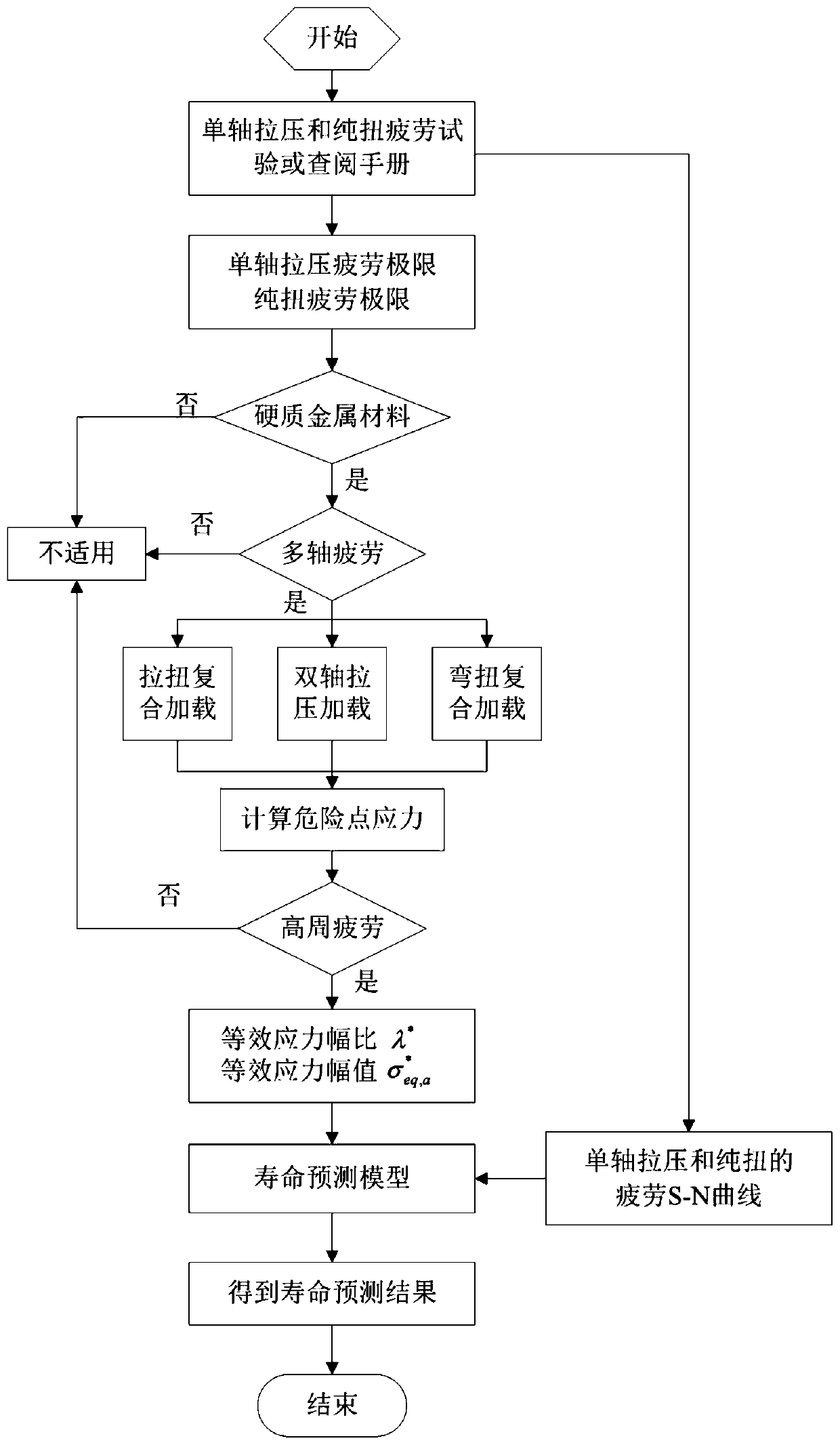

Uniaxial fatigue S-N curve-based hard metal material multi-axis high-cycle fatigue failure prediction method

A fatigue failure, hard metal technology, used in the application of stable tension/pressure to test the strength of materials, analyze materials, measuring devices, etc., can solve the problems of unclear physical meaning, lack of physical background, and complex determination of critical surfaces. To achieve the effect of easy application and simple model form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

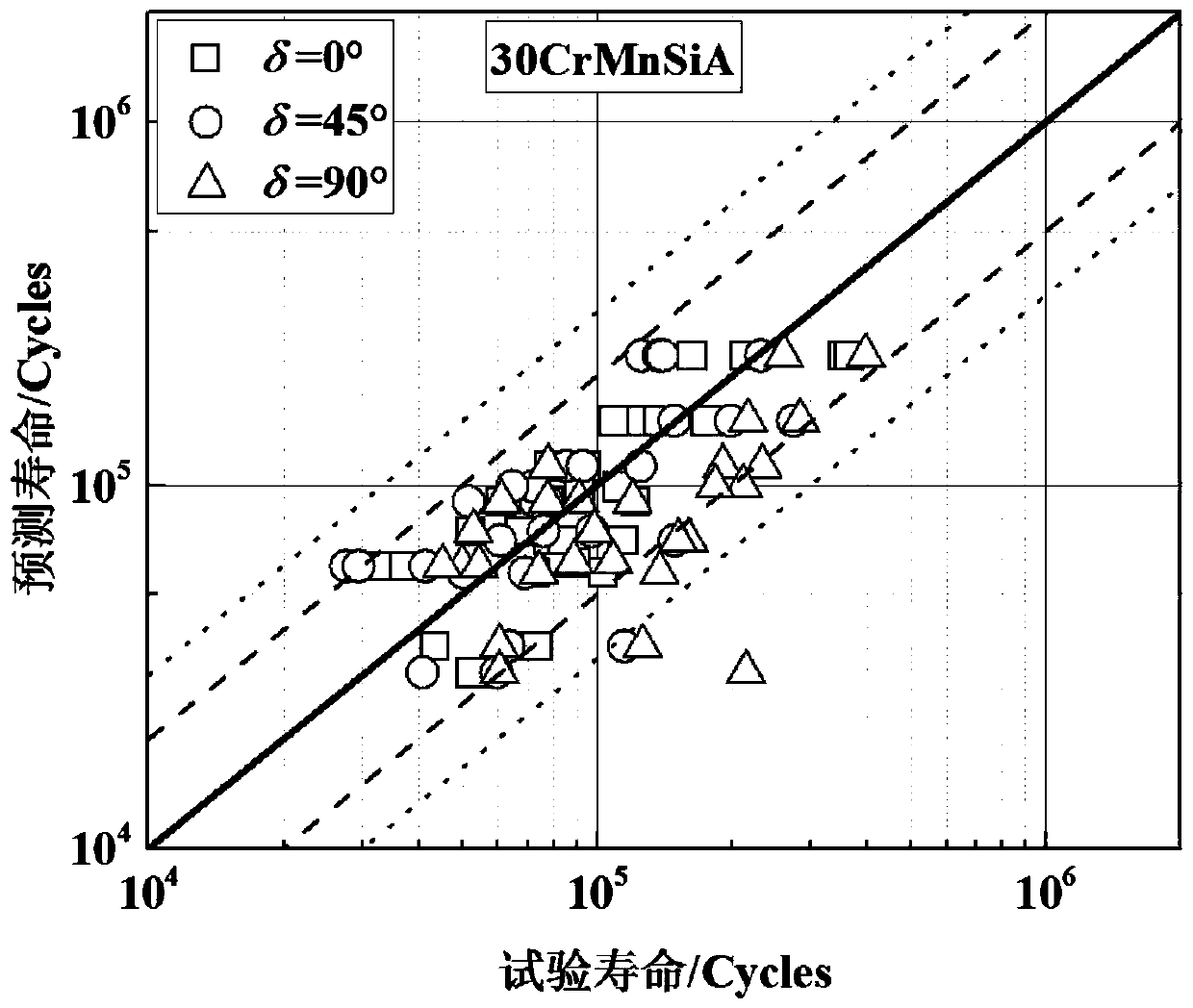

[0047] Example 1: Prediction of High Cycle Fatigue Life of 30CrMnSiA Steel under Combined Tension-Torsion Loading

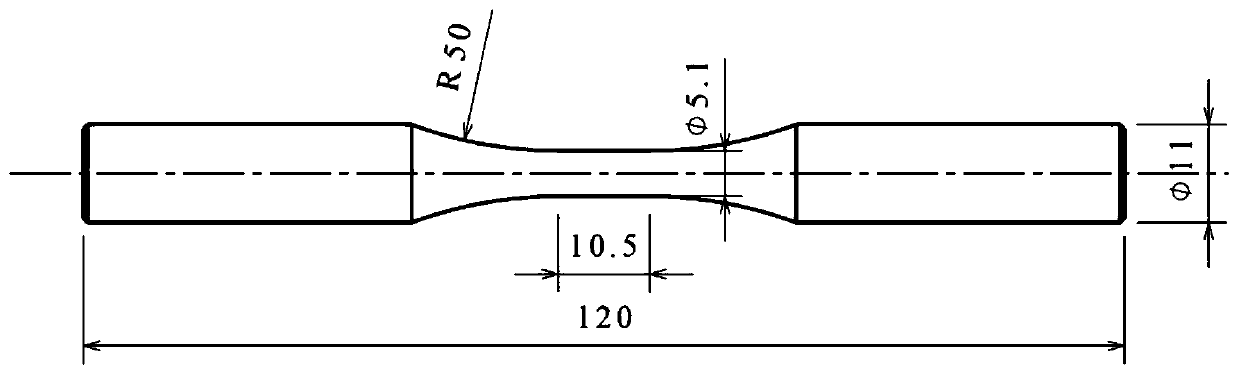

[0048] 30CrMnSiA steel tensile torsion test test piece size schematic diagram as shown figure 2 As shown, its static performance is: E=207GPa, σ s =1334MPa, G=77.2GPa, τ s =1040MPa. Through uniaxial tension-compression and pure torsion fatigue tests, the fatigue performance is obtained: the uniaxial tension-compression S-N curve is log N T =6.958-1.2294log(σ x,a -565.25), the pure torsional S-N curve is log N S =36.26-11.659logτ xy,a ; corresponds to 10 6 The condition of cycle life is that the fatigue limit of uniaxial tension and compression is σ u =565.25MPa, pure torsional fatigue limit is τ u = 393.93 MPa. The Von-Mises equivalent stress is taken as the same, and the load is applied to the test piece under different stress amplitude ratios, phase differences and average stresses, and the tensile-torsion fatigue test life of the test piece is obtain...

Embodiment 2

[0054] Example 2: Prediction of High Cycle Fatigue Life of LY12CZ Aluminum Alloy under Combined Tension-Torsion Loading

[0055] The static performance of LY12CZ aluminum alloy is: E=73GPa, σ s =545MPa, G=27.4GPa, τ s = 382MPa. The fatigue performance is: the uniaxial tension-compression S-N curve is log N T =22.72-7.37logσ x,a , the pure torsional S-N curve is log N S =24.91-8.97logτ xy,a ; The fatigue limit of uniaxial tension and compression is σ u =168.73MPa, pure torsional fatigue limit is τ u = 119.62 MPa.

[0056] 1. First, the fatigue limit ratio of the given material is equal to 0.70, which is a hard metal material. Secondly, due to the simple structure of the test piece, the stress change of the dangerous point during the tension-torsion fatigue loading process can be calculated by theoretical analysis;

[0057] 2. According to the stress change of the dangerous point obtained by calculation, it is concluded that the test piece material does not enter yield, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com