Transmission/scanning electron microscope mechanical-thermal coupling field loaded in-situ experimental platform

A scanning electron microscope and experimental platform technology, which is used in material analysis using radiation, material analysis using wave/particle radiation, measurement devices, etc. Realize problems such as crystal samples, and achieve the effect of realizing large displacement deformation experiments, reducing thermal drift, and fast heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the drawings:

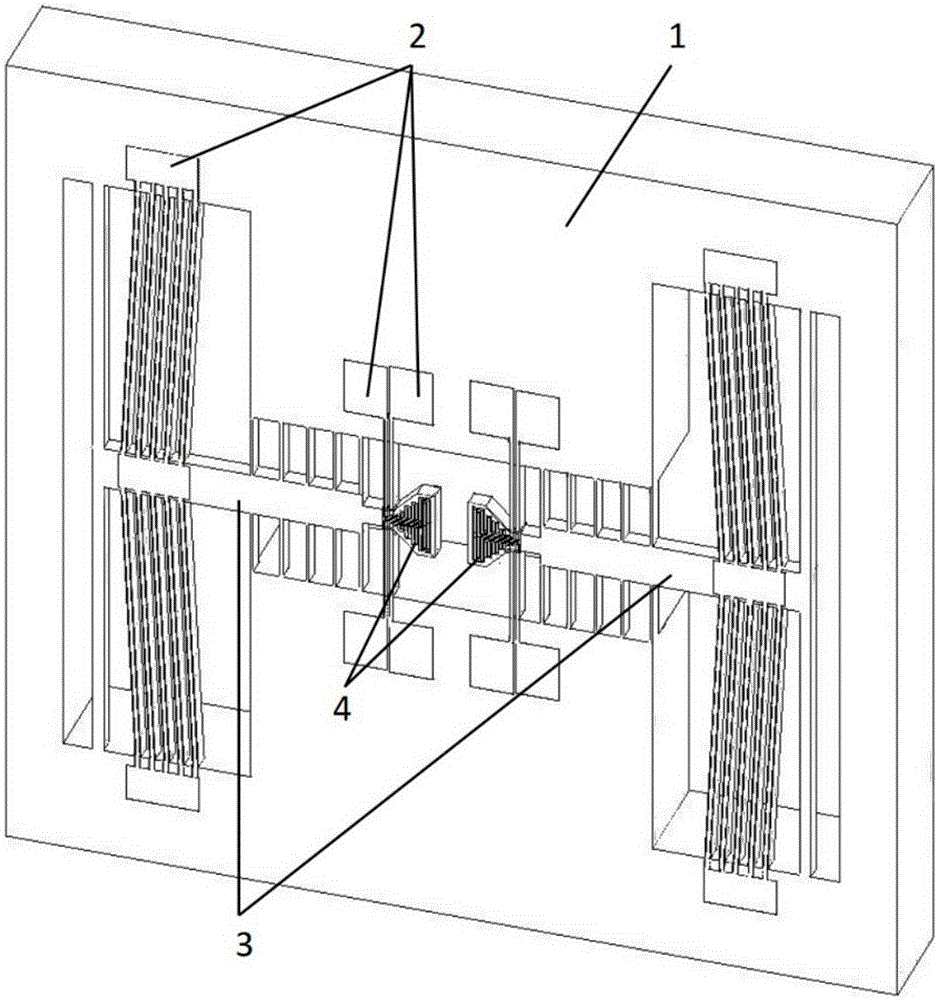

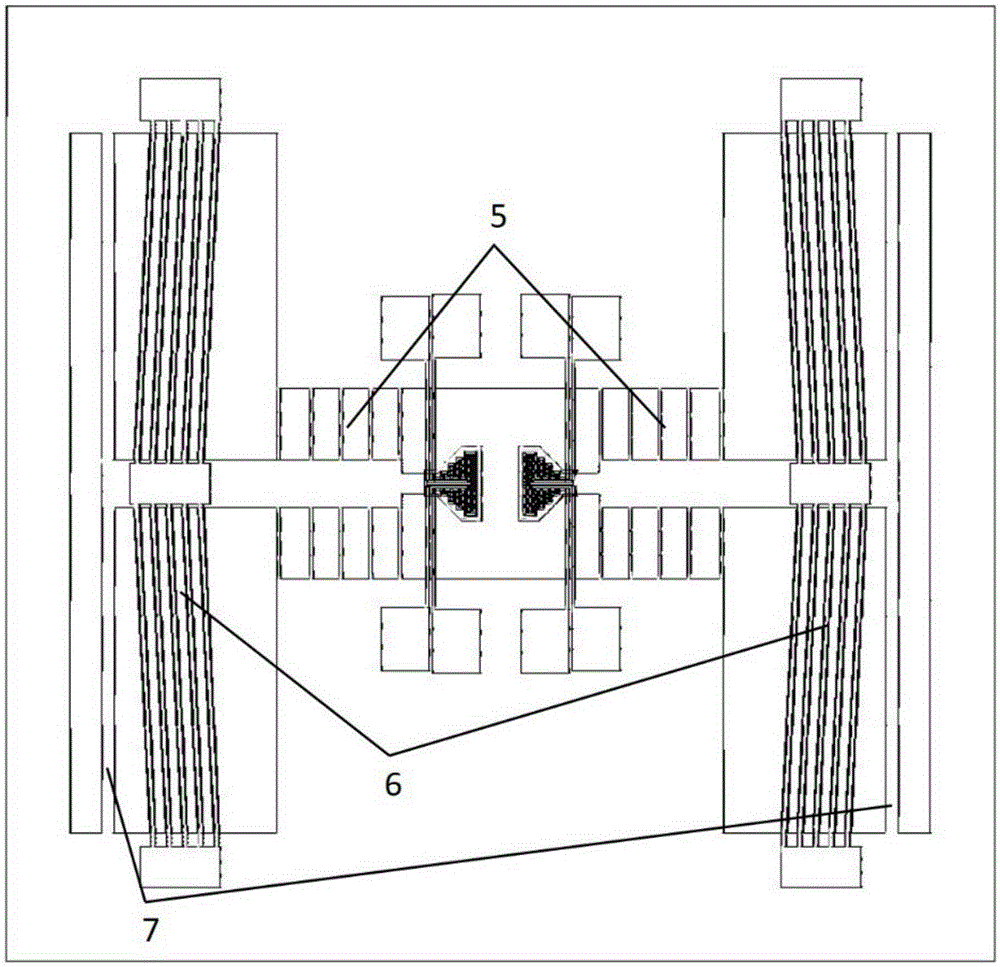

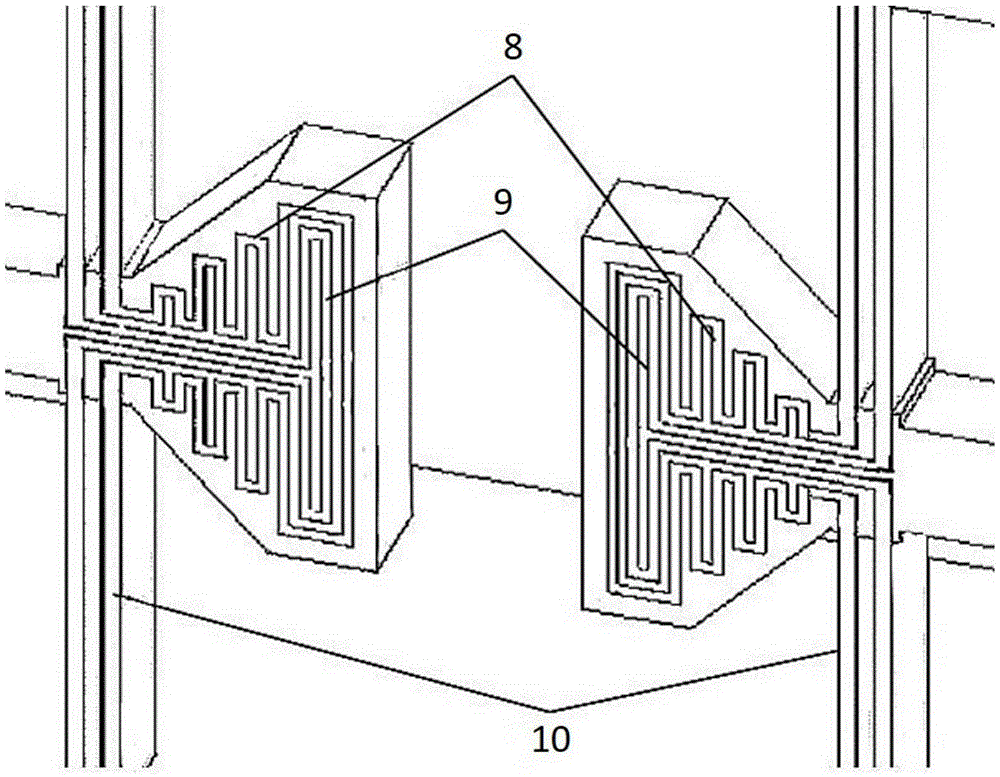

[0032] An in-situ experimental platform loaded by a transmission / scanning electron microscope force-thermal coupling field, which is characterized in that it includes six parts: a substrate, a heating zone, a mass, a heat sink beam 5, a driving beam 6 and a displacement calibration beam; The bottom is used to carry the pressure welding zone, connect the supporting mass and the heating zone; the heating zone is two triangular flat plates located in the center area of the device. One end of the heating zone carries the sample and the other end is connected to the mass. The heating upper surface is attached with a heating resistor and a measuring block. Thermal resistance; two sets of driving beams are located at the opposite end of the mass block and the heating zone, and are driven by electrothermal driving beams; the mass block is two rectangular flat plates that connect the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com