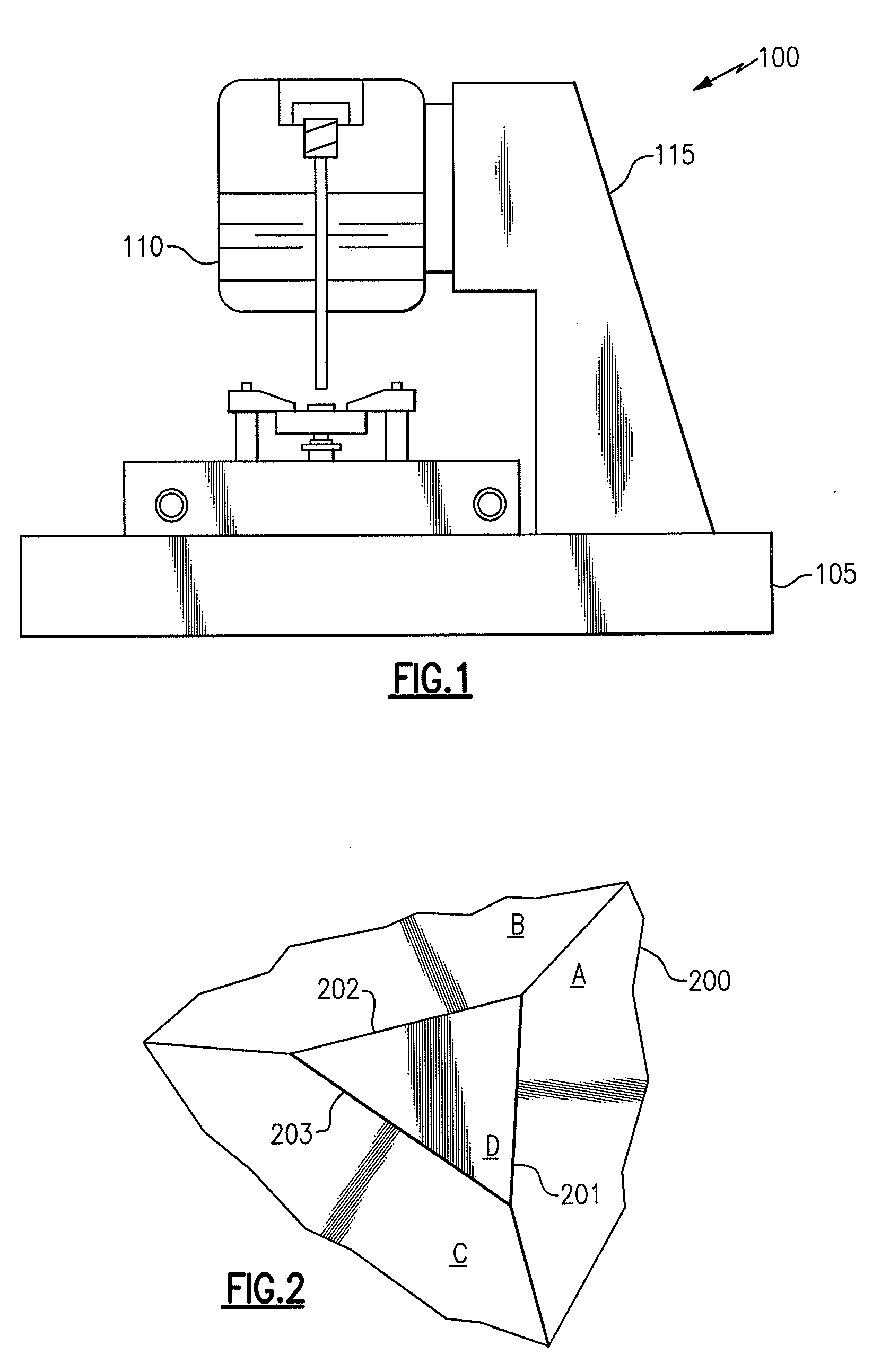

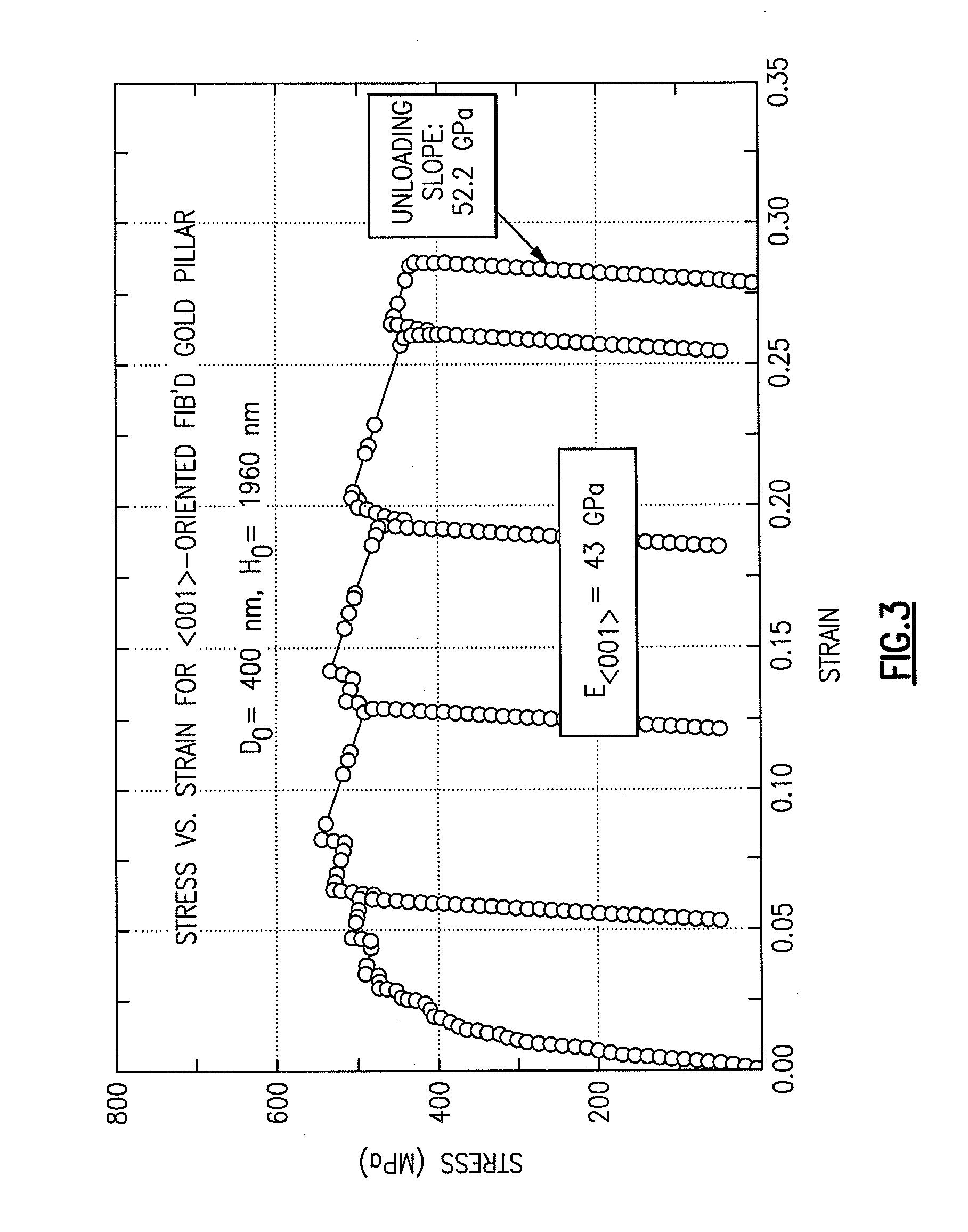

Nanoindenter tip for uniaxial tension and compression testing

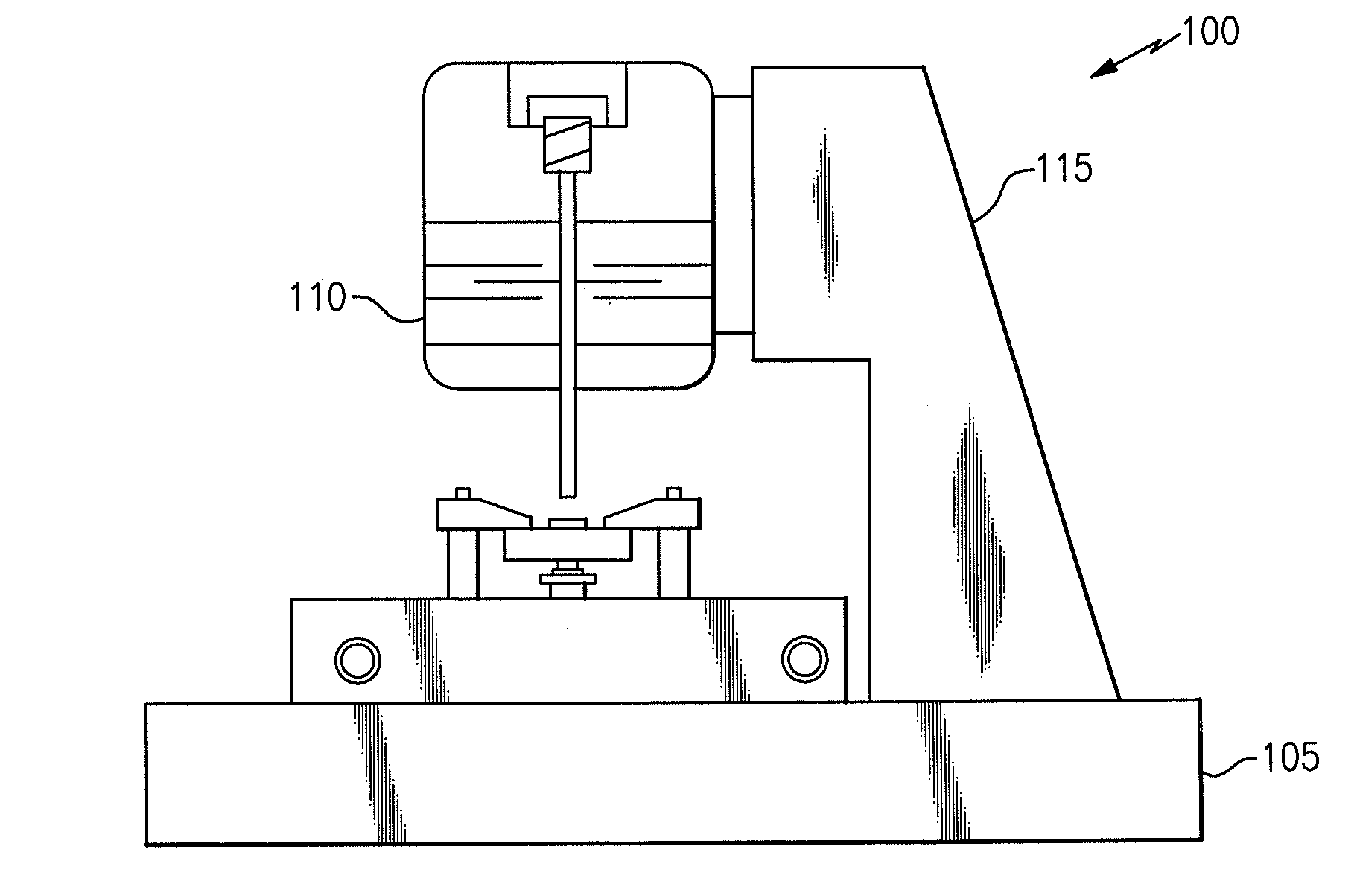

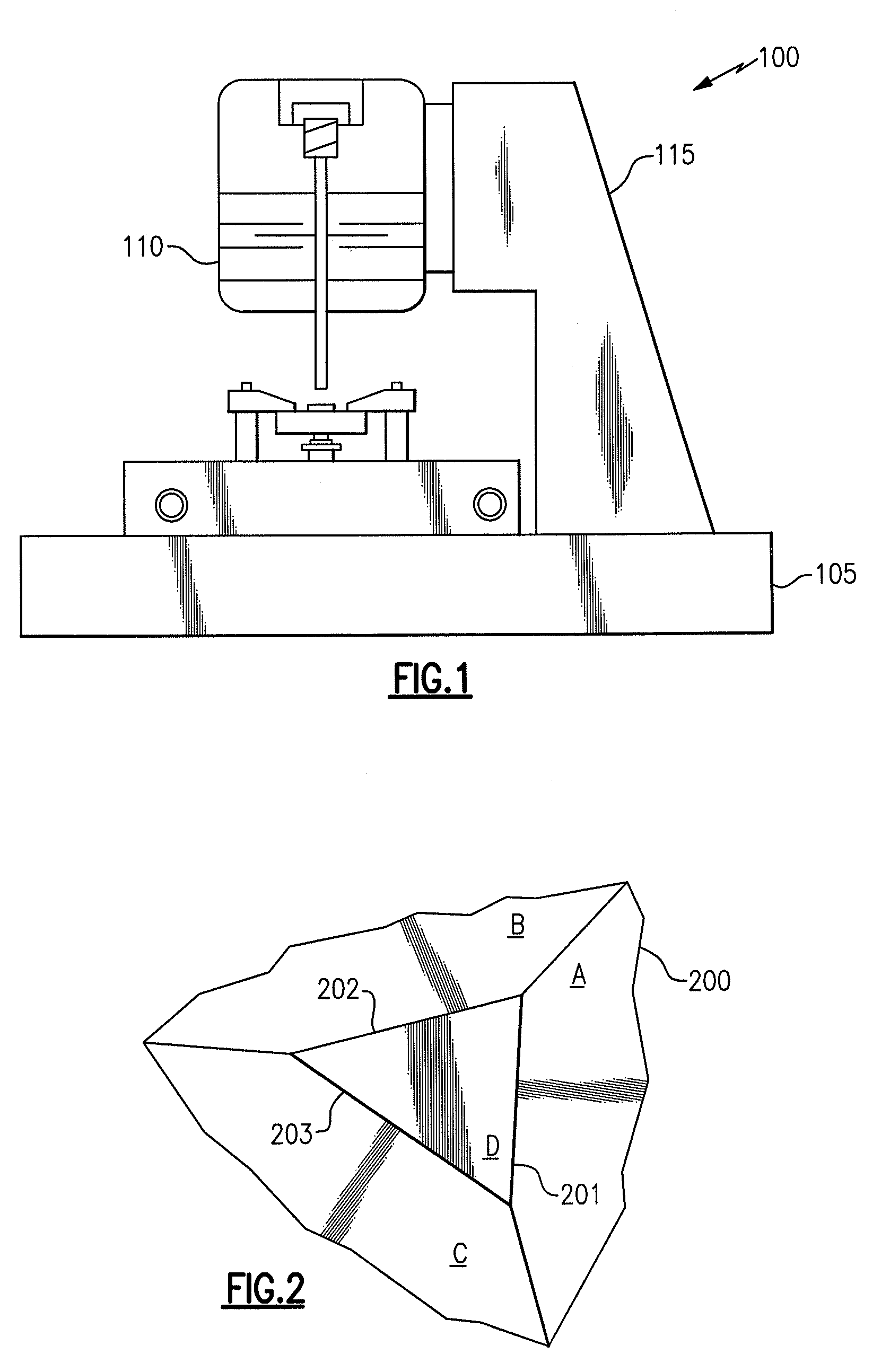

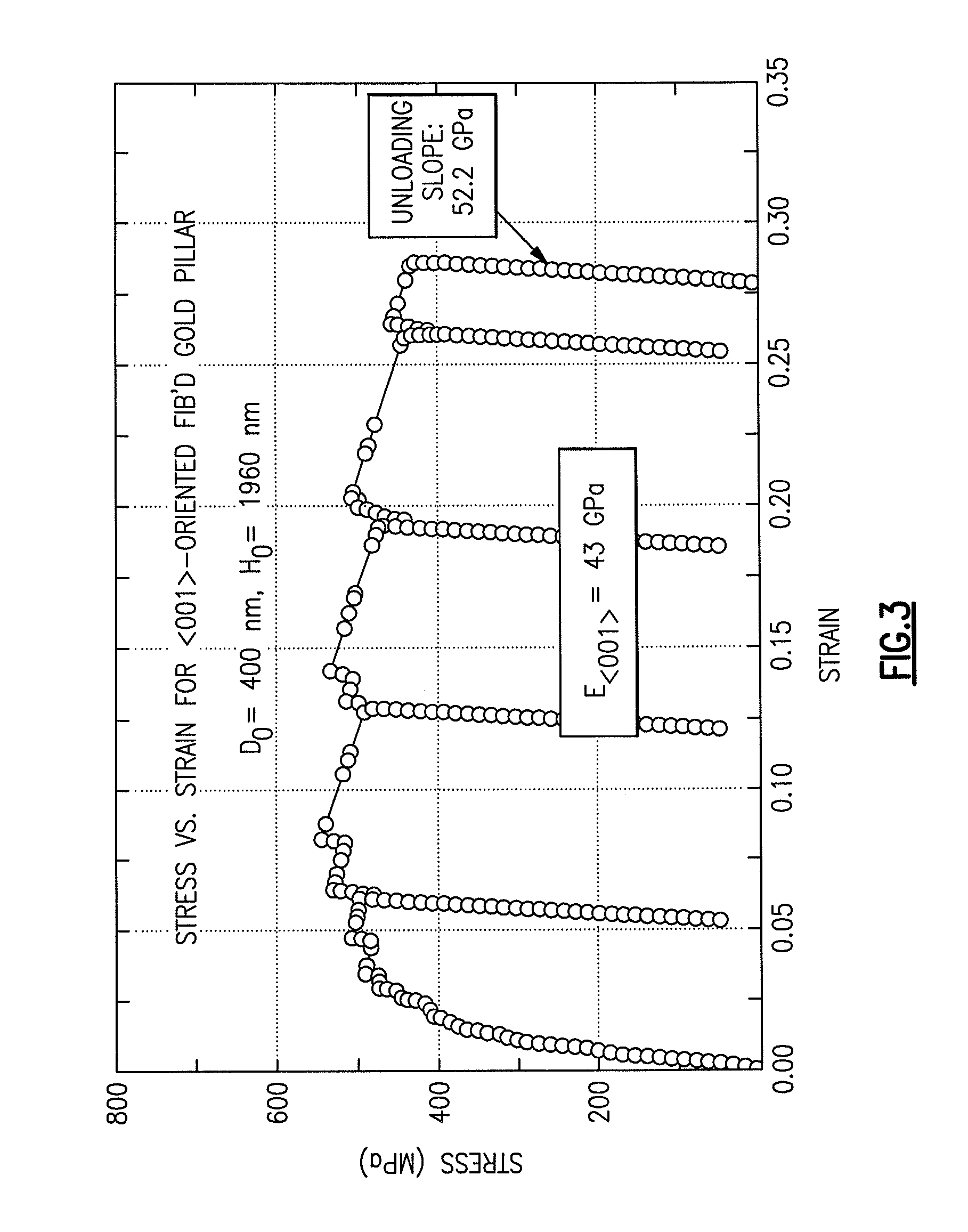

InactiveUS20100281963A1Force measurementMaterial strength using tensile/compressive forcesScanning tunneling microscopeScanning electron microscope

The invention is an indenter tip that is modified to permit both compression testing and tensile testing on samples having dimensions smaller than approximately 1 μm. The modified indenter tip has both a surface that can be used to apply compressive forces, and tines that can be used to engage a free end of a specimen to be tested in tension. The apparatus used to perform the tests includes elements of a scanning electron microscope that permit visualization of the specimen to be tested and the modified indenter tip, so as to permit appropriate alignment and engagement of the same. The apparatus also includes elements of a microindenter that provide mechanical manipulation of the relative position and orientation of the modified indenter tip and of the specimen to be tested, as well as the necessary controls and instrumentation to perform the test and to collect, record and manipulate data.

Owner:CALIFORNIA INST OF TECH

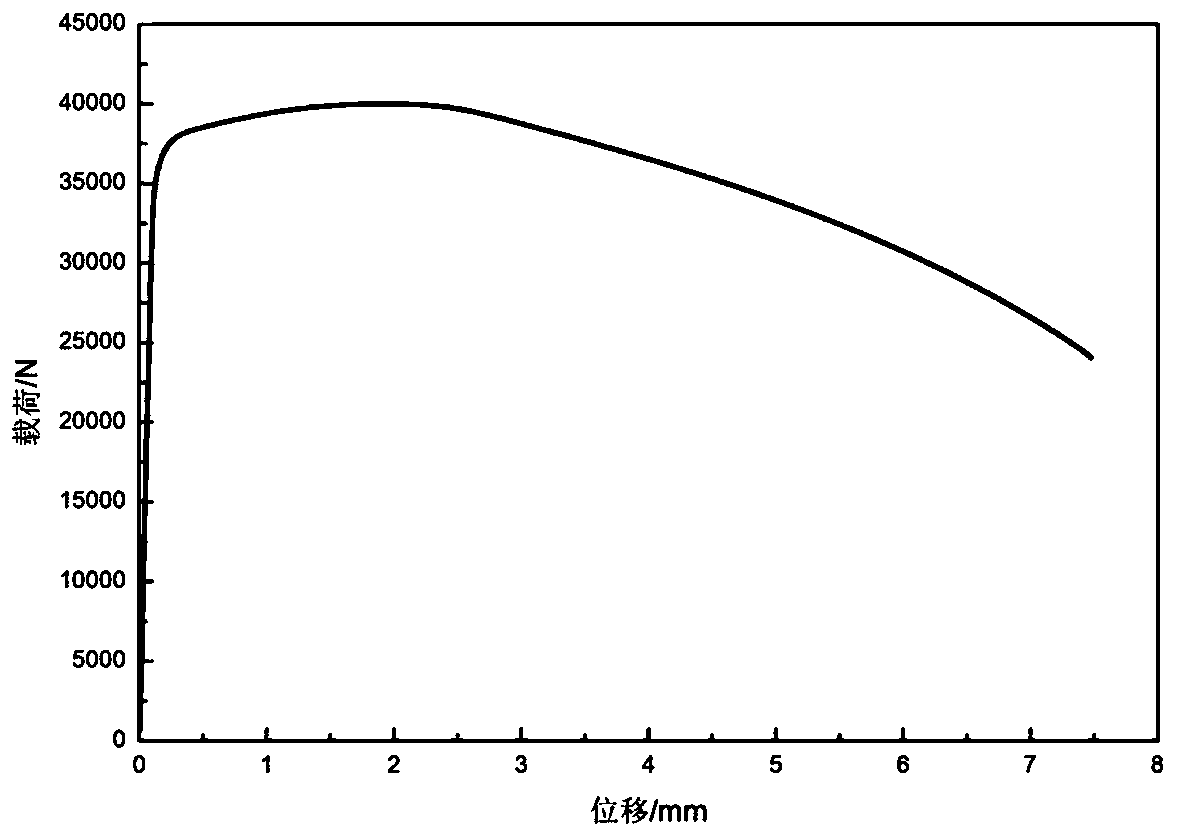

Method for measuring uniaxial tension large-strain-range hardening curve of metal round bar specimen

InactiveCN109883825AReduce demandEliminate cumbersome measurement linksMechanical diameter measurementsMaterial strength using tensile/compressive forcesMetallic materialsModel parameters

The invention discloses a method for measuring a uniaxial tension large-strain-range hardening curve of a metal round bar specimen, and belongs to the field of mechanical property testing of metal materials. The method only needs to perform the following steps of: measuring the radius of the cross section of a round bar tension specimen, calculating the stress strain value at the time of fracture,and fitting the stress strain values before necking and at the time of fracture by adopting a hardening model to determine an initial value of hardening model parameters; and then, generating a plurality of hardening parameter combinations by adopting an experimental design method, inputting hardening curves determined by the parameters into finite element software for tension simulation, outputting the corresponding simulated load displacement curves, calculating the sum of the absolute area differences between the simulated and experimental load displacement curves, constructing a responsesurface model by taking the value as the response and the hardening parameters as independent variables, taking the minimization of a response surface function as an optimization objective, optimizingan objective function by adopting a quadratic programming method, and determining that an optimal solution is a large-strain-range hardening curve of an experimental material. The scheme of the invention has the advantages of small calculation amount and high measurement accuracy.

Owner:JILIN UNIV

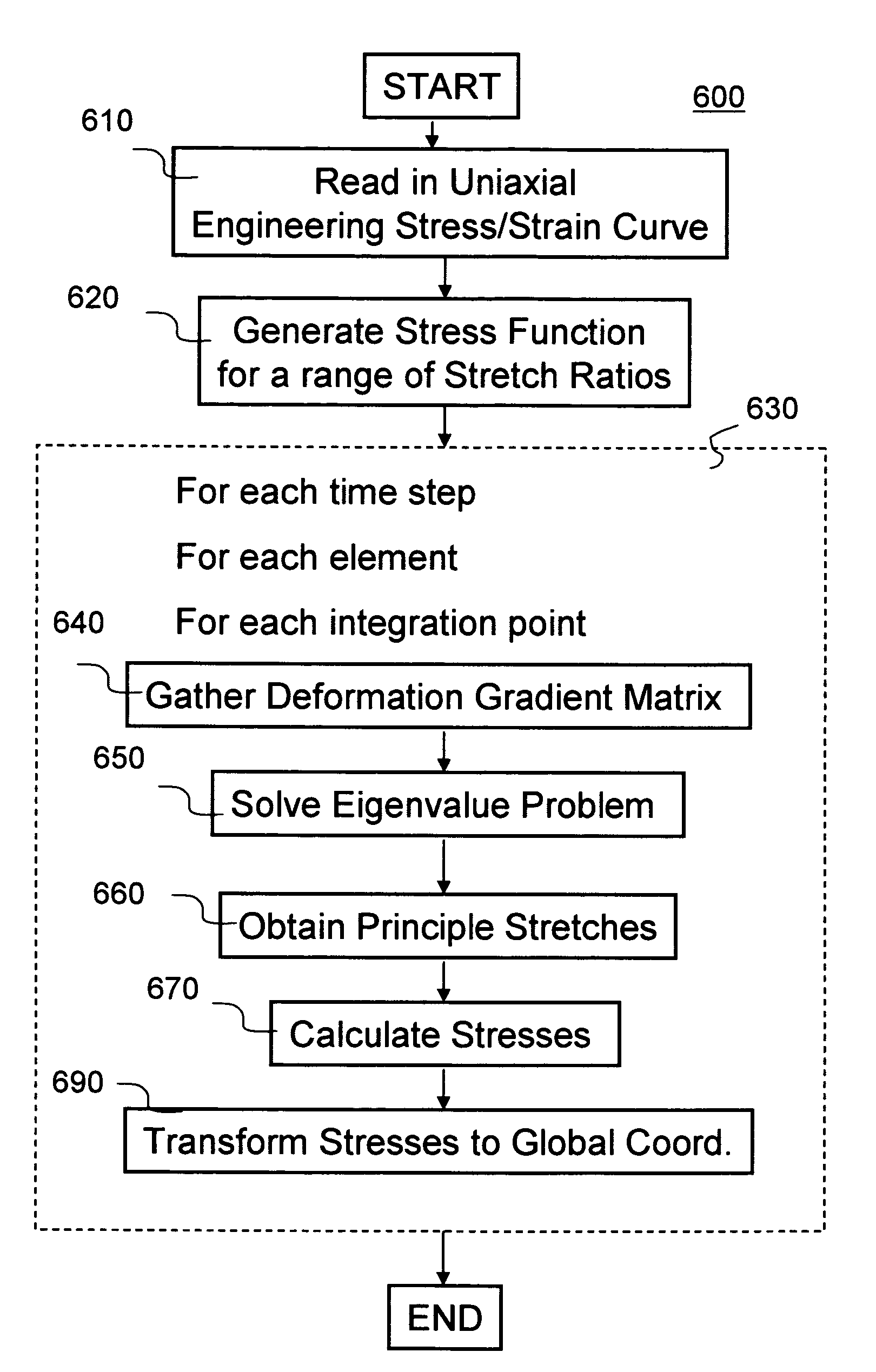

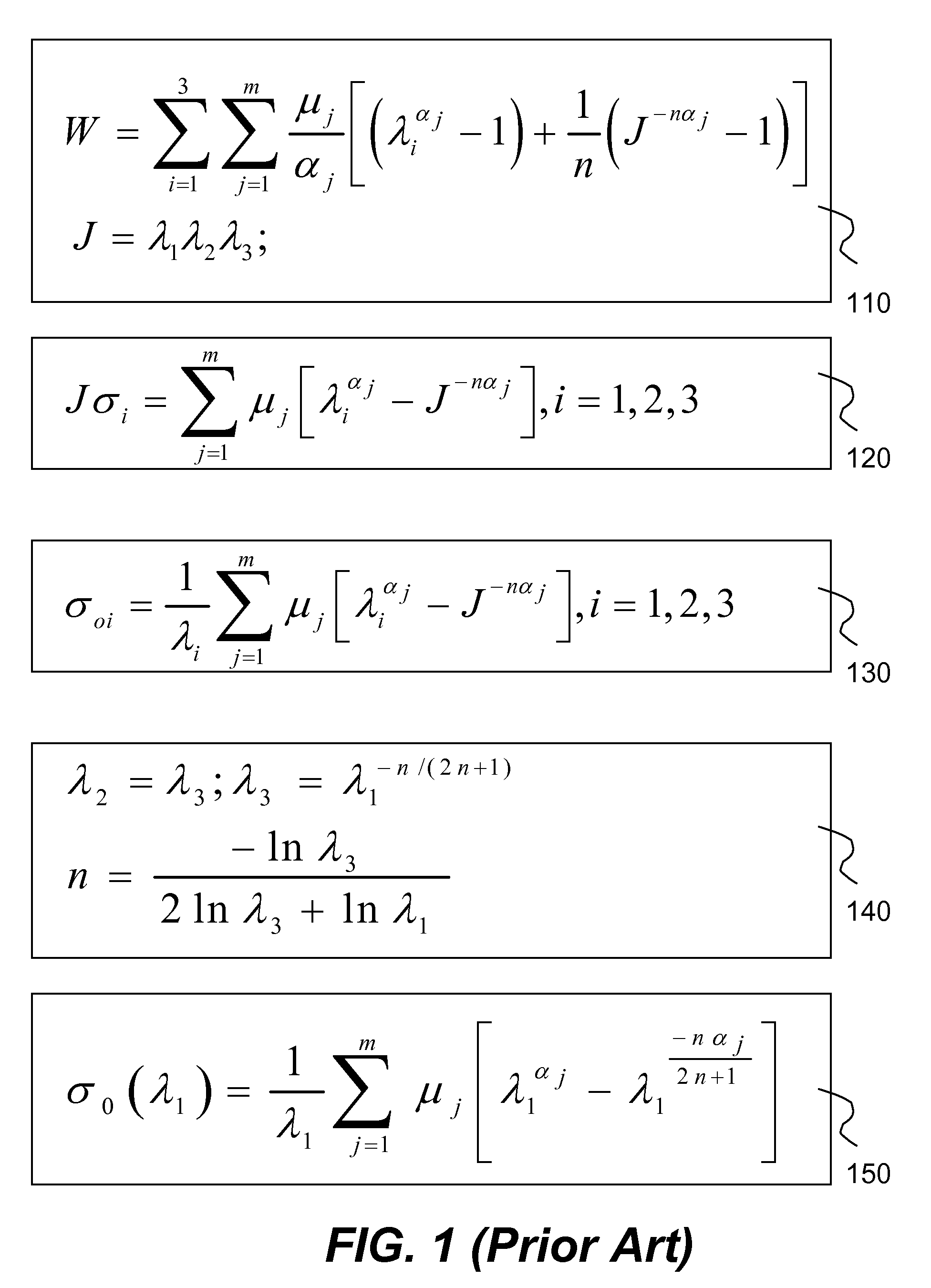

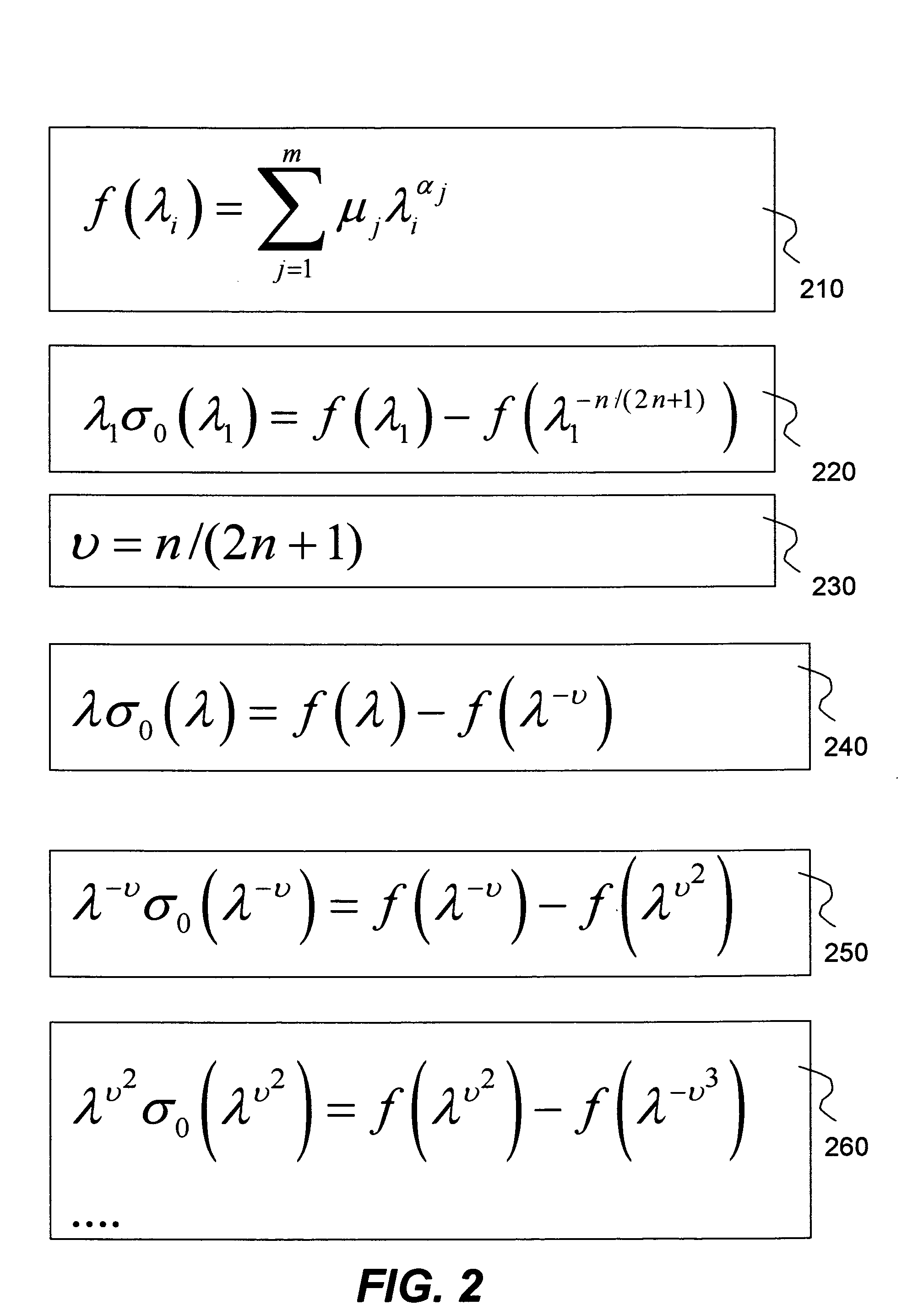

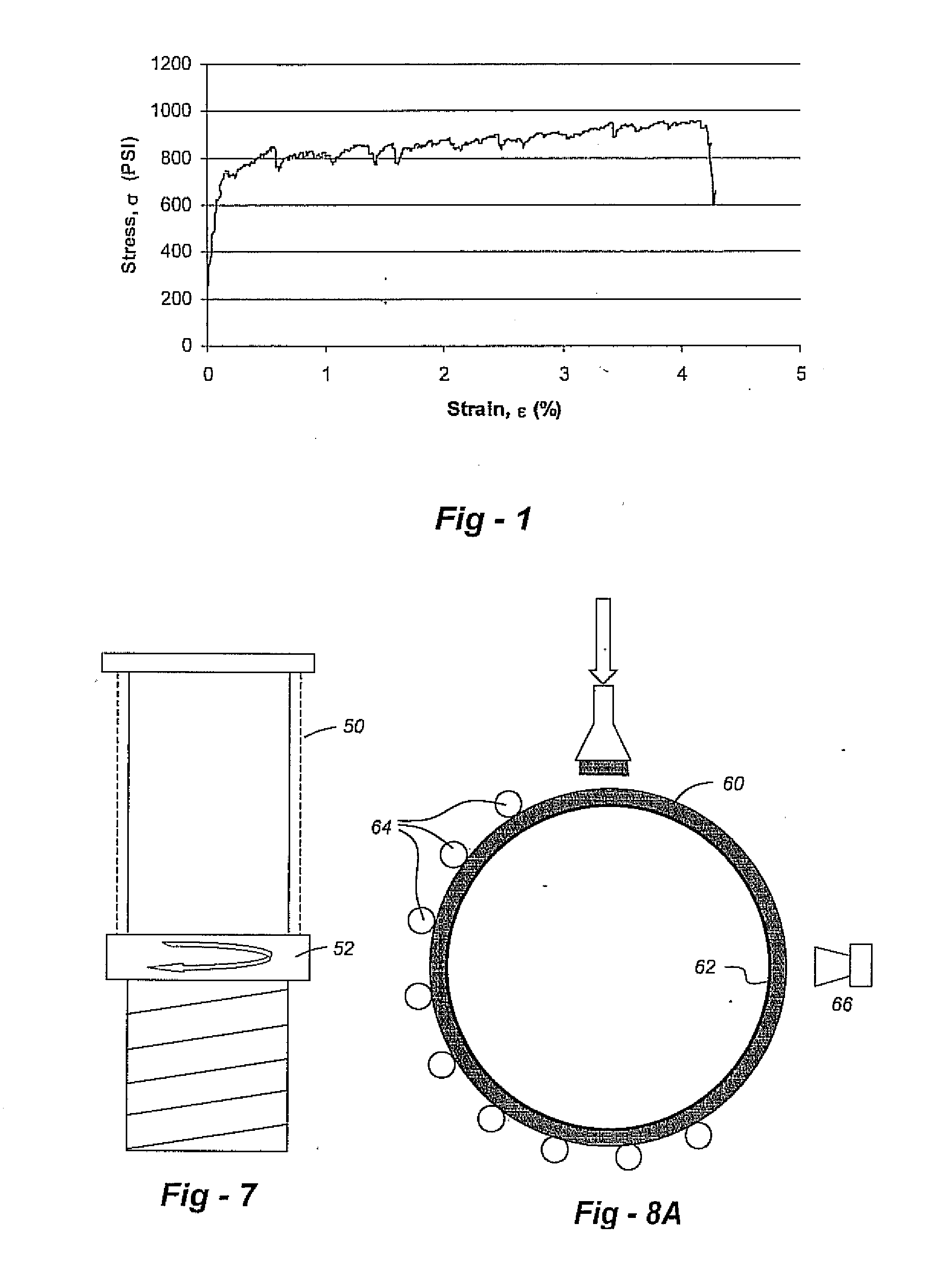

Method and system for numerically simulating foam-like material in finite element analysis

ActiveUS7308387B1High materialEliminate requirementsDesign optimisation/simulationSpecial data processing applicationsCompressible materialBi-isotropic material

A method and system to numerically simulating structural responses of a highly compressible material such as foam in finite element analysis is disclosed. According to one aspect of the simulation, a new improved method for calculating structural responses is derived using the following assumptions: uniaxial loading and isotropic material. As a result of the new method, Ogden polynomial stress function f(λ) is replaced by a tabulated function depending upon only a set of stress-strain curves obtained via uniaxial tension and compression tests. The method is implemented in a finite element analysis software product.

Owner:ANSYS

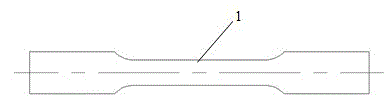

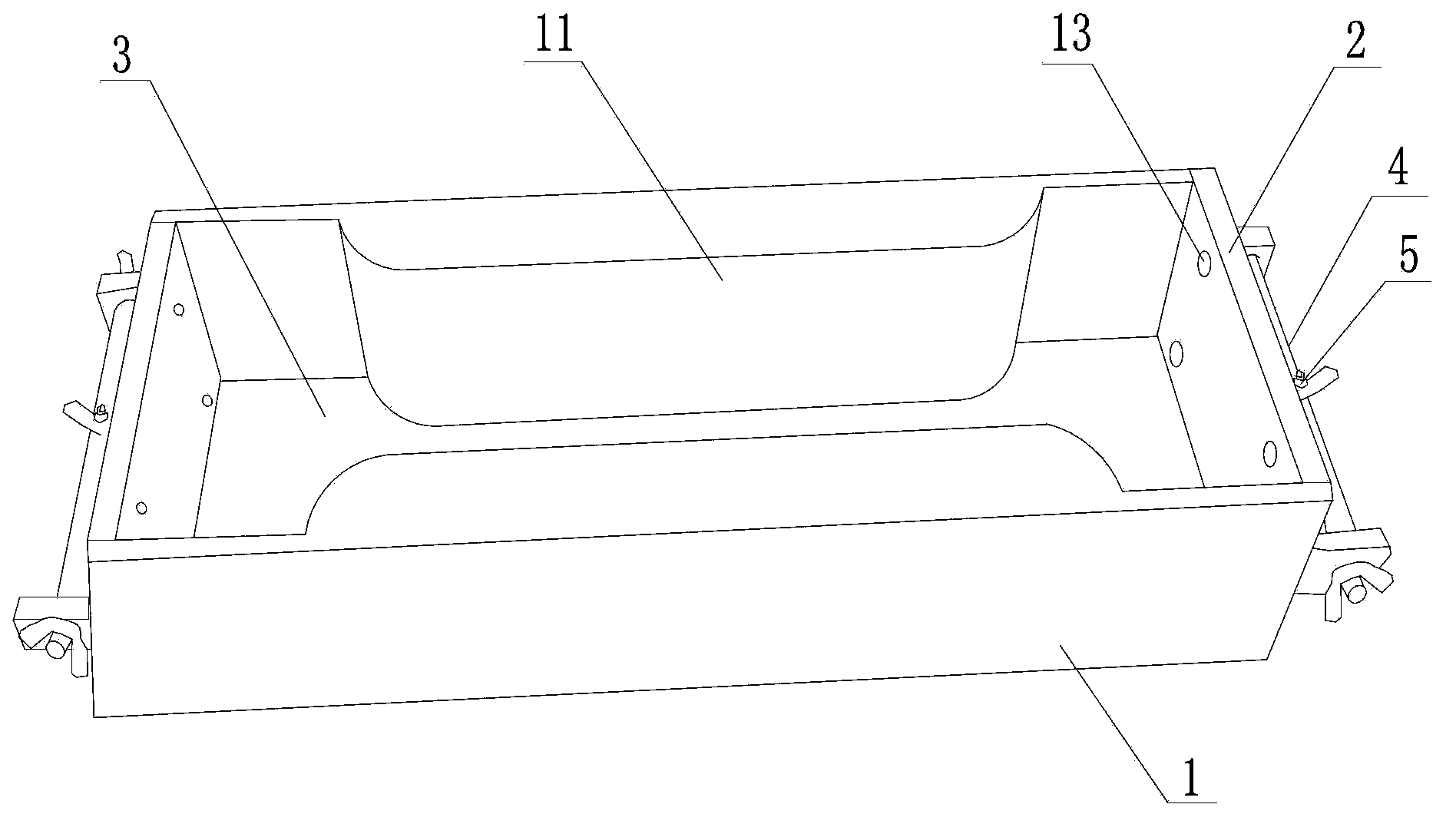

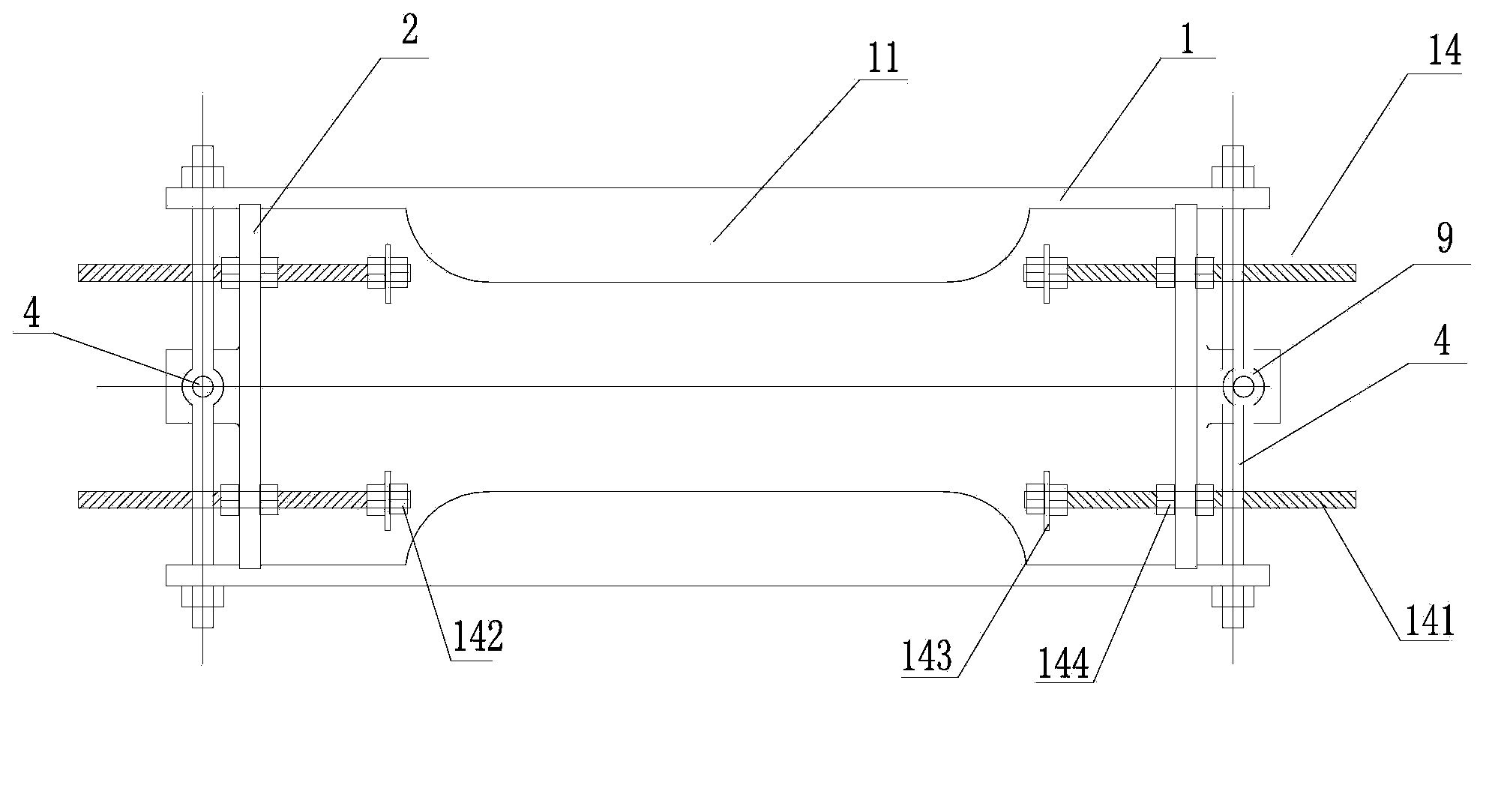

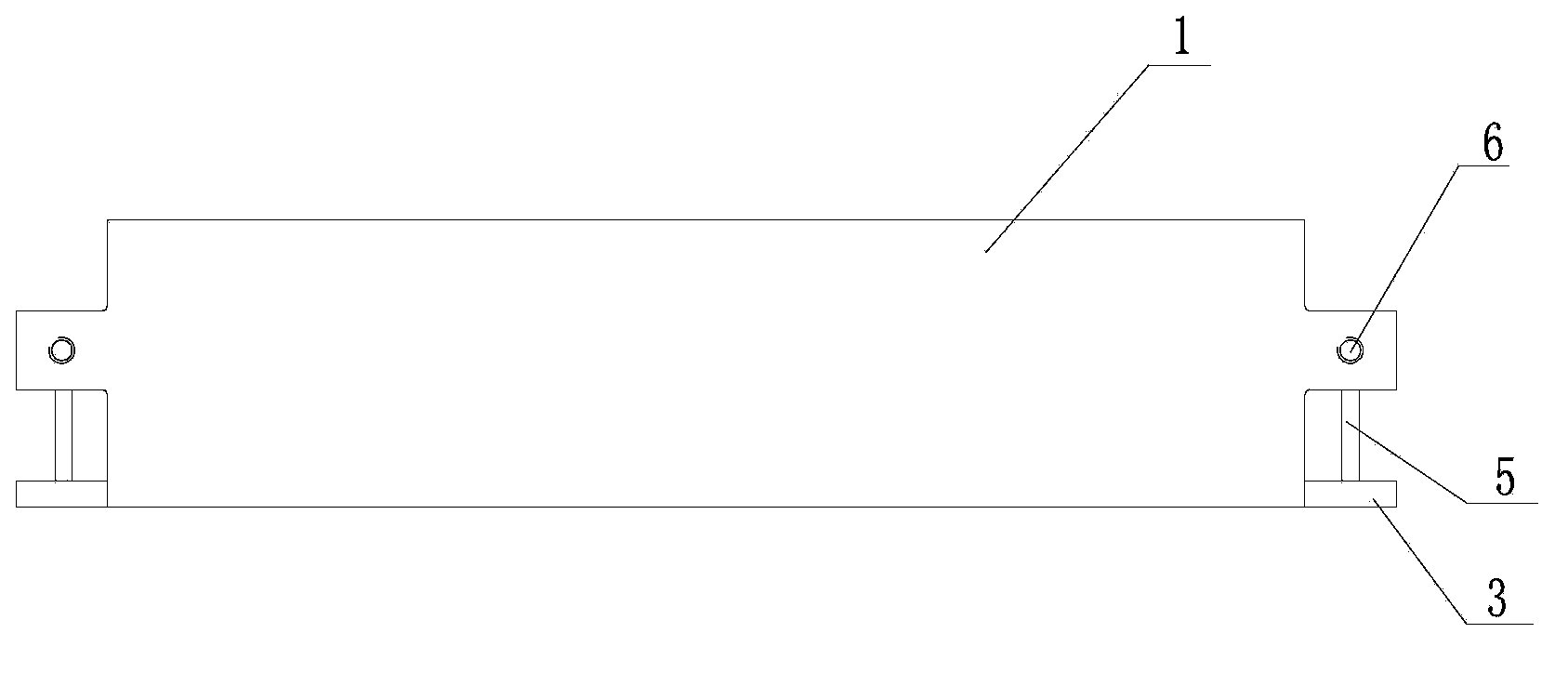

Mold for concrete axial tension test piece and rod piece pre-embedding method by using the mold

ActiveCN104236964AImprove verticalitySimplify the embedding processPreparing sample for investigationEngineeringPre embedding

The invention relates to a test mold, and particularly relates to a dumbbell-shaped mold used for concrete uniaxial tension test, and a rod piece pre-embedding method. The mold for the concrete axial tension test piece comprises a bottom plate. Two opposite sides of the bottom plate are fixedly connected with side plates; the other two opposite sides of the bottom plate are provided with end part plates; the bottom plate, the side plates and the end part plates are combined to form a hollow box with the top opening; the opposite sides of the two side plates are convex at the middle parts to form lug bosses; two sides of each side plate are provided with insert holes protruding out of the planes of the end part plates; a horizontal rod is connected between the directly opposite insert holes of the two side plates; a through hole I is formed in the middle of the horizontal rod; a vertical rod penetrates through the through hole and then is inserted in a fixed hole arranged in the bottom plate; the end part plates are limited by the horizontal rod and the vertical rod; a through hole II is formed in each end part plate respectively; and pre-embedding pieces are inserted into the through holes II. The manufacturing precision of the test piece is high and a flow for manufacturing the test piece is simple.

Owner:青岛理正建设科技有限公司

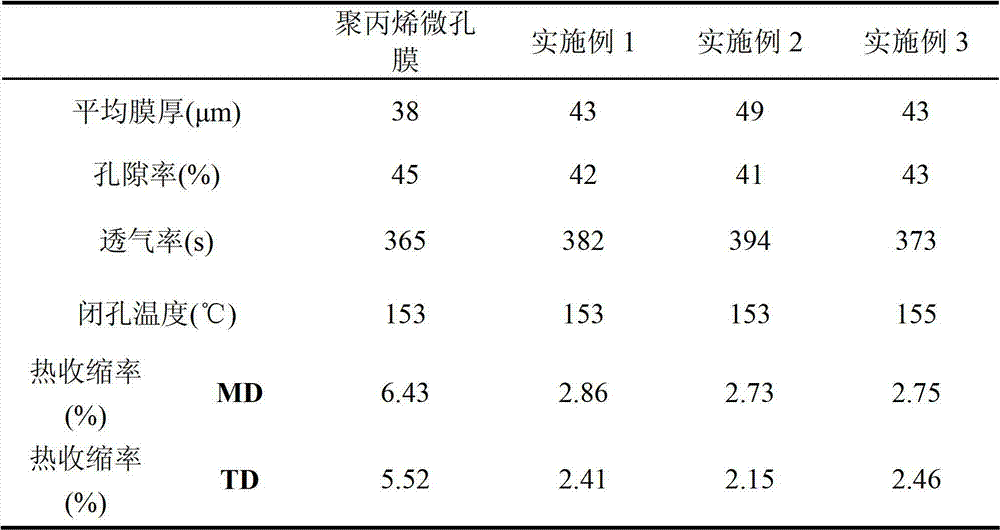

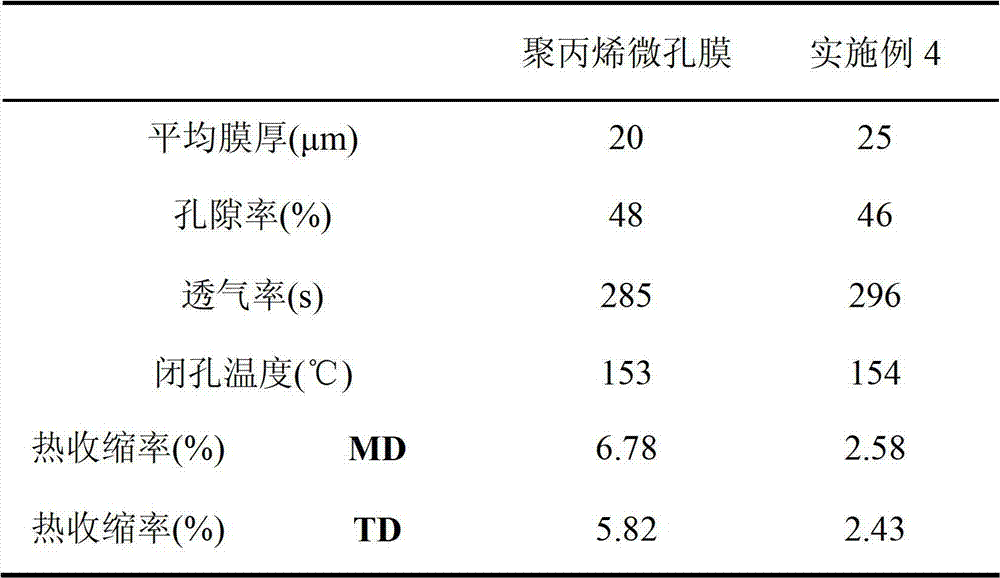

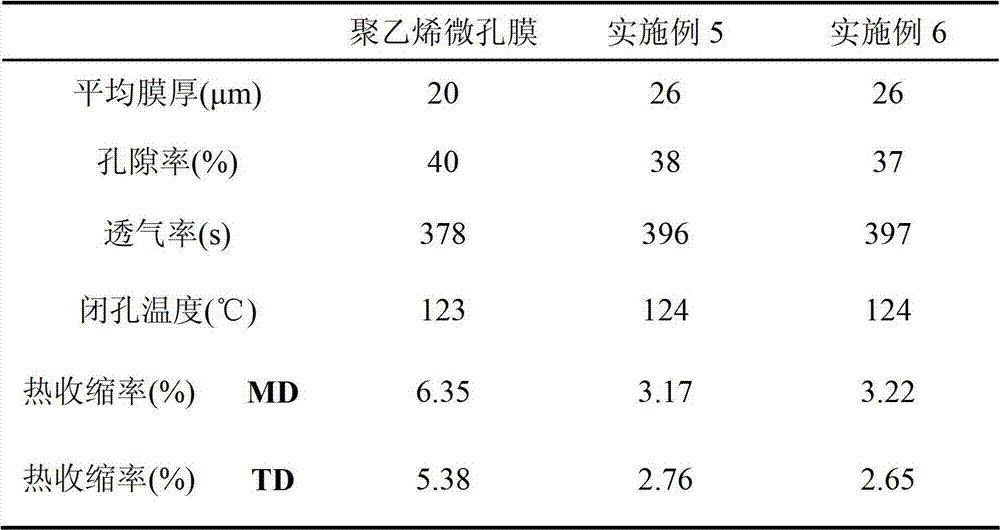

Lithium ion battery membrane with porous composite coating and preparation method thereof

The invention provides a polyolefin membrane with a porous composite coating and a preparation method of the polyolefin membrane. The polyolefin membrane with the porous composite coating comprises a microporous polyolefin membrane prepared by a uniaxial tension process and a porous composite coating with good heat-resistant quality, wherein the porous composite coating is formed on at least one surface of the microporous polyolefin membrane. The porous composite coating is formed from the mixture of a modified carbon nano tube and an organic polymer. The mixture is scattered and dissolved in an organic solution to form coating liquid. The coating liquid is coated on the surface of the microporous membrane and then is subjected to rapid vacuum drying to form the porous composite coating. The prepared polyolefin membrane with the porous composite coating has the characteristics of high porosity, high gas transmission rate, high thermal contraction distortion temperature and excellent heat resistance and dimensional stability, and is suitable for a high-capacity lithium battery.

Owner:扬州市永佳车辆配件有限公司

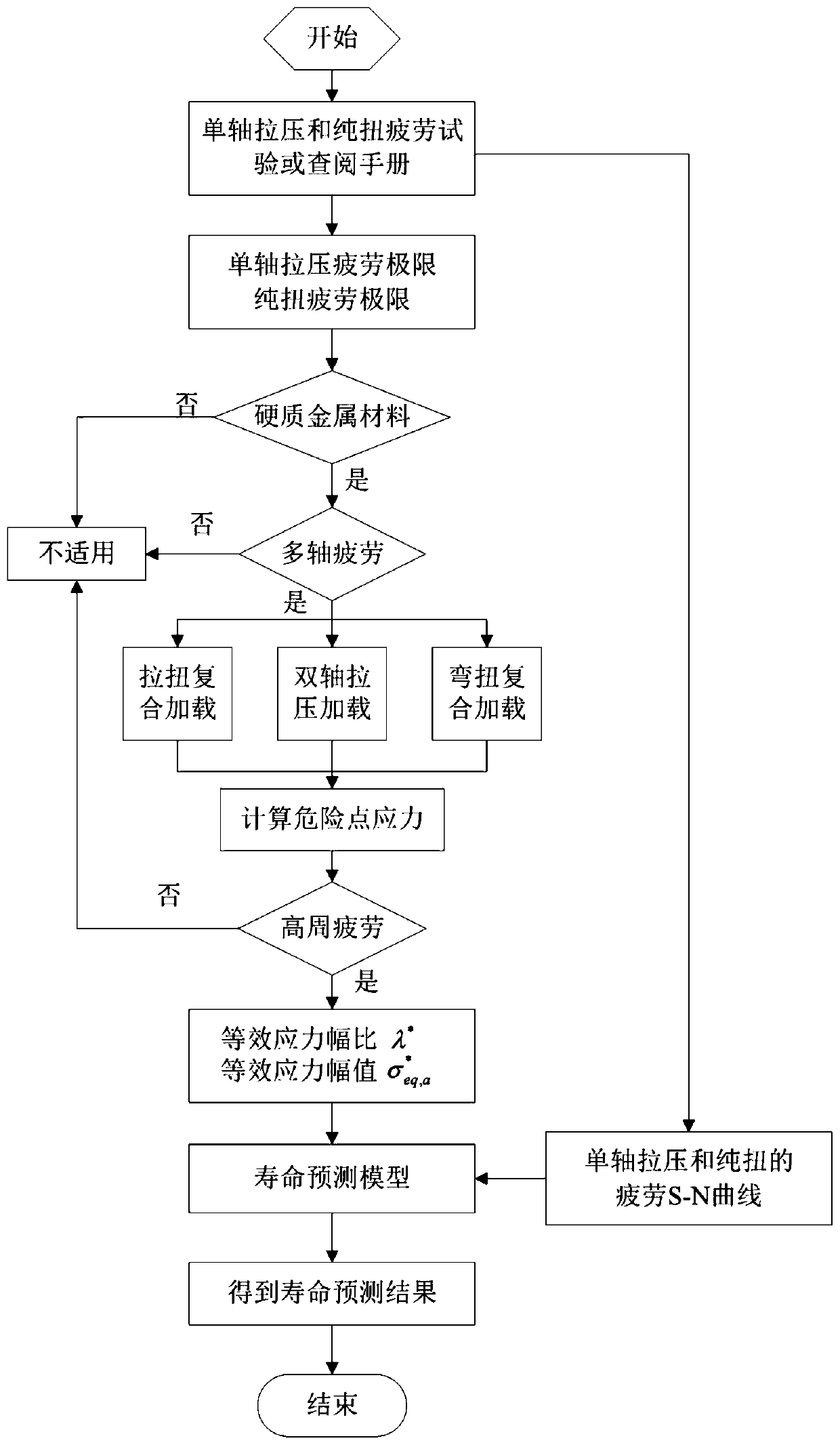

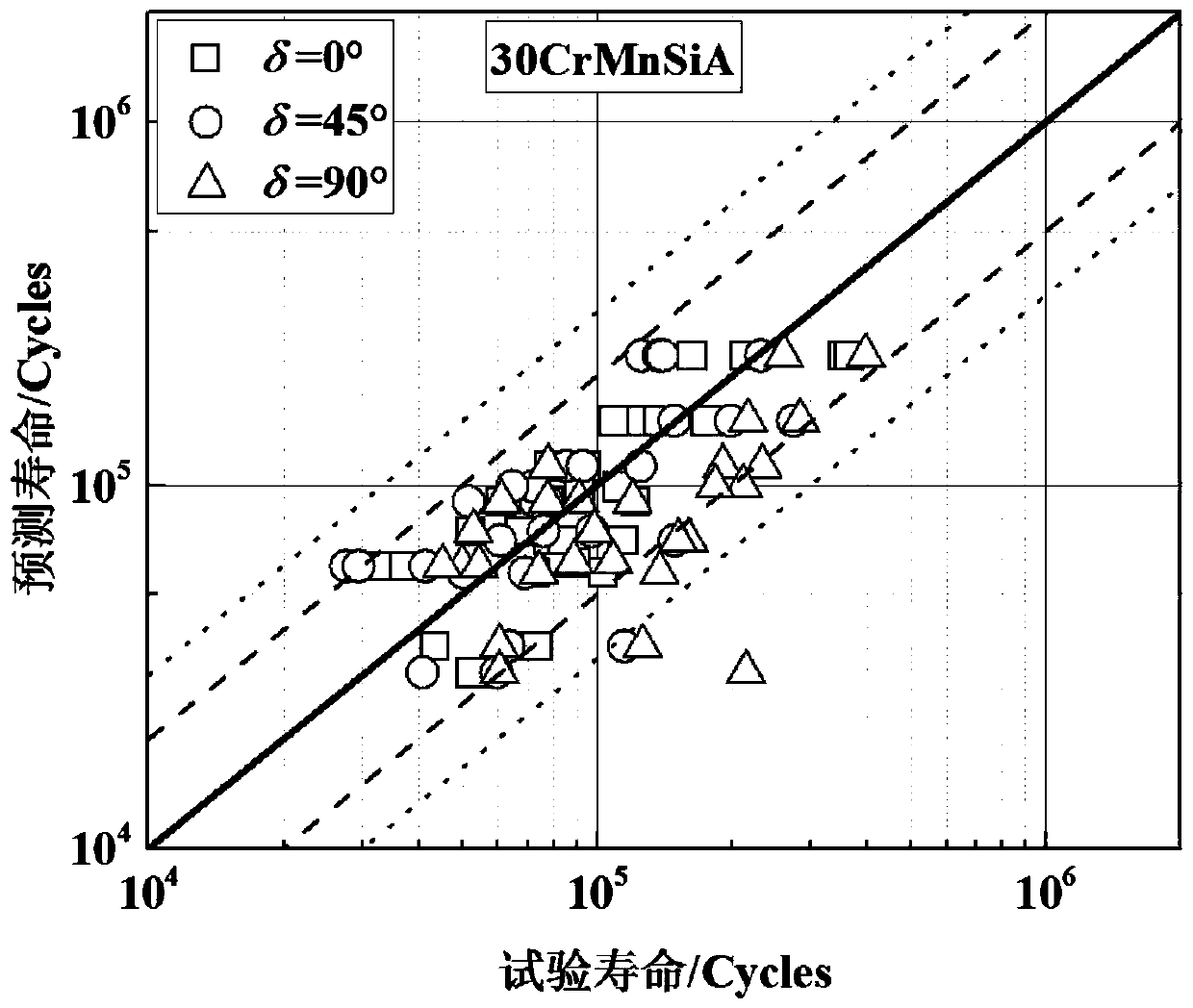

Uniaxial fatigue S-N curve-based hard metal material multi-axis high-cycle fatigue failure prediction method

ActiveCN110274826AWell formedAccurate predictionMaterial strength using tensile/compressive forcesTorsion fatigueFatigue loading

The invention discloses a uniaxial fatigue S-N curve-based hard metal material multi-axis high-cycle fatigue failure prediction method. According to the method, with a uniaxial tension fatigue and pure torsion fatigue S-N curve adopted as a boundary condition, and the equivalent stress amplitude and equivalent stress amplitude ratio of a material in the multi-axis fatigue loading process of the material are calculated; with the equivalent stress amplitude and equivalent stress amplitude ratio adopted as damage parameters, a fatigue S-N curve obtained from uniaxial fatigue is calculated; and a hard metal material multi-axis high-cycle fatigue failure life prediction model containing stress amplitude ratio and average stress influence is established. The method is suitable for a situation where average stress does not exist. Existing multi-axis fatigue life prediction models perform multi-axis fatigue tests under corresponding loading modes, and as a result, test cost is relatively high. Compared with the existing models in the prior art, the method disclosed by the invention is simple in form, and can obtain a uniaxial fatigue S-N curve just through a single-axis fatigue test or manual check, so as to accurately predict the fatigue life of a hard metal material under multi-axis high-cycle fatigue loading in the presence of a stress amplitude ratio and average stress.

Owner:BEIHANG UNIV

Rubber material viscous and superelastic constitutive model building method considering correlation effect

InactiveCN106202683AWide range of predicted strainsFew parametersDesign optimisation/simulationSpecial data processing applicationsRubber materialPolymer science

The invention discloses a rubber material viscous and superelastic constitutive model building method considering a correlation effect. The method comprises the following steps of obtaining stress-strain of a rubber material through quasi-static uniaxial tension experiment; performing impact uniaxial tension experiment through an SHTB (split hopkinson tension bar) device to obtain the stress-strain of the rubber material at a high strain rate; obtaining corresponding response rules and deformation characteristics according to the stress-strain, obtained through the quasi-static uniaxial tension experiment and the impact uniaxial tension experiment, of the rubber material; building a viscous and superelastic constitutive model of the rubber material. The method has the advantages that by aiming at the study on the tensile mechanical property of the rubber material, the viscous and superelastic constitutive model of the rubber material is built; reference is provided for the study on the tensile mechanical property of the rubber material; the problem of mechanical characterization difficulty of the rubber material at different strain rates is solved.

Owner:NANJING UNIV OF SCI & TECH

Nanoindenter tip for uniaxial tension and compression testing

InactiveUS7878071B2Force measurementMaterial strength using tensile/compressive forcesScanning tunneling microscopeScanning electron microscope

The invention is an indenter tip that is modified to permit both compression testing and tensile testing on samples having dimensions smaller than approximately 1 μm. The modified indenter tip has both a surface that can be used to apply compressive forces, and tines that can be used to engage a free end of a specimen to be tested in tension. The apparatus used to perform the tests includes elements of a scanning electron microscope that permit visualization of the specimen to be tested and the modified indenter tip, so as to permit appropriate alignment and engagement of the same. The apparatus also includes elements of a microindenter that provide mechanical manipulation of the relative position and orientation of the modified indenter tip and of the specimen to be tested, as well as the necessary controls and instrumentation to perform the test and to collect, record and manipulate data.

Owner:CALIFORNIA INST OF TECH

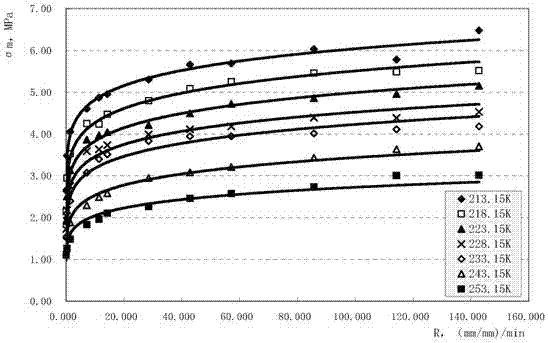

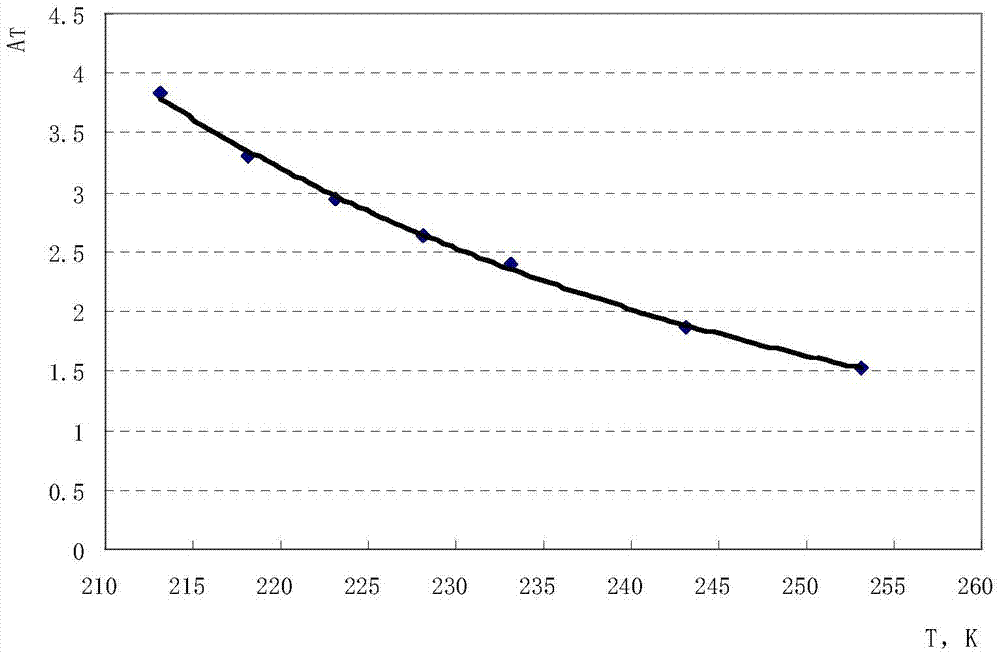

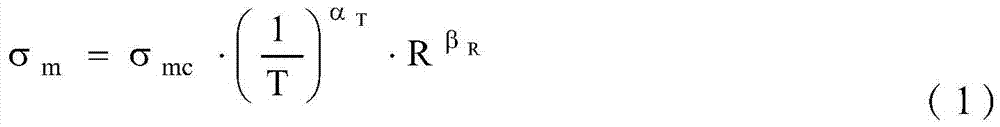

Method for assessing advantages and disadvantages of low-temperature mechanical properties of viscoelastic material

ActiveCN105445115AMaterial strength using tensile/compressive forcesMathematical modelMechanical property

The invention relates to a method for assessing the advantages and disadvantages of low-temperature mechanical properties of a viscoelastic material. According to the method, through uniaxial tension mechanical property tests under the different temperature conditions and within a relatively wide range of strain rates, a principal curve assessing method for the low-temperature mechanical properties of viscoelastic materials in different systems and a mathematical model of which the tensile strength is impacted by the temperature and strain rates are constructed, and then the advantages and disadvantages of the low-temperature mechanical properties of the viscoelastic material can be assessed by adopting a tensile strength temperature sensitivity index and a strain rate sensitivity index. Compared with the conventional method, the method provided by the invention has the advantages that the low-temperature mechanical properties of the viscoelastic material can be quantitatively forecasted, and the advantages and disadvantages of uniaxial tension mechanical properties of the viscoelastic material can be quantitatively assessed.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

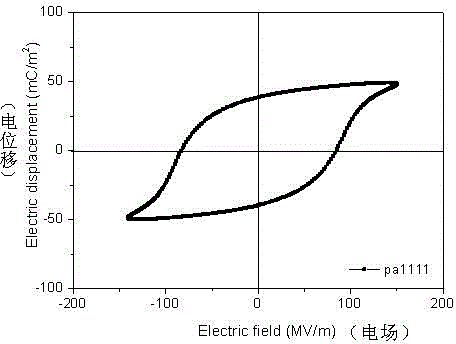

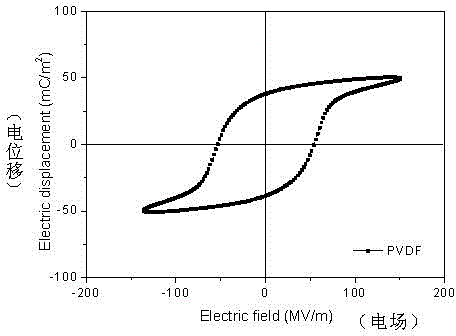

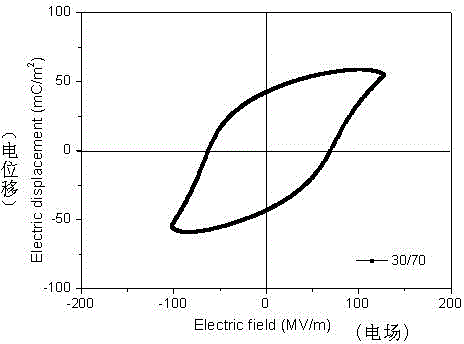

Nylon 1111/ polyvinylidene fluoride ferroelectric composite film and preparation method thereof

ActiveCN104629358AHigh remnant polarizationLow cost of industrializationMaterials preparationComposite film

The invention belongs to the field of high-polymer blending composite material preparation and discloses a nylon 1111 / polyvinylidene fluoride ferroelectric composite film and a preparation method thereof. The ferroelectric composite film disclosed by the invention is prepared by 20-80 parts of nylon 1111 and 80-20 parts of polyvinylidene fluoride. The preparation method comprises the following steps: firstly blending the nylon 1111 and polyvinylidene fluoride in melt mixing equipment, then hot-pressing the mixture by hot pressing equipment into a film, quenching the molten film and finally stretching by uniaxial tension of a stretching device to obtain the nylon 1111 / polyvinylidene fluoride ferroelectric composite film. The composite film prepared according to the invention exceeds a pure polyvinylidene fluoride film in remanent polarization strength. The preparation method disclosed by the invention has simple preparation process, industrially common equipment and easy operation. The ferroelectric composite film is low in cost, and is expected to be used for apparatus preparations in the fields of piezoelectric, pyroelectric and ferroelectric materials.

Owner:ZHENGZHOU UNIV

Tensile testing machine for thin film and tensile testing method

The invention belongs to the technical field of tensile testing of a thin film, and particularly relates to a tensile testing machine for the thin film and a tensile testing method. The tensile testing machine for the thin film comprises a base, X-axis bidirectional screw rods, X-axis movable slide bars, Y-axis bidirectional screw rods, Y-axis movable slide bars, planar movable sliders, shear forkexpansion brackets, thin film clamping devices and motor drive devices, wherein the two X-axis bidirectional screw rods and the Y-axis bidirectional screw rods are mounted on the base, and the shearfork expansion brackets are mounted between every two adjacent planar movable sliders; a plurality of thin film clamping devices are uniformly mounted on the shear fork expansion brackets; each thin film clamping device comprises a lower clamp seat, an upper clamp seat and a clamp cylinder. Testing raw materials can be substantially reduced, testing time is shortened, and testing cost is saved. Besides, the tensile temperature and the tensile speed of the tensile testing machine can be subjected to gradient selection, curing tensile test of a coating film can be performed, a uniaxial tension technology after online coating of the coating film is imitated completely, optimized research of a coating liquid formula is performed, and diversified demands are met.

Owner:TIANJIN WANHUA CO LTD +1

Transmission/scanning electron microscope mechanical-thermal coupling field loaded in-situ experimental platform

ActiveCN105301027AAchieving displacement quantificationRealize large displacement deformation experimentMaterial analysis by transmitting radiationScanning tunneling microscopeNanoscopic scale

Belonging to the field of material microstructure-mechanical property in situ characterization, the invention provides a transmission / scanning electron microscope mechanical-thermal coupling field loaded in-situ experimental platform. The platform is mainly composed of a heating and sample carrying zone, drive beams, heat sink beams, mass blocks and a substrate. The platform drive part is a V shaped electrothermal drive beam, the stepping precision can reach nanometer scale, and the deformation mode can realize uniaxial tension. The platform has a small overall size, can be placed in a small and narrow space at the front end of a multi-electrode TEM biaxial tilting sample rod, and can cooperate with the sample rod to perform biaxial tilting observation. The platform also can be used cooperatively with a scanning electron microscope and scanning electron microscope assembled accessories like various energy spectrums and microstructures (EBSD). When a material is heated and deforms, the deformation process of the material under a condition ranging from room temperature to high temperature (600DEG C) can be observed in situ at sub-angstrom, atom and nano scale to study the deformation mechanism and reveal the relationship between the microstructure and mechanical properties.

Owner:BESTRONST (BEIJING) SCI & TECH CO LTD

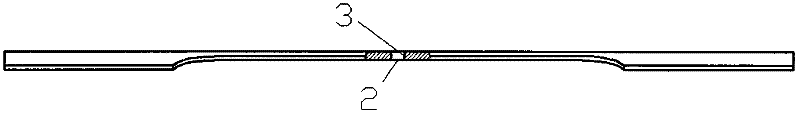

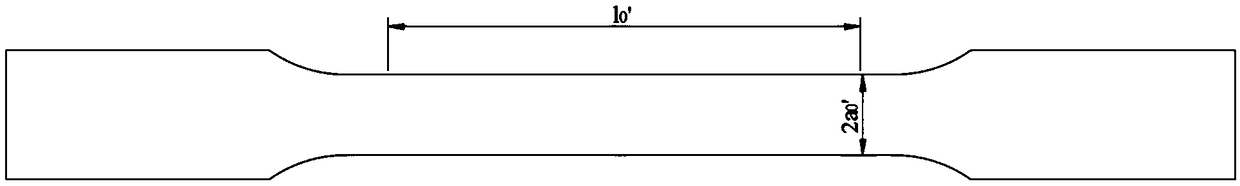

Method for measuring large-stress range stress strain in uniaxial tensile test of metal plate sample

InactiveCN108982222AEliminate cumbersome measurement linksSave time and costMaterial strength using tensile/compressive forcesBridgman methodStress–strain curve

The invention relates to a method for measuring the large-stress range stress strain in a uniaxial tensile test of a metal plate sample. The method comprises the following steps: building a step modelfor gradual expansion of unstable necking of uniaxial tension of the metal plate sample; measuring the instant gauge length and the minimum sectional width at a necking position of the plate sample after extension instability; building an interpolation curve expression of the necking profile on the basis of necking step coordinates of the necking step model at each moment; solving the parametersof the necking step model according to the mechanical relationship of necking in the width direction and the thickness direction and the principle of volume conservation; finally calculating the actual stress and actual strain at the moment through a Bridgman method. By adopting the method, the test measuring link for the necking outer profile curvature radius in the existing method is omitted, and the measuring accuracy of a large-strain range stress-strain curve is improved, so that the method has important significance to the mechanical performance test of metal materials.

Owner:JILIN UNIV

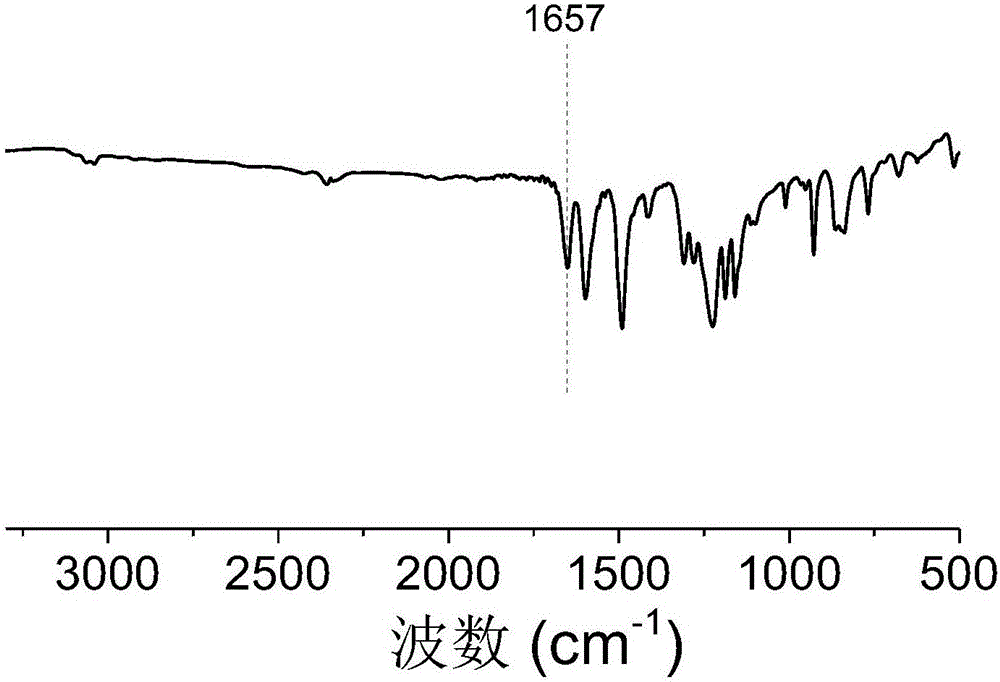

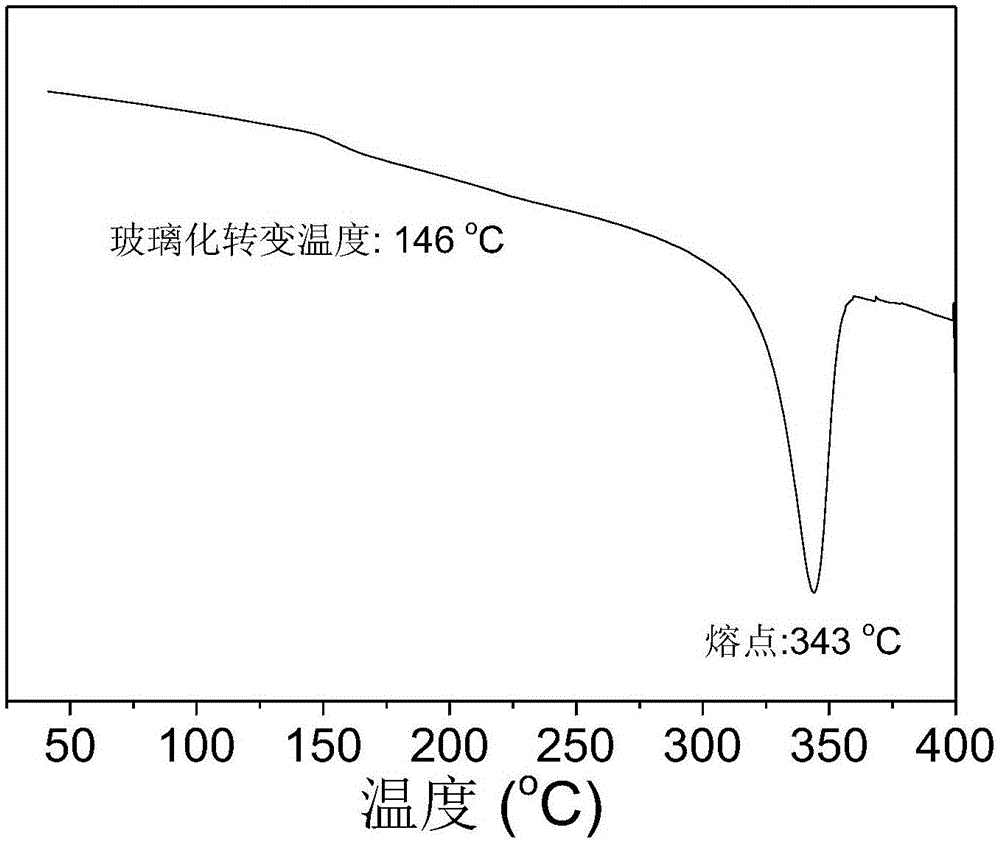

Thin film special material for polyether-ether-ketone as well as preparation method and application thereof in preparing polyether-ether-ketone/polyetherimide alloy thin film

The invention relates to a biphenyl-blocked thin film special material for polyether-ether-ketone as well as a preparation method and application thereof in preparing a polyether-ether-ketone / polyetherimide alloy thin film and belongs to the technical field of high molecular composite materials. By taking 4-hydroxyl biphenyl which is lower in cost and has a liquid crystal state as the blocking group, the prepared polyether-ether-ketone (PEEK) has a stable end group, so that not only can the stability of the resin be improved, but also the melt viscosity of the resin can be improved. By means of compatibility and performance complementarity of high molecular polymers, the polyether-ether-ketone / polyetherimide alloy thin film which is excellent in performance is prepared. By uniaxial tension of the thin film, a uniaxial tension process of the polyether-ether-ketone / polyetherimide alloy thin film and a late-stage thermal treatment process of the polyether-ether-ketone / polyetherimide alloy thin film are developed. The prepared polyether-ether-ketone / polyetherimide alloy thin film is good in processing flowability and high in toughness of the material while keeps the crystal structure of the polyether-ether-ketone material.

Owner:JILIN UNIV

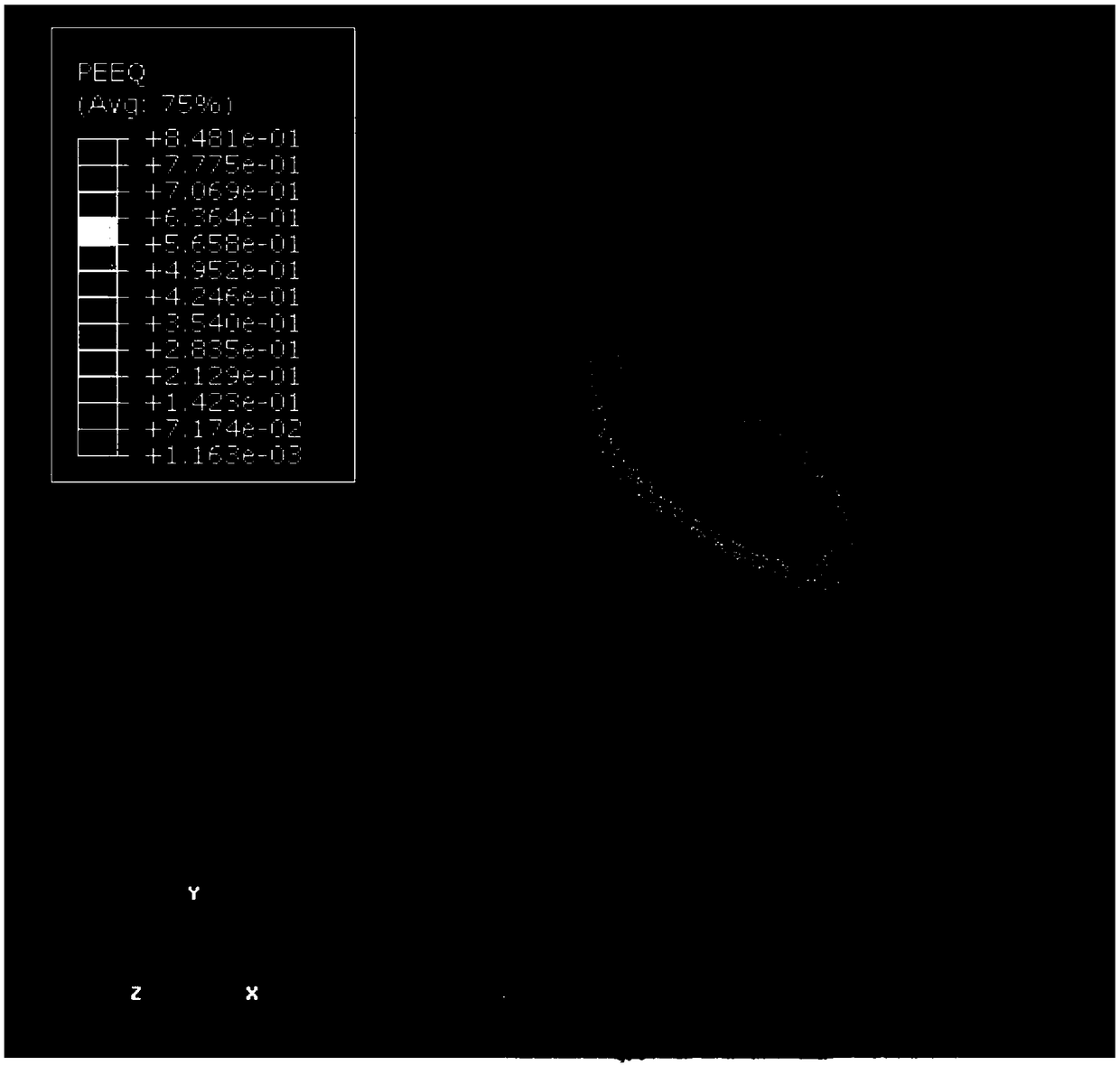

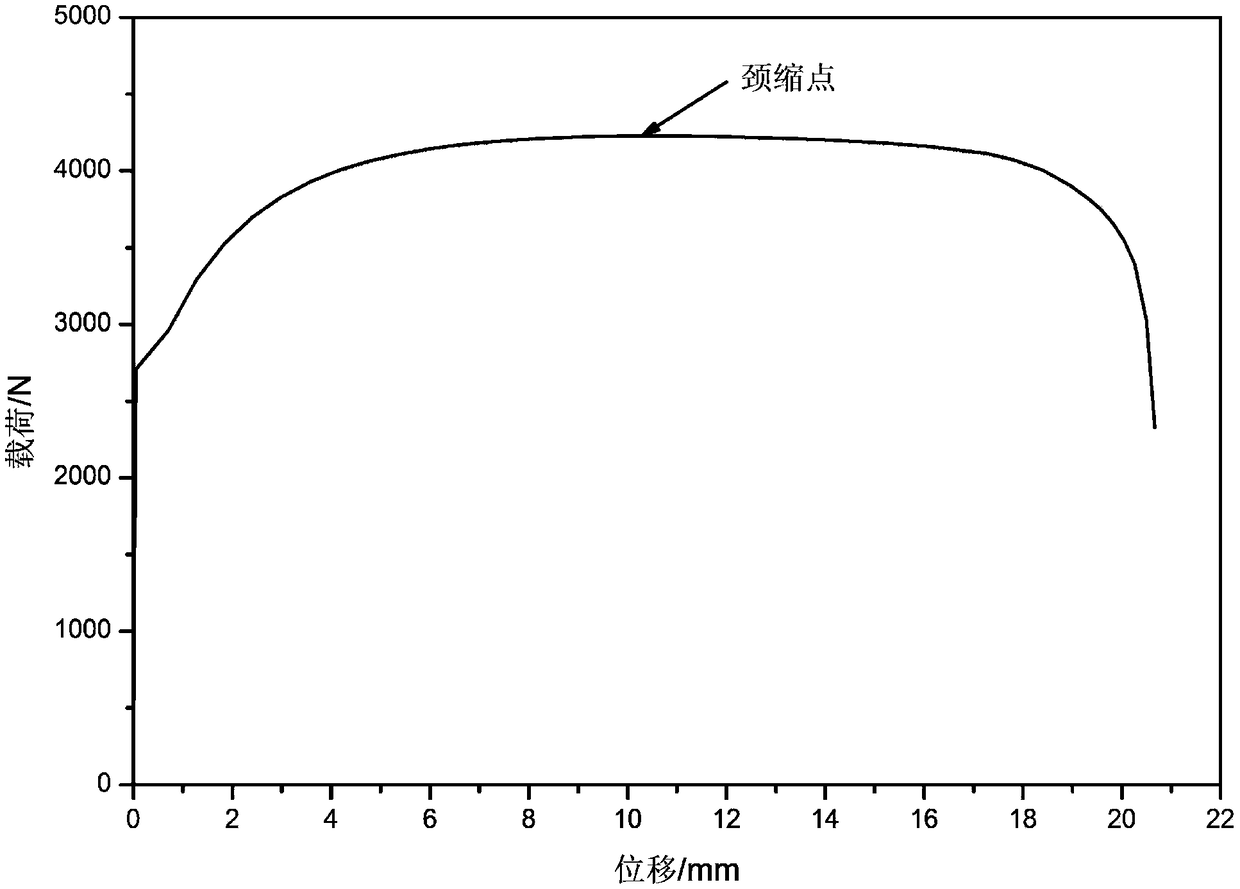

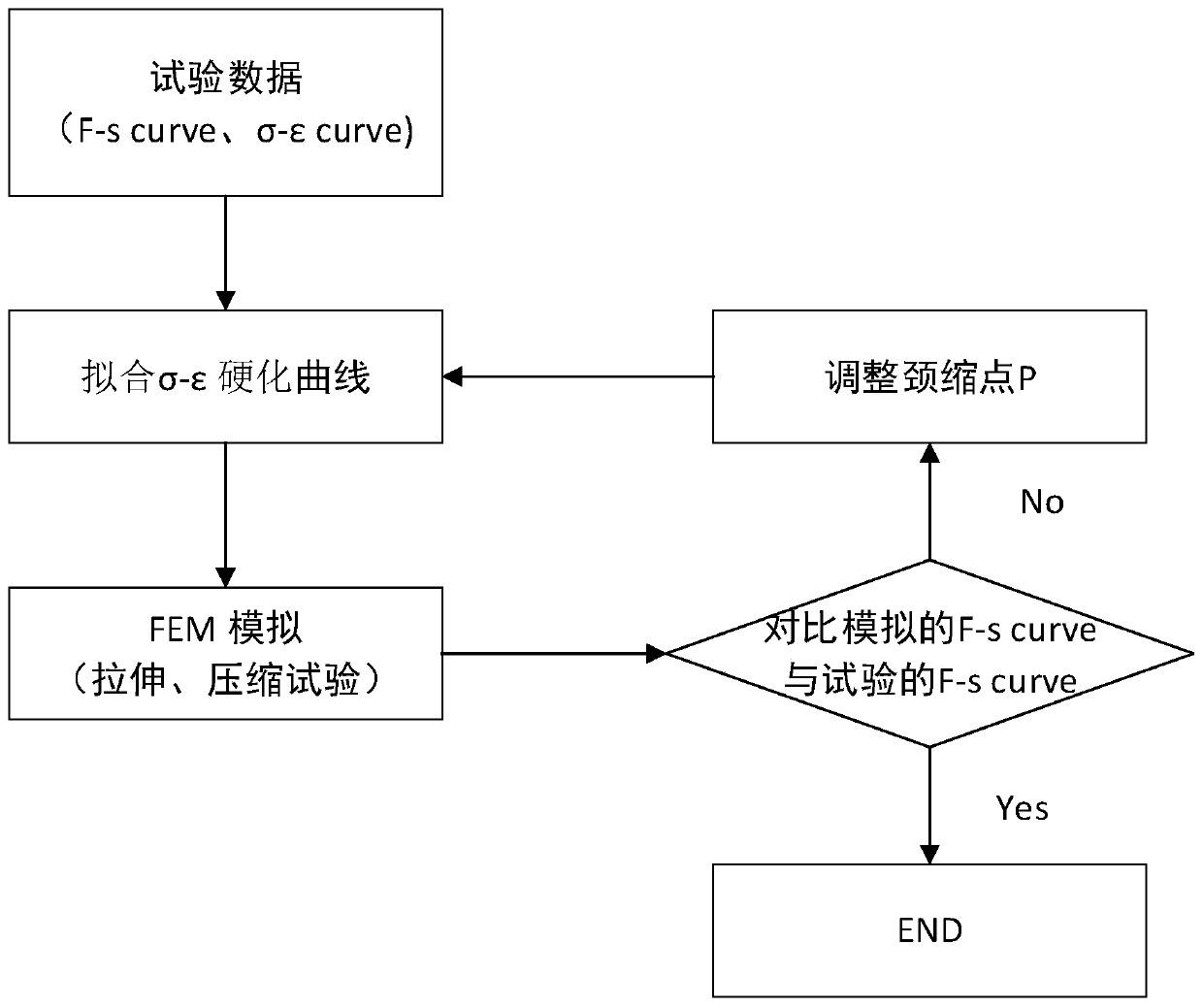

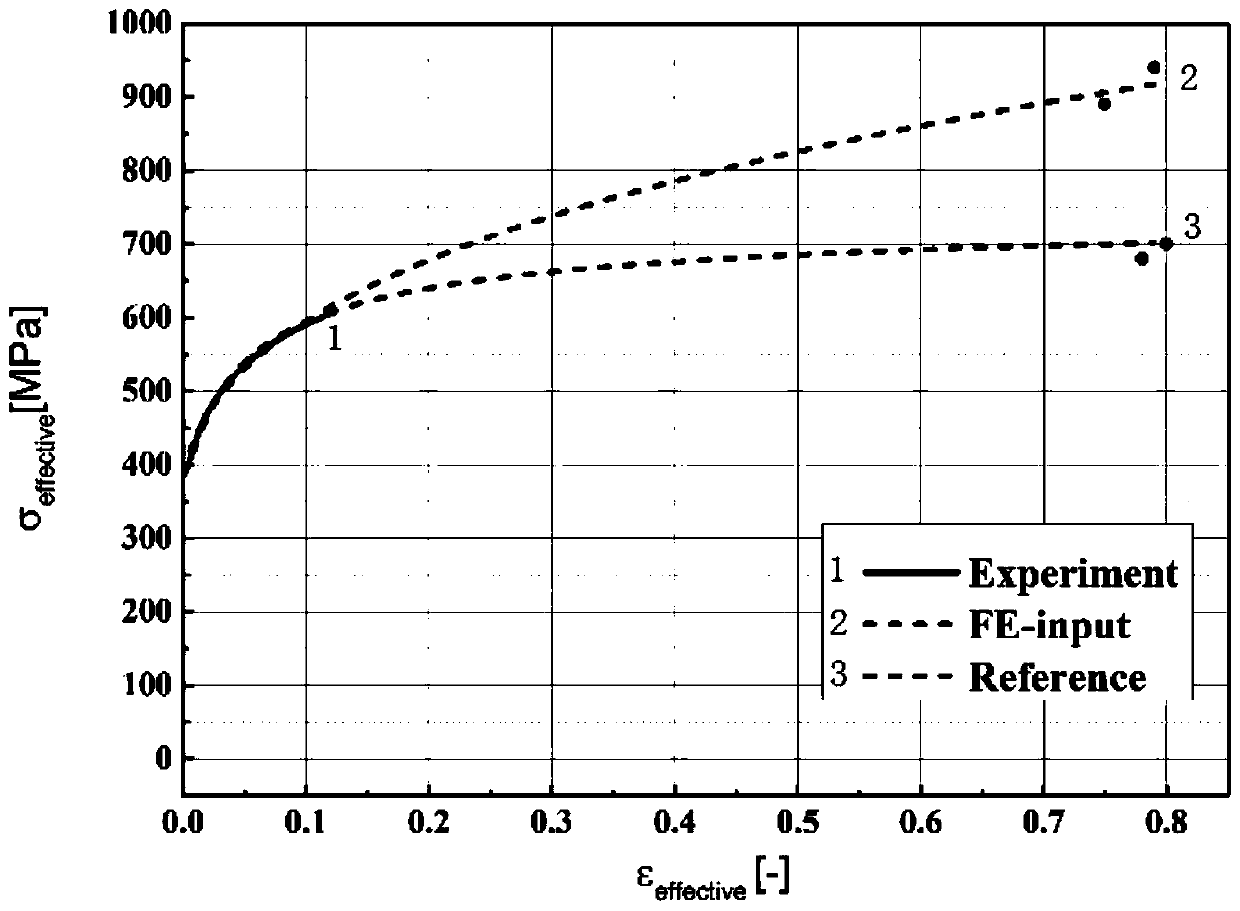

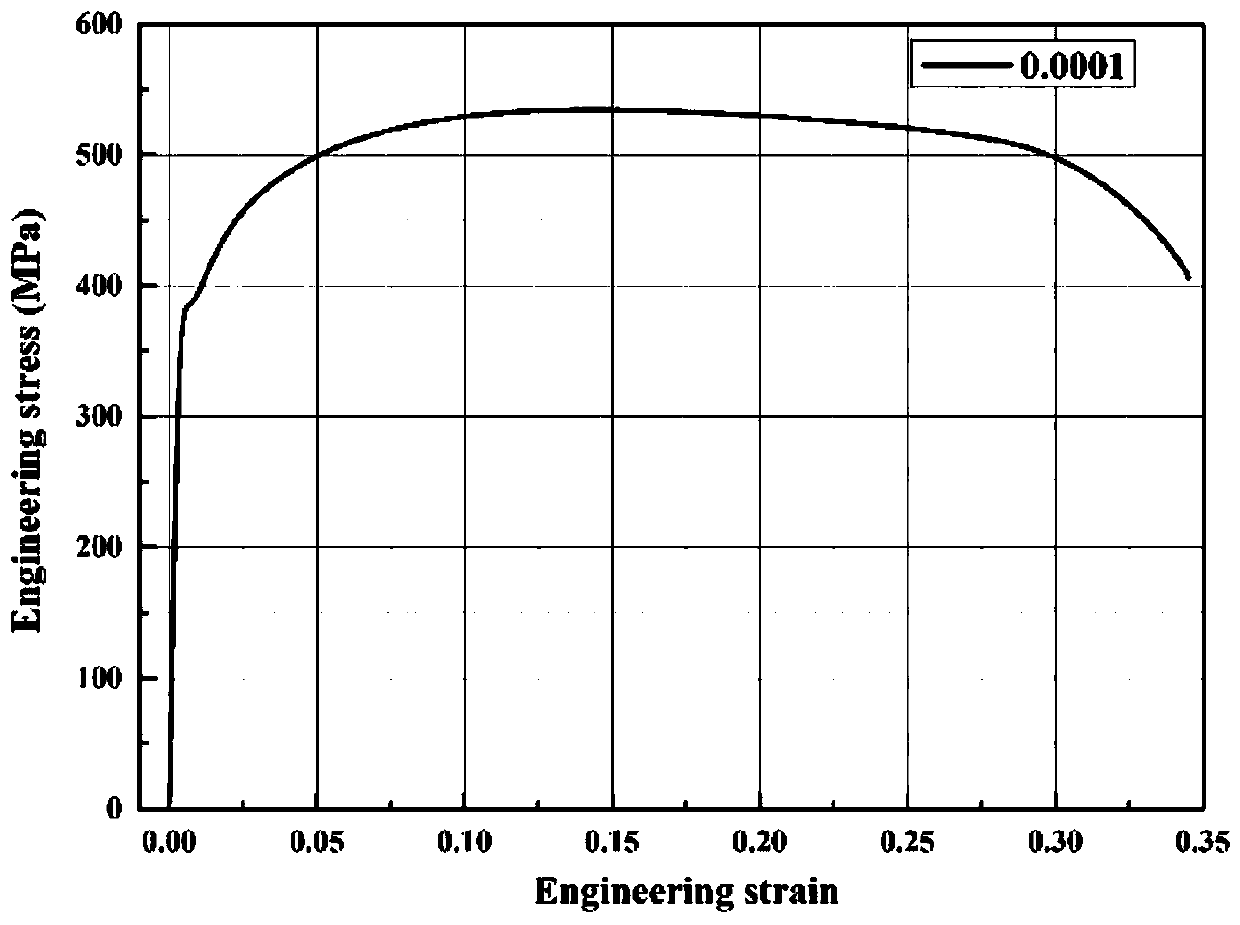

Virtual prediction method for material hardening behavior under large strain condition

PendingCN111339703AAccurate predictionAccurately simulate conditionsDesign optimisation/simulationComputational theoretical chemistryFlow curveEngineering

The invention relates to the field of mechanical property characterization, in particular to a virtual prediction method for a material hardening behavior under a large strain condition. The method comprises the following steps: obtaining force displacement and stress-strain data through a uniaxial tension test, fitting a stress-strain curve obtained through the test, establishing a finite elementmodel, simulating a uniaxial tension test process, comparing force displacement results of the simulation and the test, correcting model parameters according to a comparison result, and determining areasonable hardening model. According to the method, the mechanical behavior of the material in the plastic deformation process under the condition of large strain can be accurately predicted by utilizing a finite element method and a uniaxial tension test result. Due to the fact that the maximum strain often exceeds 0.5 in the body forming process, test data of the large strain cannot be obtained generally in the uniaxial tension test. By optimizing the parameters of the material hardening model, the flow curve of the material after epitaxy can be obtained, and the metal flow of the materialin the forging, extruding and rolling processes can also be predicted.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

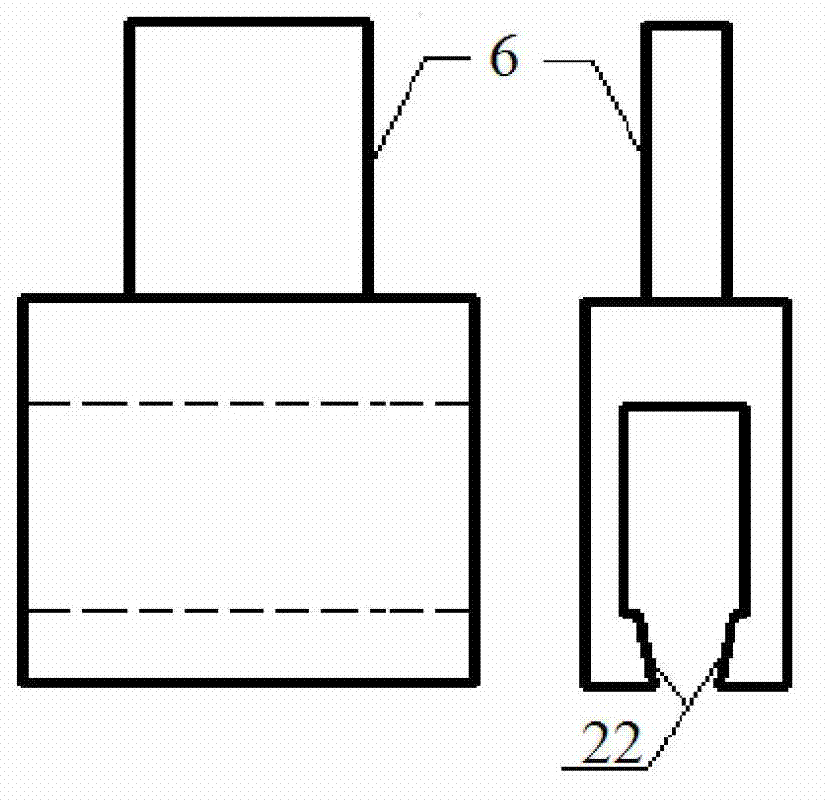

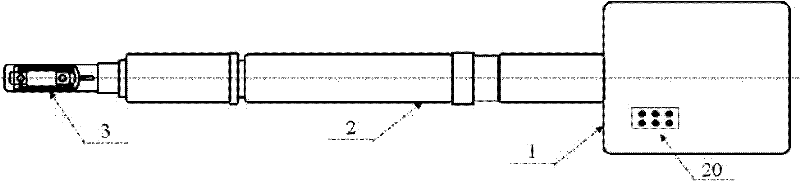

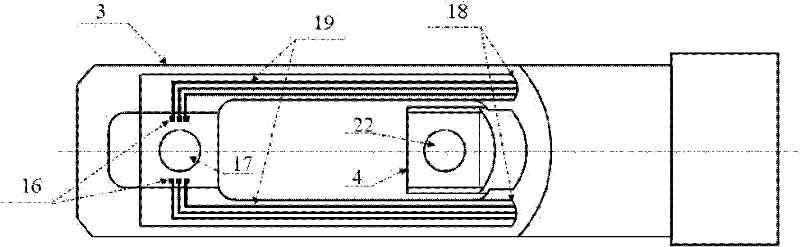

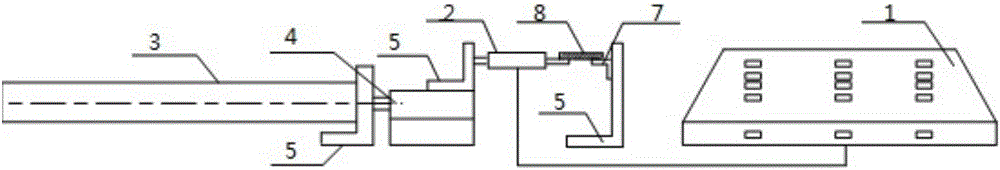

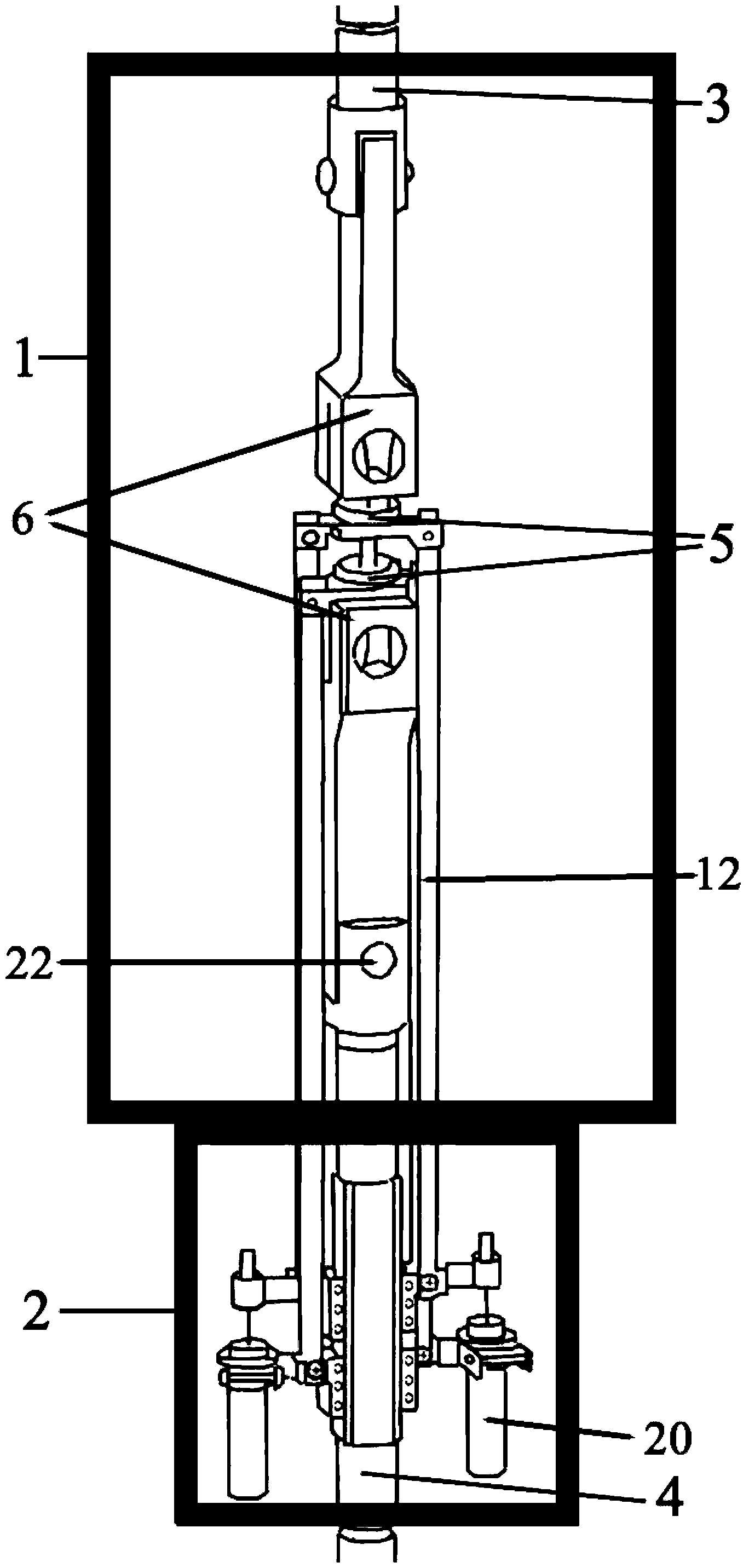

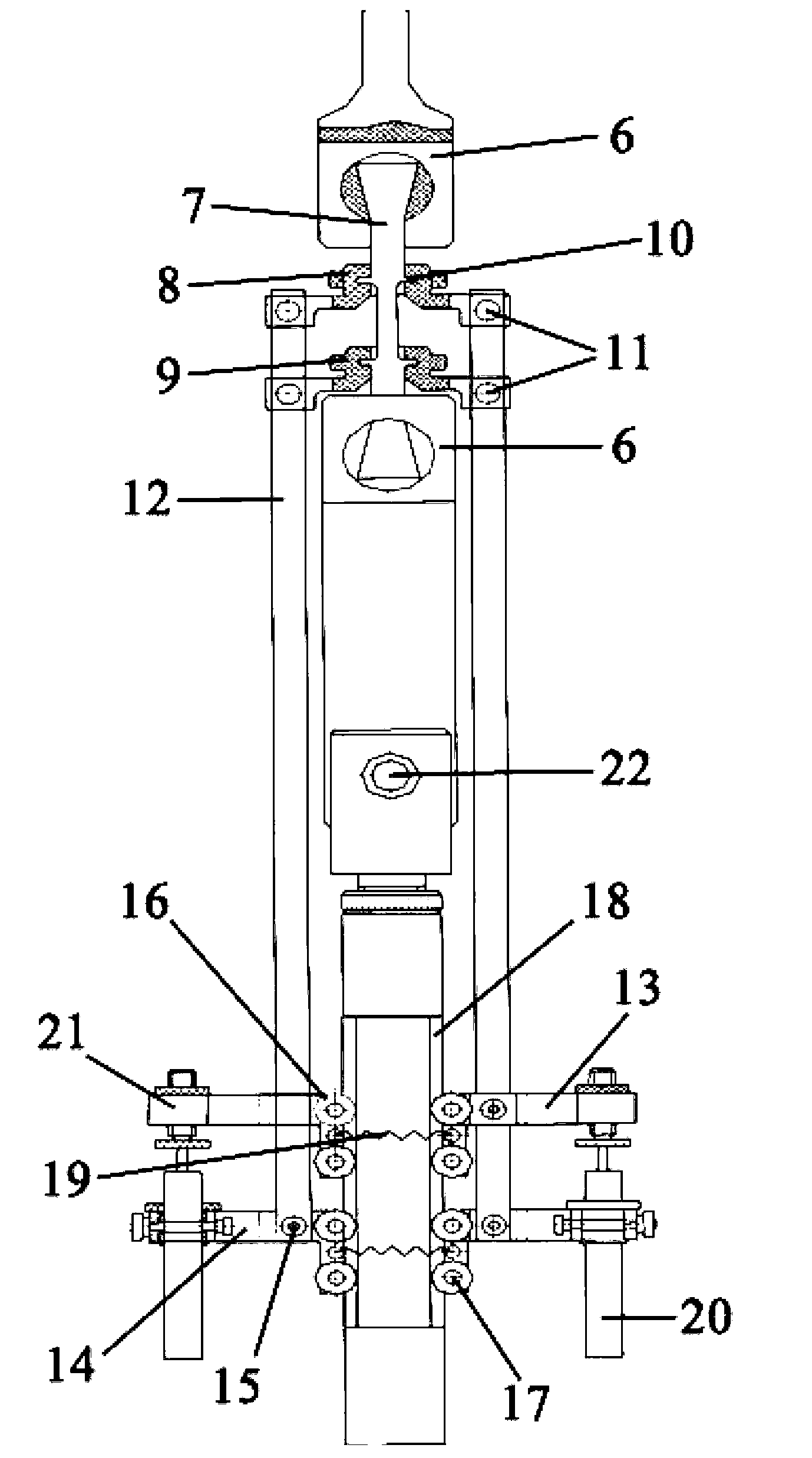

Ultrahigh-temperature outward extension type deformation measurement device

ActiveCN103308395AEnabling Quantitative ResearchAchieve mechanical propertiesMaterial strength using tensile/compressive forcesLinear variable differential transformerMeasurement device

The invention discloses a uniaxial tension test outward extension type deformation measurement device in an ultrahigh-temperature environment. The device comprises a high-temperature furnace (1), an environmental chamber small box (2), an upper loading pull rod (3), a lower loading pull rod (4), a ring sleeve (5), a clamp (6), an upper clamping ring (8), a lower clamping ring (9), a first connecting pin (11), a stretching rod (12), an upper bracket (13), a lower bracket (14), a bolt (15), a rolling bearing (16), a second connecting pin (17), a guide slot (18), a locking spring (19), a linear variable differential transformer (20), a circumference constraint device (21) and a third connecting pin (22). By the adoption of an outward extension type design, a displacement measurement part is transferred to a normal temperature area outside the high-temperature furnace from an ultrahigh-temperature area in the high-temperature furnace, the quantitative research of the ultrahigh-temperature extension test is realized, and the measurement precision is improved; instrument parts in the ultrahigh-temperature area are made of ultrahigh temperature resistant materials; moreover, the mechanical properties of the ultrahigh-temperature materials are tested and researched, the operation is simple, and the feasibility is high.

Owner:PEKING UNIV

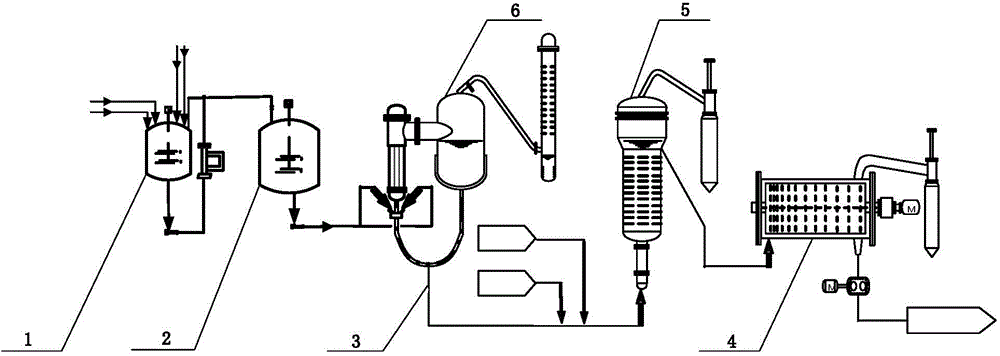

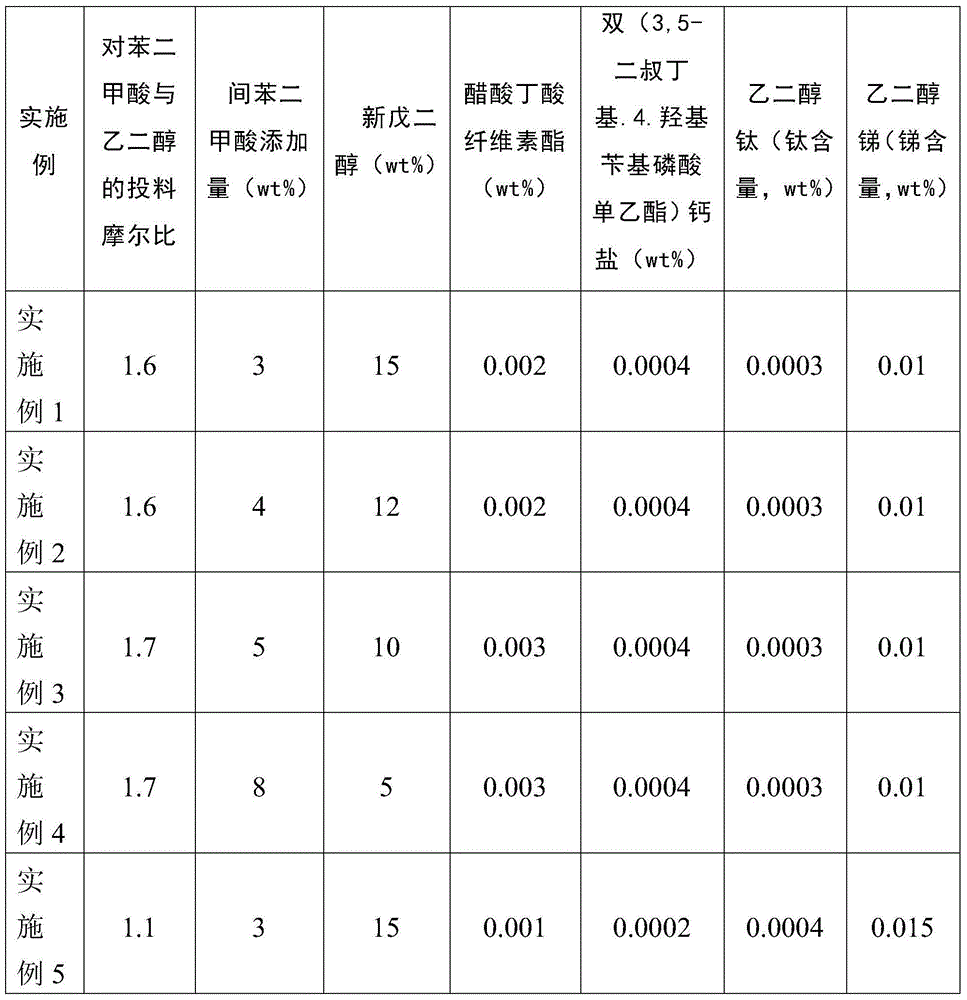

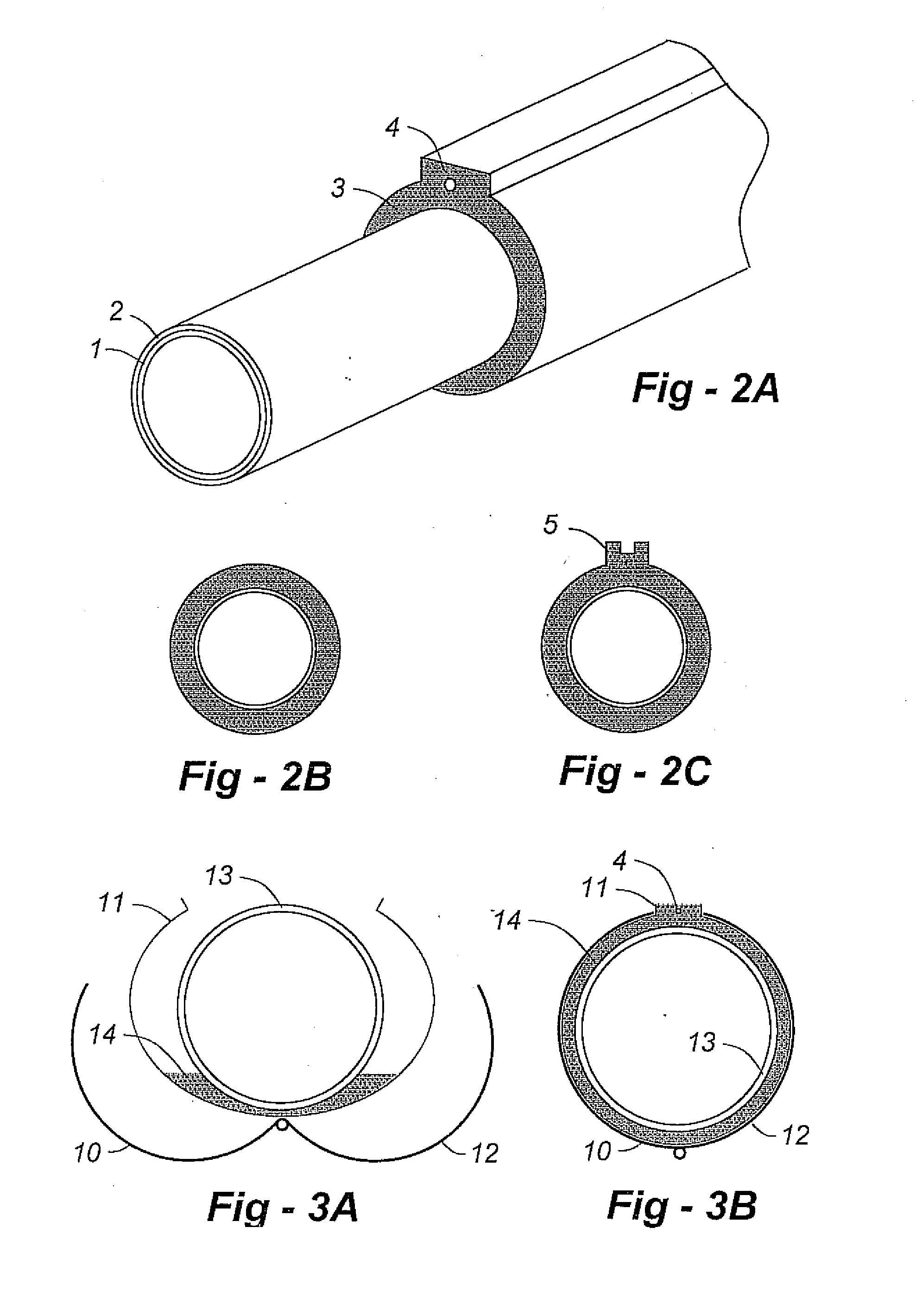

Thermoshrinking polyester and preparing method thereof

InactiveCN105585705AReduce manufacturing costVersatileMonocomponent polyesters artificial filamentArtifical filament manufacturePolymer scienceAlcohol

Thermoshrinking polyester is disclosed. Raw materials of the thermoshrinking polyester comprise terephthalic acid, ethylene glycol and a modifying agent. The modifying agent comprises 3-8 wt% of a dicarboxylic acid, 5-15 wt% of an aliphatic dihydric alcohol, 0.001-0.003 wt% of a hydrophilicity modifying agent and 0.0001-0.0005 wt% of an antioxidant heat stabilizer, with the amount of the modifying agent being calculated based on the theoretical weight of the polyester. The degree of crystallinity of the polyester is effectively reduced so that thermal degradation and oxidative degradation in subsequent processing steps can be prevented, thus preparing the thermoshrinking polyester with high heat resistance and an antistatic property. The thermoshrinking polyester can be used for high-shrinkage fiber spinning, uniaxial tension high-shrinkage film or other fields needing high-shrinkage polyester. A preparing method of the thermoshrinking polyester is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

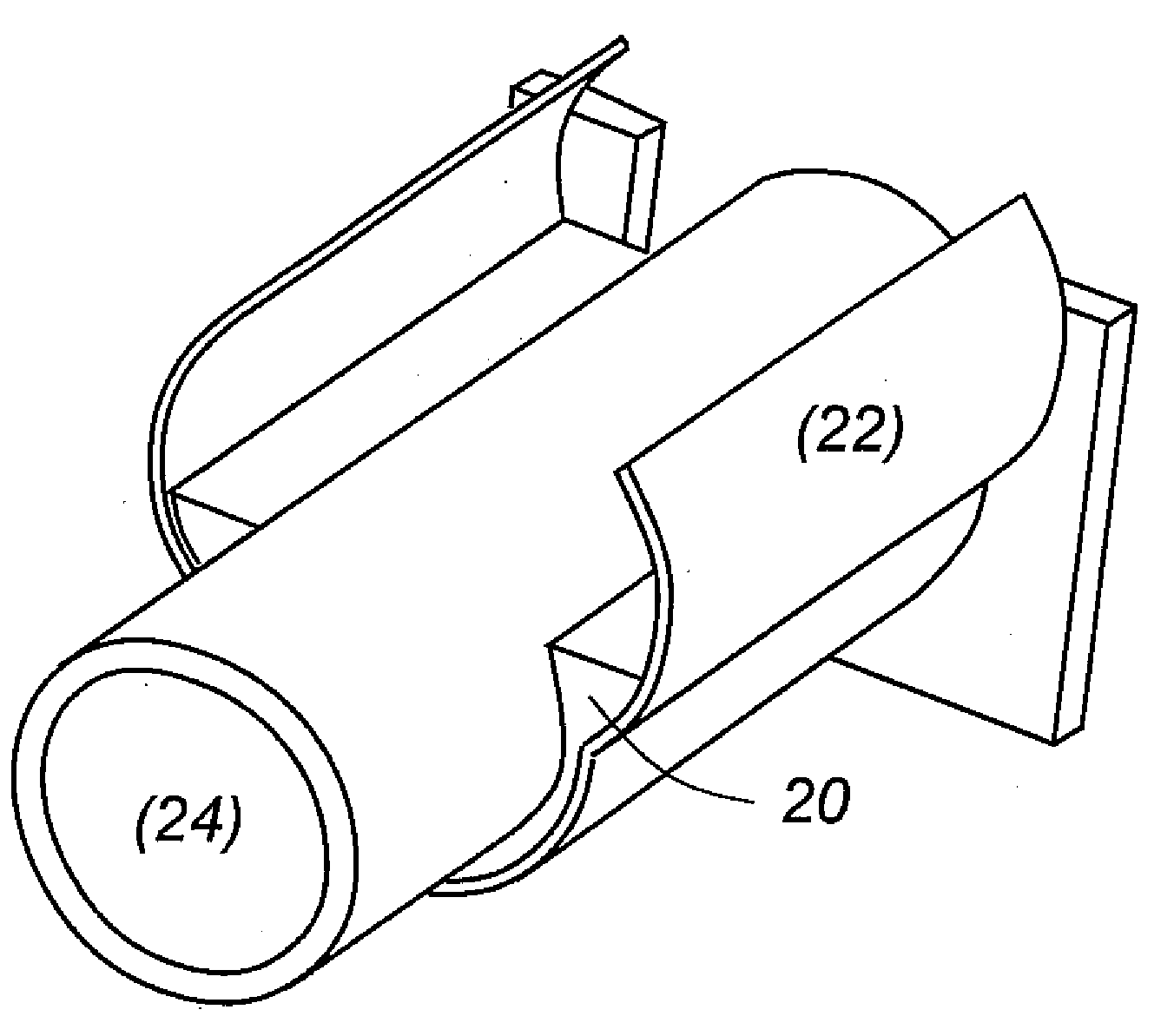

Coated pipe and method using strain-hardening brittle matrix composites

InactiveUS20090035459A1Low costReduce material volumeLiquid surface applicatorsCorrosion preventionDamage toleranceCementitious matrix

Pipe cladding is based upon a fiber-reinforced brittle matrix composite material. The coating is isotropic, demonstrating pseudo-strain hardening behavior in uniaxial tension, and damage tolerance by design, not relying on stratified layers of reinforcing mesh embedded within concrete or other brittle cementitious matrices for impact resistance, fracture toughness, or crack width control. The fiber reinforced brittle matrix composite cladding protects both the pipe and inner thin, anti-corrosion layer (if present) from impact or abrasion damage while permitting bending of coated and clad pipe. The finished composite clad can be in a simple circular form alone the pipe or in some complex form providing an integrated housing for electrical or optical fiber cables, or optical sensing sensors for continuous or intermittent sensing of pipeline leakage or failure.

Owner:MECC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com