Lithium ion battery membrane with porous composite coating and preparation method thereof

A lithium-ion battery and composite coating technology, which is applied to battery components, circuits, electrical components, etc., can solve problems such as easy to fall off, difficult to uniformly disperse inorganic particles, reduce the strength and thermal stability of composite diaphragms, and achieve guaranteed Dimensional stability, heat shrinkage reduction, and integrity maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

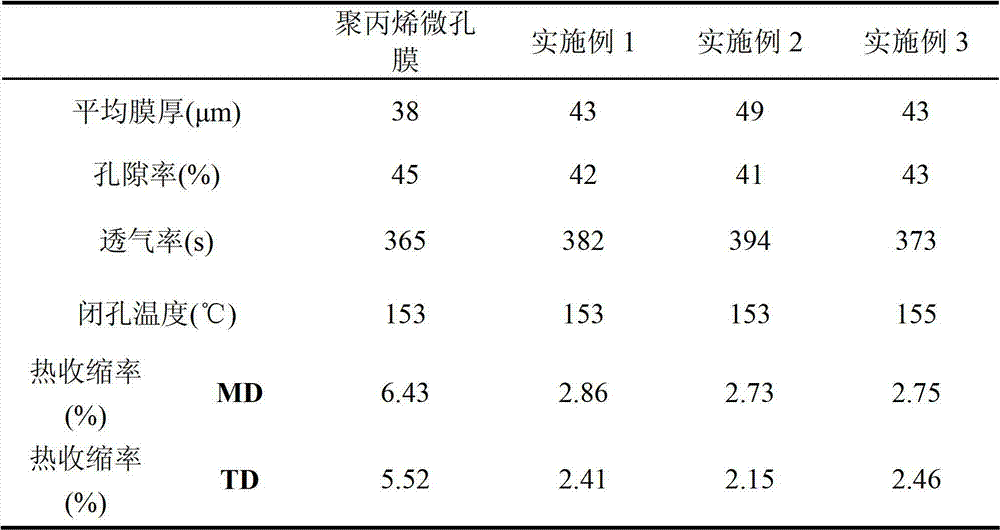

[0043] According to the existing industrial technology, a polypropylene microporous membrane was prepared by uniaxial stretching process, with a thickness of 38 μm, a closed cell temperature of 153 °C, a porosity of 45%, and an air permeability of 365 (Gurley value, unit: s). The carbon nanotubes are commercially available conventional multi-walled carbon nanotubes with a diameter in the range of 10-20 nm and a length in the range of 3-10 μm.

[0044] Surface grafting modification of carbon nanotubes: put the carbon nanotubes in an oven and raise the temperature to 400° C., heat for about 2 hours and wash with 6M HCl. Weigh 1.5g of purified carbon nanotubes, 0.075g of cerium ammonium nitrate, and 0.15g of α-methylstyrene, dissolve them in 200mL of dimethyl sulfoxide, disperse them with ultrasonic waves for 20 minutes, and react them at 70°C for 12 Hour. Afterwards, the mixed solution was cooled, washed with tetrahydrofuran, and dried to obtain modified carbon nanotubes.

[0...

Embodiment 2

[0048] The coating solution in Example 1 was coated on the other surface of the composite coating separator obtained in Example 1, and vacuum-dried to obtain a polypropylene separator with a double-sided composite coating. The performance test results are shown in Table 1.

Embodiment 3

[0050] The polypropylene microporous membrane in Example 1 was used.

[0051] Surface graft modification of carbon nanotubes: firstly, the carbon nanotubes are purified by conventional methods. Weigh 1.5g of purified carbon nanotubes, 0.075g of potassium persulfate, and 0.2g of p-phenylstyrene and dissolve them in 200mL of tetrahydrofuran, disperse them with ultrasonic waves for 20 minutes, and react at 70°C for 12 hours; then cool The mixed solution was washed with tetrahydrofuran and dried to obtain modified carbon nanotubes.

[0052] Polyp-phenylstyrene was dissolved in N,N-dimethylformamide to prepare a binder polymer solution. The modified carbon nanotubes are dispersed therein through strong stirring to obtain the desired coating solution. Wherein, the weight ratio of the modified carbon nanotubes to the binder polymer is 15:85. The coating solution is coated on the polypropylene microporous membrane, and vacuum-dried to obtain a polypropylene separator with a coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com