Tensile testing machine for thin film and tensile testing method

A technology of tensile testing machine and film, which is applied in the field of film tensile test to achieve the effect of saving test cost, reducing test raw materials and shortening test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

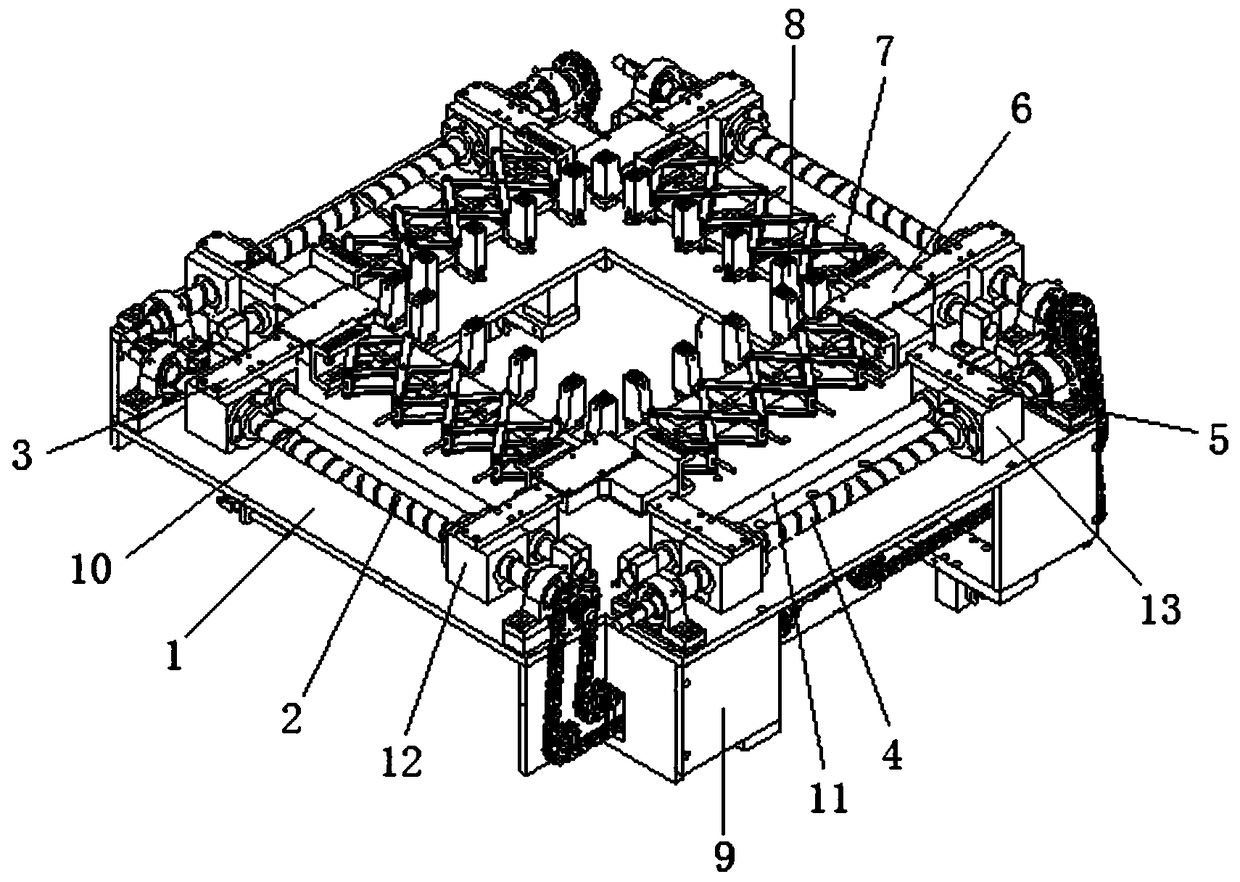

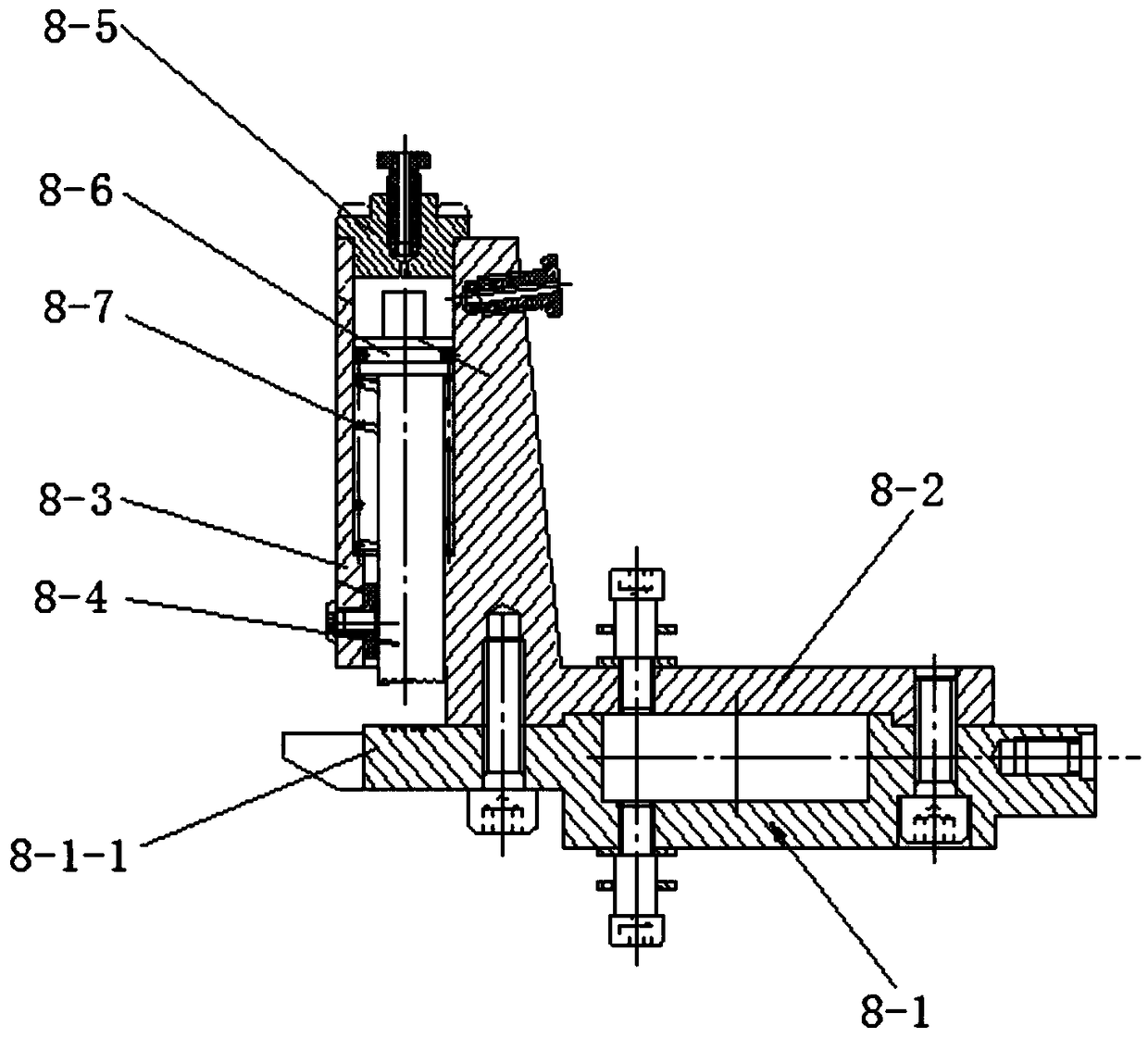

[0020] see figure 1 , a film tensile testing machine, including machine base, X-axis two-way lead screw 2, X-axis movable slide bar 3, Y-axis two-way lead screw 4, Y-axis movable slide bar, plane movable slide block 6, shear Fork telescopic frame 7, film clamping device 8, motor drive device 9.

[0021] Two mutually parallel X-axis bidirectional lead screws 2 and two mutually parallel Y-axis bidirectional lead screws 4 are installed on the base through the bearing housing, and the two X-axis bidirectional lead screws 2 and the two Y-axis bidirectional lead screws 4 circles form a rectangle. This encirclement forms a rectangle not that the X-axis bidirectional lead screw 2 and the Y-axis bidirectional lead screw 4 connect end to end to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com