Uniaxial tension sample holder capable of testing in-situ stress and electrical property for transmission electron microscope

A technology of transmission electron microscopy and uniaxial stretching, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of demanding samples, limited number of FIBs, and inability to obtain sample stress values, etc., and achieve the effect of a wide range of research fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

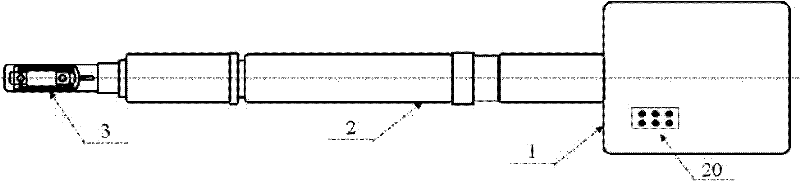

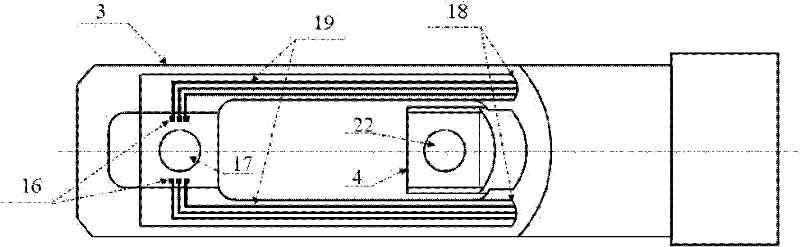

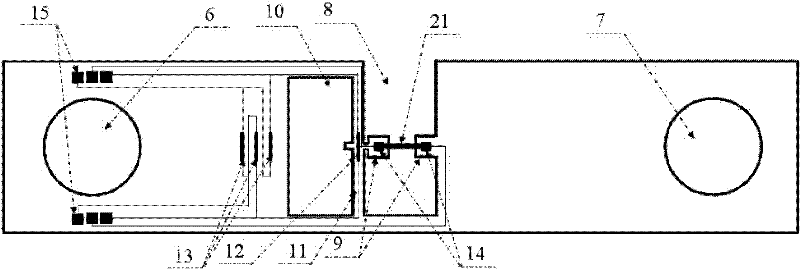

[0031] like figure 1, as shown in 2 and 3, the in-situ force and electrical performance uniaxial tensile sample rod used for transmission electron microscopy mainly includes a handle 1, a sample rod 2, and a sample head 3. The sample rod 2 is an internal hollow rod, and the internal device There is a stretching shaft 4, one end of the stretching shaft 4 protrudes from the sample rod 2 and is close to the sample head 3, and the other end is connected with the stretching shaft driver located inside the handle 1. In addition, there is also a deformation slide 5, a deformation slide 5 is a rectangular parallelepiped thin slice, and a first through hole 6 and a second through hole 7 are symmetrically arranged on both ends of the deformable carrier 5 on the center line of the major axis, and a U-shaped groove 8 is arranged at the center of the major axis, and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com